▏Product Vedio

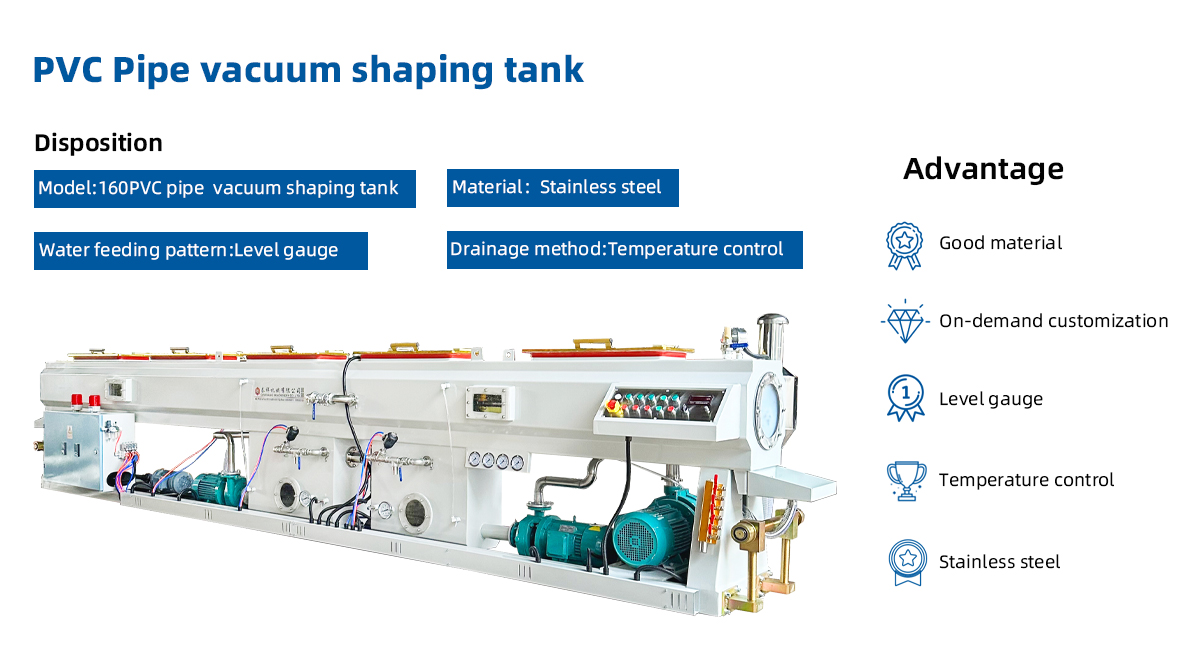

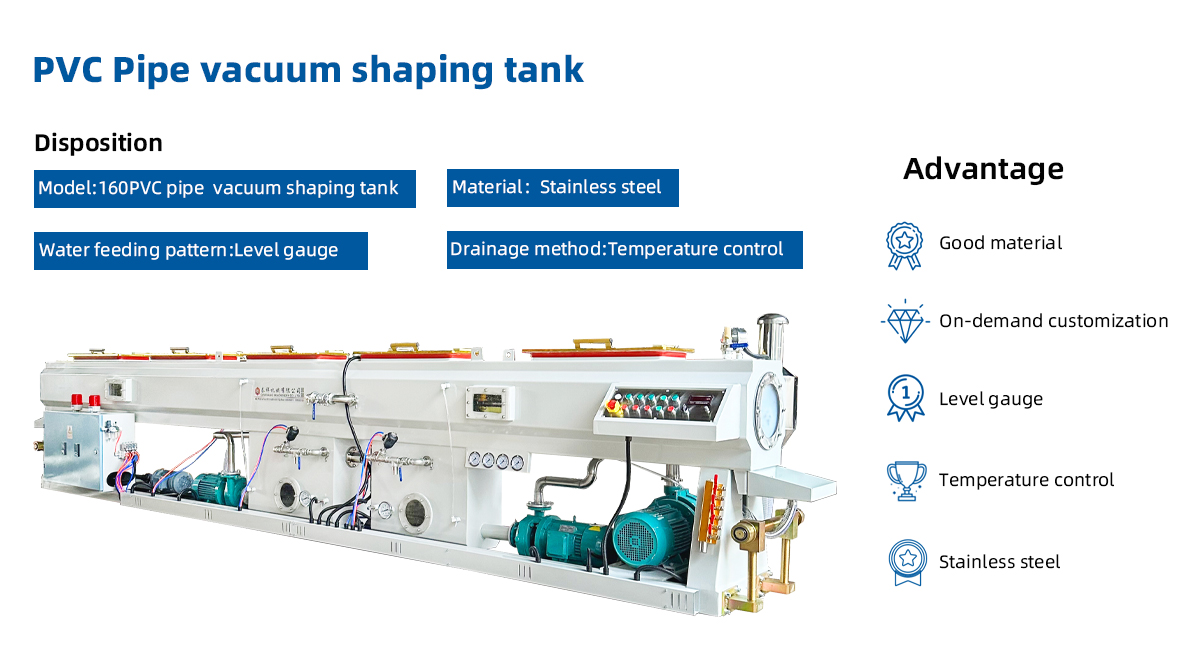

▏160 PVC Pipe Vacuum Calibration Forming Cooling Tank: Precision Engineering for Superior Pipe Manufacturing

| Introduction to the 160 PVC Pipe Vacuum Calibration Forming Cooling Tank

The 160 PVC Pipe Vacuum Calibration Forming Cooling Tank is a state-of-the-art solution designed for the precise production of high-quality PVC pipes with a diameter of 160 mm. This system integrates vacuum calibration, forming, and rapid cooling technologies to ensure dimensional accuracy, surface smoothness, and structural integrity in PVC pipe manufacturing. Ideal for industrial applications, this equipment enhances production efficiency while maintaining strict adherence to international quality standards. |

Key Components and Working Principle

| Vacuum Calibration Chamber

The vacuum calibration chamber ensures uniform wall thickness and precise outer diameter control. By applying controlled vacuum pressure, the molten PVC material is shaped against a precision-machined calibration sleeve, eliminating deformities and ensuring compliance with ISO 1452-2 specifications. |

| Forming and Cooling System

A multi-stage cooling tank with temperature-regulated zones (10°C–25°C) gradually reduces pipe temperature to prevent stress cracks. The stainless-steel construction and adjustable water flow mechanisms enable optimized cooling rates for different PVC formulations (density 3%). |

Technical Specifications

Pipe Diameter: 160 mm ±0.3 mm tolerance

Cooling Length: 6 meters (modular design for expansion)

Vacuum Pressure: Adjustable 0.08–0.12 MPa

Power Consumption: 15 kW/h with energy-saving pumps

Material: SS304 stainless steel, corrosion-resistant

Advantages Over Conventional Systems

| Enhanced Production Efficiency

Reduces cycle time by 40% through synchronized vacuum calibration and rapid cooling, enabling output of up to 400 kg/hour with consistent pipe ovality ≤1%. |

| Energy Optimization

Integrated heat recovery systems reuse 30% of thermal energy, lowering operational costs. The closed-loop water circulation minimizes waste, aligning with sustainable manufacturing practices. |

Applications Across Industries

This system is indispensable for producing PVC pipes used in:

Potable water distribution networks

Industrial drainage systems

Agricultural irrigation projects

Telecommunication conduit manufacturing

Quality Assurance and Compliance

The cooling tank incorporates real-time sensors monitoring temperature (±1°C), vacuum stability (±2%), and pipe alignment. CE-certified and compatible with Industry 4.0 automation protocols, it ensures seamless integration into smart factories.

▏Invest in Precision and Reliability

The 160 PVC Pipe Vacuum Calibration Forming Cooling Tank represents the pinnacle of pipe extrusion technology, combining rigorous engineering with operational efficiency. By minimizing material waste and maximizing output consistency, this system delivers unmatched ROI for manufacturers aiming to dominate competitive markets.

▏Technical Parameters

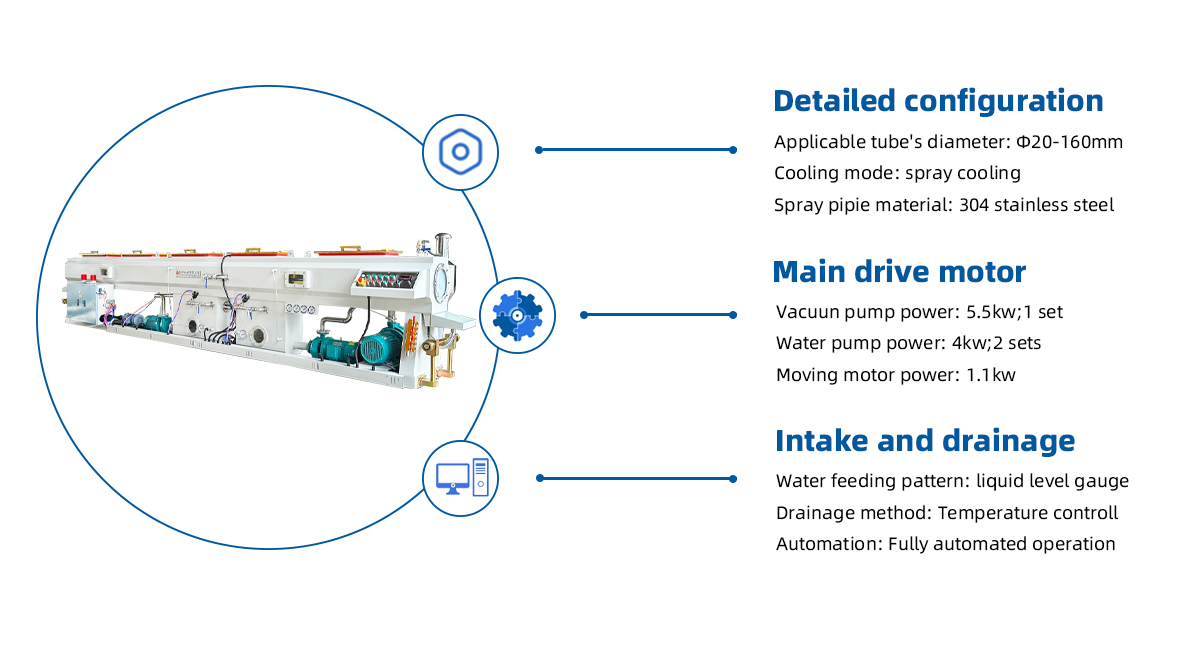

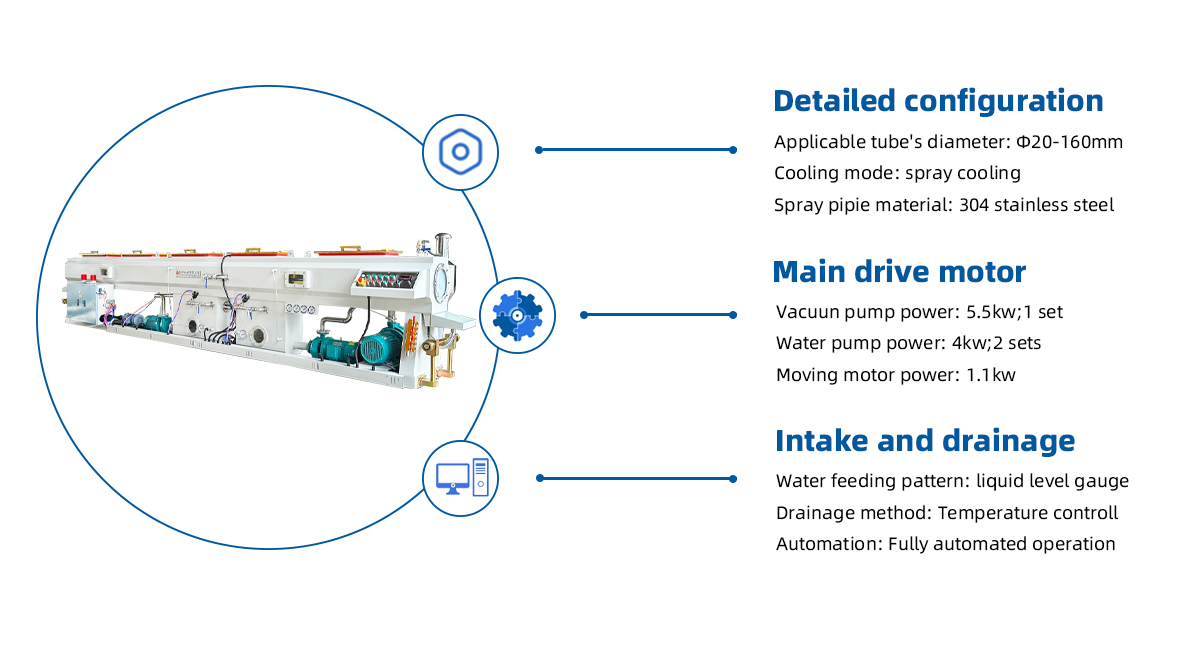

| Applicable tube's diameter | Φ20-160mm |

| Cooling mode | spray cooling |

| Spray pipie material | 304 stainless steel |

| Vacuun pump power | 5.5kw;1 set |

| Water pump power | 4kw;2 sets |

| Moving motor power | 1.1kw |

▏Main Details

▏Product Photos

160PVC pipe vacuum forming tank

Vacuum sizing water tank

Stainless steel control panel

Tempered glass cover plate

Vacuum pump power: 5.5kw;1 set

Drainage method: Temperature controll

Water feeding pattern: liquid level gauge

Cooling mode: spray cooling

Water pump power: 4kw;2sets

Spray pipie material: 304 stainless steel

▏Product Advantage

160 PVC pipe Vacuum Calibration Forming Cooling Tank shows its unique advantages in many aspects, the following is a detailed explanation of its main advantages:

| 1 | Efficient degassing and defoaming effect |

| 160 PVC pipe Vacuum Calibration Forming Cooling Tankis designed for the treatment of PVC pipe, through efficient vacuum technology, can quickly and effectively remove the air and bubbles inside the pipe. This is essential to ensure the quality and performance of the PVC pipe, helping to prevent various problems caused by bubbles or residual air during use. |

| 2 | Improve product quality |

| Through the use of empty box degassing treatment, can significantly reduce the PVC pipe defects and defective product rate. The vacuum environment helps distribute the material more evenly and eliminates potential factors that could cause cracking, deformation, or performance degradation. |

| 3 | Easy operation and automation |

| 160 PVC pipe Vacuum Calibration Forming Cooling Tank is usually equipped with advanced control system, making the operation simple and intuitive. In addition, many empty boxes support automated operation, reducing the need for manual intervention and improving production efficiency. |

| 4 | Suitable for a variety of pipe specifications |

| Although the hollow box is mainly designed for 20-160 diameter PVC pipe, its flexibility and adjustability enable it to handle a variety of different specifications of pipe. This enables the device to perform well in a variety of application scenarios. |

| 5 | Energy saving and environmental protection |

| The empty box can effectively save energy and reduce energy consumption during operation. At the same time, because it reduces the generation of defective products, it also helps to reduce the cost of waste generation and disposal, thus having environmental benefits. |

| 6 | Durability and stability |

| High-quality empty boxes usually use durable materials and advanced manufacturing processes to ensure that they have good durability and stability. This means that equipment can run stably for a long time, reducing maintenance costs and improving production efficiency. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping

▏FAQ

1.Are you a factory or trading company?

Qinxiang:We are a factory.

2.Can we visit your machine operation in your factory?

Qinxiang:You can see machine operation in our factory.

3.Can the machine be customized?

Qinxiang:Yes,it can.

4.How many electric, water, air need for the machines?

Qinxiang: technical department supply the whole layout for workshop details.

5.Can I operate machine if don’t have experienced engineers?

Qinxiang: (1) short-time engineers to customer company (5-15days) (2) Year-time working as requirements

6.Any quality checking before shipment?

Qinxiang: 100% confirm, run and test machines before shipment with quality certificate.

7.How long is the guarantee?

Qinxiang: 12 months since the first day customer operates (except wear parts).

8.How can u help us when face some technical problem?

Qinxiang: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

9.Where can we get spare part?

Qinxiang: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.