▏Product Vedio

▏∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine

▏Introduction to the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine

The ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine is a highly specialized piece of equipment designed for the pulling and cooling of small to medium-diameter plastic pipes. These pipes are typically made from materials like PE (Polyethylene), HDPE (High-Density Polyethylene), and PVC (Polyvinyl Chloride), which are widely used in industries such as plumbing, electrical systems, and telecommunications.

This haul-off machine ensures that the plastic pipes, ranging from 20mm to 63mm in diameter, maintain dimensional accuracy, high strength, and smooth surface quality throughout the extrusion process. With its advanced features, the machine provides precise control over the pulling speed, tension, and handling of the pipes, minimizing defects and ensuring high productivity. Designed for long-term performance and versatility, this machine is an essential tool in any pipe extrusion line.

▏Key Features of the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine

| Reliable Rubber Block Gripping System

The ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine is equipped with a reliable rubber block gripping system that ensures a firm yet gentle hold on the pipe during the extrusion process. The rubber blocks are designed to prevent damage to the pipe's surface while providing the necessary friction to pull the pipe through the cooling and calibration stages. The rubber blocks are made from high-quality materials that are resistant to wear and tear, ensuring long-lasting performance even during high-speed operation. This system ensures smooth pulling, preventing deformation, scratches, or other surface imperfections, and is ideal for handling sensitive materials like PE, HDPE, and PVC. |

| Adjustable Pulling Speed for Enhanced Control

One of the standout features of the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine is its ability to adjust the pulling speed. The pulling speed can be fine-tuned to match the specific needs of the pipe production process, ensuring optimal tension is applied to the pipe during extrusion. This adjustable speed control allows manufacturers to achieve consistent pipe dimensions, reducing the risk of elongation or shrinkage. Whether the production requires high-speed operation for mass production or slower speeds for high-precision results, this machine provides the flexibility needed for a variety of applications. |

| Versatile Pipe Diameter Range

The ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine is designed to handle pipes within the diameter range of 20mm to 63mm, making it an ideal choice for producing small to medium-sized pipes used in a variety of industries. The machine can easily be adjusted to accommodate different pipe diameters, ensuring compatibility with a wide range of extrusion processes. The versatility of this machine makes it suitable for the production of pipes used in plumbing systems, irrigation networks, electrical conduits, and other applications where smaller-diameter plastic pipes are required. This adaptability ensures that manufacturers can cater to a diverse range of customer needs without requiring multiple machines for different pipe sizes. |

| High-Quality Cooling and Calibration System

To maintain the pipe’s shape and ensure dimensional accuracy, the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine is integrated with a reliable cooling and calibration system. After the extrusion process, the pipe passes through a cooling system, often a water bath or air-cooling chamber, where it solidifies and retains its shape. The haul-off machine works in tandem with the cooling system, ensuring that the pipe remains consistent in size and shape throughout the cooling process. The accurate calibration process helps prevent deformation, shrinkage, or warping, guaranteeing that the finished pipe meets the required specifications for various industrial applications. |

| Low Maintenance and Durable Construction

The ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine is built with durability and long-term operation in mind. It is constructed using high-quality materials such as stainless steel and durable rubber components that resist wear and corrosion, even in harsh industrial environments. This robust construction ensures that the machine requires minimal maintenance and can withstand the stresses of continuous operation. With fewer moving parts and an easy-to-maintain design, the haul-off machine reduces downtime and increases overall production efficiency. Manufacturers can rely on this machine for consistent performance, even in high-demand production environments. |

▏Technical Parameters

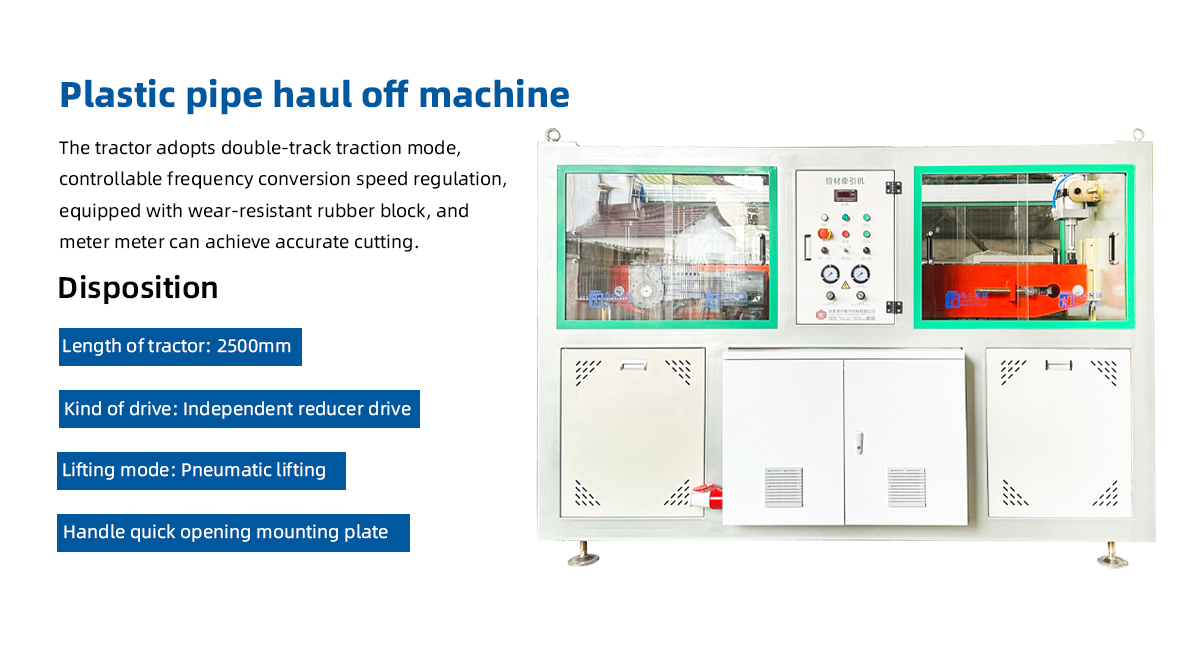

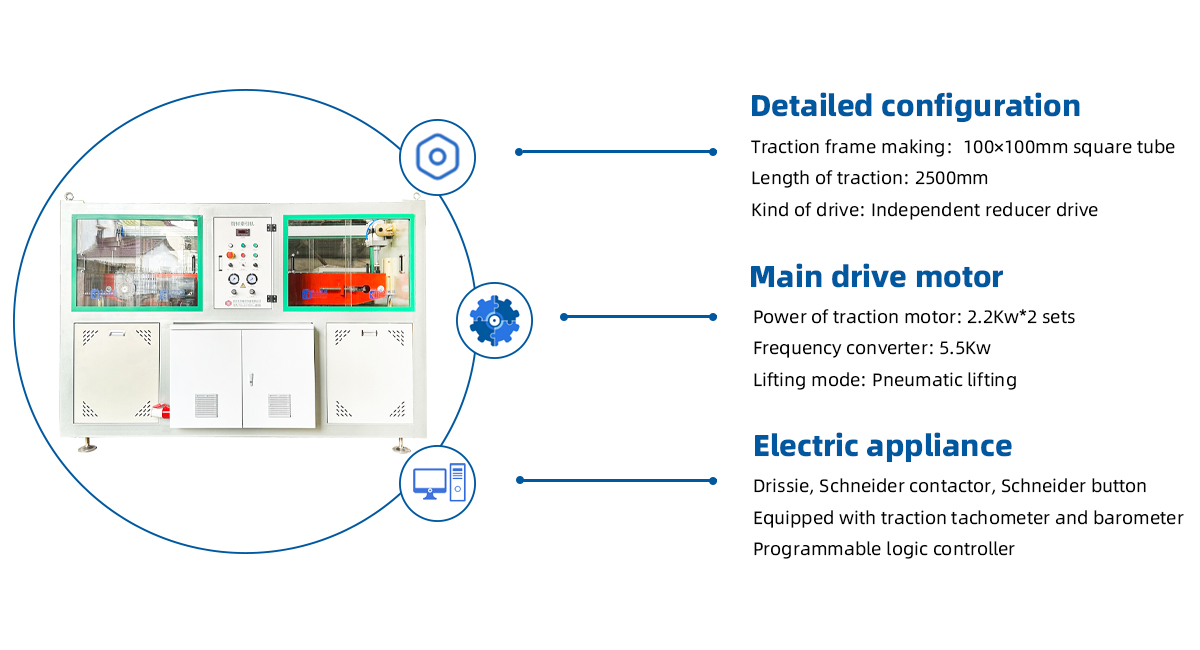

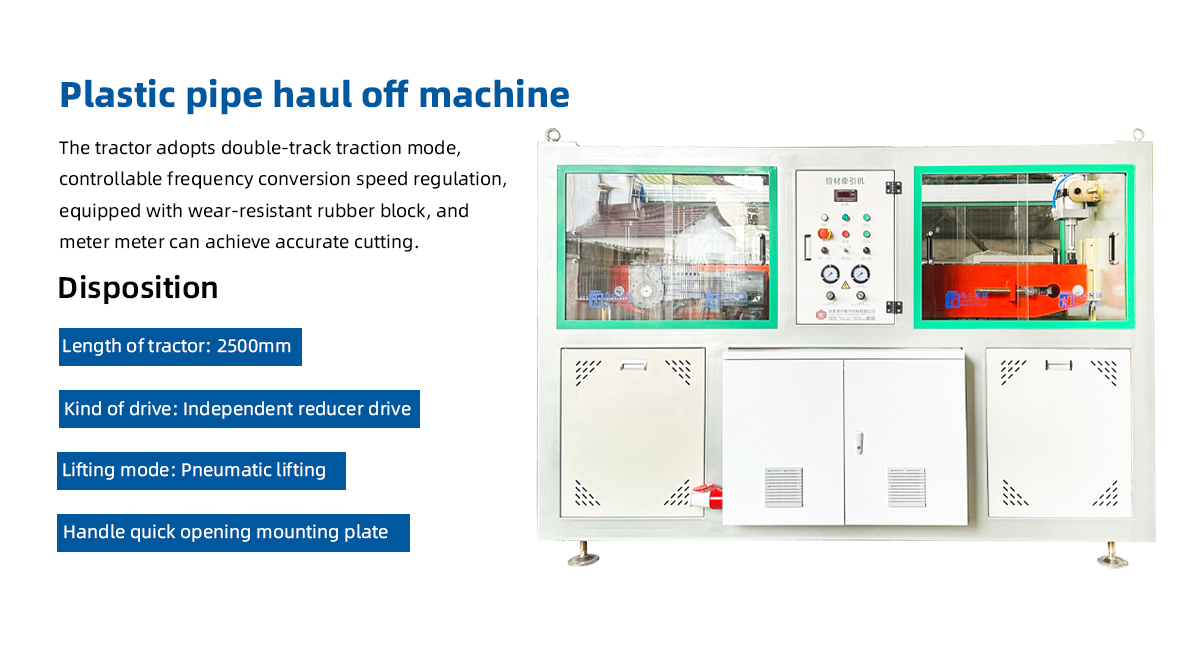

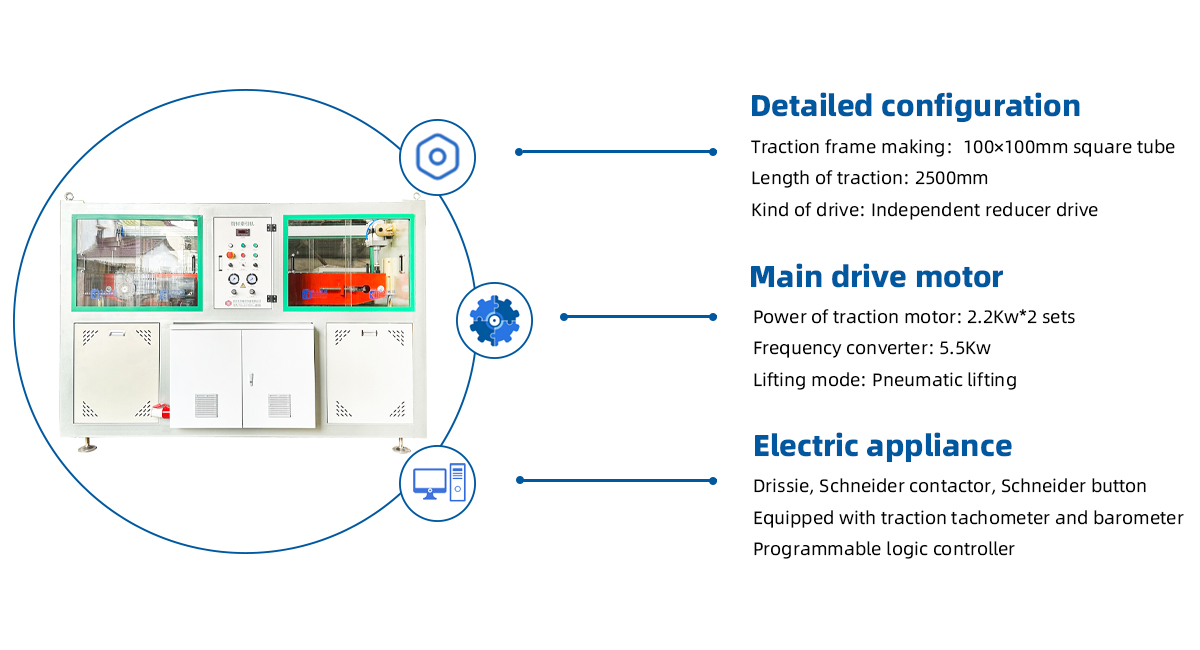

▏Product Photos

▏How the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine Works

The operation of the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine involves several key steps that ensure a smooth and precise extrusion process for small to medium-diameter plastic pipes:

| 1. Extrusion Process

In the first stage, raw plastic material, such as PE, HDPE, or PVC, is fed into an extruder, where it is melted and shaped into a pipe form. The extruder uses a specially designed die to produce the desired pipe diameter. |

| 2. Cooling and Solidification

Once the pipe exits the extruder, it enters a cooling system. The cooling process is essential for solidifying the plastic and preventing it from distorting or warping. Typically, the pipe is submerged in a water bath or exposed to air cooling to gradually lower the temperature. |

| 3. Haul-Off Mechanism

After the pipe has cooled and solidified, it enters the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine. The rubber block gripping system tightly holds the pipe and begins pulling it through the machine. The adjustable pulling speed ensures that the pipe moves steadily without experiencing stress or deformation. |

| 4. Calibration and Measurement

As the pipe is pulled through the haul-off system, it may pass through a calibration sleeve to ensure that it maintains the correct dimensions. The machine may also have a length control system to ensure that each pipe segment is produced to the required length. |

| 5. Cutting and Discharge

Once the pipe reaches the desired length, the machine stops, and an automatic cutting system is activated. The pipe is then cut to the precise length required for further processing or packaging. The finished pipes are discharged from the system and are ready for use or shipment. |

▏Benefits of the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine

| 1. High Precision and Consistency

The machine ensures that the pipes produced are consistently uniform in size and shape. By controlling the pulling speed and maintaining tension throughout the extrusion process, the machine minimizes defects and ensures high-quality pipe production. |

| 2. Increased Production Efficiency

The ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine operates with minimal downtime, allowing manufacturers to increase output and reduce labor costs. The automated cutting and length control system further streamlines the production process, increasing overall efficiency. |

| 3. Cost-Effective Operation

With its durable construction and low maintenance requirements, the machine helps manufacturers save on repair and maintenance costs over time. The reliable performance and energy-efficient design also reduce operational costs, making it a cost-effective solution for pipe production. |

| 4. Flexibility for Various Applications

The machine’s versatility in handling different pipe sizes (20mm to 63mm) and materials (PE, HDPE, PVC) makes it suitable for a wide range of industries. Manufacturers can produce pipes for various applications, from plumbing and irrigation to electrical and telecommunications, without the need for multiple machines. |

| 5. High-Quality Surface Finish

The rubber block gripping system provides a gentle yet firm hold, ensuring that the pipe’s surface remains smooth and free from damage. This feature is particularly important when producing pipes for sensitive applications, such as drinking water supply or electrical conduits. |

▏Applications of the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine

| 1. Plumbing and Water Supply

The ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine is widely used in the production of pipes for plumbing systems. It ensures that pipes used for water distribution are of the highest quality, maintaining accurate dimensions and surface integrity for reliable performance. |

| 2. Irrigation

The machine is also essential for manufacturing pipes used in irrigation systems, where precision and durability are key. The pipes produced are designed to handle pressure and wear, ensuring long-lasting performance in agricultural environments. |

| 3. Electrical and Telecommunications

Plastic pipes are commonly used to house electrical wiring and telecommunications cables. The ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine ensures that these pipes meet the necessary strength and dimensional accuracy to protect sensitive cables from environmental hazards. |

| 4. Industrial Applications

For industrial applications, such as fluid transport or chemical processing, the machine produces pipes that are resistant to corrosion and high pressure. The precision offered by the haul-off machine ensures that these pipes perform well in demanding environments. |

▏The Essential Tool for Plastic Pipe Production

The ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine is a crucial component of modern plastic pipe manufacturing. Its advanced features, such as the rubber block gripping system, adjustable pulling speed, and integrated cooling system, ensure that pipes are produced with high precision, smooth surfaces, and dimensional consistency.

With its versatility, durability, and efficiency, the ∅20-63 Plastic PE HDPE PVC Pipe Haul-Off Machine is the perfect choice for manufacturers looking to improve their production process and meet the growing demand for high-quality plastic pipes. Whether for plumbing, irrigation, or industrial applications, this machine delivers reliable, cost-effective solutions for a wide range of pipe production needs.

▏Product Introduction

| 1 | Basic parameters |

| ∅20-63 plastic PE HDPE PVC pipe Haul-off Machine is an automated production equipment designed for the production of polyethylene (PE) pipes in the 20 to 63 mm diameter range. The machine has efficient, stable and accurate production capacity, which can meet the needs of different scale production lines. Its main technical parameters include: Pipe diameter range: 20mm to 63mm Traction speed: Adjustable range, generally from 5m/min to 30m/min, depending on pipe material, wall thickness and line configuration Traction: Automatically adjusts according to the tube specifications to ensure that the tube maintains constant tension during the forming process Power source: electric drive, usually using variable frequency motor to achieve stepless speed regulation Control system: PLC programmable logic controller, equipped with touch screen operation interface, easy to operate and monitor |

| 2 | Structure composition |

| The haul off machine is mainly composed of the following parts: (1). Frame and drive system: The stable frame supports the entire equipment, and the drive system includes the motor, reduction box, sprocket chain or synchronization belt, which is used to transfer power and precisely control the traction speed. (2). Clamping device: An adjustable clamping claw or clamping wheel is designed to firmly grip the pipe and avoid sliding or deformation during traction. (3). Tension adjustment mechanism: Adjust the clamping force by hydraulic or mechanical means to ensure that the pipe maintains proper tension in different production stages. (4). Control system: Integrated PLC control unit, touch screen operation panel and necessary sensors to achieve automatic control and data monitoring. (5). Safety protection device: including emergency stop button, safety cover, etc., to ensure the safety of operators. |

| 3 | The working principle |

| ∅20-63 plastic PE HDPE PVC pipe Haul-off Machine works on the basis of continuous pulling operations. On the production line, the hot-melt PE pipe plasticized and extruded by the extruder is fed into the haul off machine. The haul off machine firmly grips the pipe through the clamping device, and pulls forward at the set speed under the drive of the motor. At the same time, the tension regulating mechanism automatically adjusts the clamping force according to the pipe diameter, wall thickness and production line speed to ensure that the pipe is evenly stressed during the stretching process to avoid fracture or deformation. |

| 4 | Performance characteristics |

|

(1).High efficiency and stability: the use of advanced control system to ensure production continuity and stability, improve production efficiency. (2). Precise traction: stepless speed regulation design can accurately adjust the traction speed according to the production demand to meet the production requirements of different specifications of pipes. (3). Intelligent adjustment: automatic tension adjustment system to ensure that the pipe in the traction process to maintain a constant tension, improve product quality. (4). Easy operation and maintenance: friendly human-machine interface, easy operation; Modular design facilitates maintenance and replacement of components. (5). Safe and reliable: equipped with perfect safety protection devices to ensure production safety. |

| 5 | Application fields |

|

∅20-63 plastic PE HDPE PVC pipe Haul-off Machine is widely used in many fields such as water supply and drainage, agricultural irrigation, gas transportation, cable protection bushing, and is an indispensable key equipment for the production of various specifications of PE pipes. |

| 6 | Adjustment methods |

|

Speed adjustment: Set or adjust the traction speed directly through the speed adjustment knob on the touch screen or control panel. Tension adjustment: According to the actual production situation, by adjusting the tension control valve or knob, change the size of the clamping force to achieve the ideal traction tension. Parameter setting: In the PLC control system, multiple groups of production parameters can be set and saved, which is convenient to quickly switch the production of different specifications of pipes. |

| 7 | Maintenance and maintenance |

|

(1). Regular inspection: Regularly check the transmission system, clamping device and control system to ensure the normal operation of all components. (2). Cleaning and maintenance: keep the surface and interior of the equipment clean, and regularly clean the residue on the gripper claw or gripper wheel. (3). Lubrication maintenance: Add or replace lubricating oil for transmission parts regularly according to the instructions to reduce wear. (4). Electrical inspection: Regularly check electrical circuits and components to ensure the safety and reliability of the electrical system. (5). Professional training: The operator should receive professional training to understand the equipment performance and operating procedures, and improve the maintenance level. |

▏Complete production line recommendation

Click the link below to view the full line description!

20-63PE Pipe Making Machine PE Pipe Production Line

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping