▏Product Vedio

▏Product Introduction

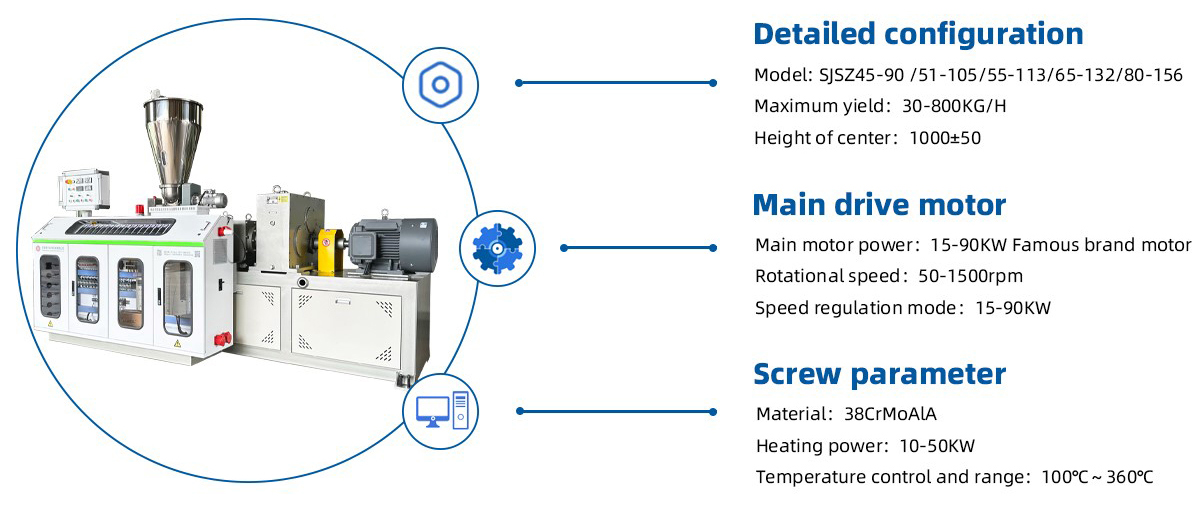

▏Technical Parameters

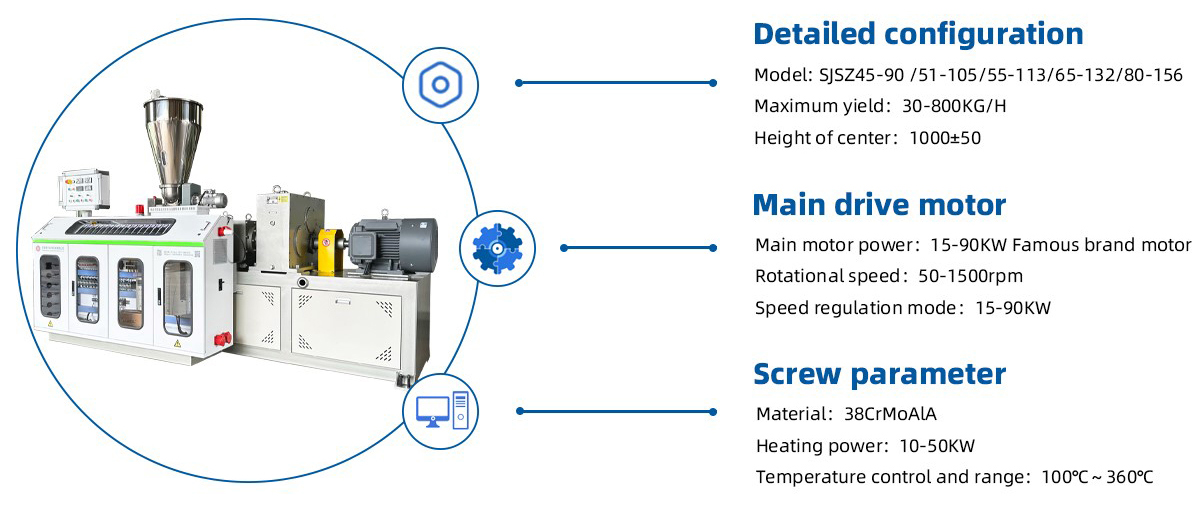

extruder | SJSZ 45/90 | SJSZ51/105 | SJSZ65/132 | SJSZ80/156 | SJSZ92/188 |

Main engine Power (kW) | 15 | 22 | 37 | 55 | 110 |

Output (kg/h) | 30-120 | 50-150 | 60-300 | 100-400 | 200-800 |

Heating power(kW) | 10 | 12 | 24 | 36 | 50 |

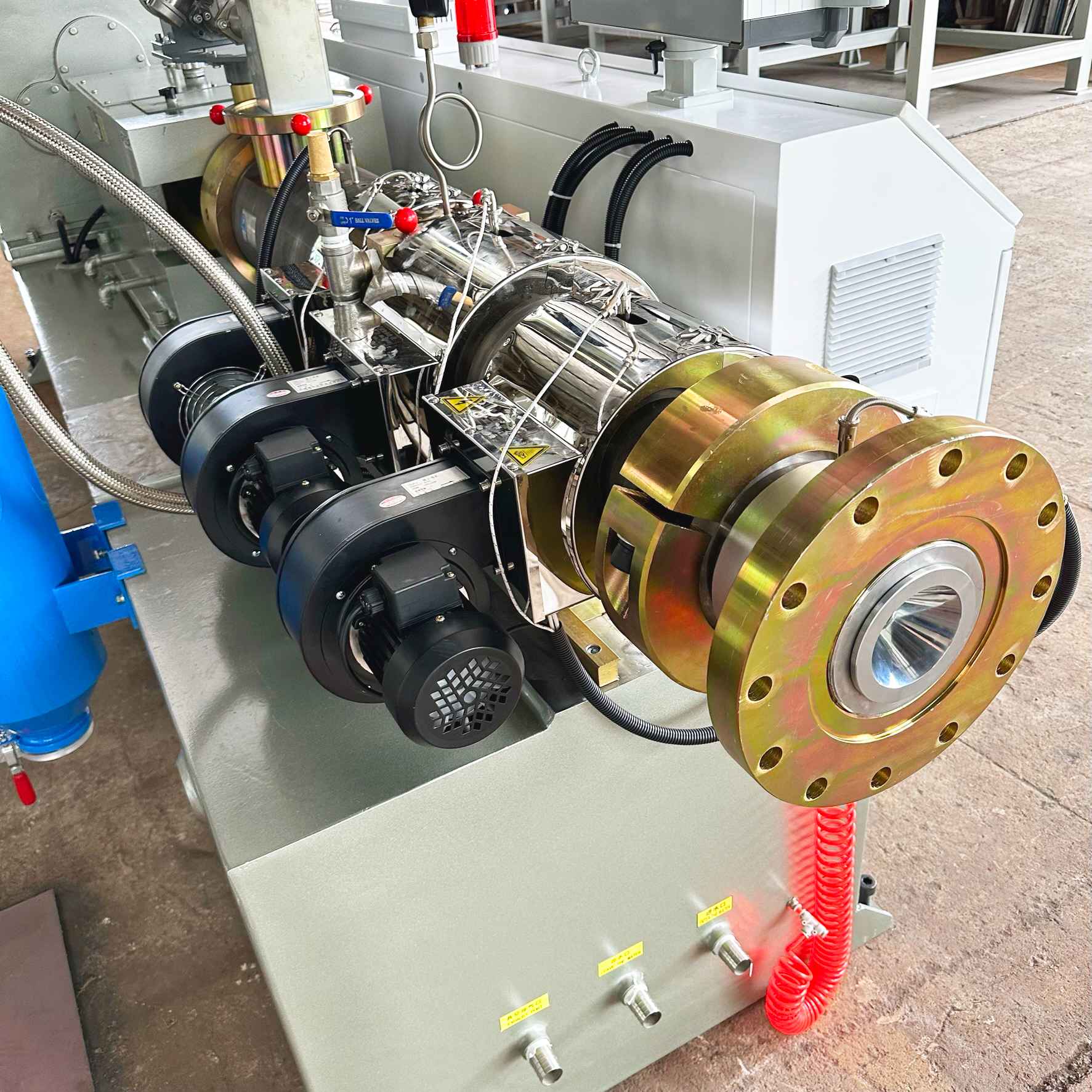

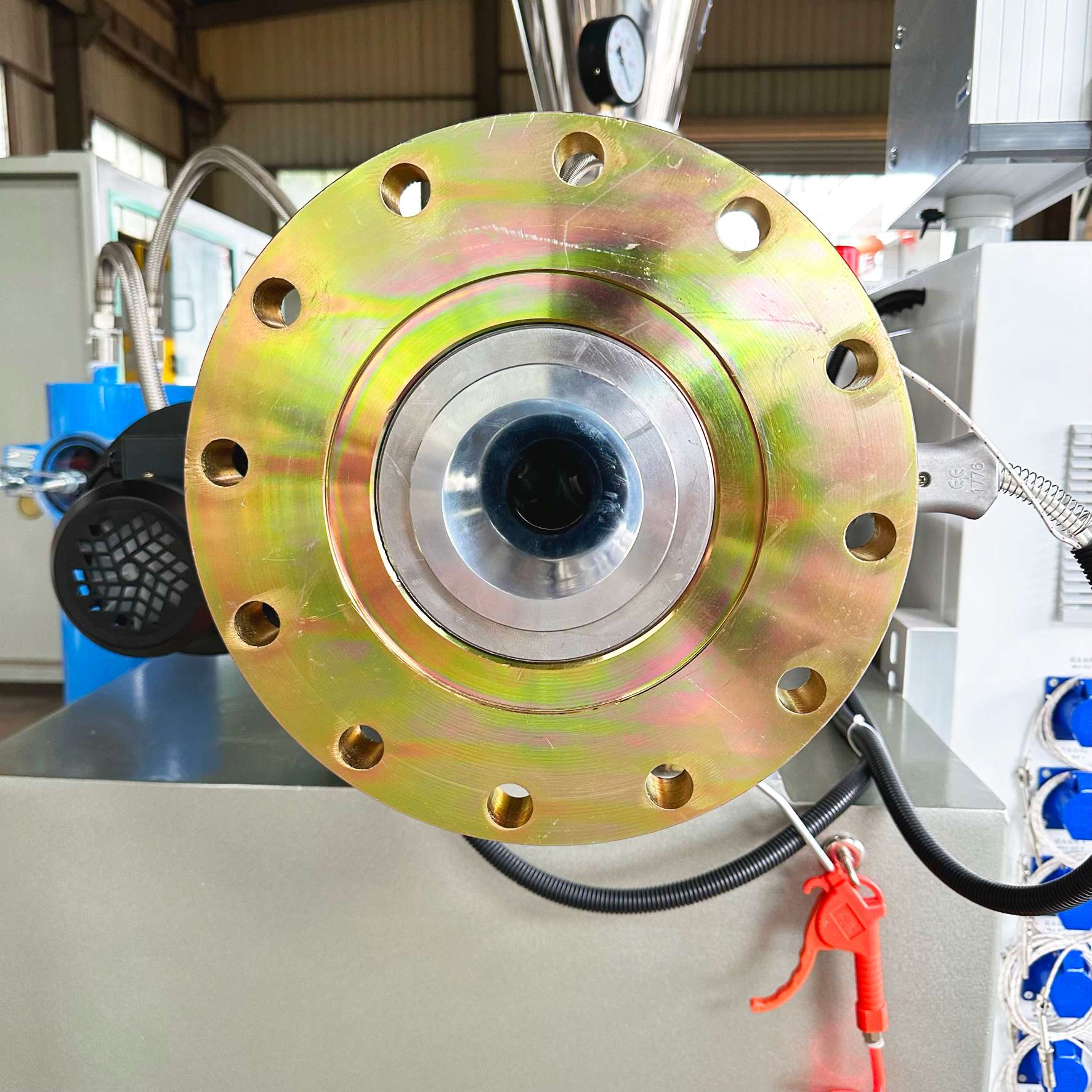

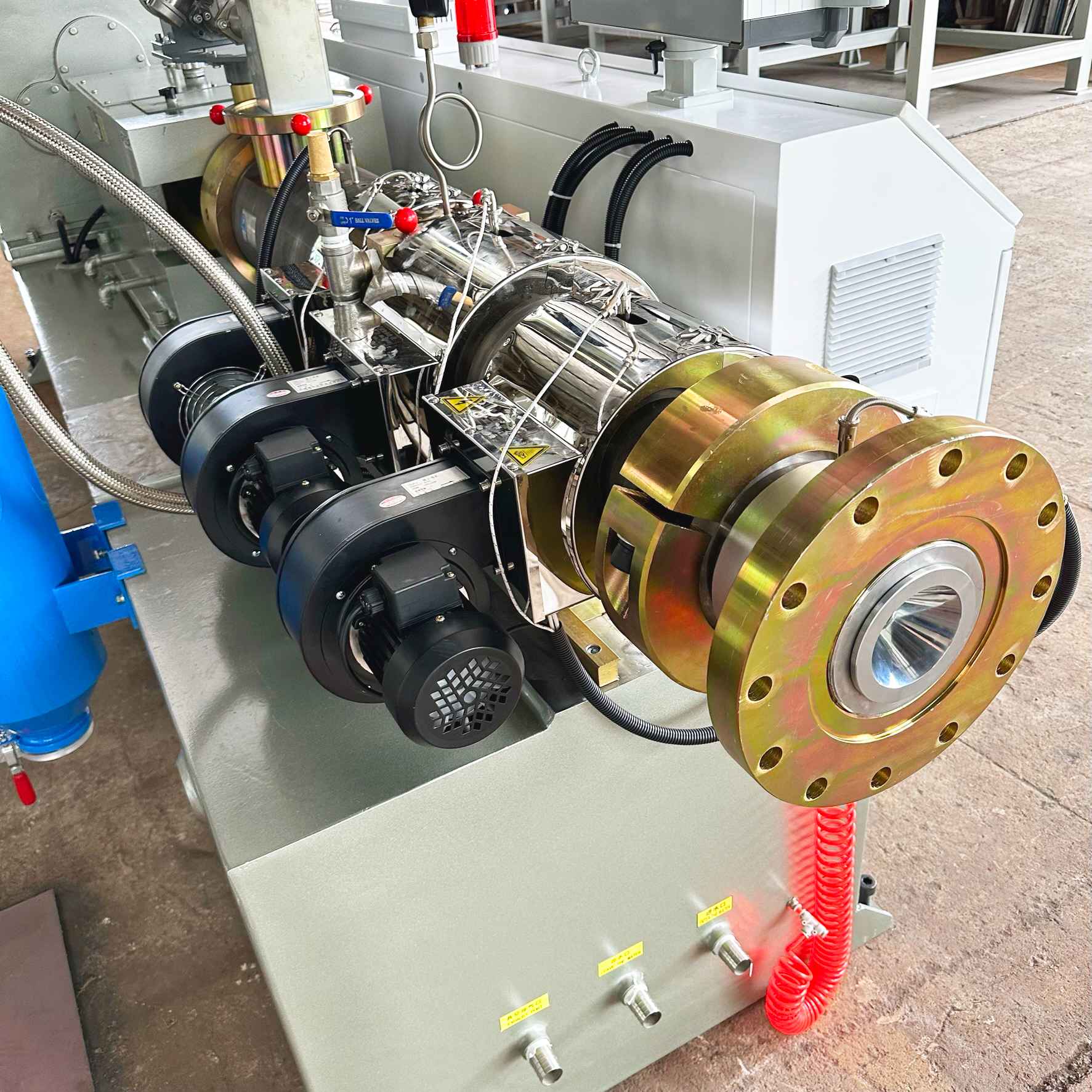

▏Main Details

▏Product Photos

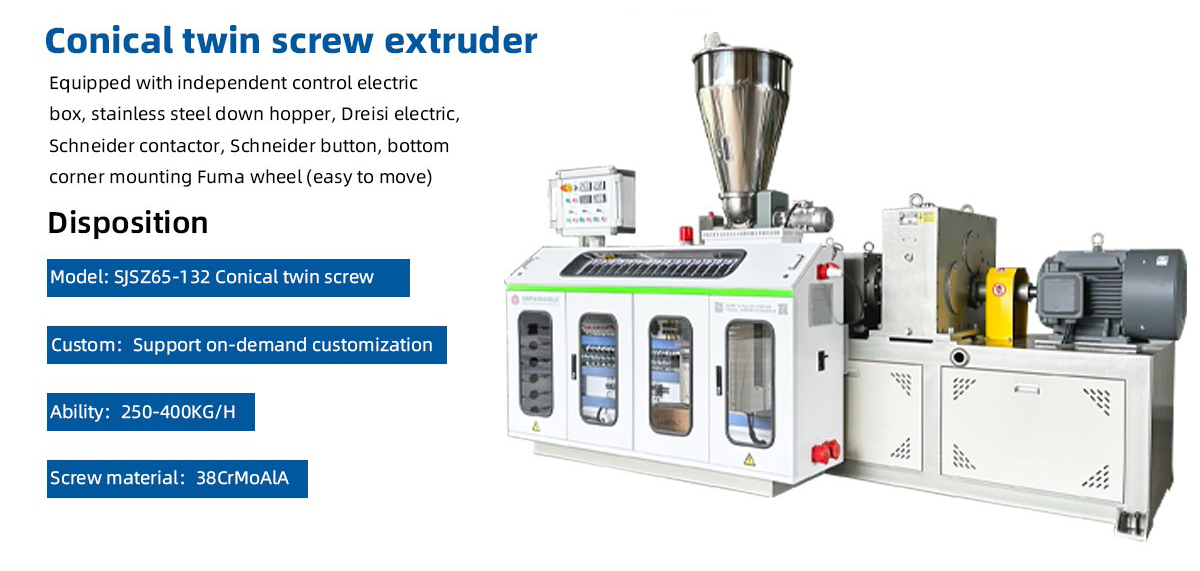

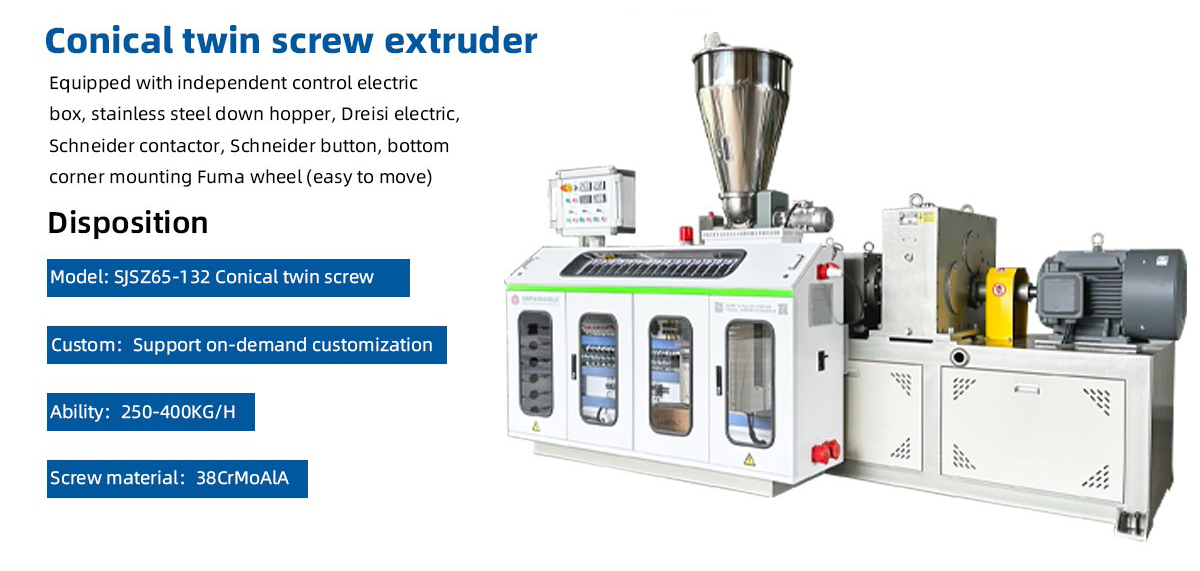

SJSZ65-132 conical twin screw extruder

Obverse show

Large hanging electric cabinet

360-degree rotating console

Heating control zone

Motor

Screw

Wing fan cooling sets

Stainless steel feeding hopper

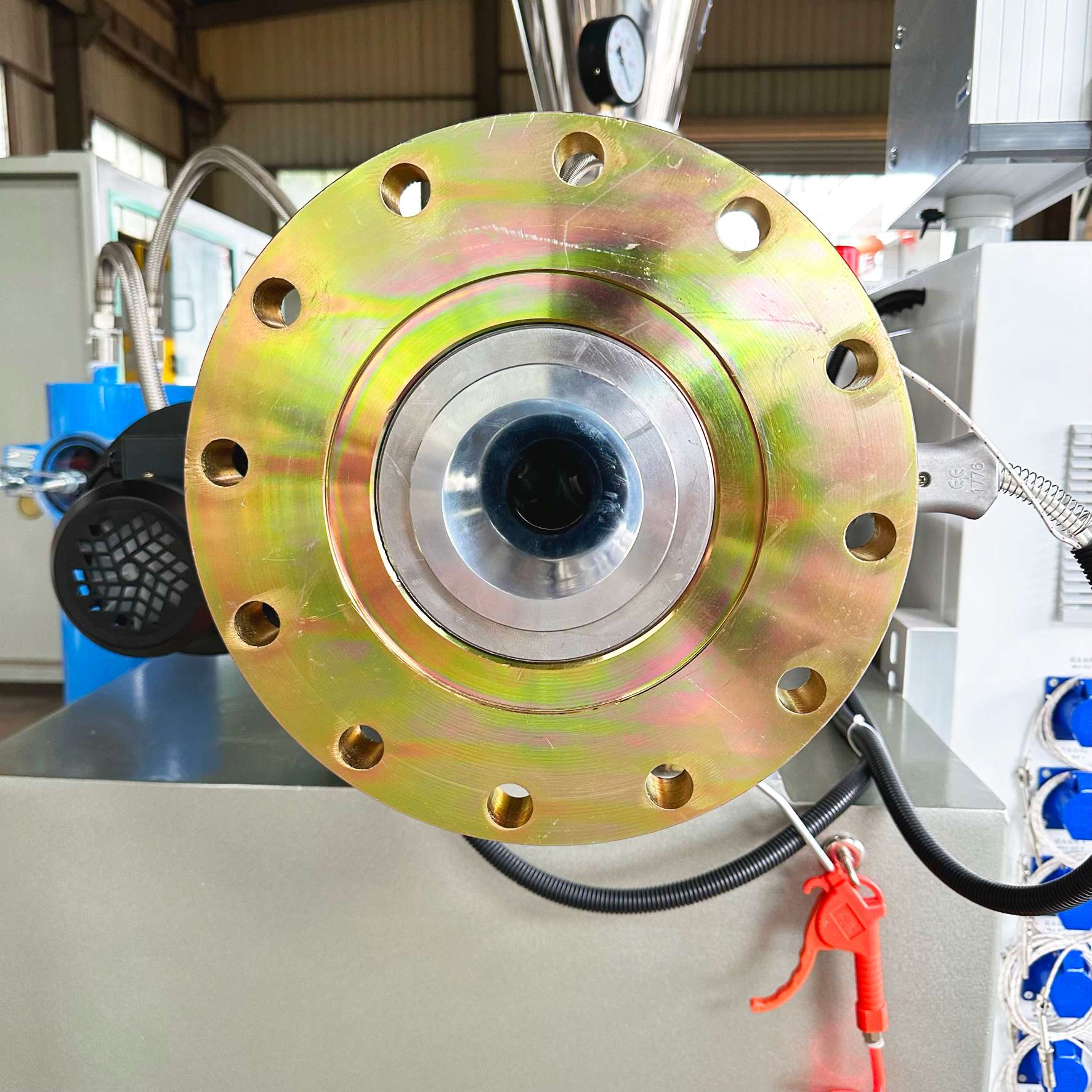

Screw head

▏Product Introduction

The SJSZ65-132 Conical Twin Screw Extruder is a high-performance machine used in the plastic processing industry for the production of a wide range of plastic products, such as pipes, profiles, sheets, and granules. It features two intermeshing screws with a conical design, offering excellent material mixing, plasticizing, and extrusion capabilities. This type of extruder is commonly used in the production of PVC and other thermoplastics.

The SJSZ65-132 model refers to the specific configuration of the extruder, where “65” denotes the diameter of the first screw (65 mm) and “132” refers to the diameter of the second screw (132 mm). The conical design of the screws—where the screws gradually taper from a wider diameter at the feed end to a narrower diameter at the discharge end—improves the efficiency of material conveying, melting, and mixing.

Key Features of the SJSZ65-132 Conical Twin Screw Extruder:

| 1. Conical Twin Screw Design:The conical screw arrangement allows for efficient material processing. The screws rotate in opposite directions, which facilitates better mixing, plasticizing, and uniform distribution of the material. The design also enables the machine to handle a variety of materials effectively, especially PVC, PE, and PP. |

| 2. High-Quality Plasticizing:The twin-screw mechanism ensures superior plasticizing performance, producing homogeneous and high-quality extrusions. This makes the extruder ideal for processing rigid and flexible PVC materials. |

| 3. High Efficiency:The conical screw design offers a high processing capacity with lower energy consumption compared to other extrusion types. This makes the machine both energy-efficient and cost-effective for large-scale production. |

| 4. Versatile Applications:The SJSZ65-132 extruder is highly versatile and can be used to produce a wide variety of plastic products such as: • PVC pipes for water supply, drainage, and electrical conduit. • Plastic profiles for doors, windows, and decoration. • Plastic sheets and films for packaging, signage, and other uses. • Plastic granules used for compounding and further processing. |

| 5. Enhanced Mixing Capabilities:The intermeshing twin screws ensure excellent dispersion of additives, colors, and fillers, resulting in uniformly blended and high-quality final products. This is particularly important in applications where color consistency and material properties need to be precisely controlled. |

| 6. Efficient Cooling System:The machine comes with an integrated cooling system that effectively manages the temperature during extrusion, preventing overheating of the material and ensuring consistent product quality. |

| 7. Automatic Control System:The extruder is typically equipped with a sophisticated PLC (Programmable Logic Controller) system that allows operators to monitor and control key parameters such as screw speed, temperature, pressure, and material feed rate. This automated system ensures consistent production and minimizes the risk of human error. |

| 8. Durable and Reliable:The SJSZ65-132 is designed for durability and long-lasting performance, with high-quality components that ensure minimal downtime and maintenance. The twin screws are made from wear-resistant materials, increasing their lifespan even under heavy-duty operation. |

Benefits:

| 1. Improved Material Homogeneity:The conical twin-screw design ensures excellent mixing, resulting in products with consistent quality, uniform texture, and no material separation. |

| 2. High-Volume Production:The machine’s high-efficiency design enables high throughput, making it ideal for manufacturers that require large production volumes. |

| 3. Reduced Energy Consumption:The conical design improves material conveying and plasticizing efficiency, leading to lower energy consumption during the extrusion process. |

| 4. Precision and Consistency:The automated control systems allow for precise adjustments to temperature, speed, and other variables, ensuring that every batch meets strict quality standards. |

| 5. Versatility:The SJSZ65-132 is adaptable to various material types and can be used for producing a broad range of plastic products, making it a versatile addition to a production line. |

| 6. Cost-Effective:With efficient material processing, reduced energy consumption, and high productivity, this extruder offers a cost-effective solution for both small and large-scale plastic production. |

Applications:

| 1. PVC Pipe Production:One of the most common applications of the SJSZ65-132 is the production of PVC pipes, which are used in plumbing, electrical conduit, and drainage systems. The extruder ensures the pipes have uniform wall thickness and smooth surfaces. |

| 2. Plastic Profiles:This extruder is ideal for producing plastic profiles, such as those used in construction for windows, doors, and decorative elements. The conical twin screws provide excellent control over the material’s texture and finish. |

| 3. Sheet and Film Production:The SJSZ65-132 is used in producing plastic sheets and films, especially for use in packaging, signage, and other applications that require flexibility and clarity. |

| 4. Compounding:The extruder is also used for plastic compounding, where additives, colors, and fillers are mixed with base resins to create materials with specific properties. The excellent mixing capabilities of the conical twin-screw design ensure that the additives are evenly distributed. |

| 5. Granule Production:The SJSZ65-132 is widely used in granule production, creating small pellets of plastic that can be further processed in other machines or used as raw material for various plastic products. |

The SJSZ65-132 Conical Twin Screw Extruder is a high-performance, versatile, and energy-efficient machine that plays a vital role in the production of a wide range of plastic products. Its conical twin-screw design ensures superior material mixing, plasticizing, and processing, making it ideal for applications such as PVC pipe production, plastic profiles, sheets, and granules. With high output capabilities, precision control, and durable construction, the SJSZ65-132 extruder is an essential piece of equipment for manufacturers looking to produce high-quality, consistent plastic products with minimal operational costs.

▏Production Advantage

| 1 | From the point of view of specifications |

| First of all, from the point of view of specifications, SJSZ65-132 conical twin screw extruder screw diameters are Φ65mm and Φ132mm, conical screw structure makes the feeding section has a larger diameter, which is conducive to the plasticization of materials, and the diameter of the metering section screw decreases, reducing the heat transfer area and the shear speed of the molten material. The melt can be extruded at a lower temperature. The drive motor power is 37-55KW, the use of frequency control mode, can flexibly adjust the screw speed according to the production demand, the range is 0\~36r/min. The center height is 1000mm, the cylinder heating section adopts cast aluminum heating ring, the total power is 22-42kw, to ensure the uniformity and efficiency of heating. |

| 2 | In terms of equipment structure |

| Secondly, in terms of equipment structure, SJSZ65-132 conical twin screw extruder adopts a horizontal reducer box and distribution box design, and the driving torque is evenly distributed to the two screws through the gear box to ensure the stability and reliability of the extrusion process. |

| 3 | In terms of control system |

| In terms of control system, SJSZ65-132 conical twin screw extruder adopts PLC automatic control or temperature control meter control, the main part uses imported components, with a number of fault alarm functions, simple operation and easy maintenance. This greatly improves the degree of automation and ease of operation of the equipment. |

| 4 | Applications |

| In addition, SJSZ65-132 conical twin screw extruder has a wide range of applications, which can be used for direct connection of PVC powder, with the appropriate head and auxiliary machinery, hard PVC powder can be processed into tubes, plates, profiles, etc., and can also be used for PVC pelleting. Due to its efficient extrusion performance and stable operation characteristics, it is an ideal choice for the plastics processing industry. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping