▏Product Vedio

▏Plastic Hose Extrusion Line

▏Introduction to the Plastic Hose Extrusion Line

The Plastic Hose Extrusion Line is a state-of-the-art manufacturing system designed for the continuous production of plastic hoses. These hoses are used in a wide range of applications, including industrial, agricultural, automotive, and medical fields, due to their flexibility, durability, and resistance to various environmental factors. This extrusion line combines advanced technology and efficient design to produce high-quality plastic hoses with consistent performance and precision.

With the growing demand for high-performance hoses, manufacturers require efficient and reliable production lines. The Plastic Hose Extrusion Line offers an all-in-one solution for producing hoses in various sizes, thicknesses, and materials, making it a crucial piece of equipment for companies in the plastic hose industry.

▏Key Features of the Plastic Hose Extrusion Line

| High-Efficiency Extruder for Superior Material Processing

The heart of any Plastic Hose Extrusion Line is its extruder. The extruder is designed to melt and homogenize plastic raw materials, such as PVC, PE, or PU, and then force the molten material through a die to create the desired hose profile. The extruder is equipped with advanced screw and barrel components that ensure smooth and uniform material flow, allowing for high-quality hose production. With precise temperature control, the extruder ensures that the material is processed at the optimal temperature to prevent degradation or inconsistency. The system also allows for the processing of various materials, enabling manufacturers to produce a wide range of hose types, including PVC reinforced hoses, medical-grade hoses, and industrial hoses. |

| Customizable Hose Diameter and Thickness

One of the key advantages of the Plastic Hose Extrusion Line is its ability to produce hoses with varying diameters and wall thicknesses. The line can be easily adjusted to accommodate different hose specifications based on the needs of the customer or application. Whether producing thin-walled, flexible hoses or thick-walled, heavy-duty hoses, the extrusion line allows for precision control over the hose dimensions. This flexibility makes it possible to cater to a wide range of industries that require hoses with specific characteristics, such as high-pressure resistance, flexibility, or chemical resistance. |

| Multi-Layer Extrusion Capabilities

Many plastic hoses require multiple layers for added strength, durability, or special properties, such as UV resistance or chemical resistance. The Plastic Hose Extrusion Line is equipped with multi-layer extrusion capabilities, allowing manufacturers to produce hoses with multiple layers of material. This can include inner and outer layers for reinforcement or specialized materials to provide protection against external factors like heat, chemicals, or abrasion. The multi-layer system ensures that each layer is applied uniformly and precisely, resulting in a hose that offers the desired performance characteristics. By combining different materials in the extrusion process, manufacturers can produce hoses that meet a wide variety of industry-specific requirements. |

| Automatic Cooling and Calibration System

After the plastic material has been extruded into a hose shape, it needs to be cooled and calibrated to maintain its dimensional accuracy. The Plastic Hose Extrusion Line is equipped with a sophisticated cooling and calibration system that ensures the hose retains its desired diameter and shape throughout the cooling process. The cooling system typically involves a water bath or air cooling system, depending on the type of hose being produced. This cooling process helps the hose solidify and prevents it from warping or losing its shape during the manufacturing process. The calibration system ensures that the hose is the correct size and that it maintains its uniformity along the entire length. |

| Advanced Haul-Off and Cutting System

The Plastic Hose Extrusion Line includes a high-performance haul-off unit that pulls the extruded hose through the production line. The haul-off system is equipped with rubber rollers or claws that grip the hose securely without damaging it, maintaining a consistent pulling force. This helps ensure uniformity in the final product, with consistent tension applied to the hose as it moves through the cooling and cutting stages. The cutting system is typically automated, with precise length control to ensure that each hose is cut to the required size. Whether the hoses are being produced for a specific length or for coiling purposes, the cutting system guarantees that the hoses are consistently cut with minimal material waste. |

| User-Friendly Control Panel

To enhance operational efficiency and simplify production management, the Plastic Hose Extrusion Line is equipped with a user-friendly control panel. The control system allows operators to monitor and adjust various parameters, including temperature, speed, and pressure, in real-time. This intuitive system enables manufacturers to optimize their production line for different materials and hose specifications, ensuring that each batch of hoses meets the highest quality standards. The control panel may also feature a touch screen interface that displays key performance indicators and alerts for maintenance or system checks. This allows for quick troubleshooting and ensures that the extrusion line operates with minimal downtime. |

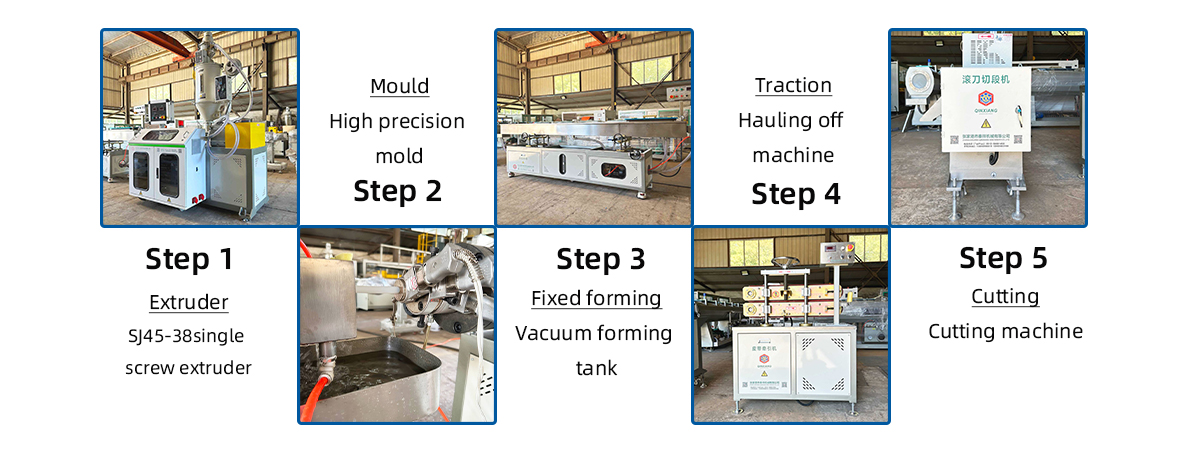

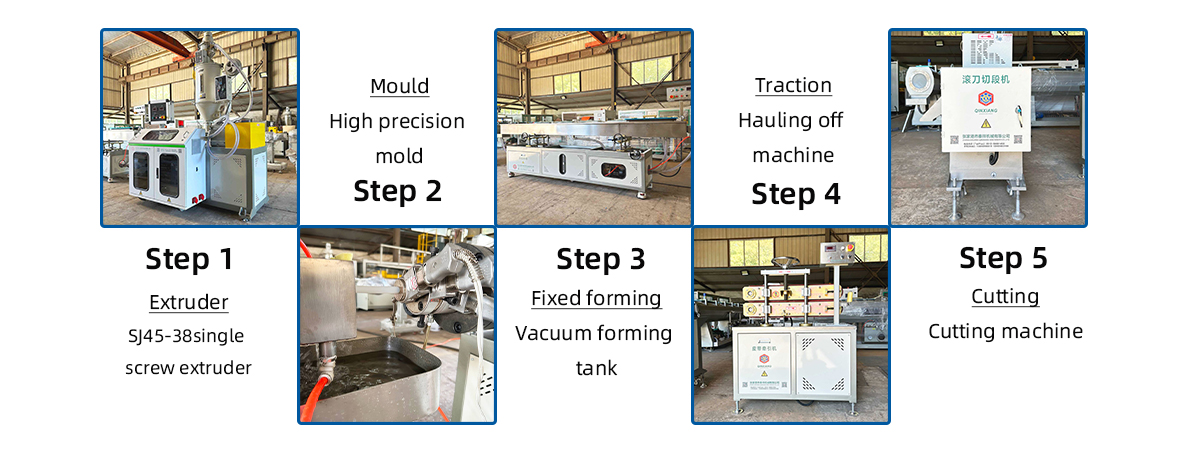

▏Production Procedure

▏Product Photos

▏How the Plastic Hose Extrusion Line Works

| 1. Feeding and Melting the Plastic Material

The extrusion process begins with the feeding of raw plastic pellets or granules into the hopper of the extruder. The material is then conveyed into the extruder barrel, where it is heated and melted by rotating screws. The extrusion line is equipped with a precise temperature control system to ensure that the plastic is processed at the optimal temperature for uniform melting and material flow. |

| 2. Extrusion Through the Die

Once the material is melted, it is forced through a specially designed die, which shapes the material into a tube or hose profile. The die design is crucial for achieving the desired hose dimensions, including diameter, thickness, and wall structure. The extrusion process can be adjusted to accommodate different hose profiles, such as single-layer or multi-layer hoses. |

| 3. Cooling and Calibration

After extrusion, the hose enters the cooling and calibration system, where it is cooled to solidify the material. The cooling system typically consists of a water bath or air-cooling chamber, which ensures that the hose retains its shape and dimensional accuracy. The calibration unit maintains the hose's diameter and prevents distortion as it solidifies. |

| 4. Haul-Off and Cutting

The cooled hose is then pulled by the haul-off unit, which maintains consistent tension throughout the process. The haul-off system ensures that the hose is pulled through the cooling and cutting stages at a constant rate, preventing defects like sagging or uneven thickness. The automatic cutting system cuts the hose to the desired length, ensuring that each piece meets the required specifications. The length control system ensures that hoses are cut with high precision, whether for coils or specific lengths. |

| 5. Discharge and Packaging

Once the hose is cut, it is discharged from the extrusion line and ready for further processing or packaging. The finished hoses are then inspected for quality, ensuring that they meet the necessary standards before they are shipped to customers or used in various applications. |

、

▏Applications of the Plastic Hose Extrusion Line

| 1. Industrial Applications

The Plastic Hose Extrusion Line is commonly used in the production of hoses for industrial applications, such as fluid transport, pneumatic systems, and machine cooling. These hoses must meet specific strength, flexibility, and chemical resistance requirements. |

| 2. Agricultural Irrigation

Plastic hoses are frequently used in irrigation systems, where flexibility and resistance to environmental factors are essential. The extrusion line can produce hoses that are UV-resistant and capable of withstanding high-pressure water flows. |

| 3. Automotive

In the automotive industry, hoses are used for fuel systems, air conditioning, and fluid transfer. The Plastic Hose Extrusion Line produces hoses with excellent pressure resistance and flexibility, making them ideal for automotive applications. |

| 4. Medical and Pharmaceutical

For medical and pharmaceutical applications, the Plastic Hose Extrusion Line can produce hoses that meet stringent quality standards for biocompatibility, cleanliness, and durability. Medical tubing and hoses are essential for fluid delivery systems and diagnostic equipment. |

| 5. Construction and Infrastructure

Plastic hoses are often used in construction projects for water, air, and concrete transport. The Plastic Hose Extrusion Line can produce hoses that are resistant to abrasion, chemicals, and pressure, making them ideal for construction applications. |

▏The Ideal Solution for Hose Production

The Plastic Hose Extrusion Line is an indispensable tool for manufacturers in the plastic hose industry. Its advanced features, such as customizable extrusion, multi-layer capabilities, precise calibration, and high-performance haul-off and cutting systems, enable the production of high-quality hoses for a wide range of applications. With its ability to produce hoses with various diameters, thicknesses, and material properties, the extrusion line provides manufacturers with the flexibility and efficiency needed to meet customer demands while maintaining high product quality.

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping