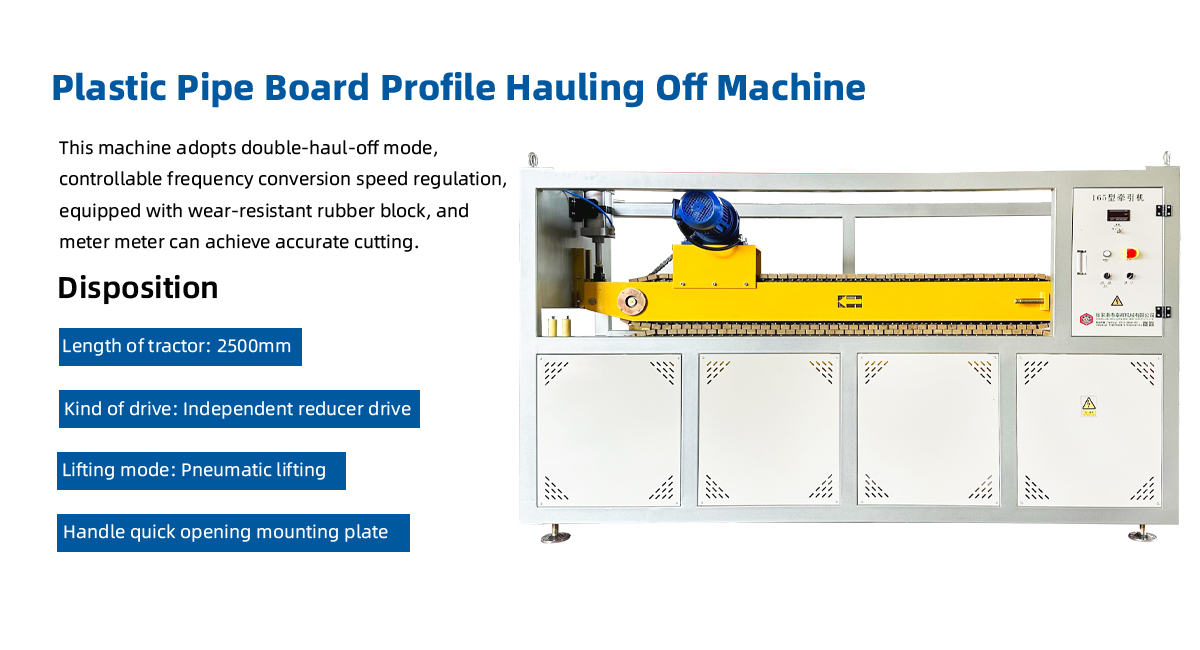

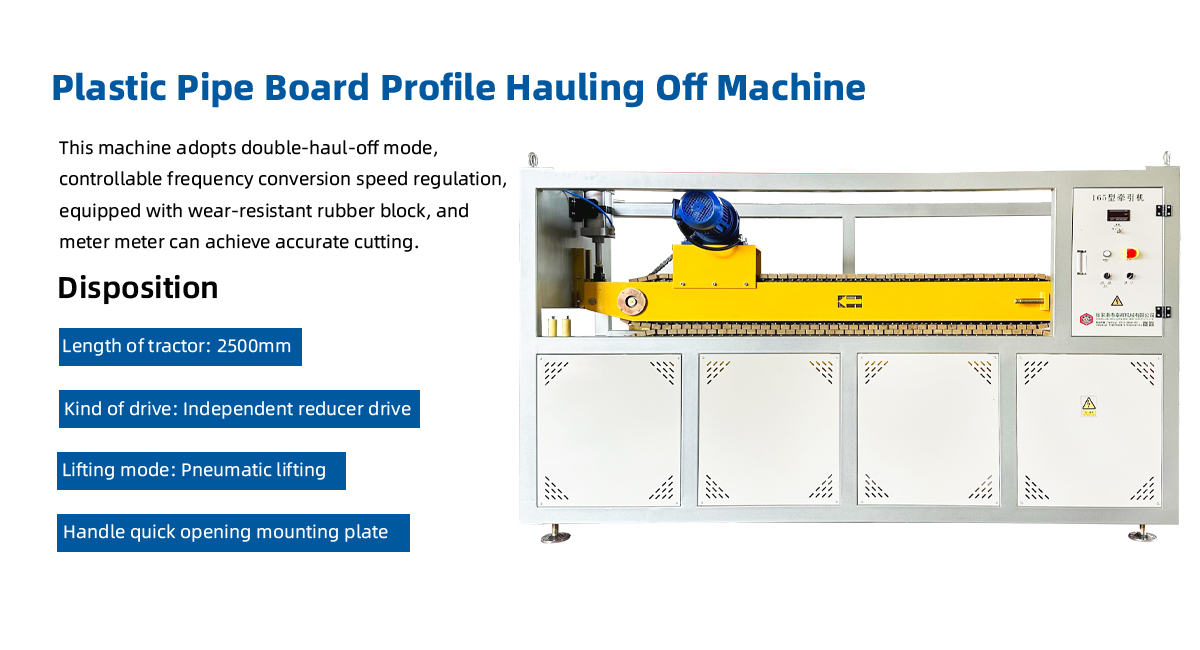

▏165 Rubber Block Hauling Off Machine: Precision and Efficiency in Pipe Production

▏Introduction to the 165 Rubber Block Hauling Off Machine

The 165 Rubber Block Hauling Off Machine is a highly efficient and reliable piece of equipment used in the extrusion process of plastic pipe manufacturing. It plays a vital role in ensuring that pipes, ranging from small to medium diameters, are cooled, calibrated, and pulled with precision through the production line. The unique feature of this machine is its rubber block hauling system, which provides an excellent grip without damaging the pipe’s surface. This mechanism makes it ideal for producing plastic pipes that meet stringent quality standards for industries such as construction, plumbing, and telecommunications.

The 165 Rubber Block Hauling Off Machine is designed for pipes with a diameter of 165 mm. It’s engineered to handle high-speed production while maintaining precise control over the pulling force, ensuring that pipes maintain their required shape and size. With its advanced technology, this hauling-off machine has become a trusted solution for manufacturers who aim to improve both product quality and production efficiency.

▏Key Features of the 165 Rubber Block Hauling Off Machine

| Durable Rubber Block Gripping System

The 165 Rubber Block Hauling Off Machine utilizes a rubber block gripping system that tightly holds and pulls the pipe during the extrusion process. Unlike traditional haul-off mechanisms, the rubber blocks provide a firm grip while offering a level of softness that prevents any damage to the surface of the pipe. This is especially important for pipes that need to maintain a flawless outer surface, such as those used in plumbing or decorative applications. The rubber blocks are designed to accommodate various pipe materials, including PVC, HDPE, PP, and others, ensuring compatibility with a wide range of extrusion processes. Their high resilience and wear resistance make them ideal for long-term, high-volume operation. |

| Adjustable Speed Control for Precision

One of the most important features of the 165 Rubber Block Hauling Off Machine is its adjustable speed control. This feature allows operators to customize the pulling speed based on the material and specifications of the pipe being produced. Fine-tuning the pulling speed ensures that the pipe maintains uniform dimensions throughout its length, preventing defects such as elongation or dimensional distortions. The ability to adjust the speed helps manufacturers optimize their production processes for efficiency, enabling high-quality outputs at varying rates of production. Whether the production requires slow speeds for high precision or fast speeds for mass production, the 165 Rubber Block Hauling Off Machine can accommodate both needs. |

| Robust Construction for Long-Term Use

The machine’s construction is built to last, made from high-quality materials such as stainless steel and durable alloys that ensure its longevity and resistance to corrosion and wear. These materials are essential in environments where continuous production is necessary. The 165 Rubber Block Hauling Off Machine is designed for low maintenance, reducing operational downtime and improving overall productivity. Its robust construction also ensures that the machine can handle the stresses of high-speed operation and maintain performance under demanding conditions. This durability makes it an excellent investment for manufacturers looking to increase the lifespan of their equipment and lower the cost of frequent repairs or replacements. |

| Versatility for Various Pipe Diameters

While the 165 Rubber Block Hauling Off Machine is designed for pipes with a diameter of 165 mm, it is versatile enough to handle a range of pipe sizes within the specified diameter range. The adjustable settings allow for quick adaptation to different pipe dimensions, making it a flexible option for manufacturers who need to produce multiple pipe sizes on the same production line. This adaptability makes the machine ideal for producing a wide range of plastic pipes used in various applications, including water supply systems, sewage pipes, and electrical conduits. Its versatility ensures that manufacturers can cater to diverse market demands while maintaining consistent product quality. |

| Integrated Cooling System

The 165 Rubber Block Hauling Off Machine works in conjunction with a cooling tank or water bath, allowing the extruded pipe to cool and solidify before it is pulled through the haul-off system. This cooling process is essential for maintaining the pipe’s shape and preventing shrinkage or warping as the material cools. The integrated cooling system helps to speed up the cooling process, ensuring that the pipe retains its structural integrity and dimensional accuracy. |

| Automatic Length Control and Cutting System

To ensure that the pipes are produced to the exact length required, the 165 Rubber Block Hauling Off Machine can be integrated with an automatic length control and cutting system. This system can be programmed to stop the machine at predetermined intervals, ensuring that each pipe is cut precisely to the desired length. This eliminates the need for manual measurement and cutting, reducing human error and increasing production efficiency. |

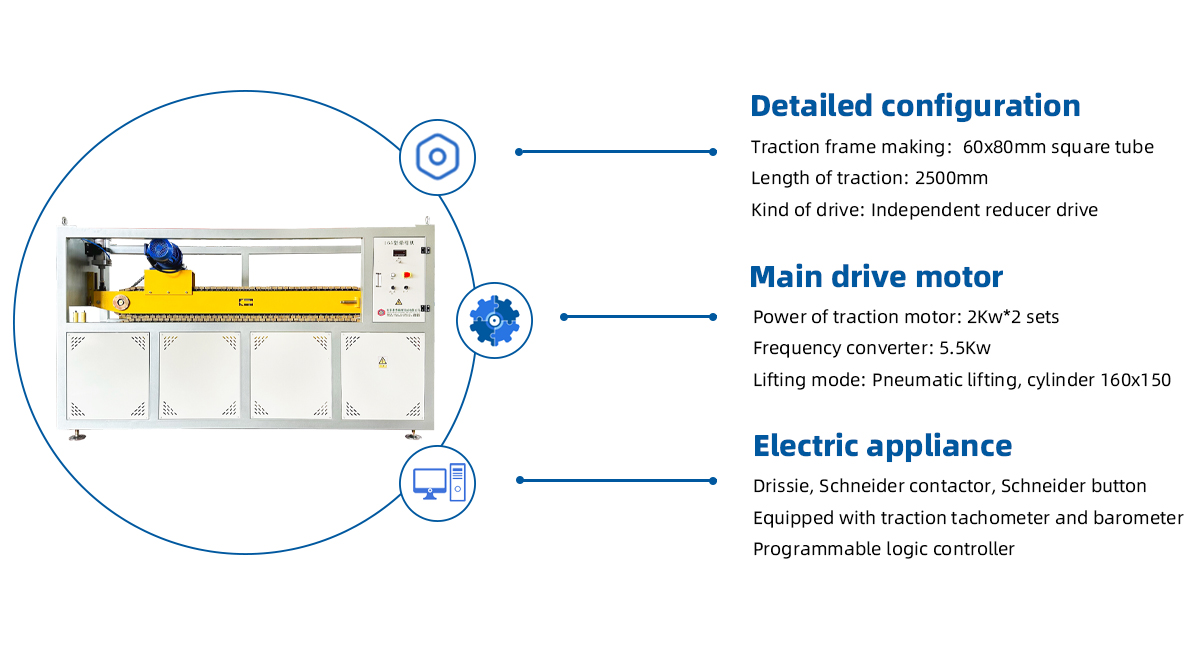

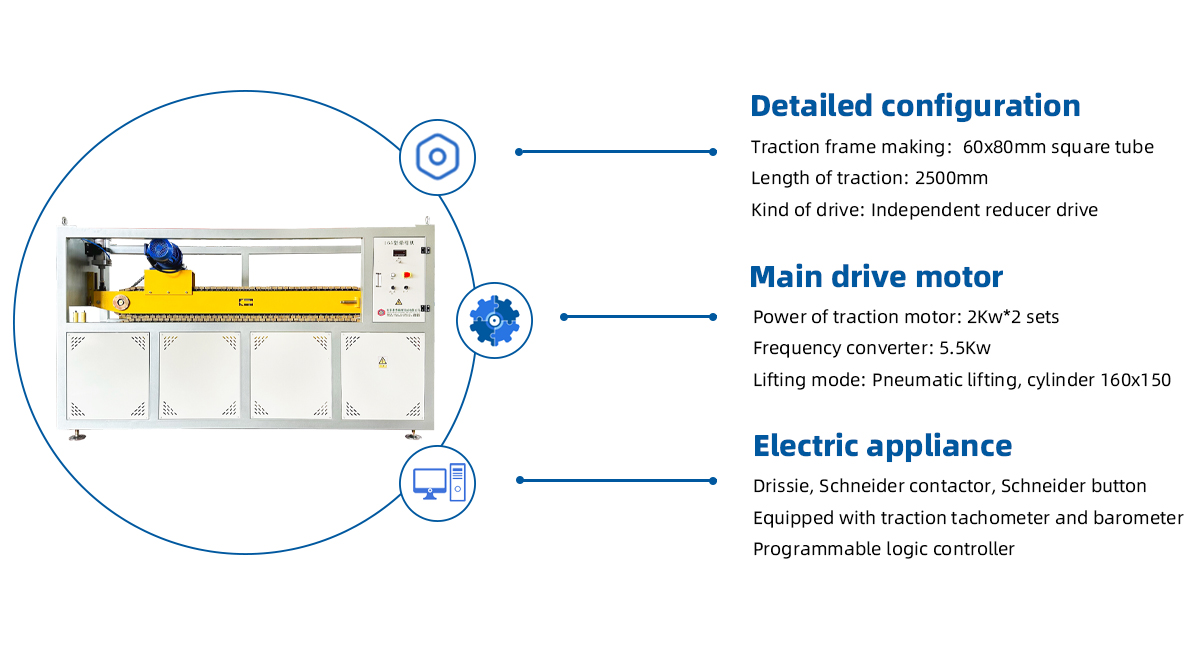

▏Technical Parameters

Traction frame making | 60x80mm square tube |

| Length of traction | 2500mm |

| Kind of drive | Independent reducer drive |

Power of traction motor | 2Kw*2 sets |

| Frequency converter | 5.5Kw |

| Lifting mode | Pneumatic lifting, cylinder 160x150 |

▏Main Details

▏Product Photos

▏How the 165 Rubber Block Hauling Off Machine Works

The 165 Rubber Block Hauling Off Machine follows a precise and efficient process to ensure that plastic pipes are produced with high quality:

| 1. Extrusion Process

The raw plastic material is fed into an extruder where it is melted and formed into the shape of a pipe. The extruder pushes the molten plastic through a die to create the desired pipe profile. |

| 2. Cooling

Once the pipe exits the extruder, it enters a cooling system such as a water bath or air cooling zone. The cooling process is critical for solidifying the pipe and ensuring that it retains its shape and size. The cooling system ensures that the pipe is uniformly cooled to avoid warping or dimensional inaccuracies. |

| 3. Hauling Off

The cooled pipe then enters the 165 Rubber Block Hauling Off Machine. The rubber blocks, which are mounted on rotating claws, grip the pipe and begin pulling it through the system. The adjustable speed control ensures that the pipe is pulled at a consistent rate, maintaining uniform dimensions. |

| 4. Length Control and Cutting

Once the pipe has been pulled to the correct length, the machine automatically halts, and the cutting system activates. The cutting system ensures that each pipe segment is uniform in length, which is important for packing and further processing. |

| 5. Discharge

Finally, the finished pipe is discharged from the system and is ready for packaging, further processing, or use in the next step of the production line. The pipe maintains its shape, surface finish, and precise dimensions, ensuring that it meets industry standards. |

▏Benefits of the 165 Rubber Block Hauling Off Machine

| 1. High Precision and Quality Control

The 165 Rubber Block Hauling Off Machine guarantees high precision throughout the production process. The adjustable speed control and rubber block gripping system ensure that the pipe maintains its shape, size, and surface quality, resulting in a consistently high-quality product. |

| 2. Improved Production Efficiency

The machine’s automatic length control and cutting system streamline the production process, reducing labor costs and minimizing human error. By automating key steps, the machine increases overall production efficiency, allowing manufacturers to produce more pipes in less time. |

| 3. Durability and Low Maintenance

With its durable construction and reliable performance, the 165 Rubber Block Hauling Off Machine requires minimal maintenance. The machine’s high-quality materials and design ensure long-lasting operation, reducing downtime and maintenance costs. |

| 4. Energy Efficiency

The machine is designed to be energy-efficient, consuming less power while maintaining high output levels. This helps manufacturers reduce operational costs and improve their bottom line by lowering energy expenses. |

| 5. Versatility for Multiple Applications

The 165 Rubber Block Hauling Off Machine is capable of handling various pipe sizes and materials, making it suitable for a wide range of industries. Whether producing pipes for plumbing, sewage systems, or electrical conduits, the machine’s versatility ensures it can meet diverse production needs. |

▏Applications of the 165 Rubber Block Hauling Off Machine

| 1. Plumbing and Water Supply

The 165 Rubber Block Hauling Off Machine is essential in the production of plastic pipes for water supply and plumbing systems. Its precision ensures that pipes maintain the necessary strength, diameter, and surface finish required for reliable water distribution. |

| 2. Sewerage and Drainage

For sewerage and drainage systems, this machine produces durable pipes that can withstand the pressures and conditions of waste management and water runoff. The precise control over pipe dimensions ensures long-term reliability and performance. |

| 3. Electrical and Telecommunications

Plastic pipes are used to house electrical cables and telecommunications wiring. The 165 Rubber Block Hauling Off Machine ensures that these pipes are produced with exact dimensions to protect sensitive cables from external damage. |

| 4. Industrial Applications

In industrial settings, plastic pipes are used in various applications such as chemical transportation, fluid systems, and air conditioning ducts. The 165 Rubber Block Hauling Off Machine ensures the production of strong, dimensionally accurate pipes for such demanding environments. |

▏The Future of Pipe Production

The 165 Rubber Block Hauling Off Machine is an advanced and reliable solution for modern plastic pipe production. Its durable rubber block gripping system, adjustable speed control, and integrated cooling and cutting systems work together to ensure that pipes are produced with high precision, low defect rates, and maximum efficiency. With its versatility and low maintenance requirements, the 165 Rubber Block Hauling Off Machine is an essential tool for manufacturers looking to optimize their production lines and deliver high-quality plastic pipes to meet the demands of various industries.

▏Product Application

| 1 | Introduction |

| kinds of efficient and accurate hauling off machine are more and more widely used in the production line. Among them, the plastic pipe board profile hauling off machine has been favored by the market for its unique performance and wide application fields. |

| 2 | Overview of application fields |

| With its stable performance and wide applicability, tplastic pipe board profile hauling off machine is widely used in the production line of rubber, plastics, chemical industry and so on. In these areas, the hauling off machine is mainly used to pull the processed rubber or plastic block out of the mold and carry out subsequent packaging, storage or further processing. Its efficient and stable working characteristics greatly improve production efficiency and reduce labor costs. |

| 3 | Production line automation |

| The application of the hauling off machine has significantly improved the automation level of the production line. Through the linkage control with upstream molding equipment and downstream packaging equipment, the hauling off machinecan precisely control the traction speed and position of the rubber block to ensure the continuous and stable operation of the production line. At the same time, the hauling off machine also has automatic fault detection function, which can alarm and stop in time when there is a fault, effectively avoiding the occurrence of production accidents. |

| 4 | Quality control and assurance |

| In terms of product quality control, the hauling off machine has played an important role. Its precise traction speed and uniform force output ensure the integrity and consistency of the rubber block pulled from the mold. At the same time, the hauling off machinecan also adjust the parameters to adapt to different specifications and materials of the rubber block, to ensure the diversity of products and quality stability. |

| 5 | Energy saving and environmental protection advantages |

| The hauling off machine pays attention to energy saving and environmental protection in design, and adopts high efficiency and energy saving motor and transmission system to reduce energy consumption. At the same time, the hauling off machine is also equipped with advanced dust removal device and noise control equipment, which effectively reduces dust and noise pollution in the production process. These energy-saving and environmentally friendly designs not only reduce the operating costs of enterprises, but also meet the requirements of modern society for environmental protection and sustainable development. |

| 6 | Convenient maintenance and operation |

| The hauling off machine also offers significant advantages in terms of maintenance and operation. The compact structure and modular design make it easier to maintain and replace parts. At the same time, the intelligent control system equipped with the tractor makes the operation more convenient, and the workers only need to carry out simple training to master. In addition, the hauling off machine also provides a wealth of fault diagnosis and alarm functions, so that maintenance personnel can quickly locate and resolve problems. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping