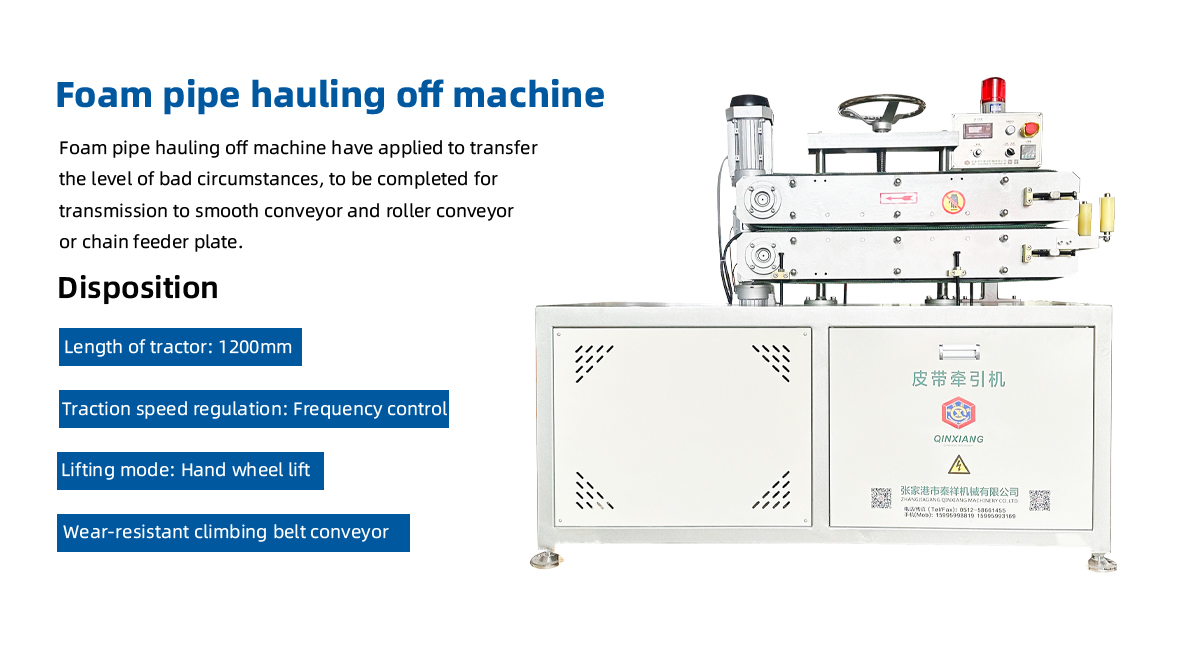

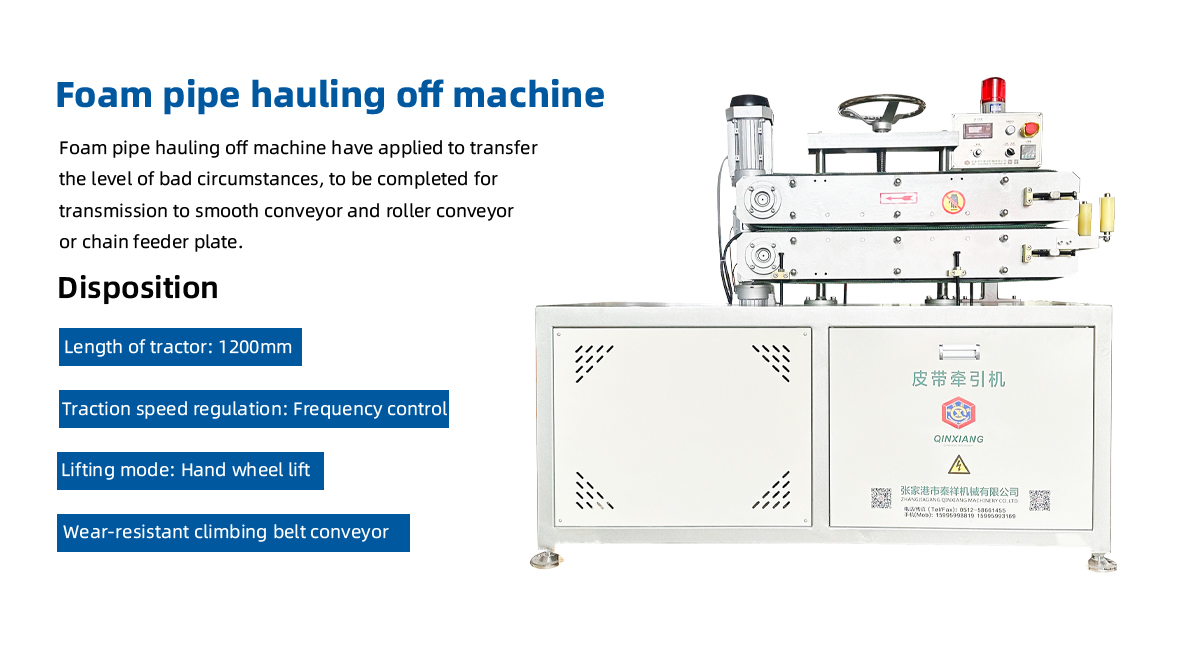

▏Product Introduction

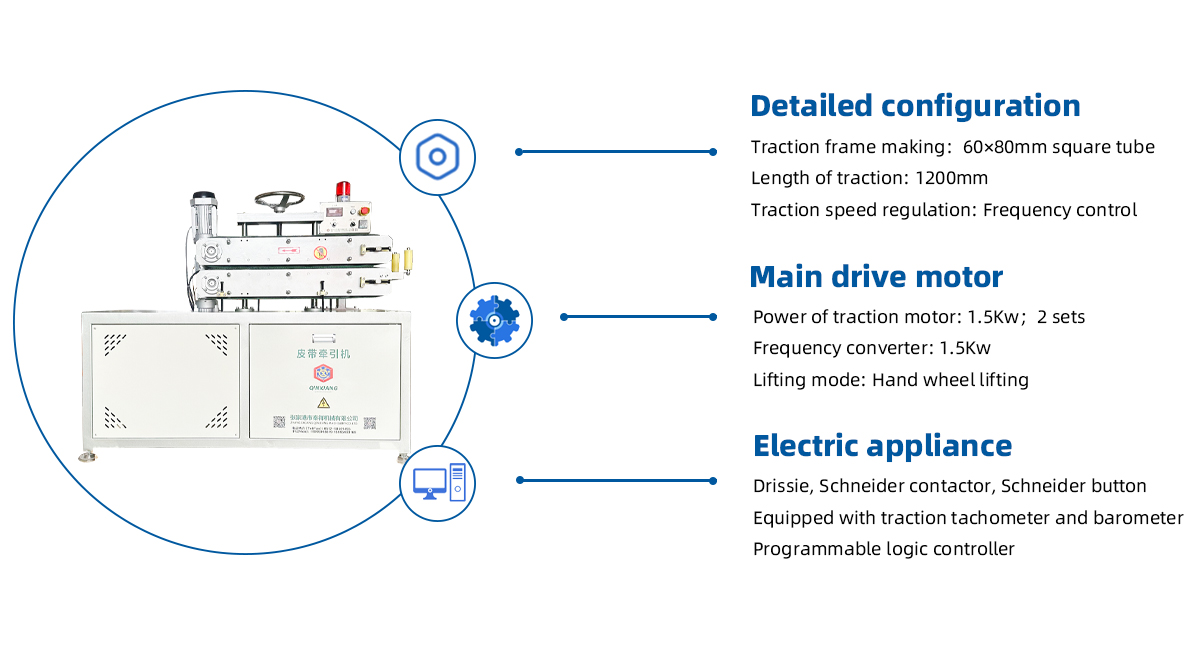

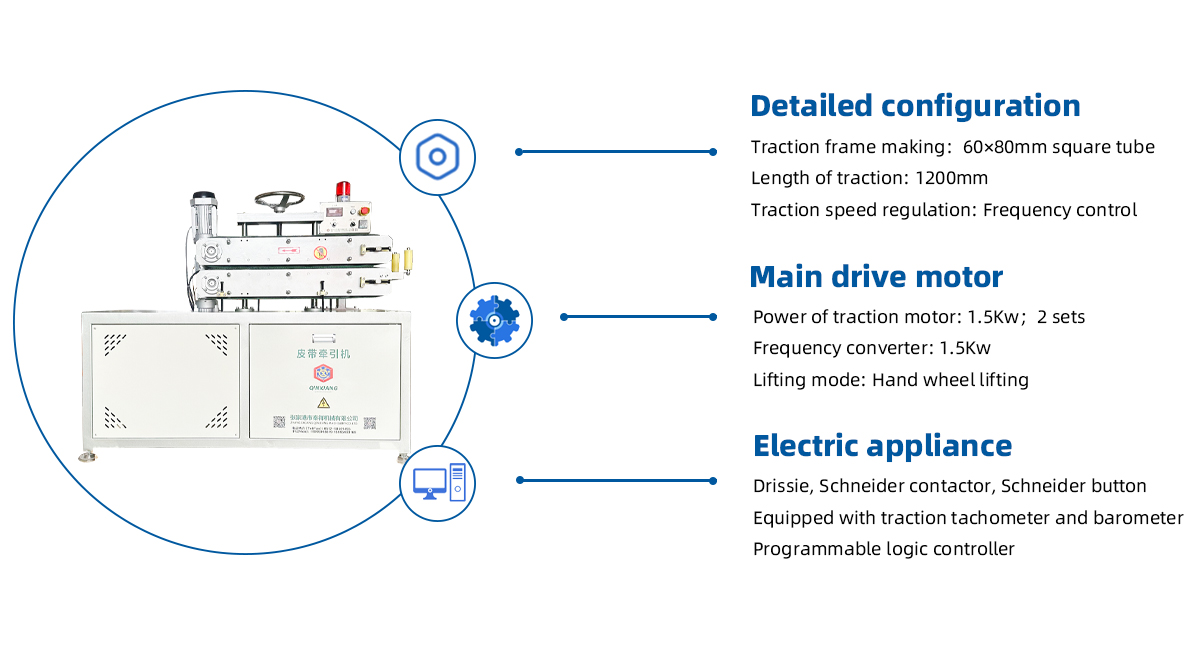

▏Technical Parameters

Traction frame making | 60×80mm square tube |

| Length of traction | 1200mm |

| Traction speed regulation | Frequency control |

Power of traction motor | 1.5Kw;2 sets |

| Frequency converter | 1.5Kw |

| Lifting mode | Hand wheel lifting |

▏Main Details

▏Product Photos

▏Product Introduciton

A Foam Pipe Hauling-Off Machine is a specialized piece of equipment used in the extrusion process to pull and transport foam pipes after they have been extruded. This machine is specifically designed for producing foam pipes, which are typically used in industries like construction, automotive, and HVAC for applications requiring lightweight, insulating, and sound-dampening properties.

Foam pipes are made by extruding a foam core surrounded by a solid outer layer, often using materials such as polyethylene (PE), polypropylene (PP), or PVC. These pipes are lightweight, provide thermal insulation, and are highly resistant to moisture and chemicals, making them ideal for insulation, protective casings, or even plumbing applications.

The foam pipe hauling-off machine plays a crucial role in ensuring that the extruded foam pipes are pulled through the extrusion line at a consistent speed and tension, ensuring proper cooling, solidification, and quality control before the pipes are cut, coiled, or processed further.

Key Features of a Foam Pipe Hauling-Off Machine:

| 1. Belt or Roller Mechanism: The machine uses a combination of belts or rollers to grip and haul the foam pipes at a controlled speed. This ensures that the pipes maintain their desired shape and size, without being deformed or damaged during the cooling and setting processes. 2. Tension Control: The machine applies the correct amount of tension to the foam pipe as it moves through the line. Proper tension is essential to avoid distortion, ensure uniform diameter, and maintain product quality. 3. Speed Control: The hauling-off machine has precise speed control that can be adjusted to match the extrusion speed, ensuring that the foam pipe is pulled at a consistent rate without causing elongation or uneven stretching of the material. 4. Cooling Integration: Foam pipes often need to be cooled as they exit the extrusion die. Many foam pipe hauling-off machines integrate cooling systems such as water baths or air-cooling devices to solidify the foam and ensure it retains its shape and properties before further processing. 5. Automatic Length Cutting: The machine may include an automatic cutting mechanism that allows the foam pipe to be cut into specific lengths as it is being hauled off. This can be adjusted to ensure that each piece is the correct size for its intended application. 6. Roller or Guide Systems: Guide rollers help direct the foam pipe smoothly through the machine, preventing misalignment or twisting that could cause product defects. 7. Customization: The machine can often be customized for specific pipe diameters, lengths, and extrusion speeds, making it highly adaptable to a wide range of foam pipe products. |

Components of a Foam Pipe Hauling-Off Machine:

| 1. Hauling Belts or Rollers: The main components responsible for gripping and pulling the extruded foam pipes. These belts or rollers are usually made of durable materials, such as rubber or polyurethane, that can handle the weight and nature of foam pipes. 2. Drive Motors: These provide the necessary power to the belts or rollers, allowing for the movement of the foam pipe through the machine at a controlled speed. 3. Tensioning Mechanism: Devices such as springs or pneumatic units adjust the tension on the belts to apply the correct amount of pull to the foam pipes, preventing overstretching or sagging. 4. Cooling System: Depending on the material used, the foam pipe hauling-off machine may integrate a cooling system, such as a water bath or air-cooling chamber, to help solidify the foam and stabilize its dimensions as it exits the extruder. 5. Cutting or Winding Unit: Many machines come with an automatic cutting system that slices the foam pipe into desired lengths or a winding system that coils the foam pipe for easier handling and storage. 6. Control Panel: The user interface that allows operators to adjust parameters such as speed, tension, and cutting length. Modern control panels may include digital screens and advanced control systems for better monitoring and automation. |

Applications:

| • Insulation: Foam pipes are often used for insulation purposes in heating, ventilation, and air conditioning (HVAC) systems. They provide excellent thermal and sound insulation. • Protective Casings: Foam pipes are used to protect cables, wires, and other sensitive materials, offering shock absorption and protection from environmental factors. • Plumbing: In some cases, foam pipes are used in plumbing systems due to their lightweight, corrosion-resistant properties. • Automotive: Foam pipes can be used in the automotive industry for noise and vibration control, as well as insulation. • Construction: Foam pipes are also used in construction for various applications such as casing for wiring or protection against pipe corrosion. |

Advantages:

| 1. Lightweight: Foam pipes are much lighter than traditional solid pipes, making them easier to transport, install, and handle. 2. Thermal Insulation: The foam core provides excellent insulation properties, making foam pipes ideal for applications where temperature control is crucial. 3. Sound Absorption: Foam pipes are effective at dampening sound, making them useful for applications requiring noise reduction, such as in HVAC systems. 4. Moisture Resistance: The closed-cell foam structure offers resistance to moisture, reducing the risk of corrosion or damage in humid environments. 5. Energy Efficiency: The use of foam pipes can improve the energy efficiency of systems by providing better thermal insulation, reducing heat loss or gain. 6. Customizability: The foam pipe hauling-off machine can be customized to handle different pipe diameters, lengths, and extrusion speeds, offering flexibility in production. |

The Foam Pipe Hauling-Off Machine is a critical component in the production of foam pipes used in various industries. By ensuring the consistent and controlled pulling of foam pipes, it guarantees that the final product maintains its shape, quality, and performance characteristics. With features like speed control, tension regulation, and integration with cooling and cutting systems, the machine plays a key role in optimizing the extrusion process and producing high-quality foam pipes for insulation, protection, and other applications.

▏Product Advantage

| 1 | high efficiency traction operation |

| The foam pipe hauling off machine has a strong traction capacity, which can quickly transport the foam pipe to the designated position in a short time. This efficient hauling off machine operation ability greatly improves the overall efficiency of the production line, shortens the production cycle, and creates more value for the enterprise. |

| 2 | strong adaptability to multi-scenario applications |

| The design of the the foam pipe hauling off machine is flexible and can adapt to the needs of foam pipe transmission in different sizes, shapes and materials. Whether it is linear transmission or curved transmission, it can easily cope with, showing strong adaptability. This makes it play an important role in all aspects of foam tube production and achieve multi-scenario applications. |

| 3 | Precise control of traction speed |

| The foam pipe hauling off machine adopts advanced control system, which can achieve accurate control of traction speed. The operator can adjust the belt speed at any time according to the production needs, ensuring the stability and continuity of the foam pipe during the transmission process. This precise control helps to improve product quality and consistency. |

| 4 | stable operation and high reliability |

| The haling off machine uses high-quality materials and precision manufacturing processes to ensure high reliability and long life of the equipment. Its strong structure enables stable operation in harsh working environments, reducing failure rates and maintenance costs. At the same time, it is also equipped with multiple safety measures to ensure the safety of the operator. |

| 5 | Easy maintenance and low cost |

| The structure design of the foam pipe hauling off machine is reasonable and easy to maintain. The key components of the equipment adopt modular design, easy replacement, reducing maintenance costs and time. In addition, its efficient performance also reduces energy consumption, further reducing production costs. |

| 6 | Excellent safety performance |

| The foam pipe hauling off machine pays attention to the design of safety performance and is equipped with perfect safety protection devices. Such as emergency braking system, overload protection, etc., to ensure that in emergencies can be stopped in time to avoid accidents. At the same time, it also conforms to the relevant safety standards and specifications, providing safety guarantees for operators. |

| 7 | Energy saving and environmental protection meet standards |

| The requirements of energy saving and environmental protection are fully considered in the design and manufacturing process of the foam pipe hauling off machine. It uses low-energy, high-efficiency drivetrains and high-quality materials to reduce energy consumption and waste emissions. In addition, it also conforms to national and industry environmental standards, providing strong support for enterprises to achieve green production. |

| 8 | compact structure occupies small space |

| The foam pipe hauling off machine is compact and has a small footprint, making it easy to install and deploy in limited production space. This helps enterprises to rationally use space resources and improve the overall layout efficiency of the production line. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping