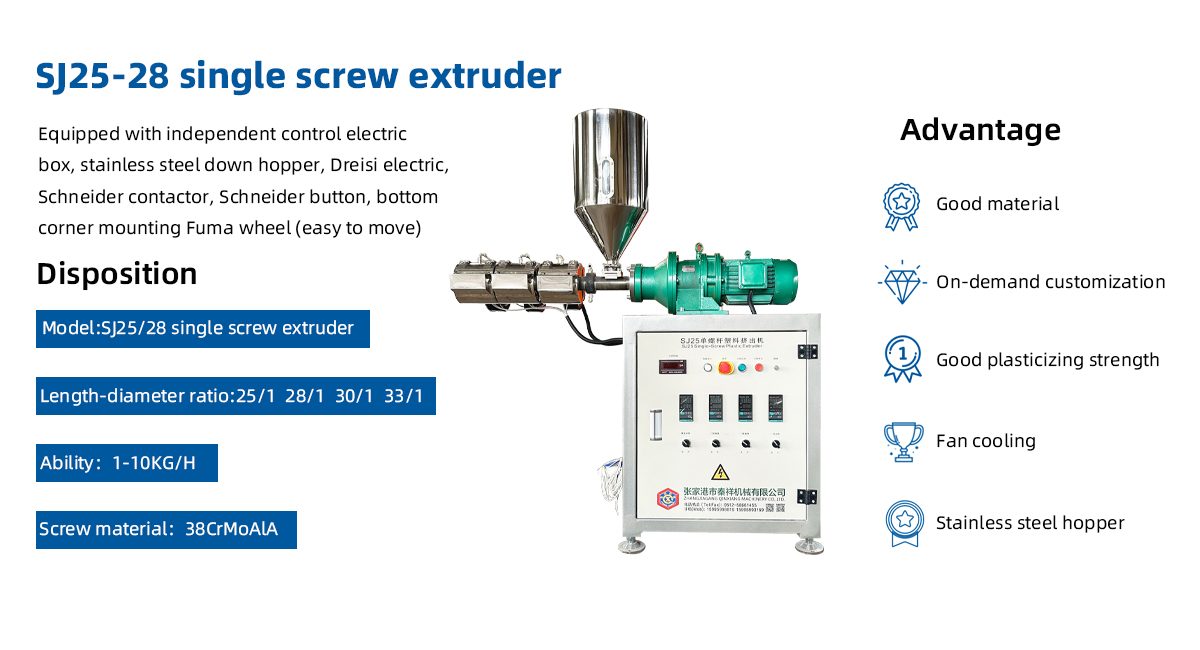

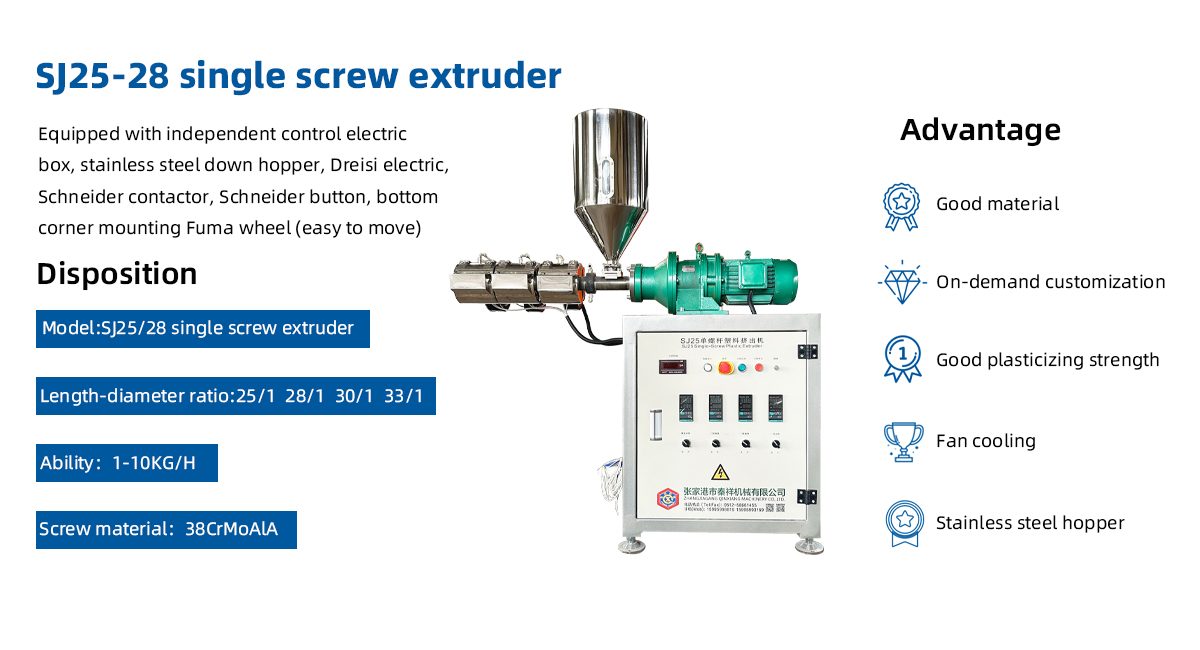

▏SJ25-28 Lab Mini Plastic Extruder

▏Introduction to the SJ25-28 Lab Mini Plastic Extruder

The SJ25-28 Lab Mini Plastic Extruder is a compact and high-performance machine designed specifically for small-scale extrusion applications. This versatile extruder is ideal for research, material development, and laboratory-scale production of plastic materials. Whether used for testing new polymer formulations, developing prototypes, or producing small quantities for quality testing, the SJ25-28 mini extruder provides precise control over critical extrusion parameters, ensuring high-quality results.

Given its compact size, the SJ25-28 extruder is particularly well-suited for laboratories, educational settings, and pilot-scale production lines. Despite its smaller footprint, it is capable of processing a wide range of thermoplastics, including PVC, PE, PP, PS, and ABS. This makes it an essential tool for various industries, including automotive, packaging, medical, and research sectors.

▏Key Features of the SJ25-28 Lab Mini Plastic Extruder

| 1 | Precision Control for Accurate Results |

| One of the standout features of the SJ25-28 Lab Mini Plastic Extruder is its precision control system. The extruder is equipped with multiple heating zones along the barrel, allowing for uniform temperature distribution. The temperature of each zone can be individually controlled, ensuring that the polymer reaches the exact processing temperature required for optimal flow. This level of temperature control helps reduce material degradation and ensures the final product meets quality standards.

In addition to temperature control, the SJ25-28 extruder offers adjustable screw speeds and torque settings, providing flexibility to process a wide range of materials. Operators can fine-tune these settings to match the characteristics of specific polymers, giving them full control over the extrusion process. This precision is essential for laboratories and research institutions that require consistent results for experimentation and development. |

| 2 | Compact and Space-Efficient Design |

| The SJ25-28 Lab Mini Plastic Extruder is designed to be compact and space-efficient, making it perfect for small-scale production or laboratory environments with limited space. Its small footprint does not compromise on functionality, as it offers the same performance and capabilities as larger extrusion machines. The extruder’s portability makes it easy to move between different research stations or departments, offering maximum flexibility.

Despite its compact size, the extruder is built with high-quality materials and robust construction, ensuring long-term durability and reliability. This makes the SJ25-28 extruder a valuable asset for institutions looking for an efficient and cost-effective extrusion solution for R&D purposes. |

| 3 | Versatile Material Processing |

|

The SJ25-28 Lab Mini Plastic Extruder is compatible with a wide variety of thermoplastics, including PVC, PE, PP, PS, and other specialty polymers. This versatility enables users to experiment with different materials, additives, and fillers to create new formulations or optimize existing ones. The extruder can handle various feedstock types, such as pellets, powders, and regrind material, offering flexibility in material selection.

From testing new polymer blends to producing small batches of materials for product development, the SJ25-28 extruder can accommodate a broad range of polymer processing needs. Its ability to handle different types of plastics makes it an invaluable tool for industries involved in plastic material research and development. |

| 4 | Customizable Die for Profile Extrusion |

|

The SJ25-28 mini extruder can be equipped with a range of interchangeable dies, enabling users to produce a variety of profiles such as pipes, films, sheets, and rods. This die-swapping feature offers great flexibility for prototyping different shapes and sizes. Whether you are producing standard profiles or creating custom products for testing, the extruder allows for quick and easy die changes, saving time and improving overall production efficiency.

The ability to produce different profiles with minimal downtime makes the SJ25-28 extruder ideal for small-batch production and research purposes, where product variety and experimentation are crucial. This flexibility also makes it a perfect choice for industries that require customized profiles for specific applications. |

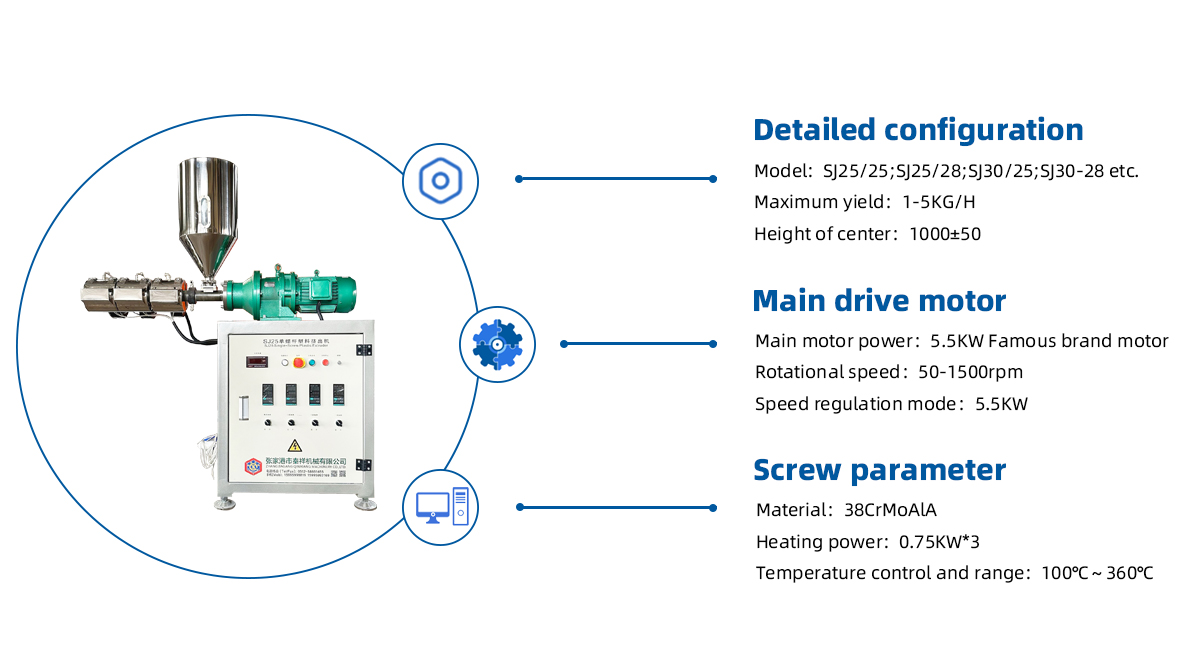

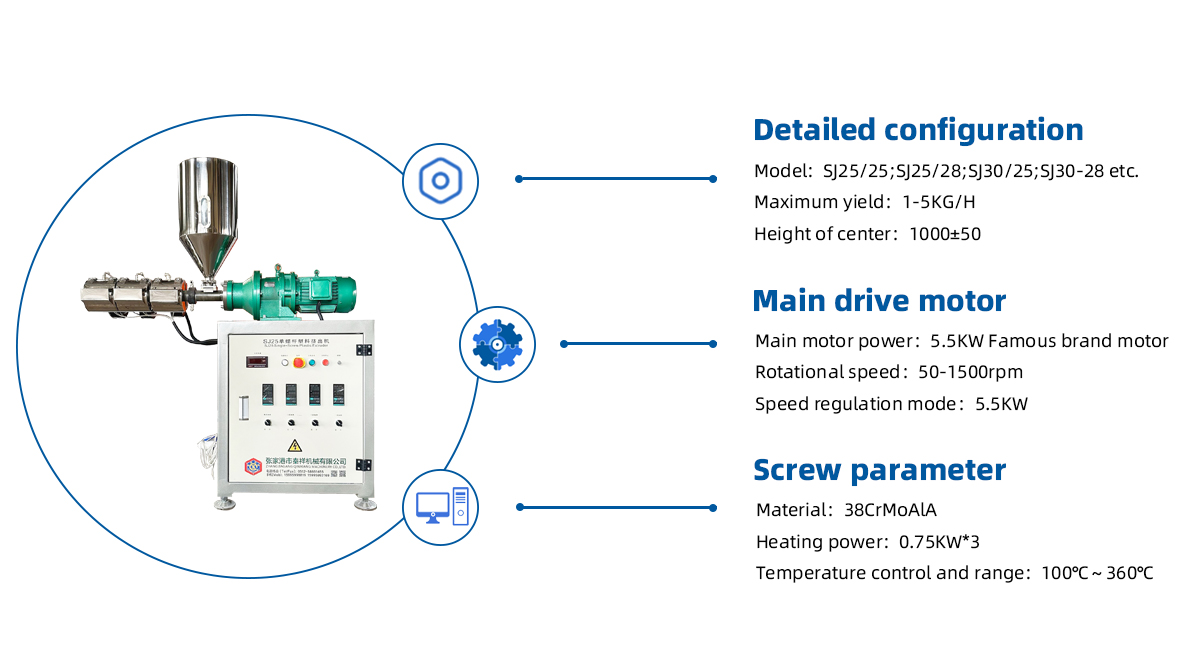

▏Technical Parameters

| Motor power | 1.1Kw |

| Heating power | 0.55Kw |

| Main engine speed regulation | frequency control |

| Screw, screw material | 38CrMoAlA;surface nitriding |

| Electrical appliance | Siemens contactor, Dongqi temperature control meter, Delixi Electric |

| Motor speed regulation | 1.1KW inverter speed regulation |

▏Main Details

▏Product Photos

High-precision extrusion

High torque output

High strength wear resistance

Low noise operation

1.5Kw motor power

Three sets of wing fan cooling

Screw:38CrMoAlA

Barrel:38CrMoAlA

Stainless steel hopper

Easy operation and maintenance

▏How the SJ25-28 Lab Mini Plastic Extruder Works

| Material Feeding and Conveying |

| The process begins when the polymer material is loaded into the hopper. The SJ25-28 mini extruder utilizes a screw feeder that moves the material into the barrel. The screw is designed to provide efficient material feeding, helping to prevent blockages and ensuring a steady flow of polymer into the extrusion system. This feeding system is essential for maintaining uniform material processing and ensuring a consistent output. |

| Heating and Melting the Material |

| Once the material enters the barrel, it is subjected to heat from multiple heating zones along the barrel. The heating zones are individually controlled to ensure even and accurate temperature distribution. This helps the polymer to melt evenly and consistently as it moves along the barrel. The screw, in turn, provides mechanical energy to further assist in melting the polymer, mixing it, and preparing it for extrusion.

Temperature control is critical in this stage to avoid material degradation and ensure that the polymer retains its desired properties. The SJ25-28 extruder allows precise temperature control at each zone, giving operators the ability to optimize the extrusion process. |

| Extrusion and Shaping the Polymer |

| Once the polymer is fully melted and homogenized, it is forced through a die to form the desired profile. The SJ25-28 extruder supports various dies, allowing users to produce pipes, sheets, films, or rods with high precision. The screw speed and extrusion pressure can be adjusted to control the rate at which the polymer exits the die, ensuring the final product meets dimensional specifications.

The ability to swap out dies quickly and easily provides significant flexibility, allowing users to experiment with different shapes and profiles based on their research or production needs. |

| Cooling and Solidification |

|

After the polymer is extruded and shaped, it must be cooled to solidify and retain its profile. The SJ25-28 mini extruder is equipped with an efficient cooling system, which can include water baths or air cooling, depending on the material and profile being produced. The cooling system helps the extruded material solidify quickly while maintaining dimensional stability.

Controlling the cooling rate is essential to achieving the desired mechanical properties in the final product. The SJ25-28 extruder offers flexibility in this regard, allowing users to adjust the cooling rate to suit different polymers and product specifications. |

| Cutting and Collection |

|

Once the extruded material has cooled and solidified, it is cut into desired lengths using a cutting system. This system can be set up to cut the extrudate into precise lengths based on the needs of the project. The cutting system ensures consistent product dimensions, whether for testing, analysis, or product evaluation. |

▏Applications of the SJ25-28 Lab Mini Plastic Extruder

| Polymer Research and Development |

| The SJ25-28 Lab Mini Plastic Extruder is widely used in research and development settings, where precise control over the extrusion process is essential. It is perfect for testing new polymer blends, exploring the effects of different additives, and analyzing how different processing conditions affect material properties. Researchers can adjust parameters such as temperature, screw speed, and pressure to study their impact on polymer behavior, making it an invaluable tool for advancing material science. |

| Prototyping and Small-Scale Production |

| In product development, the SJ25-28 mini extruder is used for prototyping and small-scale production. Manufacturers can produce test samples, conduct quality control checks, and refine product designs before moving to full-scale production. Whether developing custom profiles for new applications or experimenting with material formulations, the SJ25-28 extruder is ideal for small-batch production and prototyping. |

| Educational Use |

| The SJ25-28 Lab Mini Plastic Extruder is also an excellent tool for educational institutions that teach polymer science and engineering. It provides students with hands-on experience in the extrusion process, helping them understand material processing techniques and the relationship between processing parameters and product properties. Its compact size and ease of use make it a perfect fit for laboratory classrooms and educational settings. |

| Plastic Pipe and Profile Manufacturing |

| The SJ25-28 mini extruder is commonly used for small-scale production of plastic pipes and profiles. The ability to produce high-quality extrusions with consistent dimensions makes it suitable for testing and producing plastic components for industries such as construction, automotive, and plumbing. With adjustable parameters, the extruder can handle a variety of polymers, allowing manufacturers to produce different types of pipes and profiles based on material requirements. |

▏Advantages of the SJ25-28 Lab Mini Plastic Extruder

| High Precision Control |

| The SJ25-28 Lab Mini Plastic Extruder provides excellent control over key extrusion parameters, including temperature, screw speed, and pressure. This precision allows for consistent and repeatable results, making it ideal for research and development purposes. |

| Compact and Versatile |

| Its compact size makes the SJ25-28 extruder an ideal choice for small-scale production, research, and educational environments. The ability to process a wide variety of thermoplastic materials also adds to its versatility. |

| Customizable Die System |

| The ability to easily swap out dies for different profiles gives the SJ25-28 extruder exceptional flexibility. This feature is particularly useful for prototyping and testing different product designs or configurations. |

| Cost-Effective and Efficient |

| The SJ25-28 mini extruder offers a cost-effective solution for laboratories and small-scale production, reducing the need for larger, more expensive extrusion machines. Its efficient operation and low maintenance requirements help keep operating costs down. |

▏A Compact Powerhouse for Polymer Processing

The SJ25-28 Lab Mini Plastic Extruder is an essential tool for anyone working in polymer research, material development, and small-scale production. With its precise control, versatile material compatibility, and compact design, it offers a reliable and efficient solution for producing high-quality extrusions in laboratory settings. Whether for prototyping, testing new formulations, or educational purposes, this mini extruder delivers exceptional results that make it an invaluable asset for any facility focused on polymer processing.

▏Product Introduction

Lab Mini Plastic Extruder is a multi-functional small experimental extrusion equipment, designed for experiments and research and development, used to simulate and evaluate the performance of various plastic materials in the extrusion process. Here are some of the main features and specifications of the device:

| 1 | Screw diameter |

| The screw diameter of the equipment is 25mm, which is suitable for a wide range of raw materials, including PE, PP, EVA, PVC, PS, ABS, PA, PMMA, TPE, PET, PC, TPU, PLA-polylactic acid and other extruded plastic particles or powder resins. |

| 2 | Screw length to diameter ratio |

| Length to diameter ratio of 28:1, this design helps to achieve an efficient extrusion process, while ensuring that the material in the extrusion process evenly heated and mixed. |

| 3 | Screw speed |

| The speed range is 50\~90r/min, which can be adjusted according to different material and process requirements. |

| 4 | Production capacity |

| The production capacity is 3\~5Kg/h, the specific production capacity will vary according to the materials and process conditions used. |

| 5 | Main motor power |

| the power of the main motor is 2.2\~3.0Kw, and the frequency conversion speed regulation mode can adjust the running speed of the motor according to actual needs. |

| 6 | In addition, Lab Mini Plastic Extruder also has the following technical features |

| * High thrust bearing provides high torque output to ensure stability and reliability of extrusion process. * Gear and shaft made of high-strength alloy steel, after nitriding and grinding treatment, high hardness, good smoothness, low noise. * Equipped with hopper automatic dryer to prevent material moisture and ensure smooth extrusion process. * Equipped with automatic feeder, effectively reduce labor intensity, improve production efficiency. * The use of automatic PLC intelligent control, to achieve the interaction between the main and auxiliary machines, and with easy to monitor the human-machine interface, help to master the working state. * The controller can change the temperature and other control modes as needed to achieve accurate temperature control. * Specially designed feed port, perfect water cooling device and professionally designed trapezoid-free sleeve ensure the stability and efficiency of the extrusion process. |

| 7 | In the field of application |

| Lab Mini Plastic Extruder is suitable for extrusion processing of various plastic pipes, such as PP-R pipe, PE gas pipe, PEX cross-linked pipe, aluminum-plastic composite pipe, ABS pipe, PVC pipe and HDPE silicon core pipe. At the same time, it can also be used for sheet and sheet processing. |

▏About Us

▏Why Choose Us

▏Corporate Culture

▏Our Advantages

▏Cooperative Parts Supplier

▏Packing And Shipping