▏Product Vedio

▏Prodcut Introduction

▏Key Plastic Materials for Pipes

| 1. PVC (Polyvinyl Chloride)

PVC pipes dominate the construction and plumbing sectors due to their corrosion resistance, affordability, and ease of installation. Rigid PVC is ideal for pressurized systems, while flexible variants are used in drainage and electrical conduits. |

| 2. PE (Polyethylene)

High-density PE (HDPE) pipes excel in gas distribution and underground water networks. Their flexibility and resistance to environmental stress cracking make them suitable for dynamic terrains. |

| 3. PPR (Polypropylene Random Copolymer)

PPR pipes are favored for hot and cold water systems. Their thermal stability, low thermal conductivity, and fusion-welding compatibility ensure leak-free joints. |

| 4. MPP (Modified Polypropylene)

MPP pipes, reinforced with minerals, are engineered for high-temperature applications like cable conduits and trenchless installations. Their stiffness and heat resistance outperform traditional plastics. |

The Vacuum Forming Process in Pipe Production

Vacuum forming is a critical step in shaping thermoplastic pipes. This process ensures uniformity, structural integrity, and precise dimensions.

| How Vacuum Forming Works

1. Heating the Plastic Sheet: PVC, PE, or PPR sheets are heated to a pliable temperature. 2. Molding: The softened sheet is draped over a mold, and vacuum pressure is applied to conform it to the mold's shape. 3. Cooling and Ejection: The formed pipe section is cooled rapidly to retain its shape before ejection. |

Advantages of Vacuum Forming

| Cost-effective for medium-to-high production volumes.

Enables complex geometries with minimal material waste. Compatible with recyclable thermoplastics. |

| Calibration Tanks: Ensuring Precision in Pipe Dimensions

After vacuum forming, pipes undergo calibration to achieve exact diameters and wall thicknesses. The calibration tank is a water-cooled system that fine-tunes the extruded pipe dimensions. |

Key Functions of a Calibration Tank

| 1. Cooling and Solidification

The tank uses controlled water circulation to cool the molten plastic uniformly, preventing deformities like warping or ovality. |

| 2. Dimensional Accuracy

Adjustable vacuum pressure within the tank ensures the pipe adheres to strict tolerances (e.g., ±0.1 mm for PPR pipes). |

| 3. Surface Finish Optimization

Calibration tanks eliminate surface imperfections, enhancing the pipe's hydraulic efficiency and aesthetic appeal. |

Material-Specific Calibration

| PVC: Requires lower cooling temperatures to avoid brittleness.

MPP: Demands higher-pressure calibration due to its mineral-filled composition. |

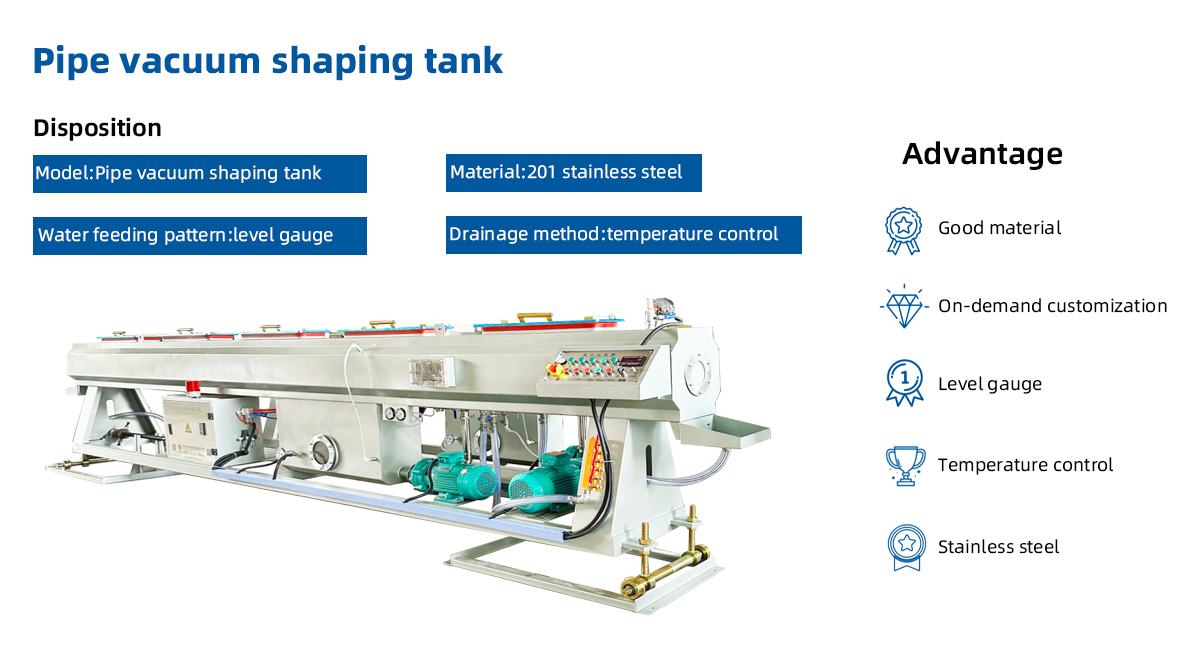

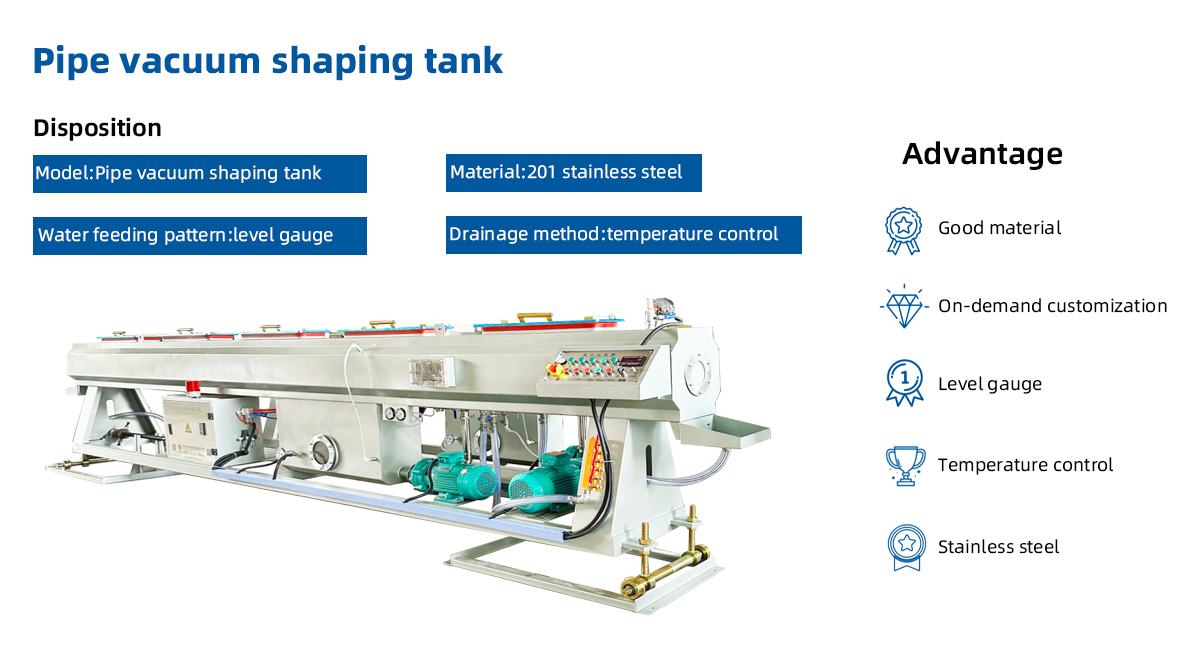

▏Technical Parameters

1、Applicable tube's diameter: Φ20-110mm

2、Cooling mode: spray cooling

3、Spray pipie material: 304 stainless steel

4、Vacuun pump power: 4.4kw;2 sets

5、Water pump power: 4.4kw; 2 sets

6、Moving motor power: 1.5kw

▏Product Photos

▏Product Introduction

20-110PE pipe production line vacuum forming calibration tank is the key equipment in the plastic pipe production line, mainly used for shaping and cooling the pipe to ensure the dimensional stability and surface quality of the pipe. Here is a detailed description of the device:

| 1 | Basic overview |

| Brand and model: Different manufacturers will provide different brands and models of vacuum shaping boxes, suitable for the production of PE pipes with a diameter of 20-110mm. Application: Widely used in industrial plants, construction and other fields, is one of the indispensable equipment for plastic pipe production. |

| 2 | The main function |

| Shaping function: Vacuum treatment is carried out inside the pipe through the vacuum system, so that the pipe is close to the shaping mold under the action of negative pressure, so as to achieve the sizing and shape stability of the pipe. Cooling function: Combined with the water circulation system, the pipe is sprayed or cooled in a water bath to accelerate the cooling process of the pipe and ensure that the pipe has reached or is close to room temperature when leaving the vacuum setting box.

|

| 3 | Technical characteristics |

|

(1). Excellent material: The main body of the vacuum forming calibration tank is usually made of stainless steel (such as SUS304 stainless steel), which has the advantages of corrosion resistance and easy cleaning. The shaping section may be made of brass, steel, or aluminum and chrome-plated to reduce friction and prevent wear between the tube and the sizing body wall. (2). Reasonable design: the sink frame with three-dimensional adjustment function can be easily adjusted to be concentric with the mold outlet to ensure that the pipe will not be offset during the shaping process. At the same time, the vacuum suction channel may be set in the form of slit and opening, and the setting suite can be adjusted independently to meet the needs of different specifications of pipe production. (3). Stable performance: high precision water ring vacuum pump is used for vacuum pumping, low noise and vacuum stability. The cooling system achieves efficient and uniform cooling by means of water bath or spray. (4). Easy operation: Equipped with microcomputer control system or other advanced automatic control devices, it can easily achieve automatic control and production process monitoring.

|

| 4 | Precautions for use |

|

Before use, ensure that the components of the vacuum forming calibration tank are tightly connected without leakage, and check the operating status of key components such as the vacuum pump and water pump. According to the production needs to adjust the vacuum degree, cooling time and water temperature and other parameters to obtain the best production results. Clean and maintain the internal and external parts of the vacuum forming calibration tank regularly to extend the service life of the equipment and maintain the production quality.

|

▏Complete production line recommendation

Click the link below to view the full line description!

20-63PE Pipe Making Machine PE Pipe Production Line

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping