▏Product Vedio

▏Product Introduction

▏20-63/110 PVC HDPE PPR Pipe Vacuum Forming Sizing Tank: Precision Engineering for Pipe Production

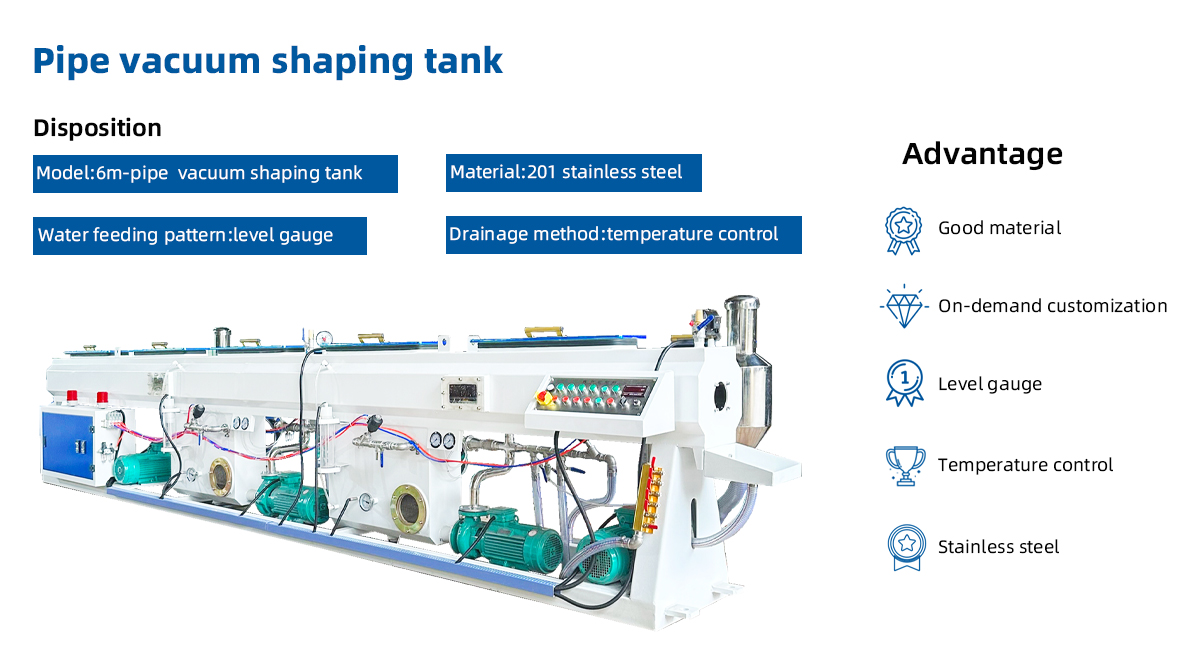

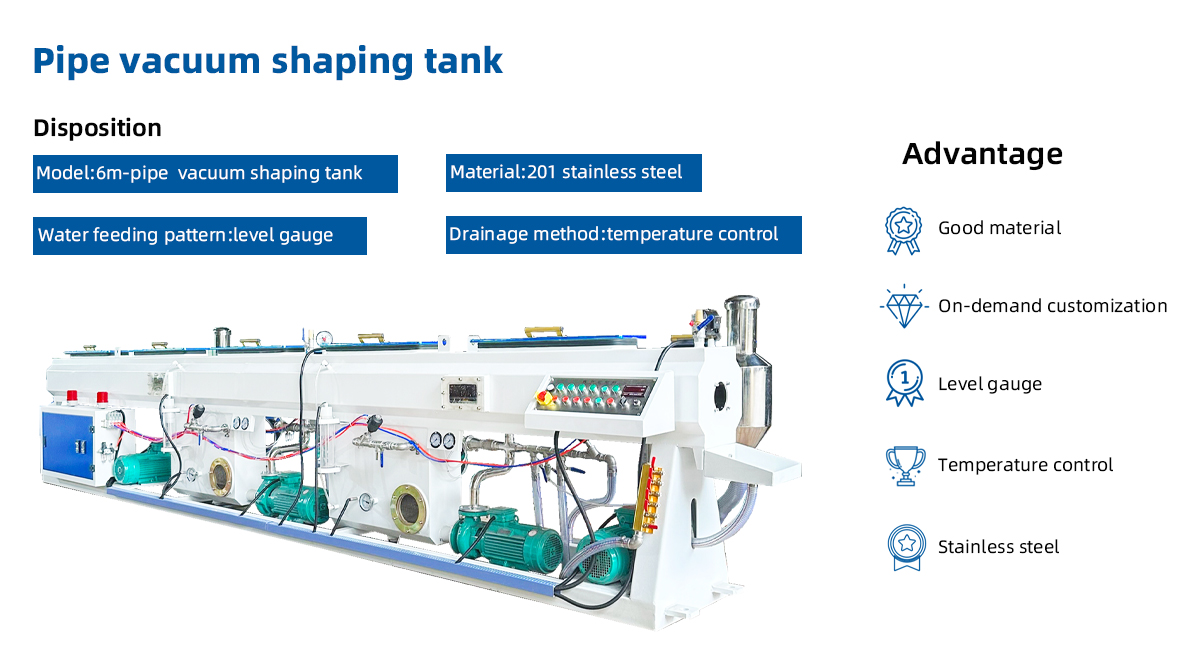

The 20-63/110 PVC HDPE PPR Pipe Vacuum Forming Sizing Tank is a critical component in modern plastic pipe extrusion lines, designed to ensure precise dimensional accuracy and surface quality for PVC, HDPE, and PPR pipes with diameters ranging from 20mm to 110mm. This advanced vacuum sizing system combines robust construction, intelligent temperature control, and adaptable design to meet the rigorous demands of water supply, drainage, agricultural irrigation, and industrial piping applications. By integrating cutting-edge vacuum technology, it guarantees consistent pipe geometry and minimizes material waste, making it indispensable for high-efficiency manufacturing.

| Core Functionality of the Sizing TankThe vacuum forming sizing tank operates by applying controlled vacuum pressure to newly extruded pipes, rapidly cooling and solidifying them while maintaining exact outer diameters and wall thicknesses. Its modular design accommodates pipe size adjustments, ensuring compatibility with diverse production requirements for PVC, HDPE, and PPR materials. |

▏Key Features of the 20-63/110 PVC HDPE PPR Pipe Vacuum Sizing Tank

| Multi-Material Compatibility

Engineered to handle PVC (rigid and flexible), HDPE (high-density polyethylene), and PPR (polypropylene random copolymer), this sizing tank features adjustable vacuum levels (0.5–0.9 bar) and cooling rates. Its corrosion-resistant stainless-steel construction ensures longevity, even when processing chemically aggressive materials. |

| Precision Vacuum Control System

Equipped with a programmable logic controller (PLC) and digital pressure sensors, the tank maintains stable vacuum conditions across multiple zones. Real-time adjustments prevent deformities like ovality or surface wrinkles, achieving tolerances as tight as ±0.1mm for pipe diameter and ±0.05mm for wall thickness. |

| Efficient Cooling Mechanism

A multi-stage water cooling system, featuring spiral flow channels and temperature-regulated water baths, ensures uniform heat dissipation. This minimizes internal stresses in pipes, enhancing their mechanical strength and resistance to cracking under pressure. |

▏Applications Across Industries

| The 20-63/110 PVC HDPE PPR Pipe Vacuum Forming Sizing Tank is vital for producing pipes used in:

Water Supply Systems: Smooth-walled PVC and PPR pipes for potable water distribution. Agricultural Irrigation: Durable HDPE pipes resistant to UV and chemical exposure. Industrial Pipelines: High-pressure PPR pipes for chemical transport. Construction Drainage: Lightweight, corrosion-resistant PVC drainage systems. |

▏Advantages Over Conventional Sizing Methods

| Enhanced Production Speed

By optimizing vacuum and cooling efficiency, the tank reduces cycle times by up to 35%, enabling output speeds of 2–6 meters per minute, depending on pipe diameter and material. |

| Reduced Material Waste

Precise dimensional control eliminates post-production trimming, lowering raw material consumption by 15–20% compared to non-vacuum sizing methods. |

| Easy Maintenance & Adaptability

Quick-release clamps and modular sizing sleeves allow rapid tooling changes between pipe sizes (20mm–110mm). Self-cleaning water filters and accessible components reduce downtime for maintenance. |

▏Technical Specifications

| Parameter | Specification |

| Pipe Diameter Range | 20–110 mm |

| Vacuum Pressure Range | 0.5–0.9 bar |

| Cooling Water Capacity | 500–1500 L/h |

| Tank Material | Stainless Steel 304/316 |

| Power Supply | 3-Phase, 380V, 5–10 kW |

▏Why Choose Our Vacuum Sizing Tank?

Our 20-63/110 PVC HDPE PPR Pipe Vacuum Forming Sizing Tank is built to outperform industry standards. With a focus on precision, durability, and energy efficiency, it supports seamless integration into existing extrusion lines. We provide customized solutions, including optional automation interfaces and remote monitoring capabilities, backed by 24/7 technical support and a 2-year warranty.

In the competitive landscape of plastic pipe manufacturing, the 20-63/110 PVC HDPE PPR Pipe Vacuum Forming Sizing Tank is a game-changer. Its ability to deliver dimensionally accurate, high-strength pipes with minimal waste positions it as a critical investment for producers aiming to optimize quality and profitability. Partner with us to elevate your pipe production capabilities and meet the growing global demand for reliable piping systems.

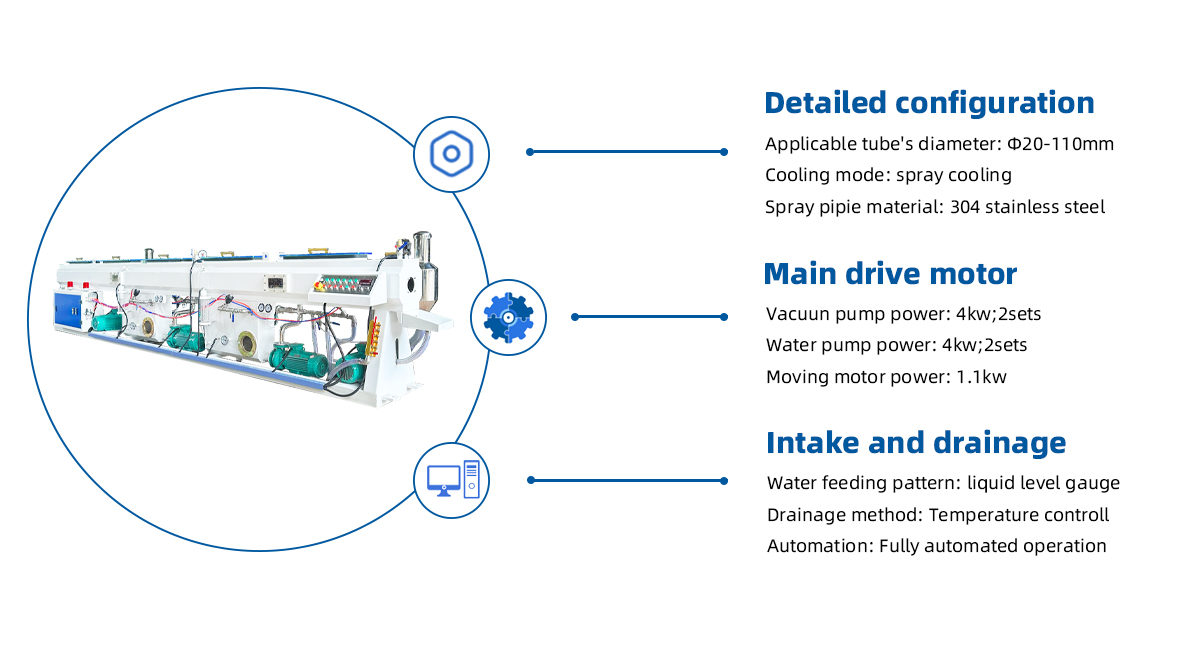

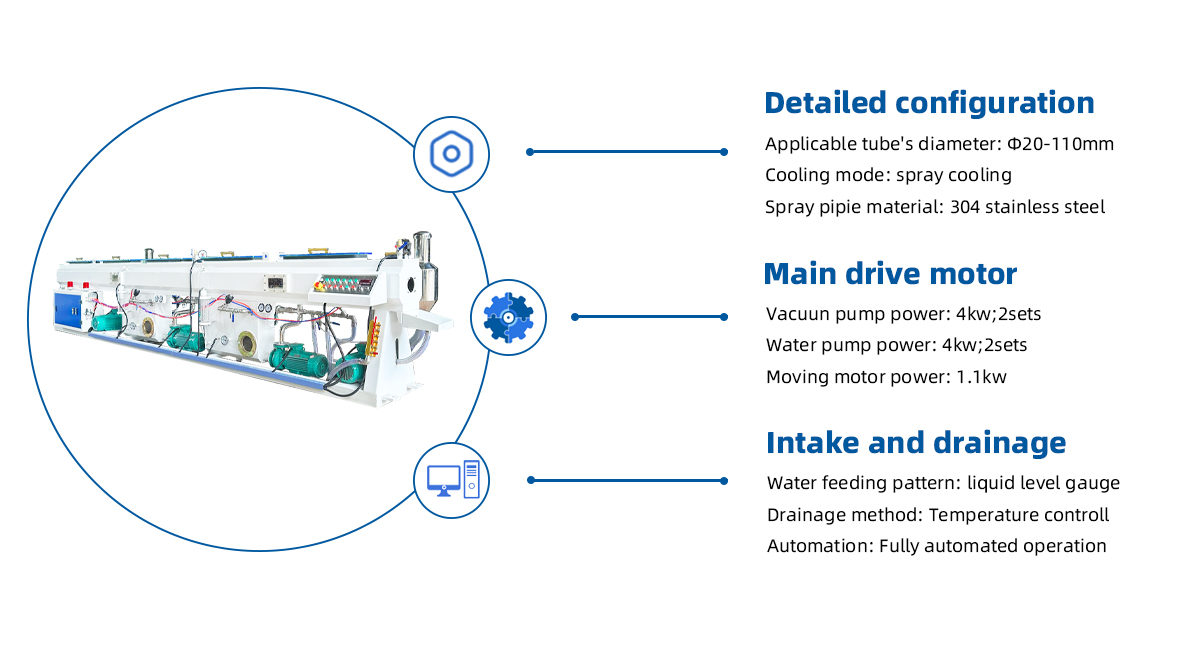

▏Technical Parameters

| Applicable pipe's diameter | Φ20-110mm |

| Cooling mode | spray cooling |

| Spray pipie material | 304 stainless steel |

| Vacuun pump power | 4kw;2 sets |

| Water pump power | 4kw;2 sets |

| Moving motor power | 0.75kw |

▏Main Details

▏Product Photos

20-110 pipe vacuum shaping box

stainless steel

Applicable tube's diameter: Φ20-110mm

Moving motor power: 0.75kw

Vacuun pump power: 5.5kw;2sets

Water feeding pattern: liquid level gauge

Drainage method: Temperature control

Coolig mode: spray cooling

Water pump power: 5.5kw;2sets

Fully automated operation

▏Product Introduction

| 1 | Equipment structure and composition |

| The 20-63/110 PVC HDPE PPR pipe vacuum forming sizing tank is mainly composed of vacuum chamber, vacuum system, control system, heating system and cooling system. The pipe vacuum forming sizing tank has excellent sealing performance and can establish a stable vacuum environment during processing. The vacuum system is responsible for pumping the air out of the pipe vacuum forming sizing tank to achieve the required vacuum degree. The control system can precisely monitor and adjust the operating state of the entire equipment to ensure that the equipment works according to the preset process parameters. |

| 2 | Working principle and advantages |

| After the tube enters the pipe vacuum forming sizing tank, the vacuum system will begin pumping air, creating a low-pressure vacuum environment. In this environment, the gas inside the pipe is extracted, making the surface of the pipe subject to negative pressure. This negative pressure environment helps to reduce the deformation and stress concentration generated during processing and improve the processing accuracy of the pipe. At the same time, the heating system and the cooling system work together to precisely control the temperature of the pipe. In the vacuum chamber, the tubes are formed and quenched by various molds. The vacuum, high temperature and high pressure environmental conditions make the pipe show the best processing state, improve the processing efficiency and quality. |

| 3 | Application field |

| This pipe vacuum forming sizing tank is widely used in the construction, water conservancy, municipal and other fields of pipe processing industry. Through the use of 20-63 tube vacuum molding box, various small diameter pipes can be accurately formed to meet different engineering needs. Its efficient, accurate and stable performance makes it a favorite in the pipe processing industry. |

| 4 | Customized service and after-sales guarantee |

| 20-63 pipe vacuum forming sizing tanksupports various types of tube production, and the number of spray routes is more, which can meet the customized needs of different customers. In addition, the manufacturer also provides one-year warranty and lifelong maintenance services to ensure that customers receive timely technical support and after-sales support during use. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping