▏Product Vedio

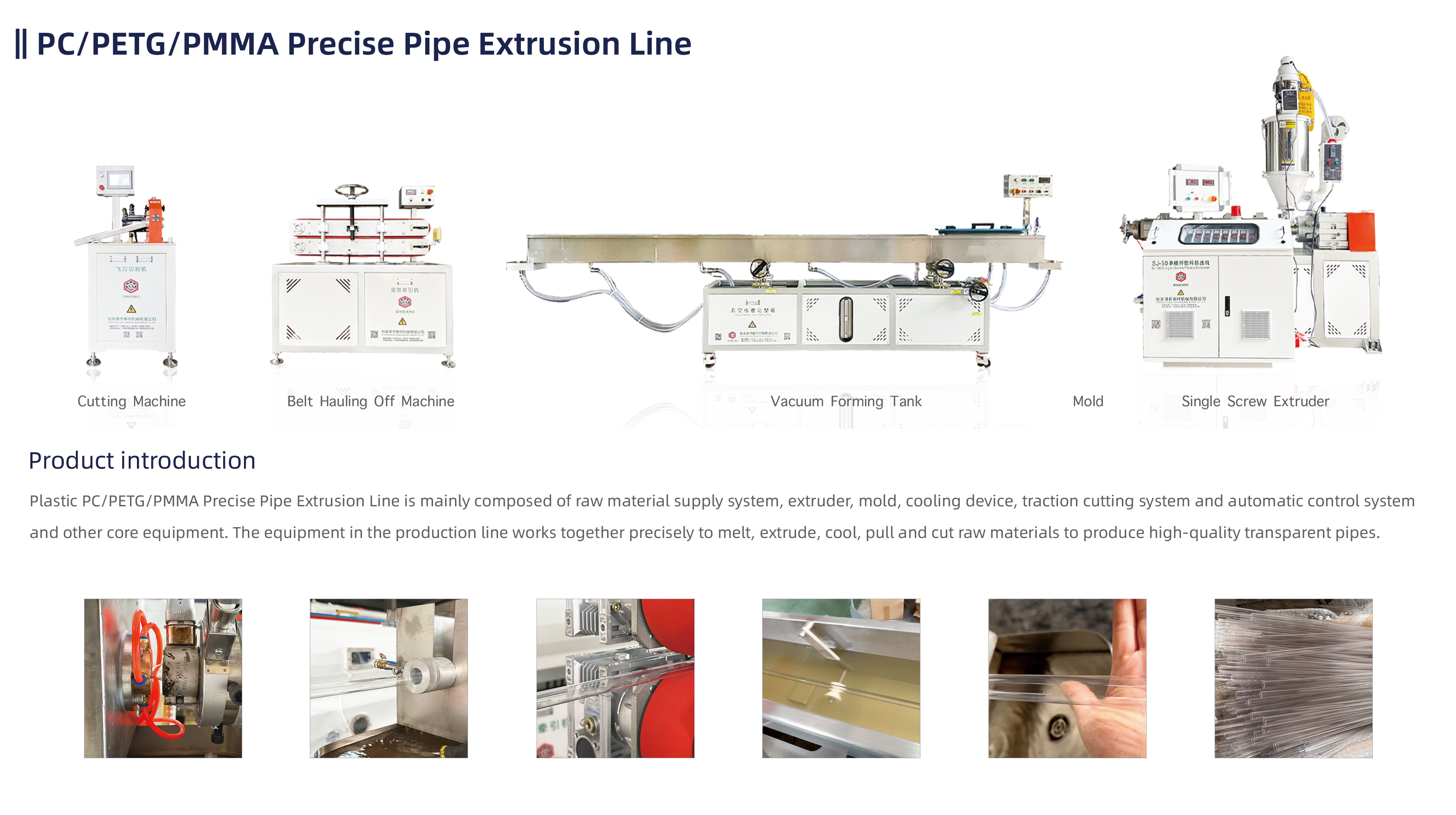

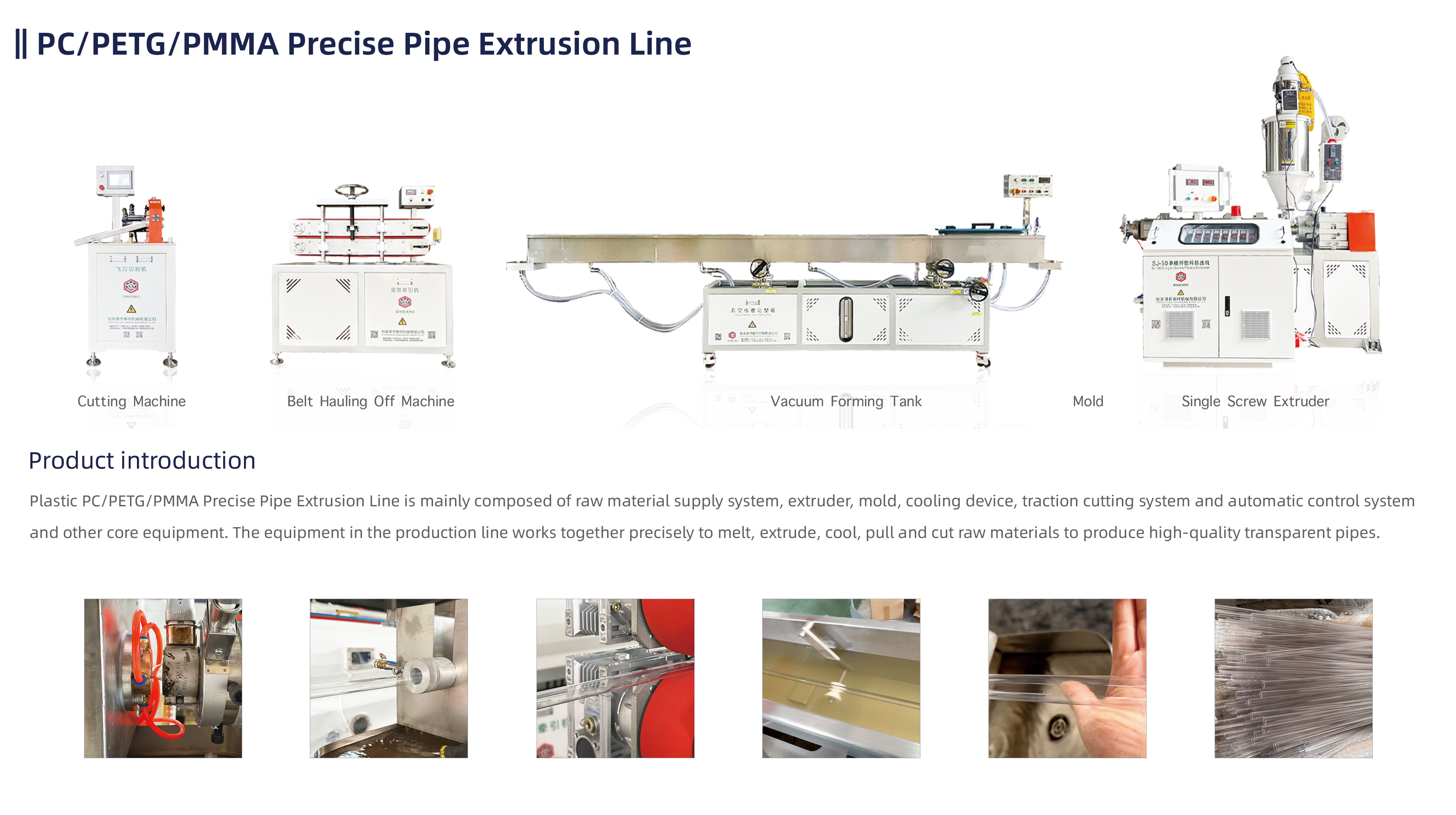

▏PC/PETG/PMMA Precise Pipe Extrusion Line

▏Introduction to PC/PETG/PMMA Precise Pipe Extrusion Line

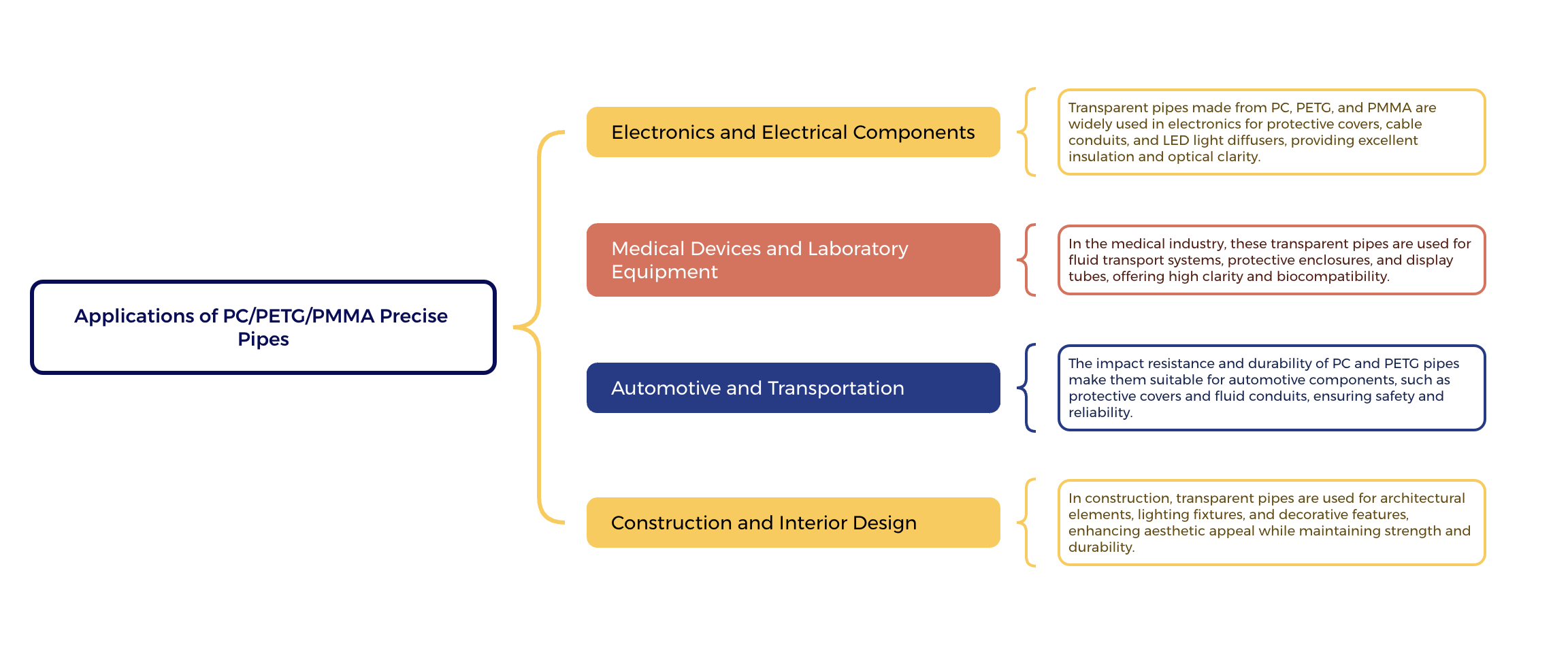

The PC/PETG/PMMA Precise Pipe Extrusion Line is an advanced manufacturing system designed to produce high-quality transparent pipes with exceptional clarity and precision. These pipes, made from Polycarbonate (PC), Polyethylene Terephthalate Glycol (PETG), and Polymethyl Methacrylate (PMMA), are widely used in various industries, including electronics, medical devices, automotive, and construction, due to their excellent transparency, impact resistance, and durability.

This extrusion line utilizes state-of-the-art technology to ensure accurate dimensions, smooth surfaces, and consistent quality, meeting the demanding requirements of high-end applications. With customizable pipe specifications and energy-efficient operation, the PC/PETG/PMMA Precise Pipe Extrusion Line is the ideal solution for manufacturers looking to produce premium-quality transparent pipes.

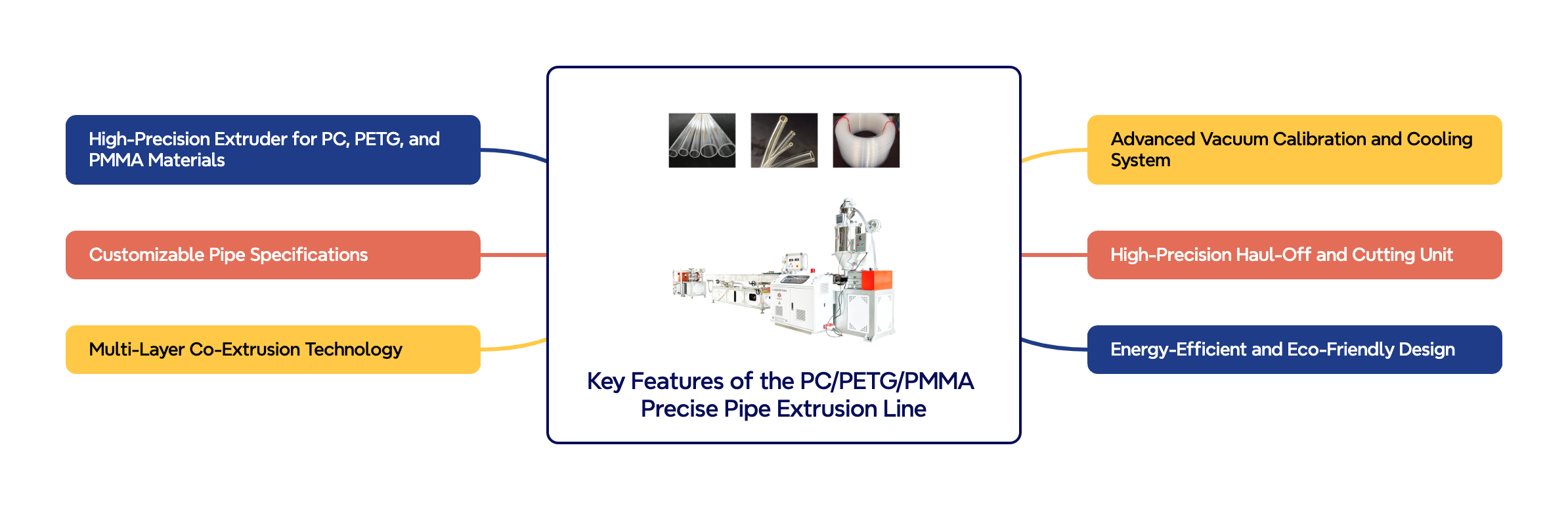

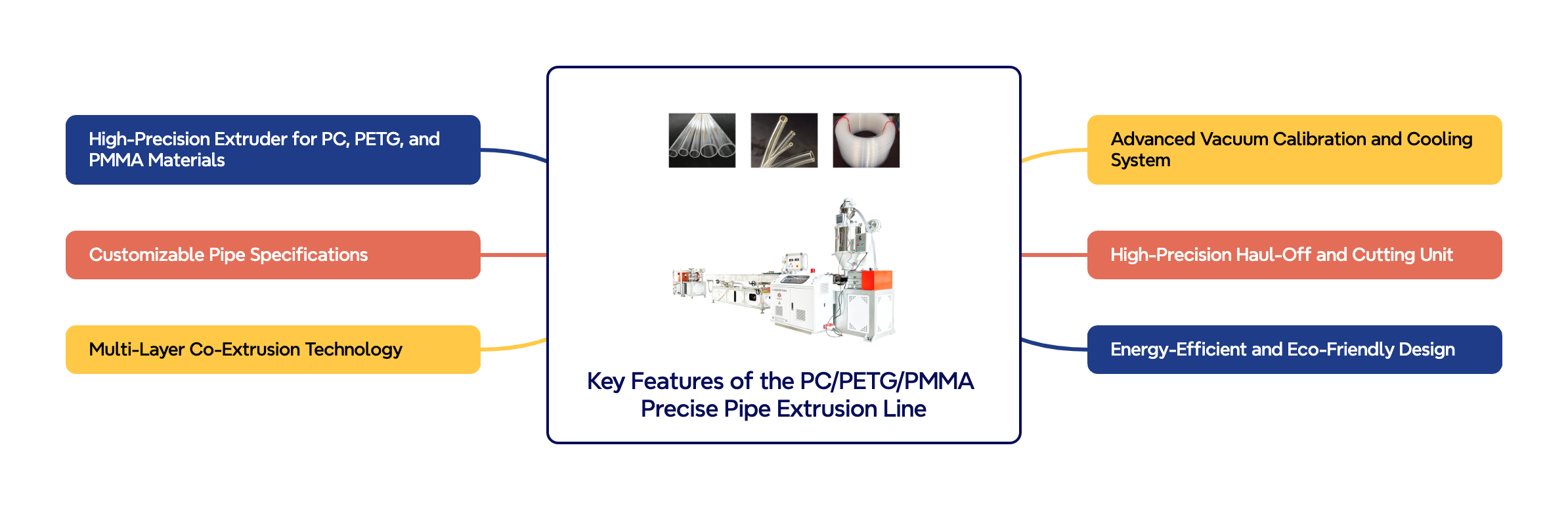

▏Key Features of the PC/PETG/PMMA Precise Pipe Extrusion Line

| High-Precision Extruder for PC, PETG, and PMMA Materials

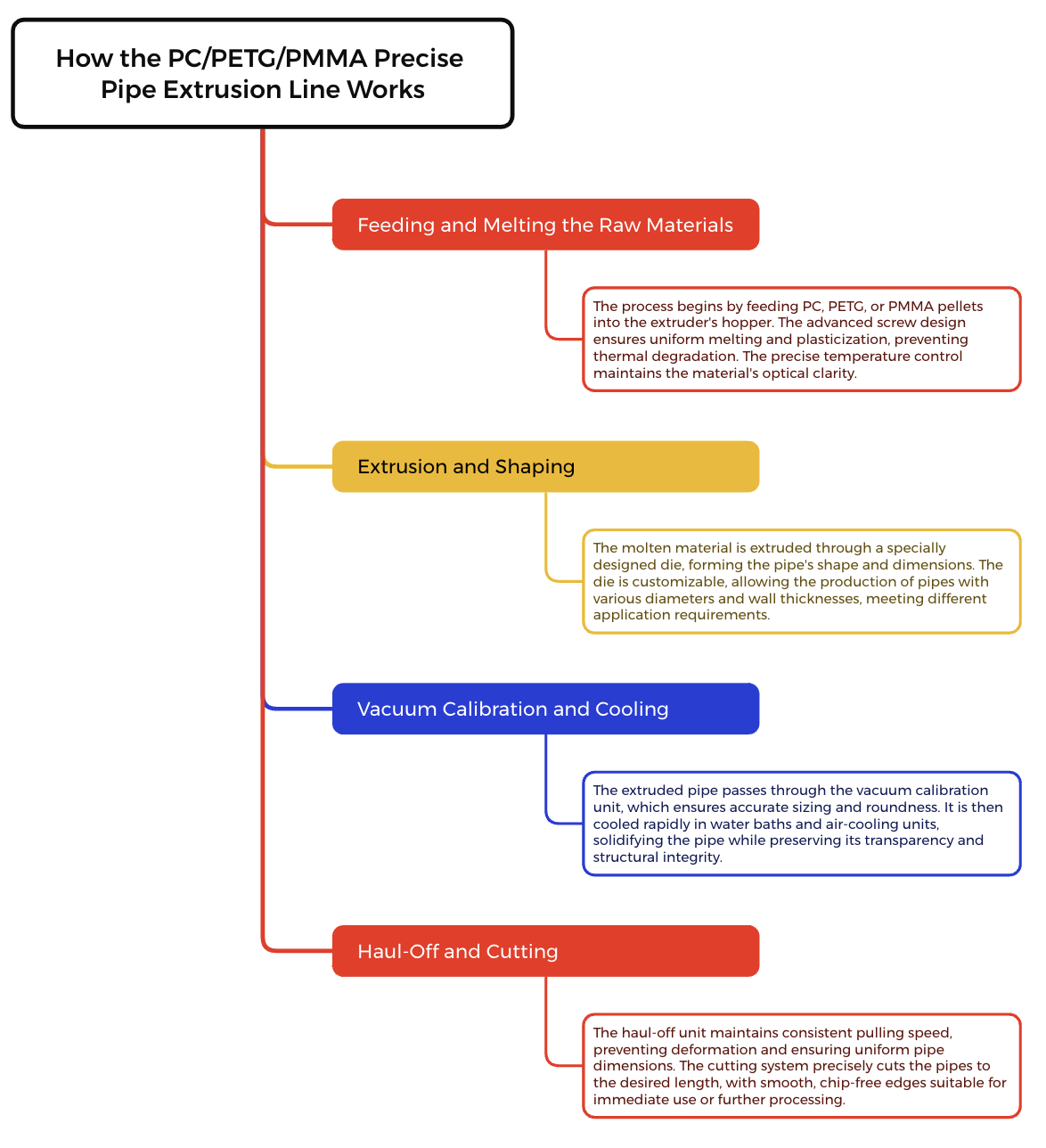

The PC/PETG/PMMA Precise Pipe Extrusion Line is equipped with a high-performance extruder specifically designed to process PC, PETG, and PMMA resins. These materials require precise temperature control and homogeneous melting to achieve their exceptional transparency and mechanical properties. The advanced screw and barrel design ensures optimal plasticization and consistent extrusion, resulting in high-quality pipes with smooth surfaces and accurate dimensions. The extruder's precise temperature and pressure control prevent degradation and yellowing, preserving the optical clarity of the pipes. |

| Customizable Pipe Specifications

One of the standout features of the PC/PETG/PMMA Precise Pipe Extrusion Line is its ability to produce pipes with customizable dimensions and properties. Manufacturers can easily adjust pipe diameter, wall thickness, and length to meet specific requirements for various applications, such as protective covers, display tubes, and fluid transport systems. The system supports a wide range of pipe diameters, from small precision tubes to large transparent pipes, ensuring flexibility in production. This customization capability makes it ideal for industries with diverse product demands, including medical, electronics, and automotive sectors. |

| Multi-Layer Co-Extrusion Technology

For enhanced functionality, the PC/PETG/PMMA Precise Pipe Extrusion Line supports multi-layer co-extrusion technology. This allows the production of composite pipes with different material layers, combining the unique properties of PC, PETG, and PMMA. For example, a multi-layer structure can provide superior impact resistance, UV protection, and chemical resistance, making the pipes suitable for harsh environmental conditions. The co-extrusion technology ensures strong interlayer adhesion while maintaining the optical clarity and surface smoothness of the pipes. |

| Advanced Vacuum Calibration and Cooling System

To achieve precise dimensions and superior surface quality, the PC/PETG/PMMA Precise Pipe Extrusion Line is equipped with an advanced vacuum calibration and cooling system. The vacuum calibration unit ensures accurate shaping and sizing, maintaining consistent pipe diameters and roundness. The cooling system, which includes water baths and air-cooling units, rapidly cools the extruded pipes, preventing deformation and preserving their transparency. This efficient cooling process ensures high production speed while maintaining the structural integrity and clarity of the pipes. |

| High-Precision Haul-Off and Cutting Unit

The PC/PETG/PMMA Precise Pipe Extrusion Line features a high-precision haul-off unit and cutting system to ensure consistent pipe length and smooth cut edges. The synchronized haul-off system maintains uniform pulling speed, preventing deformation and ensuring accurate pipe dimensions. The cutting unit, equipped with a chip-free cutting mechanism, provides clean, precise cuts without generating debris, ensuring the pipes' end surfaces remain smooth and ready for further processing or assembly. |

| Energy-Efficient and Eco-Friendly Design

Designed with energy efficiency in mind, the PC/PETG/PMMA Precise Pipe Extrusion Line reduces operational costs and environmental impact. Its optimized heating and cooling systems minimize energy consumption while maintaining high production efficiency. Additionally, the system minimizes material waste through precise control and automation, supporting sustainable manufacturing practices. The eco-friendly design contributes to lower carbon emissions, aligning with modern environmental standards. |

▏Technical Parameters

Model | Diameter (mm) | L/D | Speed (rpm) | Output (kg/h) | Drive Power (kw) | Heating | Central height (mm)

|

District | Power (kw)

|

SJ-30/25 | 30 | 25 | 60 | 8 | 4 | 3 | 3 | 1000 |

SJ-45/25 | 45 | 25 | 90 | 40 | 11 | 3 | 6 | 1000 |

SJ-45/30 | 30 | 100 | 50 | 15 | 4 | 8 | 1000 |

SJ-50/28 | 50 | 28 | 127 | 60 | 18.5 | 3 | 8 | 1000 |

SJ-55/28 | 55 | 28 | 130 | 95 | 30 | 3 | 12 | 1000 |

SJ-65/25 | 65 | 25 | 60 | 55 | 22 | 3 | 10 | 1000 |

SJ-65/30 | 28 | 110 | 140 | 37 | 3 | 15 | 1000 |

SJ-75/30 | 75 | 30 | 100 | 150 | 45 | 3 | 15 | 1000 |

SJ-80/30 | 80 | 30 | 100 | 180 | 55 | 4 | 25 | 1000 |

SJ-90/25 | 90 | 25 | 100 | 160 | 55 | 4 | 24 | 1000 |

SJ-90/30 | 30 | 80 | 210 | 75 | 5 | 30 | 1000 |

SJ-90/52 | 52 | 50 | 100 | 37 | 10 | 40 | 1000 |

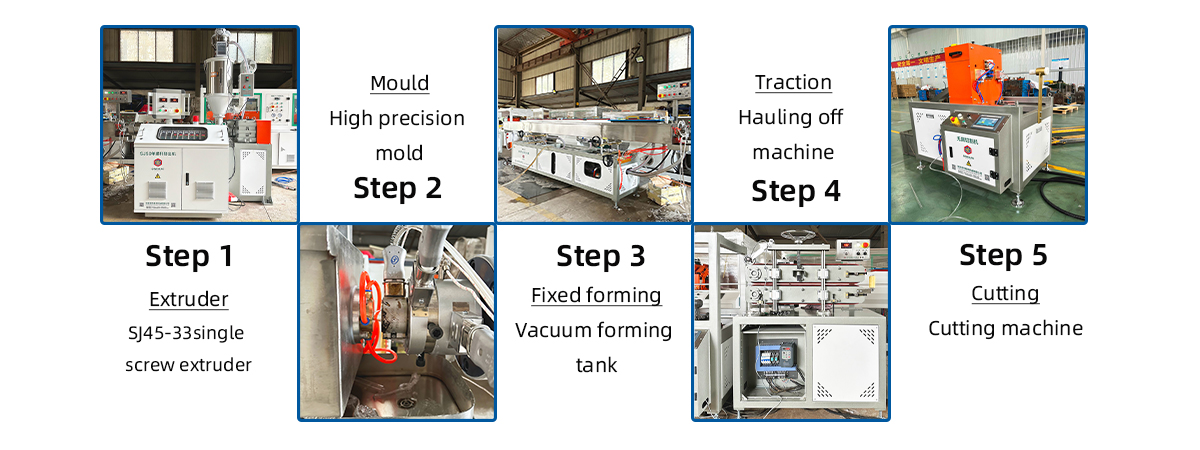

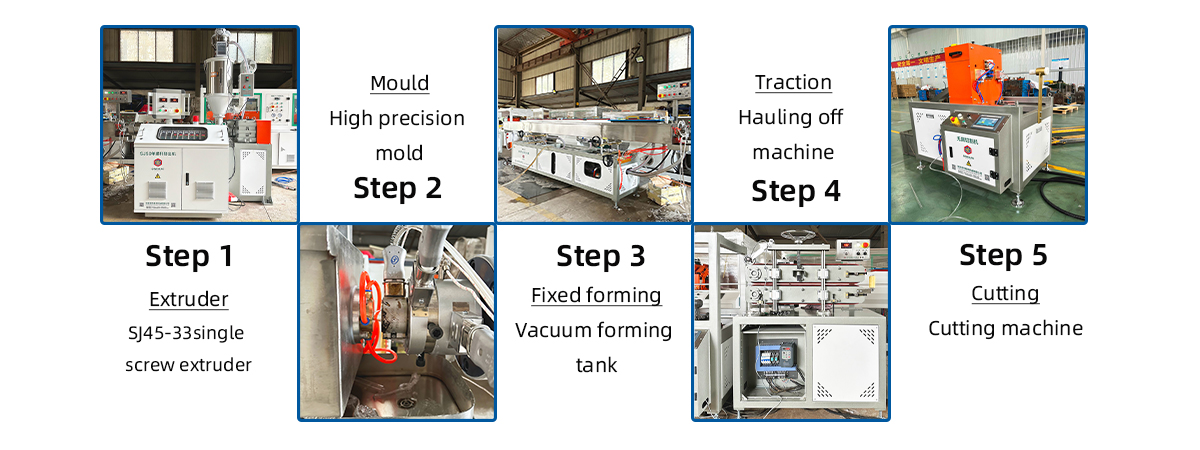

▏Production Procedure

▏Product Photos

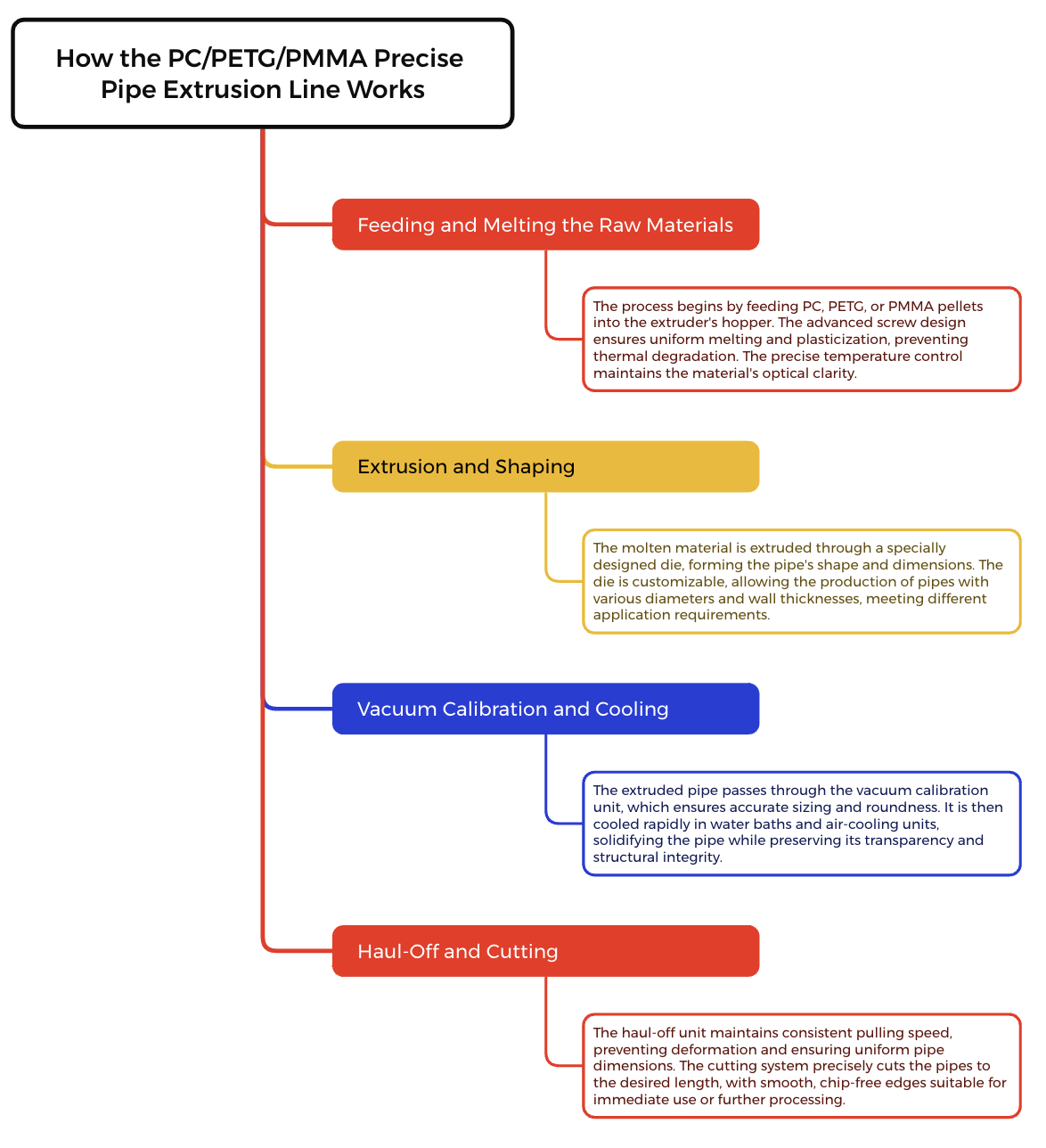

▏How the PC/PETG/PMMA Precise Pipe Extrusion Line Works

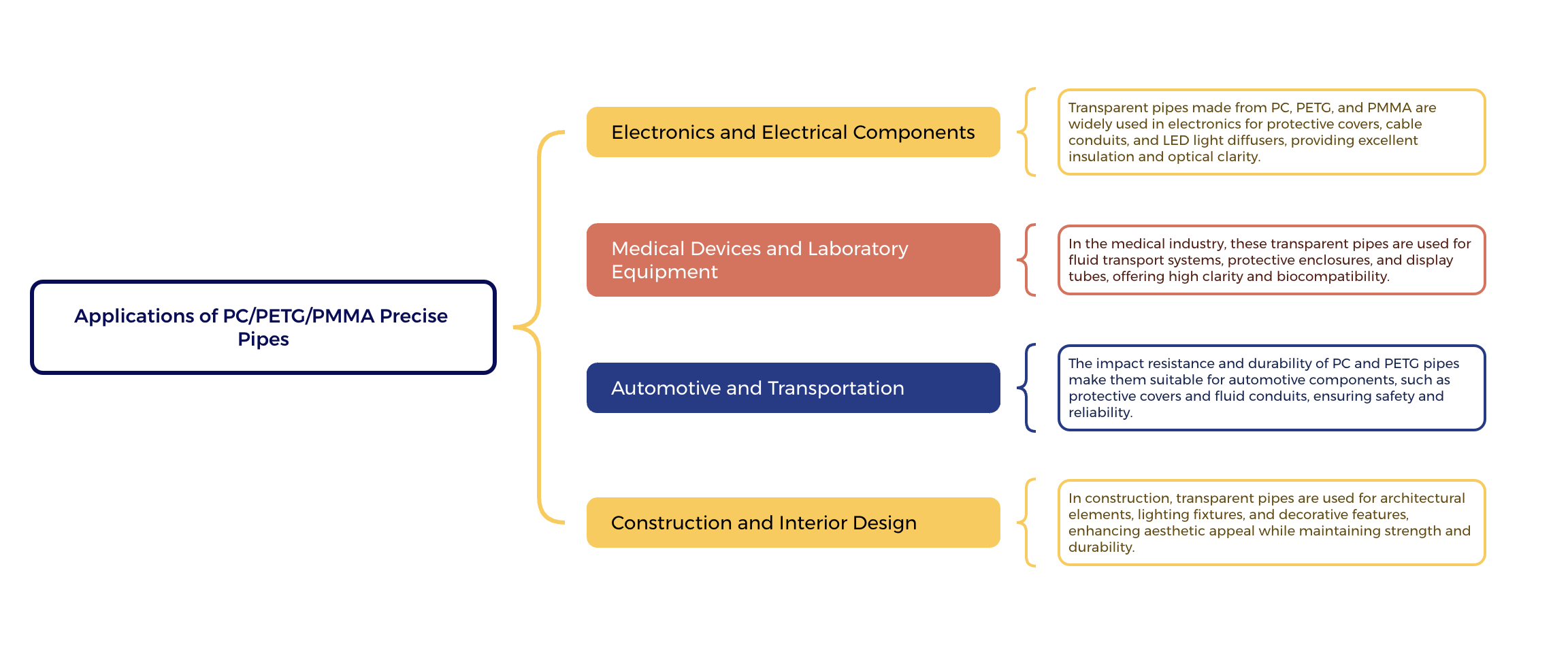

▏Applications of PC/PETG/PMMA Precise Pipes

▏Advantages of the PC/PETG/PMMA Precise Pipe Extrusion Line

| 1. High Production Efficiency

The advanced automation and continuous production capability ensure high output rates, reducing labor costs and maximizing productivity. |

| 2. Consistent Quality and Precision

The precise control of temperature, pressure, and speed ensures consistent quality, accurate dimensions, and smooth surfaces, meeting stringent industry standards. |

| 3. Customizable and Versatile Production

The extrusion line's flexibility allows manufacturers to produce a wide range of pipe sizes, shapes, and configurations, catering to various applications. |

| 4. Energy Efficiency and Sustainability

The energy-efficient design reduces operational costs and environmental impact, supporting sustainable manufacturing practices. |

| 5. Enhanced Durability and Transparency

Pipes produced with this extrusion line offer exceptional clarity, impact resistance, and UV protection, ensuring long-lasting performance. |

▏Elevate Your Production with the PC/PETG/PMMA Precise Pipe Extrusion Line

The PC/PETG/PMMA Precise Pipe Extrusion Line is a cutting-edge solution for manufacturers aiming to produce high-quality transparent pipes with exceptional clarity, precision, and durability. With its advanced features, including customizable specifications, multi-layer co-extrusion, and energy-efficient operation, this extrusion line delivers consistent product quality and high production efficiency.

By investing in this state-of-the-art extrusion technology, manufacturers can meet the evolving demands of industries such as electronics, medical devices, automotive, and construction. The PC/PETG/PMMA Precise Pipe Extrusion Line not only enhances production capabilities but also supports sustainable and cost-effective manufacturing practices, ensuring long-term business success.

▏Product Advantage

| 1 | Efficient automated production |

| The plastic PC/PETG/PMMA precise pipe extrusion line adopts advanced automatic control system to realize the automatic operation of the entire production process, which greatly improves the production efficiency. From the automatic delivery of raw materials to the automatic output of products, the entire process does not require too much manual intervention, significantly reducing labor costs, and ensuring the continuity and stability of production. |

| 2 | The product quality is stable |

| The plastic PC/PETG/PMMA precise pipe extrusion line is equipped with high-precision equipment and perfect process control system, which can accurately control various parameters in the production process, such as temperature, pressure, speed, etc., so as to ensure the stability and consistency of product quality. The plastic transparent pipe has high transparency and excellent physical properties, which can meet the strict requirements of customers. |

| 3 | Low production cost |

| By optimizing the production process and reducing energy consumption, the plastic PC/PETG/PMMA precise pipe extrusion line can effectively control the production cost. Efficient automated production reduces labor costs, while the use of energy-efficient equipment and environmentally friendly raw materials reduces energy consumption and material costs. In addition, high output and high-quality products also reduce the cost per unit of product. |

| 4 | Significant energy conservation and environmental protection |

| The plastic PC/PETG/PMMA precise pipe extrusion line focuses on energy saving and environmental protection design, and adopts low energy consumption drive system and advanced energy-saving technology to reduce energy consumption in the production process. At the same time, the emissions from the production line are treated to meet environmental protection standards, reducing environmental pollution. This is in line with the requirements of modern society for green production, and also provides strong support for the sustainable development of enterprises. |

| 5 | Easy to operate and easy to maintain |

| The plastic PC/PETG/PMMA precise pipe extrusion line has a friendly operation interface and intelligent control system, so that the operator can easily master the operation skills. Equipment maintenance is also relatively simple, regular inspection and maintenance can ensure the stable operation of the equipment. In addition, the production line is equipped with automatic fault diagnosis function to facilitate timely detection and resolution of problems. |

| 6 | A wide range of applications |

| The plastic PC/PETG/PMMA precise pipe extrusion line can produce plastic transparent pipes of different specifications and different wall thickness, which is suitable for various application scenarios and needs. Whether it is an observation window for the medical and food industries, or a liquid transport pipeline for the chemical and agricultural industries, it can meet the needs of customers. |

| 7 | High utilization rate of raw materials |

| Plastic PC/PETG/PMMA precise pipe extrusion line in the production process, the utilization rate of raw materials is very high. By precisely controlling the extrusion and cooling process, the waste of raw materials can be minimized. At the same time, the production line is also equipped with a waste recovery system, which can reuse waste materials, reducing production costs and environmental pollution. |

| 8 | Production process safety |

| The plastic PC/PETG/PMMA precise pipe extrusion line has been fully considered in terms of safety and is equipped with a variety of safety protection measures. Such as protective cover, safety switch, etc., can effectively prevent the operator in the production process of accidental injury. At the same time, the production line also has the fault automatic shutdown function to ensure that it can be stopped in time when there is an abnormal situation to ensure production safety. |

| 9 | Flexible adjustment of specifications |

| The plastic PC/PETG/PMMA precise pipe extrusion line has flexible specification adjustment ability, which can quickly adjust the configuration and parameters of the production line according to market demand and customer requirements, and produce transparent pipes with different specifications and performance. This flexibility enables the production line to adapt to changing market demands and improve market competitiveness. |

| 10 | Perfect after-sales service |

| Plastic PC/PETG/PMMA precise pipe extrusion line providers usually provide perfect after-sales service, including equipment installation and commissioning, operation training, maintenance and so on. In the process of equipment operation, any problem, the supplier can provide timely technical support and solutions to ensure the stable operation of the production line and customer satisfaction. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping