▏304 Stainless Steel Three Claw Haul Off Unit Machine

▏Introduction to the 304 Stainless Steel Three Claw Haul Off Unit Machine

The 304 Stainless Steel Three Claw Haul Off Unit Machine is an advanced and highly efficient piece of equipment used in plastic pipe extrusion systems. Designed for handling a wide variety of plastic pipes, including those made of PVC, PE, and HDPE, this machine plays a pivotal role in ensuring pipes are pulled through the extrusion line with precision and consistency. It is particularly known for its durable 304 stainless steel construction and its three-claw mechanism, which ensures a secure, stable, and efficient haul-off process.

In the competitive world of pipe manufacturing, the 304 Stainless Steel Three Claw Haul Off Unit Machine is a trusted tool for ensuring that every pipe produced maintains the desired dimensional accuracy, strength, and surface finish. With its versatile design, it is an ideal solution for producers looking to optimize their production lines while maintaining high-quality standards.

▏Key Features of the 304 Stainless Steel Three Claw Haul Off Unit Machine

| Premium 304 Stainless Steel Construction

The primary standout feature of the 304 Stainless Steel Three Claw Haul Off Unit Machine is its high-quality construction material. Made from 304 stainless steel, this machine offers superior corrosion resistance, ensuring durability even under harsh industrial conditions. The stainless steel material is not only strong but also resistant to rust, oxidation, and wear, making it ideal for long-term use in demanding environments such as pipe production plants. This corrosion resistance is especially important when the machine is used to handle various types of plastic materials, which can generate heat and moisture during the extrusion process. The 304 stainless steel construction ensures that the machine remains robust and functional, even with continuous operation. |

| Three Claw Gripping System for Superior Handling

The 304 Stainless Steel Three Claw Haul Off Unit Machine is equipped with a unique three-claw gripping system that securely holds the pipe during the haul-off process. Unlike traditional haul-off units that rely on two or more claws, the three-claw system offers enhanced stability and balance. This design allows for smooth and consistent pulling, which helps to maintain the pipe’s shape and diameter during the extrusion process. The three claws work symmetrically to grip the pipe evenly, ensuring that no part of the pipe is under excessive tension. This reduces the risk of elongation or deformation, ensuring that pipes are produced with high precision. The result is a higher-quality product that meets the stringent standards required in industries such as plumbing, construction, and telecommunications. |

| Adjustable Pulling Speed and Tension Control

Another key feature of the 304 Stainless Steel Three Claw Haul Off Unit Machine is its adjustable pulling speed and tension control. Manufacturers can fine-tune the pulling speed based on the type of material and the specific requirements of the production process. This flexibility allows for optimal pulling performance, whether the goal is to maintain slow speeds for high-precision applications or faster speeds for high-volume production. The tension control system is designed to ensure that the pulling force is evenly distributed across the entire length of the pipe, preventing distortions and ensuring uniform dimensional accuracy. By maintaining precise tension throughout the process, this machine helps eliminate defects that can occur during extrusion, such as wall thickness variations or surface imperfections. |

| High Precision Calibration and Cooling

In addition to its pulling capabilities, the 304 Stainless Steel Three Claw Haul Off Unit Machine is integrated with advanced calibration and cooling systems that work in tandem to ensure the pipe maintains its shape and size. The machine typically works alongside a cooling system that helps to solidify the extruded pipe, allowing it to retain its desired dimensions. The calibration process is critical for ensuring that the pipe’s diameter is accurate and consistent, reducing the likelihood of defects. The haul-off machine ensures that the pipe is pulled evenly through the calibration process, maintaining a smooth and precise diameter throughout its length. This feature is essential for producing high-quality pipes that meet industry specifications. |

| Minimal Maintenance and Long-Term Durability

Thanks to its durable 304 stainless steel construction and robust design, the 304 Stainless Steel Three Claw Haul Off Unit Machine requires minimal maintenance. The machine is engineered for long-term reliability, ensuring that manufacturers can rely on it for consistent performance with reduced downtime. The high-quality materials used in its construction help extend the lifespan of the machine, making it a cost-effective solution for high-volume production. The wear-resistant nature of stainless steel, combined with the machine’s precision-engineered components, ensures that the haul-off unit operates smoothly even under heavy use. With regular care and attention, the machine can function effectively for many years, reducing the need for frequent repairs or replacements. |

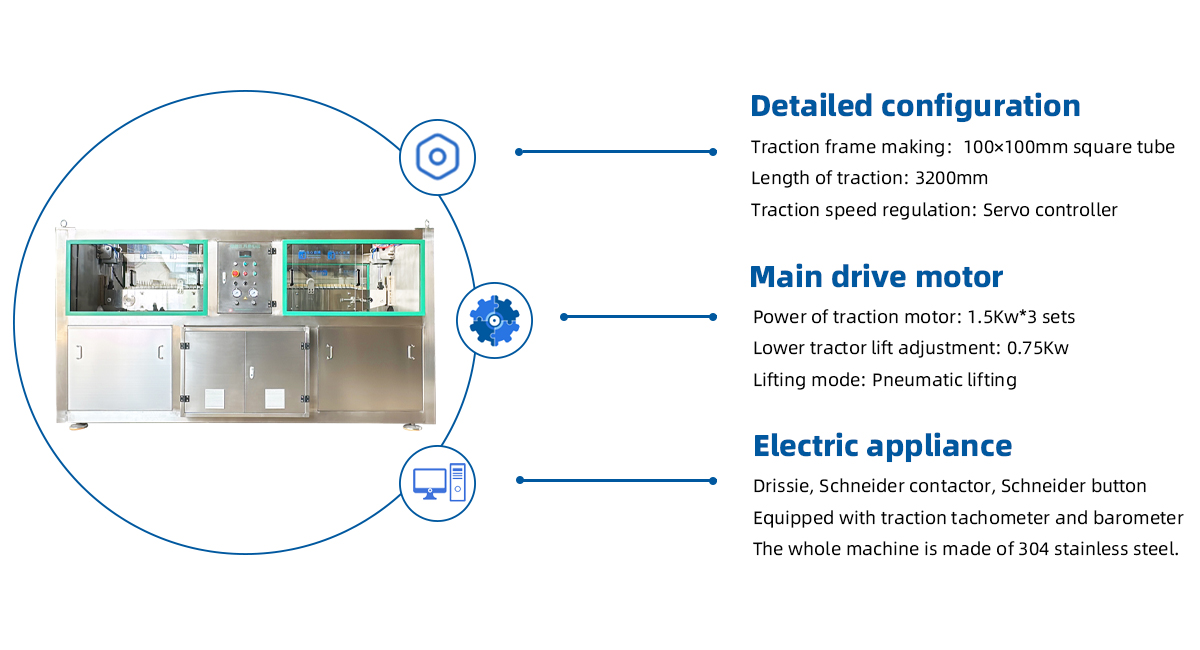

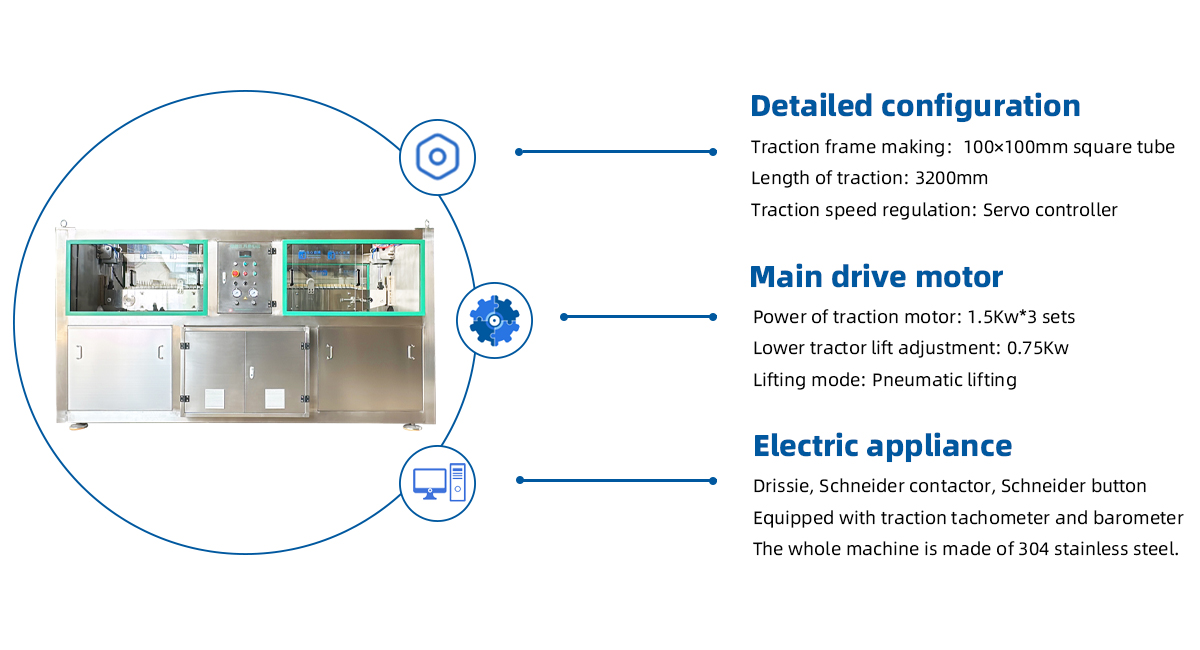

▏Technical Parameters

Traction frame making | 100×100mm square tube |

| Length of traction | 3200mm |

| Traction speed regulation | Servo controller |

Power of traction motor | 1.5Kw*3 sets |

| Lower tractor lift adjustment | 0.75Kw |

| Lifting mode | Pneumatic lifting |

▏Main Details

▏Product Photos

▏How the 304 Stainless Steel Three Claw Haul Off Unit Machine Works

The operation of the 304 Stainless Steel Three Claw Haul Off Unit Machine follows a precise sequence of steps to ensure that the pipes are produced with high-quality standards:

| 1. Extrusion of the Pipe

The process begins with the extrusion of the pipe, where the raw plastic material (such as PVC, PE, or HDPE) is melted and shaped by an extruder. The extruder pushes the molten plastic through a die to create the pipe’s desired profile. |

| 2. Cooling and Calibration

After the pipe exits the extruder, it enters a cooling zone, typically involving a water bath or air-cooling system. During this stage, the pipe solidifies and takes on its final shape. The machine’s calibration unit ensures that the pipe’s diameter is accurate and that it retains its intended dimensions as it cools. |

| 3. Three Claw Gripping and Pulling

The cooled pipe then moves toward the 304 Stainless Steel Three Claw Haul Off Unit Machine, where the three-claw gripping system securely holds the pipe. The claws gently pull the pipe through the system, with adjustable speed settings that allow for precise control of the pulling force. |

| 4. Tension Control and Uniform Pulling

As the pipe is pulled, the tension control system ensures that the pulling force is evenly distributed across the length of the pipe. This uniform pulling ensures that the pipe does not suffer from uneven tension, which could lead to defects or dimensional variations. |

| 5. Cutting and Length Control

Once the pipe reaches the required length, the machine’s automatic cutting system activates. The length control system ensures that each pipe segment is cut to the precise length needed, reducing waste and improving the overall efficiency of the production process. |

| 6. Discharge and Packaging

After cutting, the finished pipe is discharged from the machine and ready for further processing or packaging. The pipes are then inspected for quality before being shipped out for use in various industrial applications. |

▏Benefits of the 304 Stainless Steel Three Claw Haul Off Unit Machine

| 1. Enhanced Durability and Longevity

The machine’s high-quality 304 stainless steel construction ensures that it is resistant to rust, corrosion, and wear. This durability guarantees that the machine can handle continuous operation without deteriorating, which is crucial for high-volume production environments. |

| 2. Precision and Dimensional Consistency

The three-claw gripping system, along with adjustable tension and speed controls, ensures that the pipe is pulled uniformly and consistently. This results in dimensional accuracy and a high-quality finish, making the machine suitable for applications that require tight tolerance and reliability. |

| 3. Improved Production Efficiency

The 304 Stainless Steel Three Claw Haul Off Unit Machine is designed for high-speed operation, allowing manufacturers to produce large quantities of pipes in less time. With its adjustable settings, the machine is adaptable to various production requirements, enhancing efficiency in different production environments. |

| 4. Cost-Effective Operation

By reducing the need for frequent maintenance and extending the lifespan of the machine, the 304 Stainless Steel Three Claw Haul Off Unit Machine helps manufacturers reduce overall operational costs. Its efficient design also minimizes downtime, further boosting production efficiency and profitability. |

| 5. Flexibility for Various Pipe Sizes and Materials

The machine’s adjustable settings and versatile design make it compatible with a range of pipe diameters and materials, including PE, HDPE, PVC, and more. This adaptability makes it an excellent choice for manufacturers that need to produce a variety of pipe types and sizes on the same production line. |

▏Applications of the 304 Stainless Steel Three Claw Haul Off Unit Machine

| 1. Plumbing Systems

The machine is commonly used in the production of pipes for plumbing systems, where accuracy and durability are critical. The precise pulling and calibration process ensures that pipes meet industry standards for strength and dimensional consistency. |

| 2. Irrigation and Water Distribution

For irrigation and water distribution systems, the 304 Stainless Steel Three Claw Haul Off Unit Machine ensures that pipes are produced with the necessary strength and durability to withstand pressure and environmental stressors. |

| 3. Electrical Conduits and Telecommunications

The machine is also used to produce pipes for electrical conduits and telecommunications cables. The precision of the machine ensures that the pipes maintain the required dimensions to protect sensitive wiring and cables. |

| 4. Industrial Applications

In industrial sectors, such as chemical processing or fluid transport, the 304 Stainless Steel Three Claw Haul Off Unit Machine produces pipes that are strong, reliable, and resistant to corrosion, ensuring long-lasting performance in demanding environments. |

▏The Ultimate Solution for Pipe Production

The 304 Stainless Steel Three Claw Haul Off Unit Machine offers manufacturers a reliable and efficient solution for producing high-quality plastic pipes. With its durable construction, precision pulling mechanism, and minimal maintenance requirements, this machine is an excellent choice for any extrusion line. By delivering consistent performance, dimensional accuracy, and long-term durability, it helps manufacturers optimize their production processes while maintaining top-notch product quality. Whether producing pipes for plumbing, electrical systems, or industrial applications, this machine is a key tool for achieving superior results in plastic pipe manufacturing.

▏Product introduction

| 1 | Overview |

| The three-jaw haul off unit machine is a kind of advanced equipment specially designed for the production of plastic pipes. It adopts a unique three-jaw structure design, which has strong traction ability and excellent stability. The haul off unit machine is widely used in plastic pipe production line, which provides a strong guarantee for continuous and efficient production of pipe. The core components of the three-jaw haul off unit machine include traction claws, transmission system, control system, etc. The cooperative work of these components enables the haul off unit machine to achieve accurate traction and stable transmission of plastic pipes. |

| 2 | 304 stainless steel material characteristics |

| The main parts of the three-jaw haul off unit machine are made of 304 stainless steel, which has excellent corrosion resistance and oxidation resistance and can resist a variety of harsh environments. At the same time, 304 stainless steel also has high strength and good toughness, so that the haul off unit machine can maintain long-term stability and reliability during use. The choice of this material not only extends the service life of the haul off unit machine, but also reduces the maintenance cost of the equipment. |

| 3 | the applicability of plastic pipes |

| The three-jaw tractor is especially suitable for the production process of plastic pipes. Because the plastic pipe has the characteristics of light texture and good flexibility, it needs a stable and continuous traction equipment. Through its unique three-claw structure and precise control system, the three-claw haul off unit machine can realize the smooth traction of the plastic pipe and avoid the phenomenon of shaking or slipping during the haul off process. In addition, the haul off unit machine is also suitable for plastic pipes of different specifications and materials, and has a wide range of applicability. |

| 4 | the working principle of the haul off unit machine |

| The working principle of the three-jaw haul off unit machine is relatively simple and efficient. When the pipe passes through the haul off unit machine, the three-claw structure tightly grips the pipe and rotates through the haul off claw driven by the transmission system. This rotational motion transmits traction to the tube, causing it to move continuously in a predetermined direction. At the same time, the control system will monitor the traction speed and traction force in real time to ensure the stability and accuracy of the pipe during the transmission process. |

| 5 | Performance advantage analysis |

| The three-jaw haul off unit machine has a significant advantage in performance. First of all, its traction is large and stable, which can ensure that the pipe is not easy to slip or shake during the transmission process. Secondly, the haul off speed is fast and adjustable, which can meet the needs of different production speeds. In addition, the haul off unit machine also has an accurate meter function, which allows users to monitor the length and quantity of pipes in real time. |

| 6 | Application fields and scenarios |

| The three-claw haul off unit machine is widely used in plastic pipe production line, including PVC pipe, PE pipe, PP pipe and other kinds of pipe production. In addition, it can also be used in laboratories, small production lines and other scenarios to facilitate scientific research and trial production work. |

| 7 | operation and maintenance points |

| When operating the three-jaw haul off unit machine, the user should strictly follow the operation manual to ensure the correct start, stop and parameter setting of the equipment. At the same time, regular maintenance and maintenance of the equipment is also very important, including cleaning the surface of the equipment, checking the operating status of each component, timely replacement of worn parts, etc. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping