▏Product Vedio

▏Plastic PE Pipe Extrusion Line

▏Introduction to the Plastic PE Pipe Extrusion Line

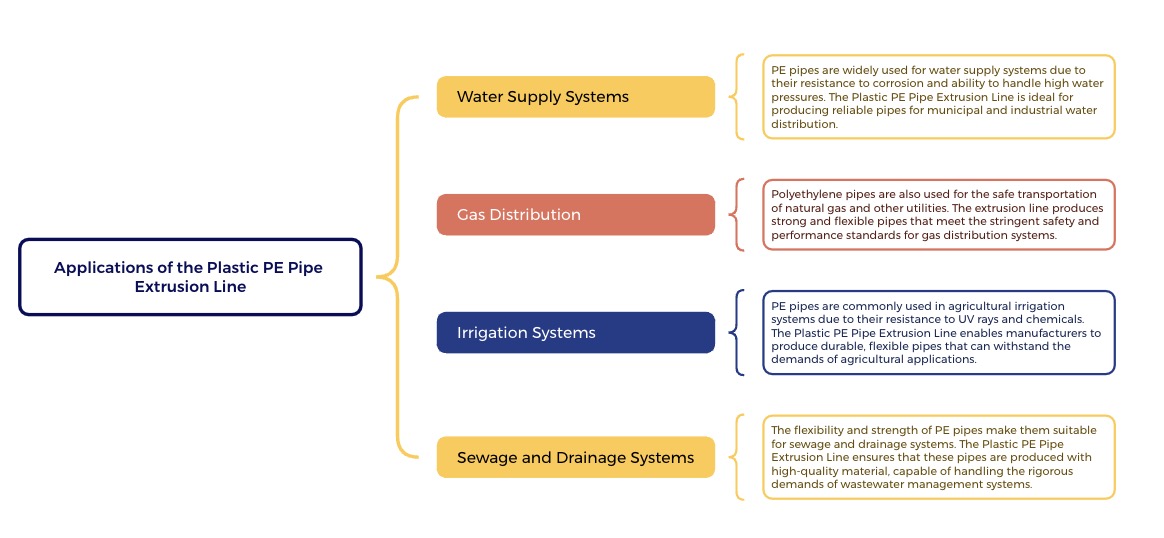

The Plastic PE Pipe Extrusion Line is an advanced and versatile manufacturing system designed for the efficient production of polyethylene (PE) pipes used in various industries, including water supply, gas distribution, sewage, and irrigation systems. Polyethylene pipes are known for their exceptional resistance to corrosion, durability, and flexibility, making them ideal for both residential and industrial applications.

With the growing demand for reliable and sustainable infrastructure solutions, the Plastic PE Pipe Extrusion Line offers manufacturers an automated, high-performance solution to produce PE pipes in different diameters, thicknesses, and lengths. By leveraging advanced technology, the extrusion line delivers high-quality pipes that meet stringent industry standards and regulations.

▏Key Features of the Plastic PE Pipe Extrusion Line

| High-Precision Extruder for Optimal Material Processing

The core component of the Plastic PE Pipe Extrusion Line is its high-precision extruder, which is designed to process polyethylene (PE) resins with optimal efficiency. The extruder uses a screw and barrel system to melt and homogenize the raw material, ensuring consistent material flow and preventing degradation. Equipped with state-of-the-art temperature and pressure control systems, the extruder can be adjusted to process various grades of PE, including HDPE (High-Density Polyethylene) and MDPE (Medium-Density Polyethylene), allowing manufacturers to produce pipes with different mechanical properties to suit specific applications. The extruder guarantees uniform melting and minimal material degradation, ensuring high-strength pipes. |

| Customizable Pipe Specifications

The Plastic PE Pipe Extrusion Line is highly flexible, allowing manufacturers to produce pipes in a wide range of sizes and specifications. With the ability to adjust the die and extrusion parameters, the line can produce PE pipes with varying diameters, wall thicknesses, and lengths. Whether producing small diameter pipes for residential plumbing or large-diameter pipes for municipal water distribution, the extrusion line accommodates various sizes and configurations. Additionally, the system can be fine-tuned to meet specific requirements for pressure resistance, flexibility, and chemical resistance, ensuring that the pipes are fit for their intended purpose. |

| Multi-Layer Extrusion for Enhanced Performance

Many applications, particularly in harsh environments, require multi-layer pipes for added strength, durability, and chemical resistance. The Plastic PE Pipe Extrusion Line is equipped with multi-layer extrusion capabilities, enabling the production of pipes with multiple layers of different materials. This feature enhances the performance of the pipes by providing additional protection against external factors such as UV radiation, abrasion, and chemicals. The inner layer of the pipe can be designed for smooth fluid flow, while the outer layer offers increased protection and resistance to environmental stress. Multi-layer PE pipes are commonly used in industrial and agricultural applications where higher performance is necessary. |

| Advanced Calibration and Cooling System

Once the polyethylene material is extruded into a pipe profile, it is essential to ensure that the pipe maintains its desired shape and dimensions. The Plastic PE Pipe Extrusion Line includes a highly efficient calibration and cooling system that guarantees the pipes retain their uniformity and strength. The calibration system ensures that the pipe is consistently shaped to the correct diameter, while the cooling system, often comprising water baths or air-cooling units, rapidly solidifies the extruded material. This combination of calibration and cooling prevents warping and ensures the production of pipes with high dimensional accuracy and a smooth surface finish. |

| High-Performance Haul-Off and Cutting System

The Plastic PE Pipe Extrusion Line is equipped with a high-performance haul-off system, which is responsible for pulling the extruded pipe through the cooling and cutting stages. The haul-off unit uses rubber rollers or other gripping mechanisms to ensure that the pipe is pulled with the correct tension, preventing any stretching or deformation. Once the pipe reaches the desired length, the automatic cutting system precisely cuts the pipe to the required length. The cutting unit is synchronized with the haul-off system to ensure that each pipe is cut with minimal material waste and maximum efficiency. |

| Intelligent Control System for Enhanced User Experience

The Plastic PE Pipe Extrusion Line is equipped with an intelligent control system that allows operators to monitor and adjust all critical parameters throughout the production process. This includes controlling extrusion speed, temperature, pressure, and cooling rates. The system uses advanced sensors and real-time data analytics to ensure optimal performance and to minimize downtime. The user-friendly interface provides operators with an easy way to track production metrics, identify potential issues, and make adjustments as needed. This reduces human error, improves process stability, and increases overall production efficiency. |

▏Customer Case

▏Technical Parameters

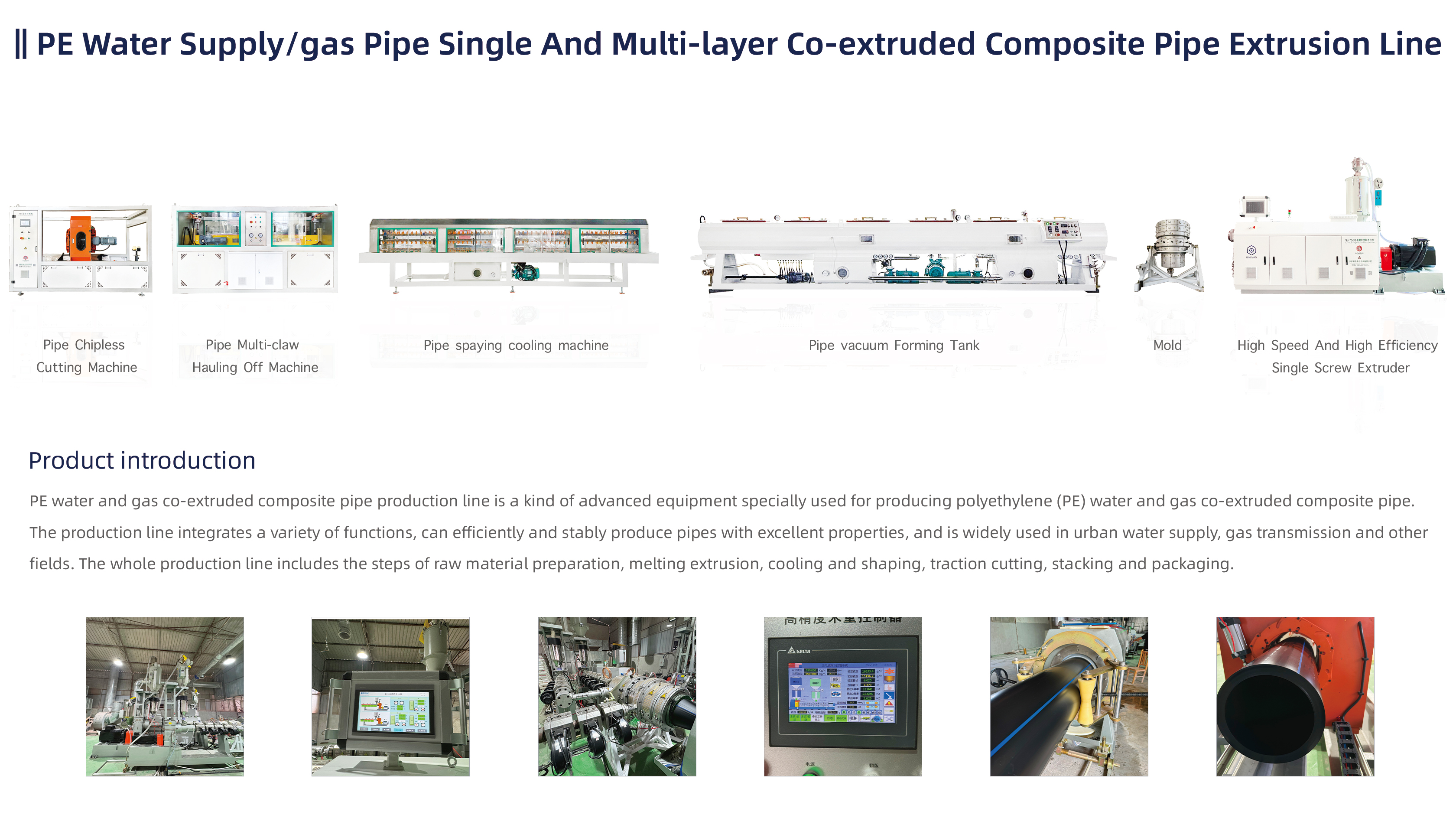

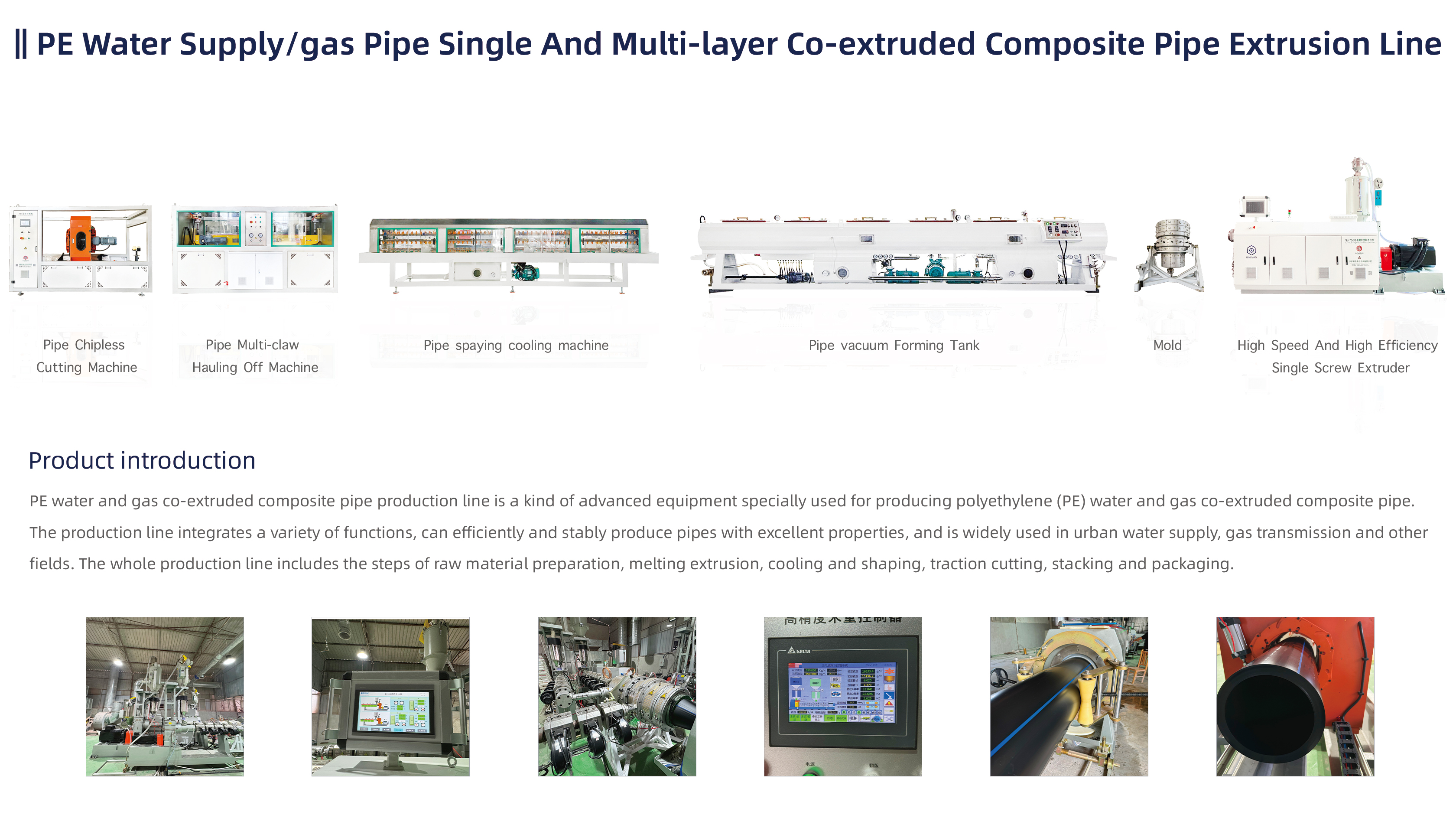

| 1 | Extruder: SJ70-38single screw extruder |

| 2 | Fixed forming: Vacuum calibration forming tank |

| 3 | Fixed forming: Water forming tank |

| 4 | Traction: Hauling off machine |

| 5 | Cutting: Cutting machine |

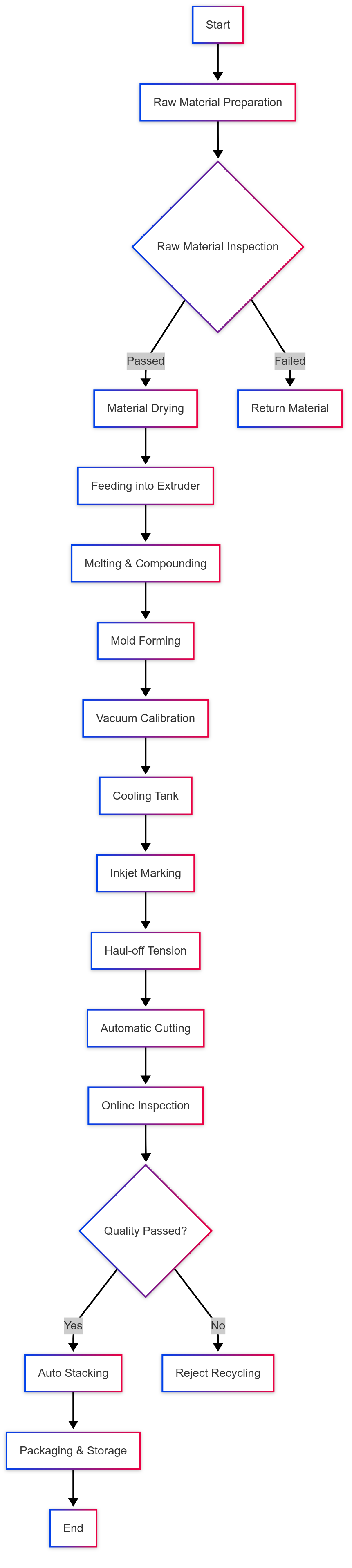

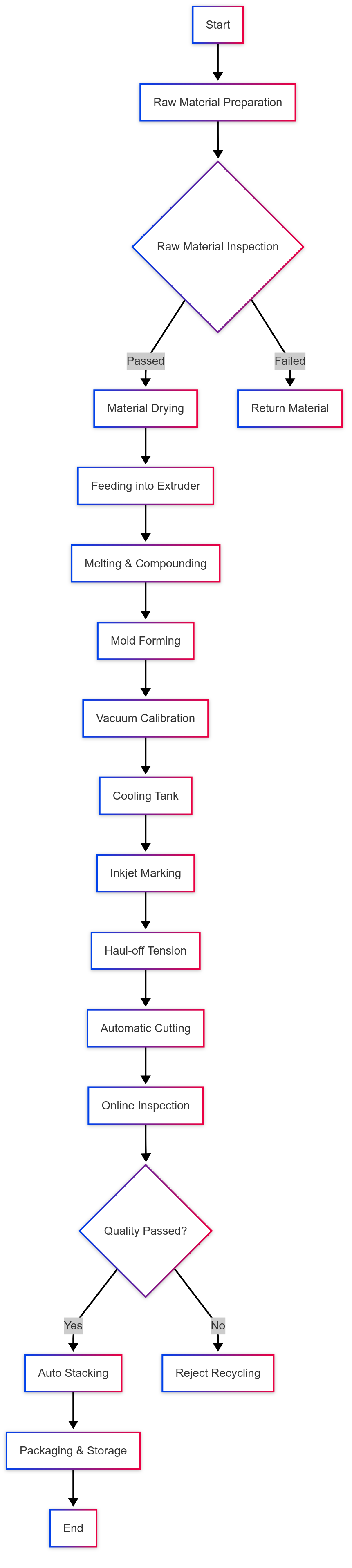

▏Production Procedure

▏How the Plastic PE Pipe Extrusion Line Works

▏Benefits of the Plastic PE Pipe Extrusion Line

| 1. High Efficiency and Output

The Plastic PE Pipe Extrusion Line is designed for high-speed production and efficiency. The fully automated system reduces labor costs and minimizes human error, while the optimized design allows for continuous operation with minimal downtime. This high efficiency translates into faster production times and increased output, making it a cost-effective solution for manufacturers. |

| 2. Customizable Pipe Specifications

With its adjustable dies and extrusion settings, the Plastic PE Pipe Extrusion Line offers great flexibility in terms of pipe size, thickness, and material properties. Manufacturers can easily adapt the line to produce pipes for a wide variety of applications, from small residential pipes to large industrial pipes. |

| 3. Superior Product Quality

The precision of the Plastic PE Pipe Extrusion Line ensures that every pipe produced is of consistent quality. From the uniformity of the pipe’s diameter to the smoothness of its surface, the line guarantees high-performance pipes that meet strict industry standards for durability, strength, and flexibility. |

| 4. Multi-Layer Capabilities

For applications that require enhanced pipe performance, such as resistance to UV radiation, chemicals, or extreme temperatures, the Plastic PE Pipe Extrusion Line can produce multi-layer pipes with different material properties. This ensures that the pipes are tailored to meet the specific needs of various industries. |

| 5. Cost-Effectiveness and Sustainability

The Plastic PE Pipe Extrusion Line is designed to reduce material waste and optimize energy usage, making it an environmentally friendly option. The efficient cooling, extrusion, and cutting systems minimize energy consumption while ensuring high output. |

| 6. Low Maintenance Requirements

The Plastic PE Pipe Extrusion Line is built with durability and ease of maintenance in mind. The high-quality components and automated control system ensure smooth operation and reduce the need for frequent repairs or maintenance. This lowers operational costs and improves overall efficiency. |

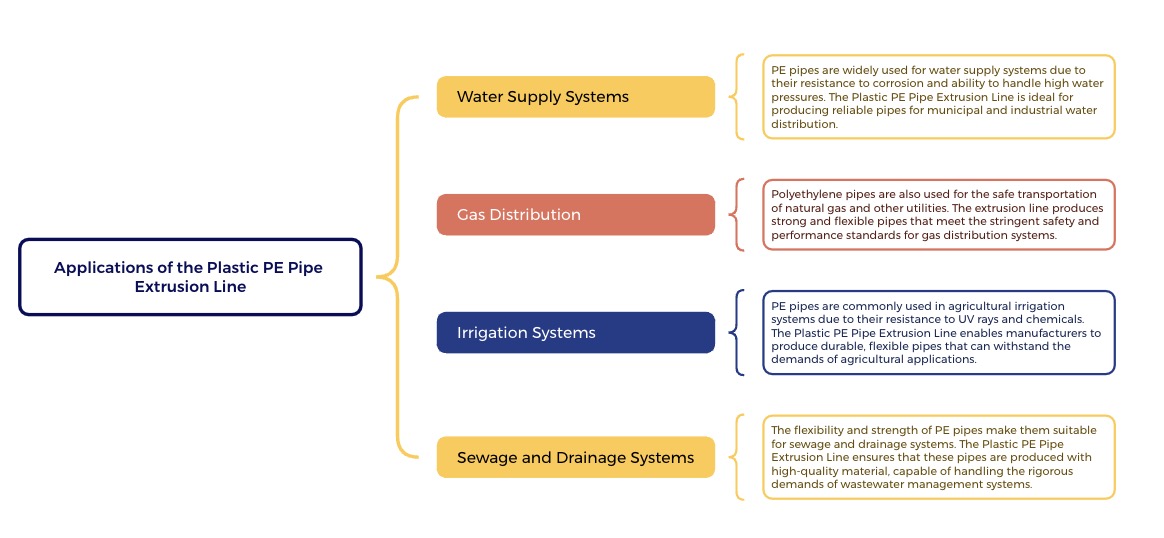

▏Applications of the Plastic PE Pipe Extrusion Line

▏Product Advantage

PE pipe extrusion line has a number of significant advantages, these advantages make it widely used in the field of plastic pipe production. The following is a detailed summary of the advantages of PE pipe extrusion line :

| 1 | Efficient and stable production capacity |

| Efficient extrusion: The plastic PE pipe extrusion line adopts high-speed and efficient single screw extruder, screw design is reasonable, plasticizing and mixing effect is good, to ensure high-speed and high-performance extrusion. The extrusion capacity is large and stable, suitable for large-scale production needs. Stable production: The line uses proprietary sizing and cooling systems, such as water film lubrication and water ring cooling, to ensure the stability of diameter and roundness during high-speed production. |

| 2 |

Excellent product quality

|

| High precision: The plastic PE pipe extrusion line adopts a specially designed multi-stage vacuum measuring box to control the vacuum degree to ensure the dimensional stability and roundness of the pipe. The mold material is excellent, the extrusion is stable and reliable, and the water film lubrication and water ring cooling are used to further improve the product quality. Excellent performance: The PE pipe produced has moderate rigidity and strength, and has good flexibility, creep resistance, environmental stress cracking resistance and good hot melt performance. These characteristics make PE pipes the preferred product for urban gas transmission pipelines and outdoor water supply pipes. |

| 3 | Highly automated and intelligent |

| Automatic control: The operation and time of the plastic PE pipe extrusion line are programmed by PLC, with a good man-machine interface, and all process parameters can be set and displayed by touch screen. This highly automated control method greatly improves production efficiency and operation convenience. Precise cutting: The use of no chip automatic cutting saw or automatic planetary cutting machine, cutting cross-section smooth and flat, high precision, low noise. The cutting depth and position of the large diameter pipe can be flexibly adjusted to ensure the reliability of the cutting saw. |

| 4 | Wide applicability and flexibility |

| Wide application fields: The pipes produced by plastic PE pipe extrusion line can be widely used in urban water supply system, food and chemical field conveying system, mineral sand mud conveying system, landscaping pipe network and replacement cement pipe, cast iron pipe and steel pipe and other fields. Flexible configuration: The plastic PE pipe extrusion line can be flexibly configured according to the production needs, such as the special extruder can be assembled to produce pipes with color line. |

| 5 | Energy conservation, environmental protection and sustainability |

| Energy saving and environmental protection: The plastic PE pipe extrusion line adopts high efficiency energy-saving equipment such as frequency conversion speed saving motor, and realizes stepless speed regulation by frequency converter. It has the characteristics of wide speed regulation range, power saving, small control power, good starting performance and large torque. Long life: PE pipe has the characteristics of long life, and the safe service life can reach more than 50 years, reducing the frequency of pipe replacement and resource waste. |

PE pipe extrusion line equipment occupies an important position in the field of plastic pipe production with its efficient and stable production capacity, excellent product quality, high degree of automation and intelligence, wide applicability and flexibility, as well as energy saving, environmental protection and sustainability.

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping