▏Product Introduction

▏Product Photos

▏Product Introduction

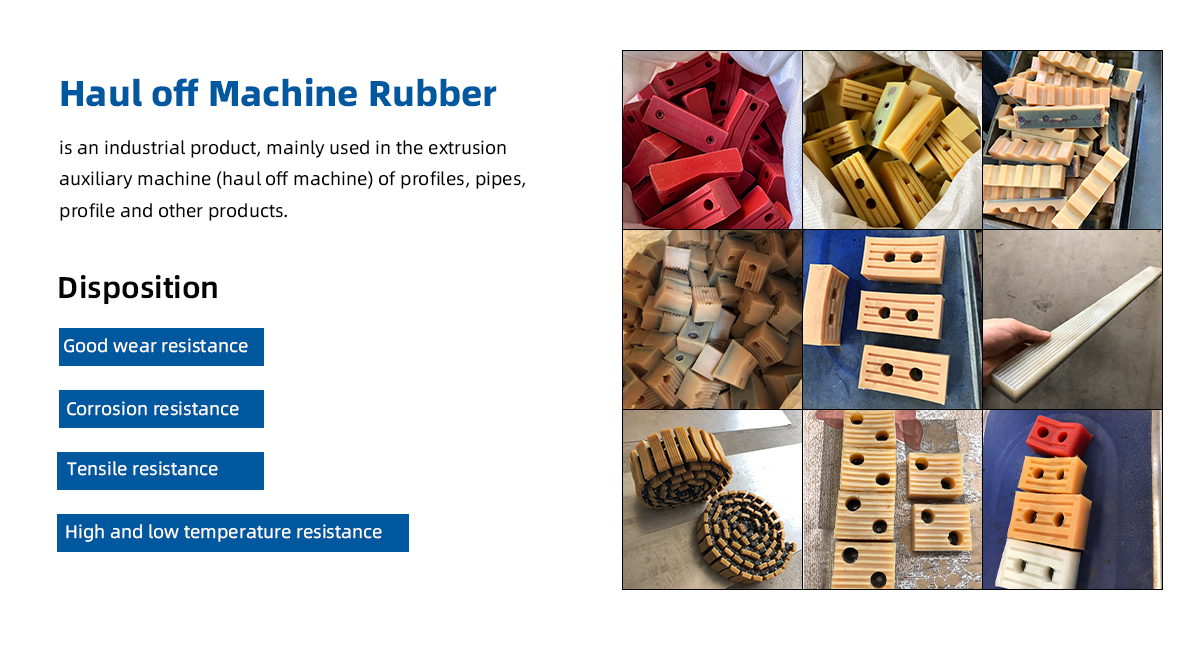

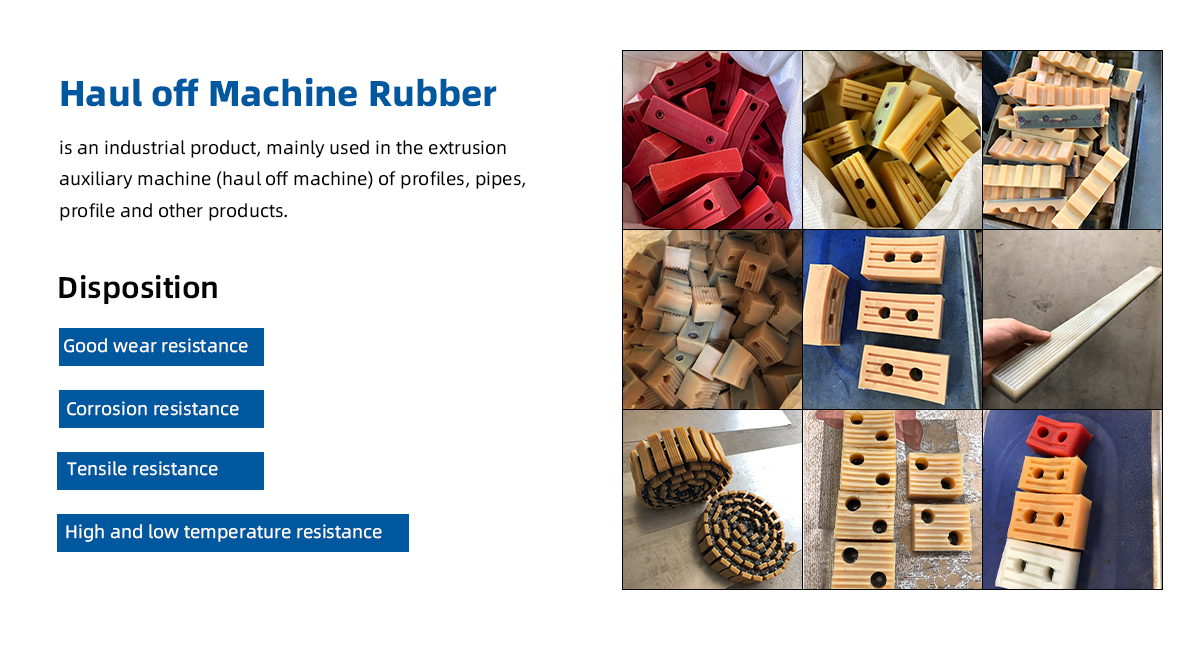

The Rubber Block of Haul-off Machine is a crucial component designed to ensure the efficient and precise pulling of extruded materials during the production process. Typically used in industries such as wire and cable, plastic extrusion, and rubber processing, this rubber block plays an essential role in controlling the tension and speed of the extruded material, ensuring a uniform and consistent output.

Made from high-quality, wear-resistant rubber, the rubber block is engineered to withstand the harsh conditions of continuous operation, including exposure to high temperatures, chemicals, and mechanical stress. The block is designed to have optimal friction properties, which allows for smooth and reliable material movement, without causing any damage or deformation to the extruded products. This helps maintain the integrity and surface quality of the finished products.

The design of the Rubber Block allows for easy installation and adjustment, making it a versatile solution for different production lines and applications. Its precise gripping and pulling action minimizes the risk of material breakage, stretching, or wrinkling, which is critical for ensuring high-quality production.

Additionally, the rubber block’s durability significantly reduces the frequency of replacements and maintenance, thus contributing to a more cost-effective and efficient production process. The material’s resistance to wear and tear, along with its ability to function effectively at varying temperatures and speeds, makes the rubber block an indispensable part of the haul-off machine setup.

Whether you're working with rubber, plastic, or other extruded materials, the Rubber Block of Haul-off Machine offers the reliability and performance needed to achieve high productivity and precision in your manufacturing operations. Its robust design and advanced material composition make it an ideal solution for enhancing the performance and longevity of your haul-off machinery.

| 1 | Material and composition |

| The rubber block of the tractor is composed of a variety of rubber materials and metal fixing plates, mainly including natural rubber, EPDM rubber, nitrile rubber, silicone rubber, styrene butadiene rubber, neoprene rubber and so on. Among them, the silicone rubber drawing machine rubber block has excellent heat resistance, cold resistance, ozone resistance, atmospheric aging resistance, and has good insulation properties. In addition, the color and shape of the glue block of the tractor are diverse, such as the silicone is translucent, the beef rubber is beige or red, and the natural rubber is black and white. |

| 2 | Use and classification |

| The rubber block is mainly used for the traction and pulling of profiles, pipes and other products to improve product production efficiency and reduce production costs. According to the conditions of use, the tractor rubber block is divided into type I tractor track rubber block and type V tractor track rubber block. Type I flat rubber block is mostly used in the puller of plate extrusion, while type V or curved rubber block is mostly used in the puller of tube extrusion. According to the size of the pipe diameter of the product profile, the tractor rubber block is divided into two track tractor rubber block and multi-track tractor rubber block. |

| 3 | Performance and characteristics |

| The rubber block of the tractor has good wear resistance, corrosion resistance and tensile resistance, and can adapt to various complex working environments. In addition, the rubber block also has good insulation properties and high and low temperature resistance, and the temperature range is generally -55~250℃. |

| 4 | Installation and use |

| The installation and use of rubber block is relatively simple, generally the use of screws fixed on the chain, the chain with the drive sprocket operation, traction rubber block also drives the product to move together, so as to achieve the purpose of traction products. In the process of installation and use, attention should be paid to selecting the appropriate type and specification of the tractor rubber block, and adjusting and maintaining it according to the product requirements. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping