▏Pipe Chip-Free Cutting Machine: Precision Cutting for Pipe Materials

▏Introduction to the Pipe Chip-Free Cutting Machine

The Pipe Chip-Free Cutting Machine is a high-performance industrial solution designed to provide clean, precise, and efficient cutting of pipes without generating chips or debris. Unlike traditional cutting methods that produce unwanted chips, burrs, or dust, this machine ensures smooth, burr-free cuts with minimal material waste, making it ideal for applications where high-quality cuts are essential.

This advanced cutting technology is primarily used in industries such as plumbing, manufacturing, construction, and aerospace, where precision and cleanliness are paramount. Whether cutting metal, plastic, or composite pipes, the Pipe Chip-Free Cutting Machine provides a consistent and reliable method to cut pipes to the desired length and specification.

▏Key Features of the Pipe Chip-Free Cutting Machine

| Chip-Free and Burr-Free Cuts

One of the most significant advantages of the Pipe Chip-Free Cutting Machine is its ability to cut pipes without generating chips, burrs, or other debris. Traditional cutting methods often leave jagged edges or metal filings, which can be problematic, especially for applications requiring tight tolerances or cleanliness. The chip-free cutting process results in smooth, precise edges, reducing the need for post-processing and ensuring the pipes are ready for immediate use. |

| High Cutting Precision and Accuracy

The Pipe Chip-Free Cutting Machine is designed to deliver exceptional precision and accuracy in every cut. It uses advanced cutting technologies such as laser cutting, plasma cutting, or water jet cutting, depending on the material and application. These technologies allow for fine adjustments, ensuring that each cut is consistent and meets the required specifications. The high precision is critical in industries where even minor deviations can affect the integrity or performance of the final product. |

| Versatile Cutting Capability

The Pipe Chip-Free Cutting Machine can handle a variety of materials, including metals (stainless steel, copper, aluminum), plastics (PVC, HDPE), and composite pipes. This versatility allows manufacturers to use the same machine to cut different types of materials, reducing the need for multiple machines and improving overall production efficiency. |

| Reduced Material Waste

By providing precise cuts without chips or burrs, the Pipe Chip-Free Cutting Machine helps reduce material waste. Traditional cutting methods often result in excess material being removed, which not only increases costs but also contributes to waste. With this machine, the cutting process is cleaner, more efficient, and uses less raw material, contributing to a more sustainable production process. |

| Minimal Maintenance and Long-Term Durability

Thanks to its advanced design and cutting technology, the Pipe Chip-Free Cutting Machine is built to withstand heavy use with minimal maintenance requirements. The machine’s durable construction and efficient cutting mechanisms reduce wear and tear, ensuring long-term performance and reliability. Regular maintenance intervals are kept to a minimum, helping businesses save on operational downtime and maintenance costs. |

| Automation and User-Friendly Interface

Modern Pipe Chip-Free Cutting Machines often feature automation capabilities, allowing for hands-free operation once the pipes are loaded into the system. The machine is typically equipped with a touchscreen control panel that allows operators to easily input cutting parameters, such as pipe size, cut length, and cutting speed. The automated systems enable fast and efficient processing, improving productivity and reducing human error. |

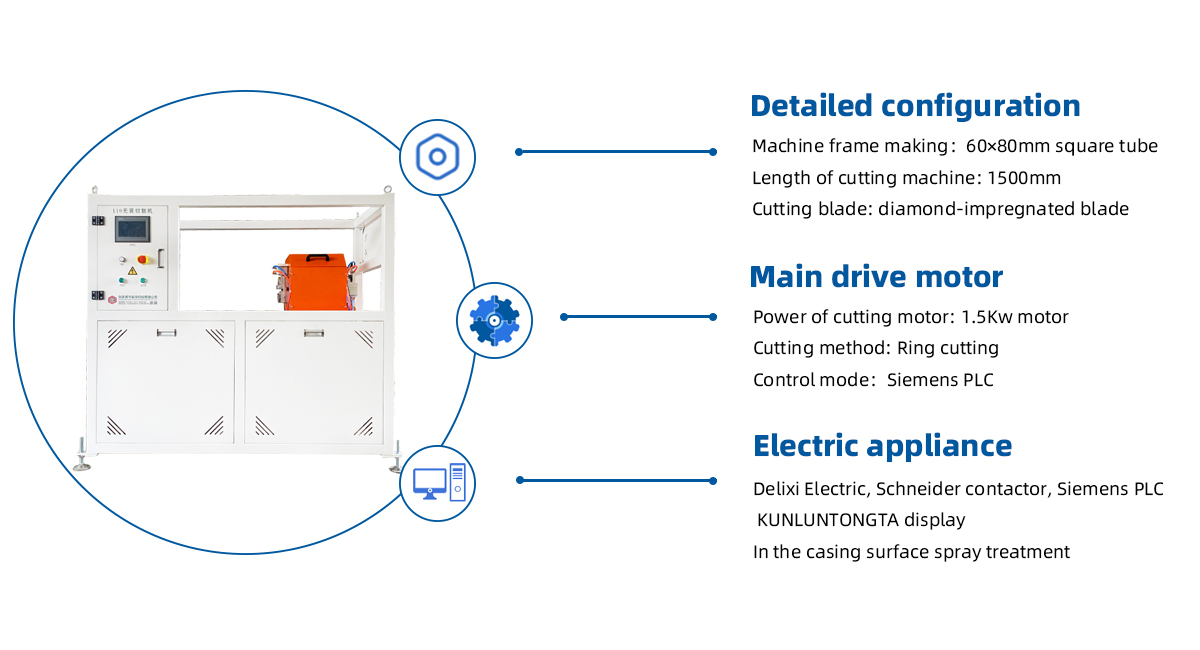

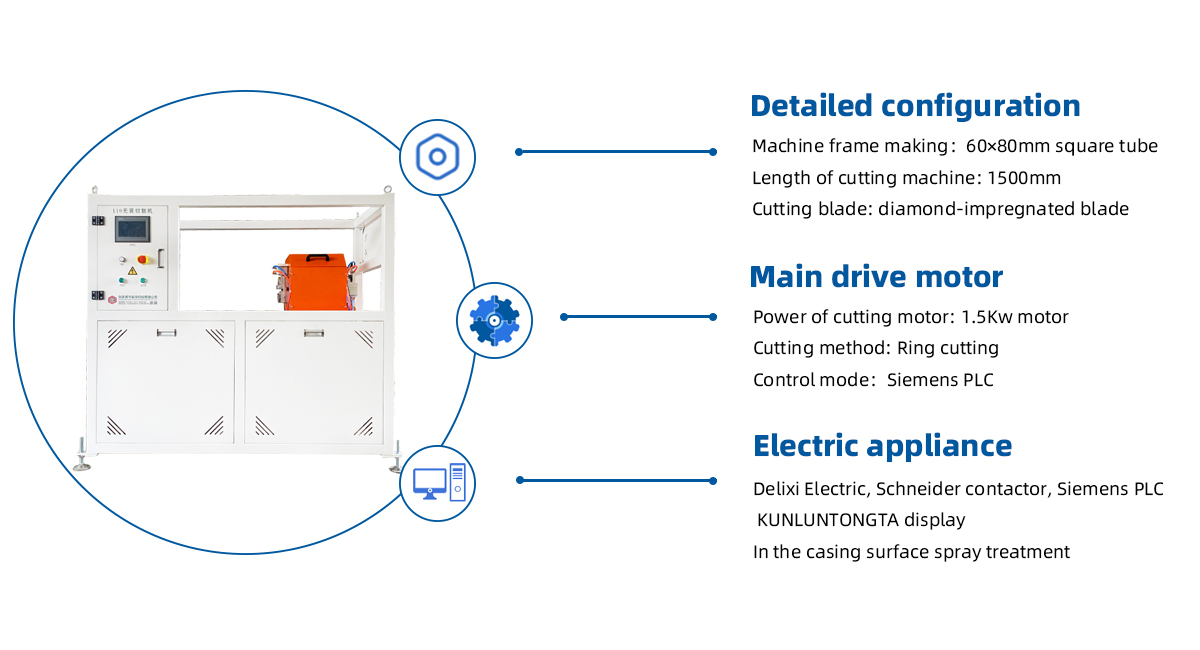

▏Technical Parameters

Machine frame making | 60×80mm square tube |

Length of cutting machine | 1500mm |

| Cutting blade | diamond-impregnated blade |

Power of cutting motor | 1.5Kw motor |

| Cutting method | Ring cutting |

| Control mode | Siemens PLC |

▏Main Details

▏Product Photos

▏How the Pipe Chip-Free Cutting Machine Works

The operation of the Pipe Chip-Free Cutting Machine relies on a highly controlled cutting process that ensures the pipe material is sliced without the formation of unwanted debris. Here's how it works:

| 1. Material Loading

The first step involves securely loading the pipe into the machine’s feeding system. Most machines are equipped with automatic or manual feeding mechanisms to handle pipes of various sizes. Once loaded, the pipe is positioned for cutting with high precision. |

| 2. Cutting Mechanism Activation

The machine uses an advanced cutting method such as laser cutting, water jet cutting, or plasma cutting, depending on the type of material being cut. Each of these methods uses a focused energy beam or jet to create a clean, precise cut without producing chips. For example: Laser Cutting: A focused laser beam is directed at the pipe material, instantly heating and vaporizing it along the cutting path. Water Jet Cutting: High-pressure water mixed with abrasives is used to slice through the pipe without causing heat distortion or material stress. Plasma Cutting: An electrically conductive gas is ionized to form a plasma that cuts through metal pipes quickly and cleanly. |

| 3. Pipe Cutting and Precision

Once the cutting mechanism is activated, the machine follows the programmed parameters, cutting the pipe into the desired lengths with high precision. The cutting speed and parameters can be adjusted based on the material type and thickness. |

| 4. Discharge and Collection

After the cutting process, the pipe segments are discharged and collected for further use. Some systems include an automatic ejection system to transport the cut pipes to a collection area. Because there are no chips or debris created during the process, the final product is ready for immediate handling or assembly. |

| 5. Post-Cutting Quality Control

In some models, an integrated quality control system monitors the cuts to ensure that the pipes meet the required tolerances. Sensors or cameras can be used to inspect the edges of the cuts, verifying that they are burr-free and within specification. |

▏Benefits of the Pipe Chip-Free Cutting Machine

| Enhanced Productivity and Efficiency

The Pipe Chip-Free Cutting Machine improves overall productivity by significantly reducing downtime associated with manual labor and secondary processes. The automated cutting system speeds up the cutting process, allowing for higher throughput and faster turnaround times. The chip-free operation eliminates the need for additional deburring or cleaning steps, further enhancing efficiency. |

| High-Quality Results

For industries where pipe quality is critical, such as aerospace, automotive, and construction, the Pipe Chip-Free Cutting Machine delivers consistent and high-quality results. The smooth, burr-free cuts ensure that pipes fit together perfectly during assembly and meet the exacting standards of these industries. |

| Cost Savings

By reducing material waste and eliminating the need for post-processing, the Pipe Chip-Free Cutting Machine helps reduce overall production costs. Fewer defects and less downtime mean more efficient use of resources, ultimately leading to cost savings in both materials and labor. |

| Improved Workplace Safety

Traditional cutting methods that generate chips, sparks, or sharp edges can present significant safety hazards in the workplace. The Pipe Chip-Free Cutting Machine minimizes these risks by ensuring a clean and controlled cutting environment. Additionally, automated features reduce the amount of manual handling required, further improving operator safety. |

| Reduced Environmental Impact

With a focus on precision and efficiency, the Pipe Chip-Free Cutting Machine contributes to a more sustainable production process. Reduced material waste and energy-efficient cutting methods help lower the environmental impact of manufacturing operations. |

▏Applications of the Pipe Chip-Free Cutting Machine

| 1. Pipe Manufacturing

In the pipe manufacturing industry, the chip-free cutting machine is used to cut pipes to precise lengths for use in various products, such as plumbing systems, HVAC systems, and structural components. |

| 2. Automotive Industry

The Pipe Chip-Free Cutting Machine is an invaluable tool in the automotive industry, where it is used to cut pipes for exhaust systems, fuel lines, and hydraulic components. Precision cutting ensures the pipes fit together perfectly in complex assemblies. |

| 3. Aerospace and Defense

In the aerospace and defense industries, where strict tolerances and material integrity are essential, the Pipe Chip-Free Cutting Machine ensures clean cuts for critical components. Whether cutting titanium, aluminum, or composite materials, the machine delivers precise results that meet the highest industry standards. |

| 4. Construction

For construction applications, particularly in plumbing and HVAC systems, the Pipe Chip-Free Cutting Machine is used to quickly and accurately cut pipes made from a variety of materials, including PVC, copper, and steel. |

| 5. Oil and Gas

In the oil and gas industry, where pipelines often need to be cut for installation or maintenance, the Pipe Chip-Free Cutting Machine ensures that the cuts are clean and precise, helping to avoid any issues during assembly or operation. |

▏A Revolutionary Solution for Pipe Cutting

The Pipe Chip-Free Cutting Machine is a game-changing tool for industries that require clean, precise, and efficient pipe cutting. By eliminating chips, burrs, and debris, it ensures high-quality cuts that are ready for immediate use, minimizing post-processing time and reducing material waste. With its versatility, automation features, and robust performance, the Pipe Chip-Free Cutting Machine is an essential investment for companies seeking to improve productivity, reduce costs, and maintain high standards of quality in their pipe cutting operations.

▏Production introduction

| 1 | working principle and characteristics |

| Plastic pipe chipless cutting machine is a kind of mechanical equipment using advanced cutting technology, which is specially used for plastic pipe chipless cutting. Its working principle mainly relies on high-speed rotating blades and precise feeding and control systems. Through the high-speed rotation of the blade and the precise cutting force control, the equipment can achieve smooth and chip-free cutting of the pipe, thereby improving the processing quality and utilization rate of the pipe. The main features of the equipment include fast cutting speed, high cutting quality and easy operation. At the same time, the chip-free cutting technology effectively reduces the waste and dust generated in the cutting process, reducing environmental pollution and cleaning costs. |

| 2 | intelligent automation function |

| The plastic pipe chip-free cutting machine is equipped with advanced intelligent and automatic functions, making the operation of the equipment more convenient and efficient. These features include automatic feeding, automatic positioning, automatic cutting and automatic chip removal. Users only need to set the cutting parameters and length, and the equipment can automatically complete the entire cutting process without too much manual intervention. In addition, the equipment also has intelligent fault diagnosis and alarm function, once there is a fault or abnormal situation, the equipment will automatically stop and display error information, convenient for users to troubleshoot and solve problems in time. |

| 3 | high efficiency and energy saving advantages |

| Plastic pipe chip-free cutting machine pays attention to high efficiency and energy saving in the design and manufacturing process. The equipment uses an advanced motor and control system, which can adjust the power and speed according to the actual working needs, thus reducing energy consumption. At the same time, the optimized design and good thermal balance of the equipment further improve energy efficiency and save operating costs for users. |

| 4 | accurate and reliable performance |

| Chip free cutting machine with excellent cutting accuracy and reliability. It uses high-precision sensors and measuring devices to ensure the accuracy of pipe cutting length and accuracy. The equipment also has excellent durability and stability, and can maintain stable cutting performance even under continuous long working conditions. |

| 5 | Application scope and specifications |

| Plastic pipe chipless cutting machine is widely used in construction, water conservancy, power, transportation and other fields of plastic pipe processing. The types of pipes it cuts include PVC, PE, PP and other materials, while adapting to different specifications and thickness of the pipe cutting needs. The equipment has a flexible cutting length adjustment range, which can meet the requirements of different projects on pipe length. |

| 6 | Easy operation and stability |

| The operation interface of the plastic pipe chip-free cutting machine is simple and clear, and the user only needs to make simple Settings according to the operation prompts to start the cutting work. The stability of the equipment is high, and it is not easy to jitter or offset during the cutting process, so as to ensure the cutting quality and production efficiency. In addition, the equipment also has fault self-diagnosis and alarm functions, making maintenance and maintenance more convenient. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping