▏Product Introduction

▏Production Details

▏Product Photos

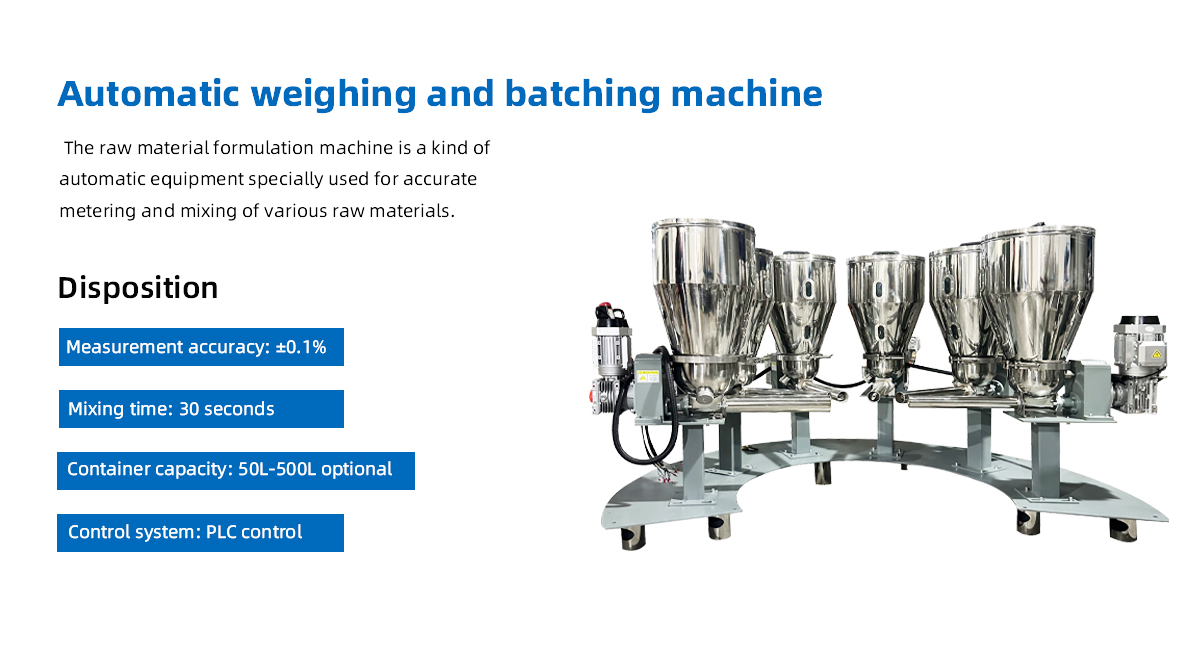

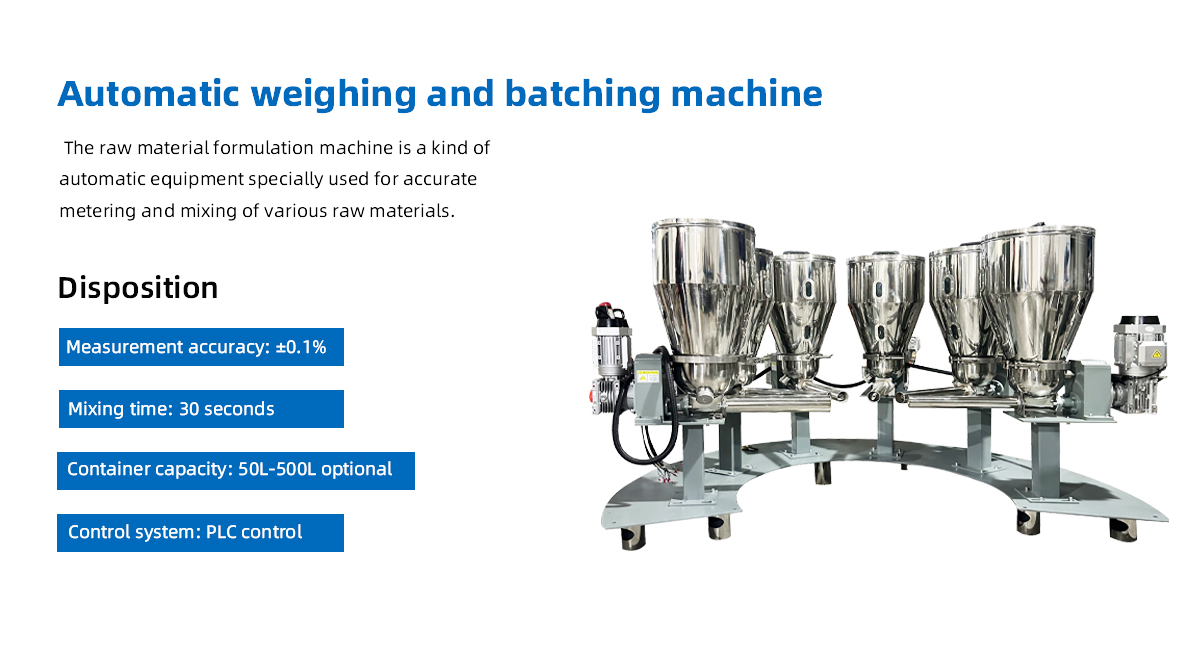

▏Product Introduction

An Automatic Weighing and Batching Machine is an advanced system designed to accurately measure and combine raw materials or ingredients in predetermined proportions for a variety of industrial processes. These machines are commonly used in industries such as food processing, pharmaceuticals, chemicals, construction, and plastics, where precise measurements are essential for product quality and consistency.

The primary function of an automatic weighing and batching machine is to automate the process of weighing, dosing, and mixing ingredients, ensuring that each batch meets the exact specifications required for the next stage of production. By using automated controls, load cells, and sensors, these machines eliminate human error, improve efficiency, and reduce material waste.

Key Features of an Automatic Weighing and Batching Machine:

| 1. Precise Measurement: The machine uses advanced load cells, sensors, or scales to ensure accurate and consistent weighing of ingredients, reducing measurement errors and improving the quality of the final product.

2. Automation: The process of weighing, dosing, and batching is fully automated, with little to no manual intervention required. This reduces the labor needed and speeds up production while maintaining consistent quality. 3. Multiple Ingredients Handling: These machines can handle a wide range of materials (such as solids, liquids, or powders) and can batch multiple ingredients simultaneously or in sequence, depending on the recipe or formulation. 4. Flexible Programming: The machine can be programmed to follow specific recipes or formulations, which can be adjusted based on production needs. It ensures that each batch is produced to the exact required specifications. 5. Real-time Monitoring and Control: Many automatic weighing and batching machines feature advanced control systems that allow operators to monitor the process in real-time, making adjustments as needed to maintain accuracy and consistency. 6. Integration with Other Systems: These machines can be integrated with other production equipment, such as mixers, conveyors, or packaging machines, to streamline the entire production process. |

Components of an Automatic Weighing and Batching Machine:

| 1. Weighing Platform or Hopper: The part of the machine where materials are placed or fed into for weighing. It often includes load cells or scales to measure the weight of the material. 2. Batching Control System: The computer or PLC (programmable logic controller) that manages the operation of the machine, including setting the target weight for each ingredient and controlling the dosing mechanism. 3. Dosing Mechanism: This can be a feeder, valve, or pump that dispenses ingredients into the appropriate container or hopper based on the specified weight. 4. Conveyor or Transport System: Used to transport ingredients from the storage area to the machine or between different stages of the production process. 5. Sensors and Load Cells: These components continuously monitor the weight of the ingredients and send feedback to the control system, ensuring that the correct quantities are dosed. 6. User Interface: A touch screen or other interface that allows operators to input recipe information, monitor the batching process, and make adjustments. |

Applications:

| • Food Industry: For accurately dosing ingredients such as flour, sugar, spices, and additives for the production of baked goods, snacks, beverages, and packaged foods. • Pharmaceuticals: Used for the precise measurement and mixing of active ingredients and excipients in drug formulation or supplement production. • Chemicals and Plastics: Used to batch raw materials, resins, and additives to produce chemicals, plastics, and other materials with precise specifications. • Construction: In the production of concrete, where accurate batching of cement, sand, water, and other additives is critical for ensuring the strength and consistency of the final product. |

Advantages:

| 1. Accuracy and Consistency: The automation of the weighing and batching process ensures that each batch is consistently produced to the exact specifications, improving product quality. 2. Increased Efficiency: The system eliminates manual weighing and measuring, reducing labor costs and production time while increasing throughput. 3. Reduced Material Waste: With precise dosing and minimal human intervention, material waste is significantly reduced, leading to cost savings and more sustainable production. 4. Flexibility: The ability to program different recipes and batch sizes allows manufacturers to easily switch between products or adjust production without lengthy setup times. 5. Improved Traceability and Compliance: Automated systems can track and record the details of each batch, ensuring better traceability for quality control and regulatory compliance. |

An Automatic Weighing and Batching Machine is an indispensable tool in modern manufacturing, offering precision, speed, and flexibility for industries that require accurate material handling. By automating the process of weighing, dosing, and batching, these machines help improve operational efficiency, reduce costs, and maintain consistent product quality, making them essential in high-precision sectors such as food, pharmaceuticals, and chemicals.

| 1 | Equipment overview |

| The raw material formulation machine is a kind of automatic equipment specially used for accurate metering and mixing of various raw materials. It is widely used in food, chemical, pharmaceutical and other industries, which can improve production efficiency and ensure the accuracy and consistency of product ratio. Through the highly automated control system, the raw material formulation machine can precisely control the amount of raw materials, achieve rapid and uniform mixing, so as to meet the continuous and automated needs of the production line. |

| 2 | composition structure |

| Raw material formulation machine is mainly composed of the following parts: 1. Measurement system: including high-precision measurement sensors and metering devices for accurate measurement of raw material dosage. 2. Mixing system: includes mixing container and stirring device to ensure that raw materials are evenly mixed in the container. 3. Control system: Advanced PLC control system is adopted to realize automatic control and operation of equipment. 4. Conveying system: responsible for transporting raw materials from the storage area to the metering and mixing system to ensure a continuous supply of raw materials. |

| 3 | functional characteristics |

|

1. Accurate measurement: The use of high-precision measurement sensors and algorithms to ensure the accuracy of raw material dosage. 2. Fast mixing: equipped with efficient mixing device, can quickly and evenly mix a variety of raw materials. 3. Easy to operate: the control system is intuitive and easy to understand, and the operation is simple, reducing the skill requirements for the operator. 4. High degree of automation: The equipment supports one-click start, stop and reset operations, reducing manual intervention. 5. Programmable formula: Multiple recipes can be stored for easy call and adjustment at any time. |

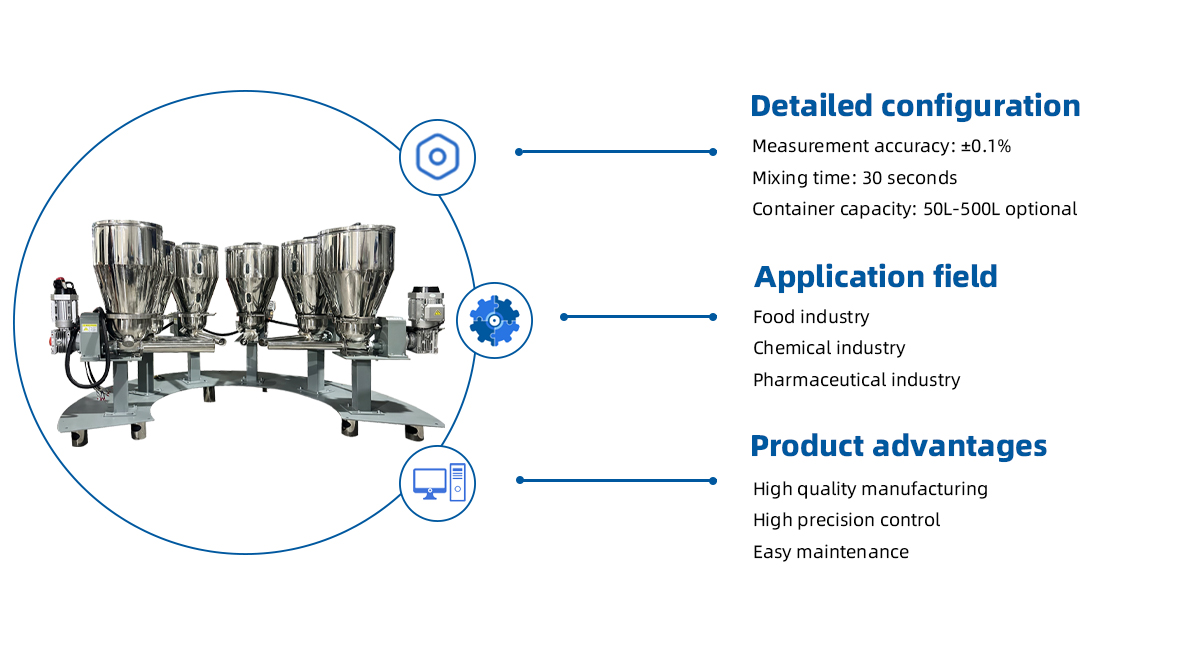

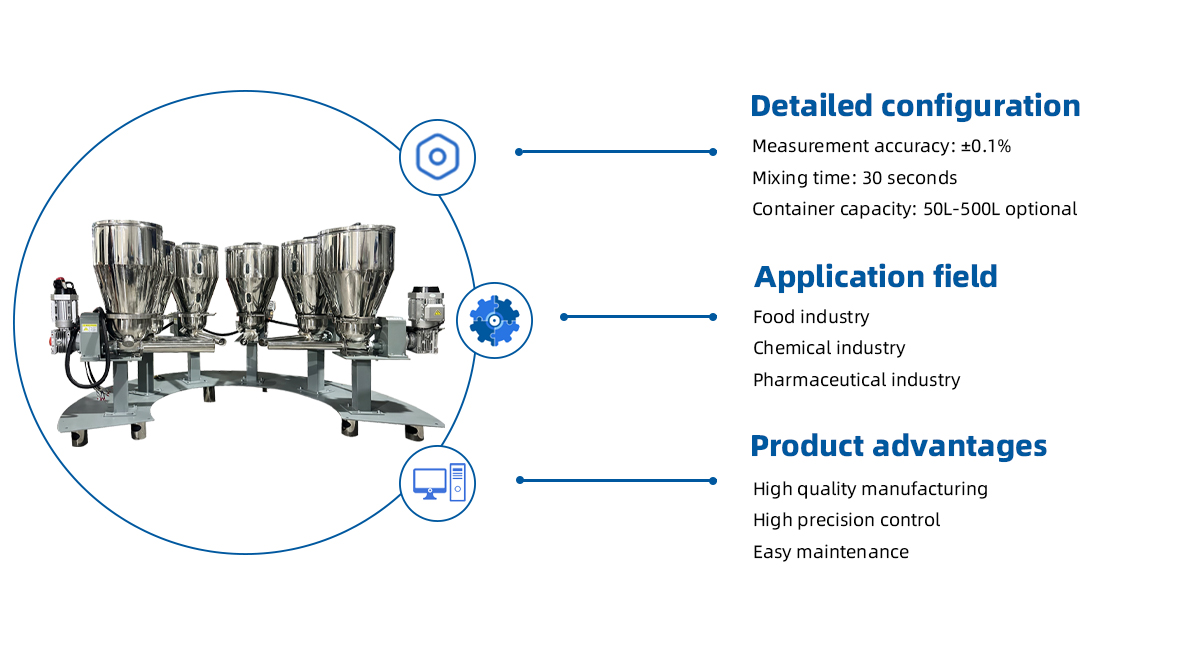

| 4 | Application field |

|

The raw material formulation machine is suitable for the following industries: 1. Food industry: used for the mixing ratio of baked goods, candy, condiments and other raw materials. 2. Chemical industry: used for the mixing and preparation of chemical raw materials such as paints, coatings and pigments. 3. Pharmaceutical industry: used for the mixing and preparation of pharmaceutical raw materials to ensure the quality and stability of drugs. |

| 5 | Advantages |

|

1. Improve production efficiency: high degree of automation, reduce manual operation, improve production efficiency. 2. Ensure product quality: accurate measurement and uniform mixing to ensure the accuracy and consistency of the product ratio. 3. Easy maintenance and cleaning: equipment design is reasonable, easy to daily maintenance and cleaning. 4. Energy saving and environmental protection: The optimized design reduces energy consumption and meets the requirements of energy saving and environmental protection. |

| 6 | Technical parameters |

|

The following parameters are examples and may vary depending on the device model and configuration.) 1. Measurement accuracy: ±0.1% 2. Mixing time: 30 seconds 3. Container capacity: 50L-500L optional 4. Power requirements: 220V/50Hz 5.Control system: PLC control |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping