▏Product Vedio

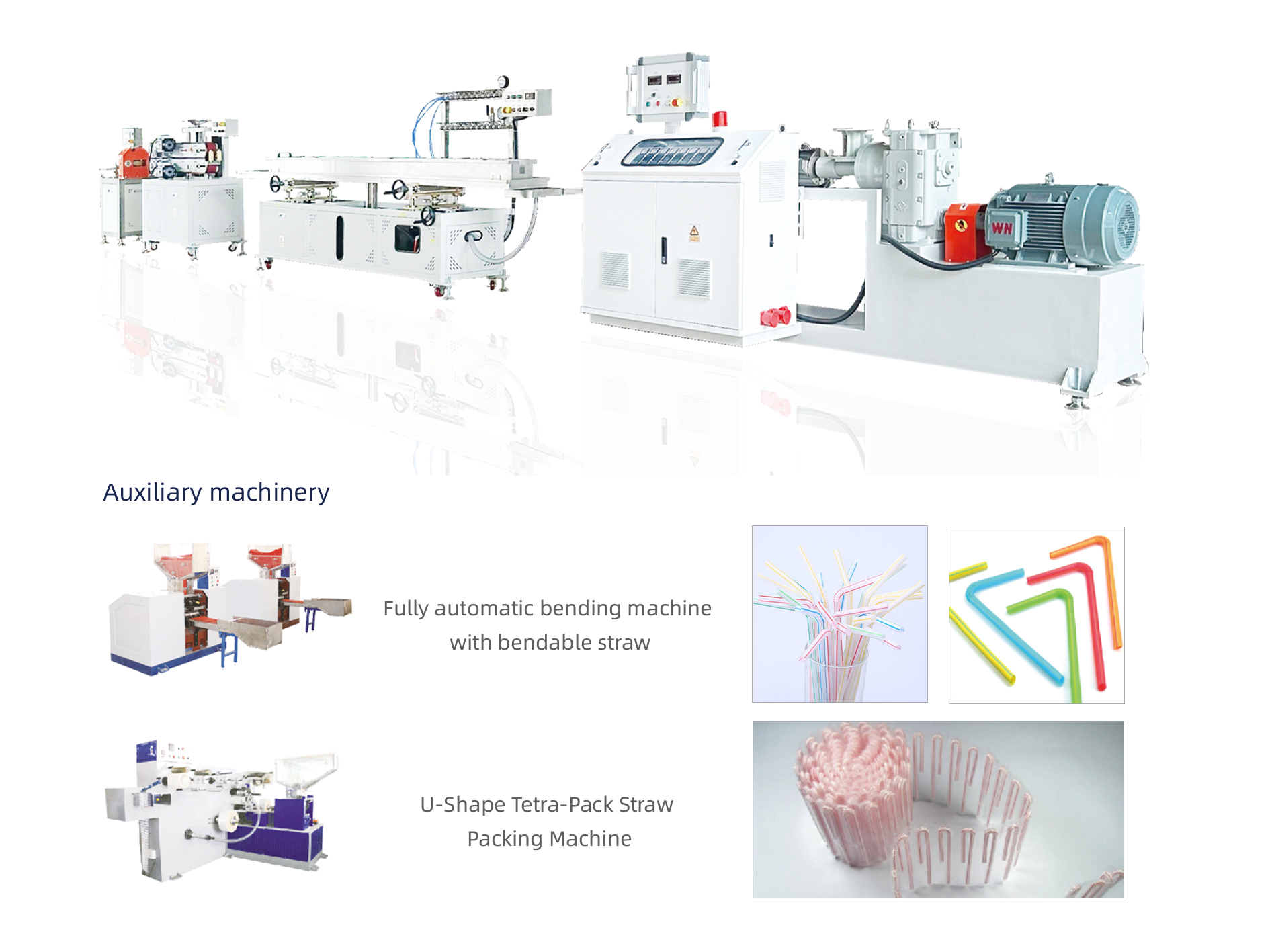

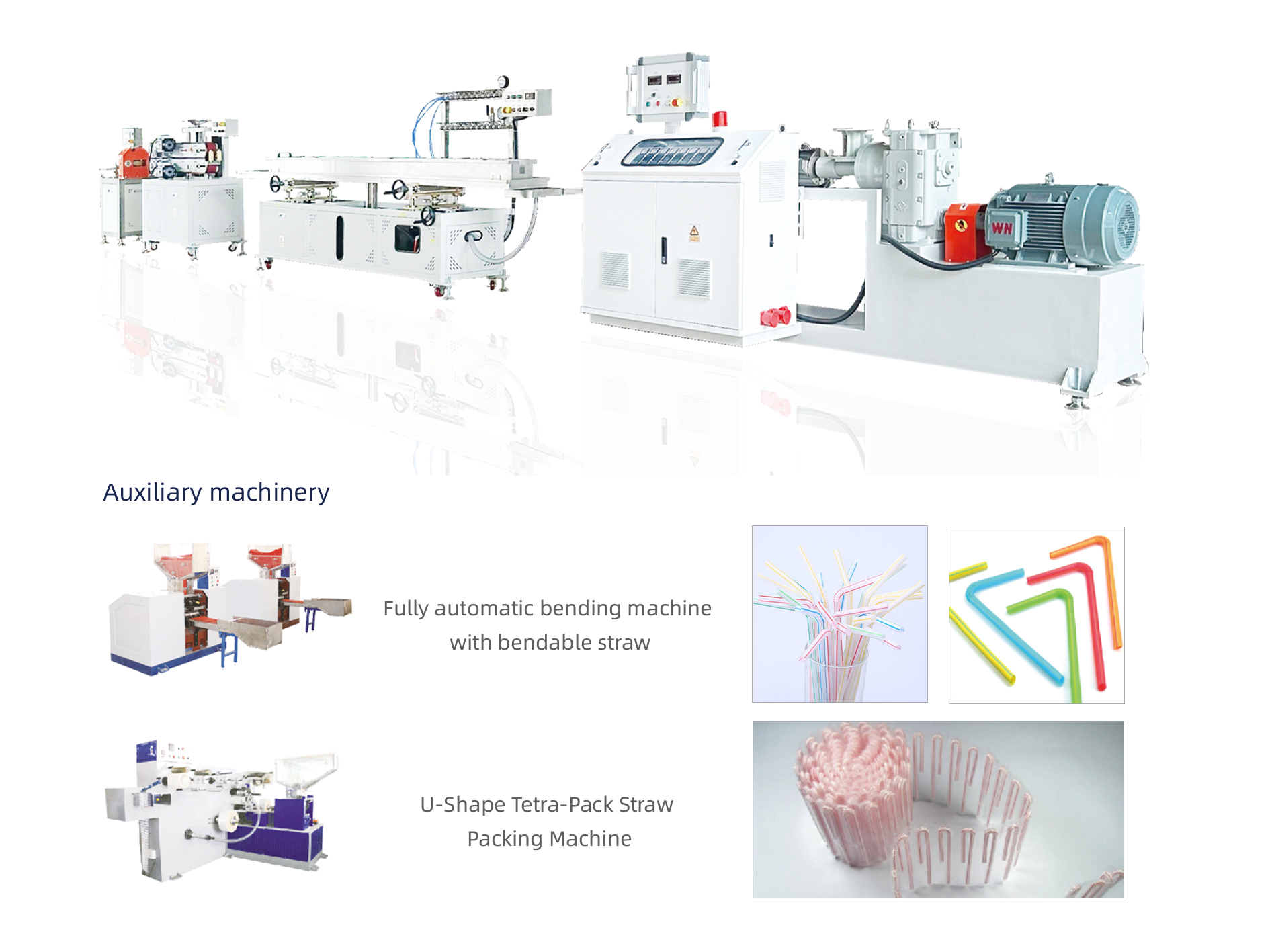

▏Plastic Drinking Straw Extrusion Line

‖ PP/PLA Straw Extrusion Line

▏Introduction to the Plastic Drinking Straw Extrusion Line

The Plastic Drinking Straw Extrusion Line is a cutting-edge system designed for the continuous production of plastic drinking straws. These straws are commonly used in the food and beverage industry and come in a variety of sizes, colors, and designs to cater to different customer preferences and needs. The extrusion line combines advanced engineering with high efficiency to produce straws that meet the highest quality standards.

In recent years, with increasing concerns over plastic waste, there has been a push for more sustainable alternatives. However, plastic drinking straws continue to be a necessary and essential part of the beverage industry. The Plastic Drinking Straw Extrusion Line provides a solution for manufacturers by offering an automated, high-output system that ensures precise production while optimizing material usage.

▏Key Features of the Plastic Drinking Straw Extrusion Line

| High-Precision Extruder for Consistent Quality

At the heart of the Plastic Drinking Straw Extrusion Line is its high-precision extruder, which is responsible for melting and processing plastic materials like polyethylene (PE), polypropylene (PP), or polylactic acid (PLA). The extruder is equipped with an advanced screw and barrel system, ensuring uniform melting, consistent material flow, and minimal degradation of the plastic. The extruder is designed with temperature and speed control systems that allow for precise adjustments based on the material being used and the desired straw characteristics. Whether producing soft, flexible straws or rigid, durable ones, the extruder ensures that the plastic is processed to perfection, resulting in straws of consistent size and strength. |

| Customizable Straw Dimensions and Length

The Plastic Drinking Straw Extrusion Line offers excellent flexibility when it comes to customizing the dimensions and length of the straws. By adjusting the extrusion die, manufacturers can produce straws in various diameters and lengths to meet market demand. The line can produce standard-sized straws as well as wider straws for specific applications, such as smoothies or bubble teas. The ability to fine-tune the size and length of the straws ensures that manufacturers can cater to the diverse needs of customers. Whether producing short, narrow straws or long, wide ones, the extrusion line provides the precision needed to maintain high product quality across a range of straw specifications. |

| Multi-Layer Extrusion for Enhanced Performance

While single-layer straws are commonly produced, the Plastic Drinking Straw Extrusion Line also offers multi-layer extrusion capabilities. This feature allows manufacturers to create straws with multiple layers, each offering unique properties. For instance, an inner layer may be designed for flexibility and smooth fluid flow, while an outer layer provides durability and resistance to environmental stress. Multi-layer straws can be used to improve the strength, appearance, and functionality of the product. They can also be used to incorporate biodegradable or eco-friendly materials, contributing to sustainability in an industry that is under increasing pressure to reduce plastic waste. |

| Efficient Cooling and Shaping System

Once the plastic is extruded into the desired shape, it is critical to cool and shape it properly to maintain dimensional accuracy and consistency. The Plastic Drinking Straw Extrusion Line features a high-efficiency cooling system that quickly solidifies the extruded straws without causing warping or distortion. The cooling system is usually a combination of water baths and air cooling units that ensure that the straws retain their round shape and smooth surface. A precise calibration system ensures that the straws maintain their exact diameter throughout the production process, minimizing defects and ensuring a uniform product. |

| High-Precision Cutting and Length Control

The cutting system of the Plastic Drinking Straw Extrusion Line is equipped with an automatic cutting unit that ensures each straw is cut to the desired length with high precision. The system is integrated with a length control system that continuously monitors and adjusts the cutting process to ensure that the straws meet the required specifications. The cutting unit ensures minimal material waste, improving overall efficiency and reducing production costs. Additionally, the high-precision cutting system helps ensure that each straw is of the same length, allowing for a consistent and reliable product that meets customer expectations. |

| Automated Packaging System

Once the straws are cut to length, they are ready for packaging. The Plastic Drinking Straw Extrusion Line may be integrated with an automated packaging system that groups the straws into bundles or individual packs for shipping. This system ensures that the straws are packaged efficiently and securely, ready to be delivered to customers in a timely manner. The automated packaging system helps streamline the overall production process, reducing labor costs and increasing productivity. Additionally, the packaging system can be customized to accommodate different types of packaging, such as paper or plastic wrappers, depending on the manufacturer's needs. |

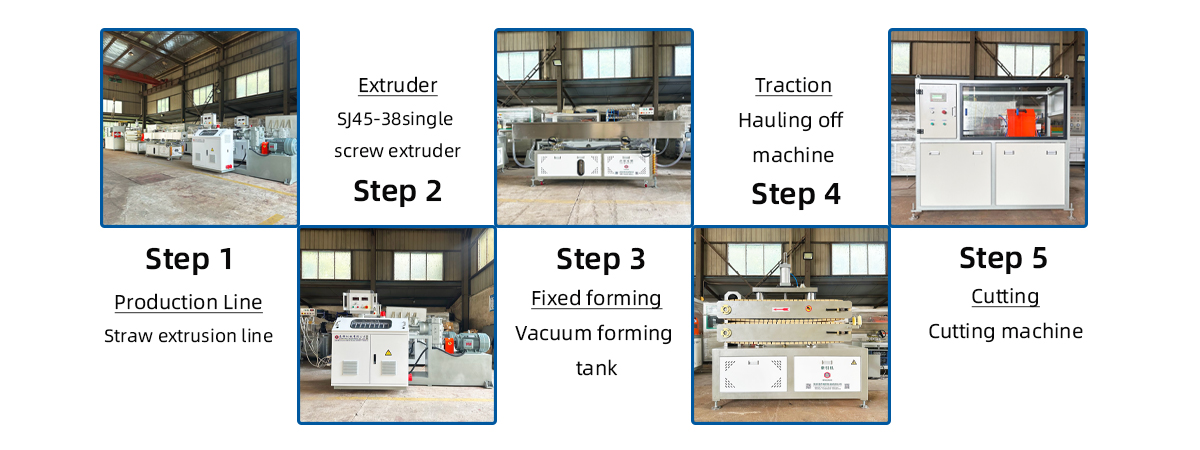

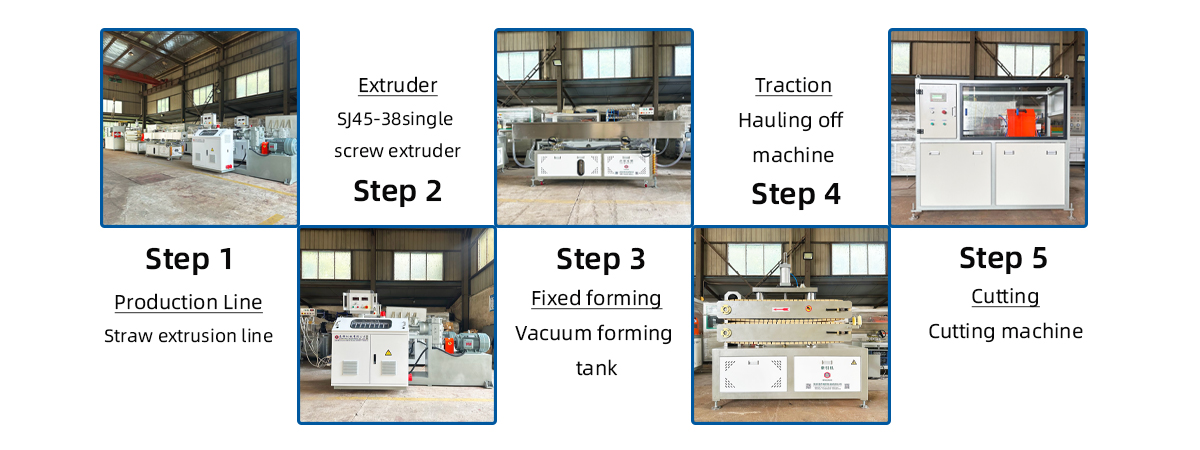

▏Production Procedure

▏Product Photos

▏How the Plastic Drinking Straw Extrusion Line Works

▏Benefits of the Plastic Drinking Straw Extrusion Line

| 1. High Efficiency and Productivity

The Plastic Drinking Straw Extrusion Line is designed for high output, making it ideal for manufacturers who need to produce large quantities of straws. The automated system ensures that the production process is streamlined and efficient, reducing manual labor and increasing overall productivity. |

| 2. Customizable Specifications

The extrusion line provides great flexibility in terms of straw size, length, and material. Manufacturers can easily adjust the parameters to produce straws that meet the specific needs of customers or industries. Whether producing single-use straws for quick service restaurants or high-strength straws for smoothies, the line can be customized to produce a wide range of products. |

| 3. High-Quality Consistency

With precise temperature control, cutting systems, and calibration mechanisms, the extrusion line ensures that all straws are of the same high quality. Consistent dimensions, smooth surfaces, and uniform strength are key attributes that make the Plastic Drinking Straw Extrusion Line a preferred choice for manufacturers who prioritize quality. |

| 4. Energy Efficiency

The system is designed to be energy-efficient, reducing operational costs and environmental impact. Optimized heating and cooling processes, as well as efficient material usage, contribute to lower energy consumption throughout production. |

| 5. Reduced Material Waste

The automated cutting system ensures that straws are produced to the exact required length, minimizing waste material. This contributes to more sustainable production and helps reduce overall costs by making better use of raw materials. |

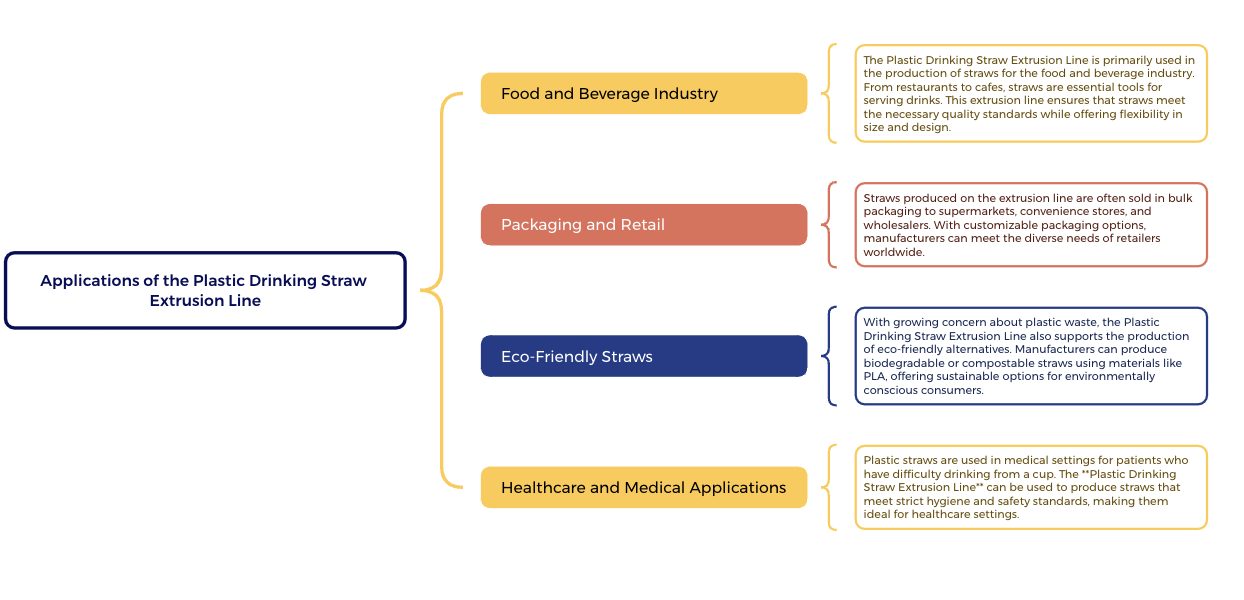

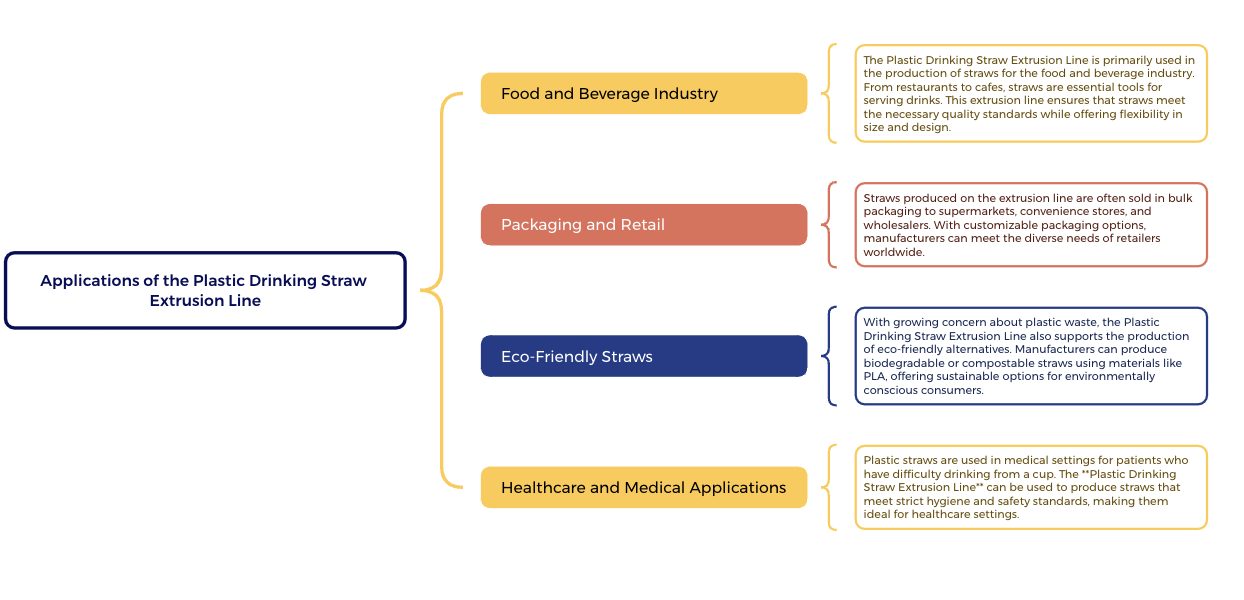

▏Applications of the Plastic Drinking Straw Extrusion Line

▏Innovating Straw Production with Precision and Efficiency

The Plastic Drinking Straw Extrusion Line offers a highly efficient and customizable solution for producing plastic straws in a variety of sizes, materials, and designs. With advanced technology, precise control systems, and eco-friendly options, this extrusion line meets the growing demand for high-quality, cost-effective straws in the food and beverage industry and beyond.

▏Range Of Application

| 1 | Overview of the Plastic Drinking Straw Extrusion Line |

| Plastic drinking straw extrusion line is a fully automatic production line specially used for the production of plastic straws. The line integrates modern equipment and technology to produce high-quality, multi-specification plastic straws efficiently and accurately to meet the needs of the food and beverage industry. |

| 2 | The main equipment |

| Plastic drinking straw extrusion line mainly includes the following equipment: 1. Extruder: used to extrude molten plastic raw materials into tubes. 2. Molding mold: The extruded tubular plastic material is shaped into a straw of specific cross-section shape and size. 3. Cooling device: The molded straw is cooled quickly to fix its shape. 4. Traction cutting equipment: Traction and precise cutting of the cooled straw to the specified length. 5. Detection and screening system: automatically detect the quality of the straw, such as length, diameter, curvature, etc., and screen out the defective products. 6. Packaging machinery: Packaging qualified straws for easy storage and transportation. |

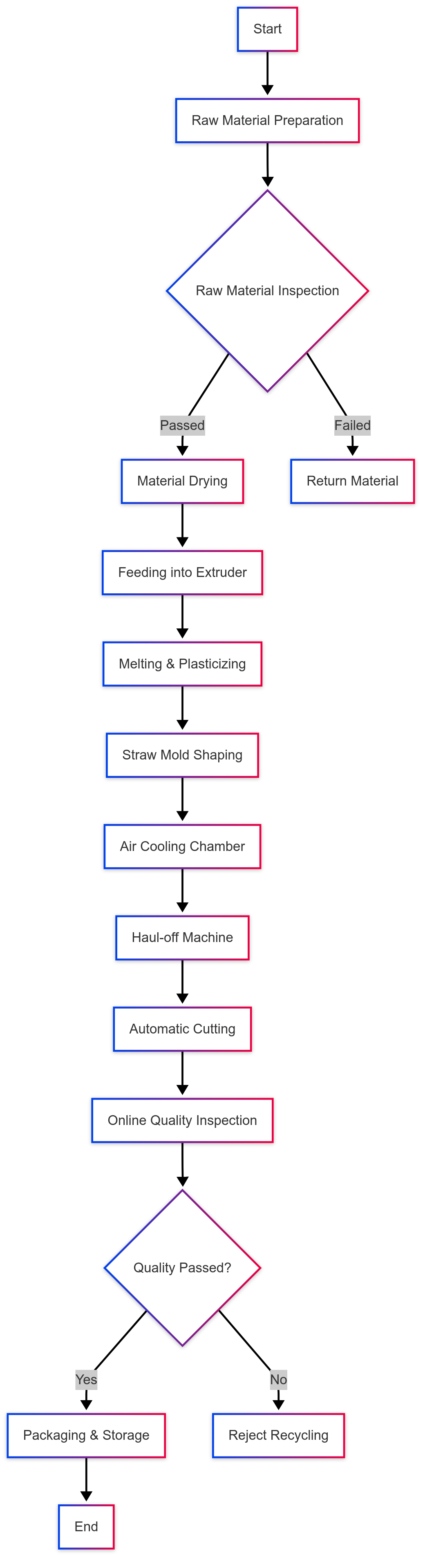

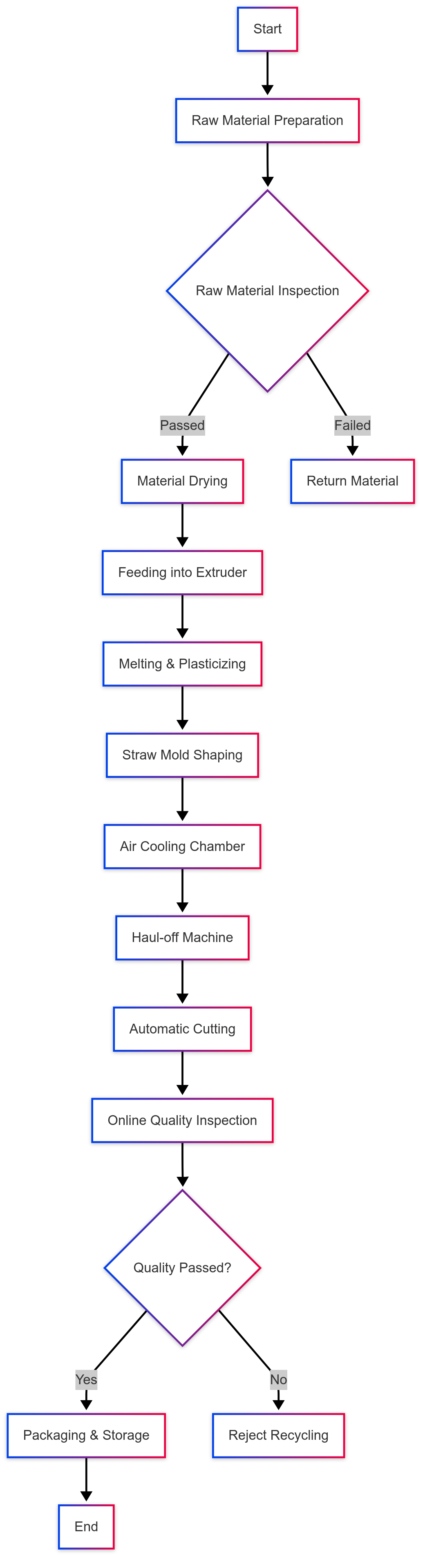

| 3 | Process flow |

|

The production process of plastic straws is roughly as follows: 1. Raw material preparation: Mix plastic raw materials according to a certain proportion, and preheat to the appropriate temperature. 2. Extrusion molding: The molten plastic raw materials are extruded into tubes by the extruder, and the shape of the straw is formed by the molding mold. 3. Cooling and shaping: Use a cooling device to quickly cool the molded straw to ensure that the shape of the straw is stable. 4. Traction cutting: the suction pipe is continuously drawn out through the traction equipment, and cut into the required length through the cutting device. 5. Detection and screening: Use the detection and screening system to check the quality of the straw and screen out defective products. 6. Packaging and warehousing: The qualified straws are packaged and stored in the warehouse. |

| 4 | Technological innovation |

|

1. Intelligent control system: Through the introduction of advanced control system, to achieve accurate control of the production line parameters, improve production efficiency and product quality. 2. Energy-saving technology: The use of energy-efficient equipment and processes to reduce energy consumption in the production process. 3. Environmental protection materials: the selection of recyclable and degradable environmental protection materials to reduce environmental pollution. |

| 5 | Environmental protection characteristics |

|

Plastic drinking straw extrusion line in the design and production process fully consider environmental factors, with the following characteristics: 1. Use recyclable and degradable environmental protection materials to reduce environmental pollution. 2. Efficient and energy-saving production process and equipment to reduce energy consumption and carbon emissions. 3. Strict waste gas and waste water treatment system to ensure that the discharge in the production process meets environmental protection standards. |

| 6 | Application fields |

|

Plastic straws are widely used in the following areas: 1. Food industry: used for packaging and smoking of all kinds of drinks and food. 2. Beverage industry: Used with bottled beverages to meet the drinking needs of consumers. 3. Catering industry: straws are provided in restaurants, cafes and other places for the convenience of customers. |

| 6 | Production efficiency |

|

The plastic drinking straw extrusion line has efficient production capacity and can achieve continuous and stable production. By optimizing the production process and introducing advanced technology, production efficiency can be further improved, production costs can be reduced, and greater economic benefits can be created for enterprises. At the same time, the efficient production line also ensures the stability of market supply and meets the needs of our customers. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping