▏Plastic Capillary Production Line

▏Introduction to Plastic Capillary Production Line

The Plastic Capillary Production Line is an advanced system designed to produce high-precision plastic capillary tubes used in various industries, including electronics, automotive, medical devices, and more. These capillary tubes, typically made from materials like PVC, PE, or PET, are used for fluid transportation, insulation, and protection of small cables, among other applications. The production line employs cutting-edge technology to ensure consistent quality, high throughput, and precise dimensions, making it a perfect solution for manufacturers looking to scale production while maintaining top-tier product standards.

The plastic capillary production line is engineered to meet the growing demand for small-diameter tubes in specialized applications. With automated systems for extrusion, cooling, sizing, and cutting, the line delivers a highly efficient and reliable solution for mass-producing capillary tubes. This enables manufacturers to meet the needs of industries that require small and precise components with great consistency.

▏Key Features of Plastic Capillary Production Line

| High-Efficiency Extruder for Plastic Material

The extruder serves as the heart of the Plastic Capillary Production Line, designed to melt and process plastic materials such as PVC, PE, or PET. The high-efficiency extruder ensures optimal plasticization, allowing for smooth, consistent extrusion of materials into capillary tubes. The extrusion process is closely monitored with advanced temperature and pressure controls, ensuring that the plastic material is heated evenly to prevent degradation and to achieve the desired mechanical properties. Thanks to the precision of the extruder, manufacturers can produce capillary tubes that meet strict dimensional and mechanical tolerances, including high flexibility, durability, and chemical resistance. |

| Precise Die Head for Capillary Tube ShapingA key component of the Plastic Capillary Production Line is the die head, which shapes the melted plastic into capillary tubes. The die head is designed with precise control mechanisms to produce tubes with consistent diameter, wall thickness, and surface smoothness. This is especially important when producing capillary tubes for sensitive applications, such as medical or electronic systems, where dimensional accuracy is paramount. The die head is fully customizable, allowing manufacturers to produce a variety of tube sizes to meet specific industry requirements. Whether small, medium, or large capillary tubes are needed, the die head ensures uniformity and precision in every batch. |

| High-Precision Sizing and Cooling SystemAfter extrusion, the plastic capillary tube enters the cooling and sizing section of the Plastic Capillary Production Line. A highly efficient water bath or air-cooling system is employed to rapidly solidify the tube, preventing deformation and ensuring dimensional stability. The cooling process is critical in ensuring that the tube retains its shape and does not warp or collapse as it cools. The sizing system plays a vital role in maintaining the tube's precise diameter and wall thickness. The tube is calibrated during the cooling phase to maintain its circular shape and ensure uniformity. This advanced sizing system ensures that the final product meets the stringent quality standards required by industries such as automotive, electronics, and medical sectors. |

| Automated Haul-Off and Cutting MechanismThe Plastic Capillary Production Line includes an automated haul-off unit that precisely pulls the extruded tube through the cooling section and ensures smooth, continuous processing. The haul-off unit controls the pulling speed to prevent stretching or deformation of the tube, ensuring uniformity in both length and diameter. The cutting system is integrated into the line and automatically trims the capillary tubes into the desired lengths. The cutting process is designed to minimize waste and ensure clean, precise cuts that require minimal post-processing. This automation reduces labor costs and helps manufacturers achieve a high level of productivity. |

| Energy-Efficient and Eco-Friendly DesignThe Plastic Capillary Production Line is designed with energy efficiency in mind, incorporating advanced technologies to reduce power consumption and optimize the production process. This energy-saving approach helps manufacturers minimize operational costs and increase profitability. Additionally, the line is designed to generate minimal material waste during production, which further contributes to its eco-friendly operation. This sustainable design ensures that manufacturers can produce high-quality plastic capillary tubes while maintaining a focus on reducing their environmental impact. The energy-efficient systems also reduce the overall carbon footprint of the production process, making the line suitable for companies committed to eco-friendly manufacturing practices. |

| Energy-Efficient and Eco-Friendly DesignThe Plastic Capillary Production Line is designed with energy efficiency in mind, incorporating advanced technologies to reduce power consumption and optimize the production process. This energy-saving approach helps manufacturers minimize operational costs and increase profitability. Additionally, the line is designed to generate minimal material waste during production, which further contributes to its eco-friendly operation. This sustainable design ensures that manufacturers can produce high-quality plastic capillary tubes while maintaining a focus on reducing their environmental impact. The energy-efficient systems also reduce the overall carbon footprint of the production process, making the line suitable for companies committed to eco-friendly manufacturing practices. |

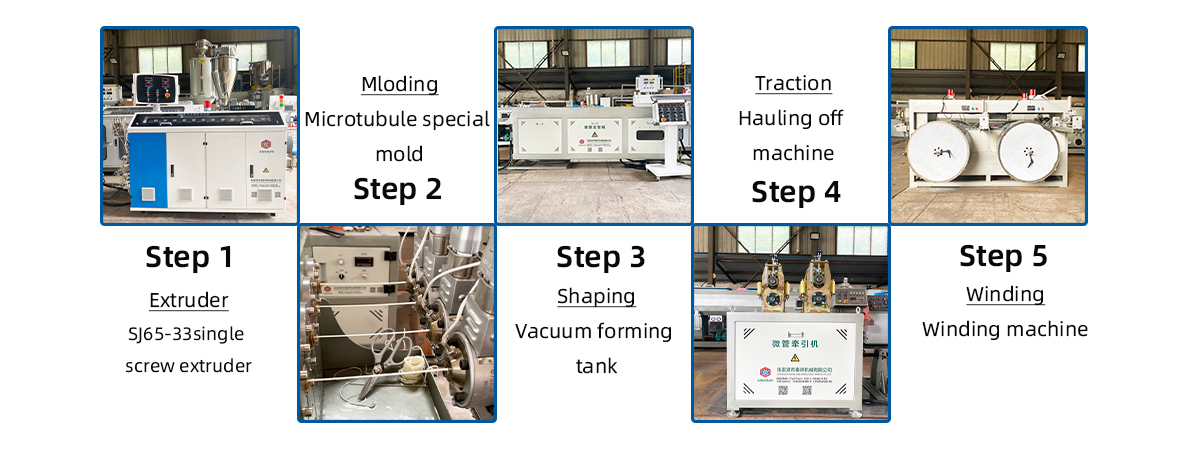

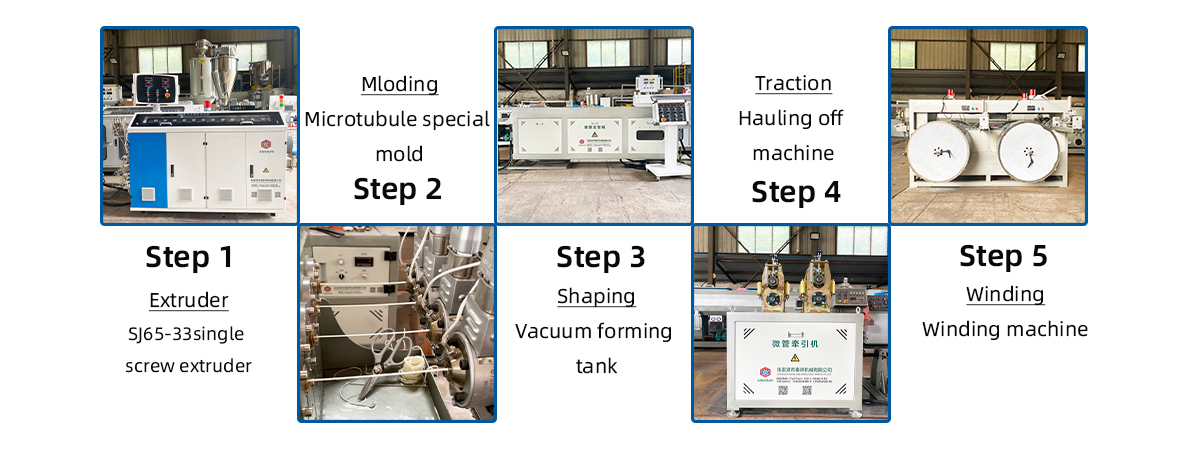

▏Production Procedure

▏Product Photos

▏How the Plastic Capillary Production Line Works

| 1. Material Feeding and Melting

The production process begins with the feeding of plastic resin, such as PVC, PE, or PET, into the extruder. The resin is melted and processed under controlled heat and pressure to create a homogeneous, meltable mass. This is essential for ensuring smooth and consistent extrusion. The extruder is equipped with a screw and barrel system that ensures uniform melting and plasticization, preparing the material for the extrusion phase. 2. Extrusion and ShapingThe molten plastic is then fed through the die head, where it is shaped into the desired tube form. The die head is meticulously engineered to produce capillary tubes with specific dimensions, ensuring precise control over the tube's internal and external diameters. The extruder is synchronized with the die head to ensure continuous and uninterrupted flow of the material, resulting in high-quality tubes. 3. Cooling and SizingAfter extrusion, the newly formed capillary tubes enter the cooling and sizing section of the production line. A water bath or air-cooling system quickly cools the tubes, allowing them to retain their shape and preventing any collapse or deformation. The sizing system ensures that the tubes' dimensions remain uniform and precise, which is crucial for the quality of the final product. This phase ensures that the capillary tubes meet industry standards for size and tolerance. 4. Haul-Off and CuttingThe haul-off unit pulls the tube through the cooling system at a consistent speed, maintaining the tube’s integrity while preventing stretching or warping. Once the tube has cooled and solidified, the cutting system automatically trims it to the required length, providing clean, precise cuts without any further handling. This automated cutting process ensures minimal waste and high efficiency, contributing to overall productivity. 5. Quality Control and PackagingAfter cutting, the capillary tubes are subjected to a final quality inspection to ensure that they meet the required specifications. The inspection process checks the tubes for dimensional accuracy, surface quality, and any defects. If the tubes pass the quality control tests, they are packed for shipment, ready for use in various applications. |

▏Applications of Plastic Capillary Tubes

| 1. Medical Devices

Plastic capillary tubes are widely used in the medical industry for applications such as blood collection, laboratory analysis, and infusion systems. Their small size, durability, and precision make them ideal for use in medical equipment where space is limited and accuracy is critical. The Plastic Capillary Production Line ensures that the capillary tubes produced are of the highest quality, meeting stringent medical standards. 2. Electronics and TelecommunicationsCapillary tubes are also used in electronics and telecommunications for the protection of wires and cables. These tubes provide excellent insulation and protection against mechanical damage and environmental exposure. The high-quality capillary tubes produced by the extrusion line ensure reliable performance in sensitive electronic applications. 3. Automotive IndustryIn the automotive sector, plastic capillary tubes are used in a variety of systems, including fuel lines, fluid transfer systems, and sensors. The flexibility and chemical resistance of the capillary tubes make them suitable for the demanding conditions found in automotive environments. The Plastic Capillary Production Line produces tubes with precise dimensions and consistent performance, making them an essential component in automotive manufacturing. 4. Fluid Transfer SystemsCapillary tubes are widely used in fluid transfer systems, especially in applications where precise flow control is required. The tubes are commonly found in medical and industrial systems that require fluid transport in small quantities. The ability to produce capillary tubes with consistent wall thickness and uniformity ensures optimal fluid flow and minimizes leakage. |

▏Advantages of the Plastic Capillary Production Line

| 1. High Precision and Consistency

The Plastic Capillary Production Line is engineered for high precision, producing capillary tubes with excellent dimensional accuracy. The system ensures consistent product quality across large production runs, making it ideal for industries that require high-tolerance components. 2. Flexible ProductionThe extrusion line is versatile and can accommodate various plastic materials, such as PVC, PE, and PET. Additionally, it can be easily adjusted to produce capillary tubes in different sizes and lengths, allowing manufacturers to meet the diverse needs of their customers. 3. Energy-EfficiencyThe system is designed with energy-saving technologies that reduce power consumption without compromising performance. This makes the Plastic Capillary Production Line a cost-effective solution for manufacturers seeking to lower operational expenses while maintaining high productivity. 4. Low Maintenance and DurableThe Plastic Capillary Production Line is built with high-quality components that ensure long-term reliability and low maintenance requirements. This reduces downtime and increases production efficiency, ultimately leading to higher profitability. 5. High-Volume ProductionThe line is designed for high-volume production, enabling manufacturers to meet large orders and scale operations efficiently. The automation and continuous processing ensure that production runs smoothly, resulting in a high output of high-quality capillary tubes. |

▏Invest in the Future of Capillary Tube Production

The Plastic Capillary Production Line offers a cutting-edge solution for manufacturing high-precision plastic capillary tubes used in various industries such as medical devices, automotive, electronics, and fluid transfer systems. With its advanced technology, energy efficiency, and customizable features, the extrusion line provides manufacturers with the tools they need to produce reliable, high-quality capillary tubes efficiently and cost-effectively.

By investing in the Plastic Capillary Production Line, manufacturers can enhance their production capabilities, reduce operational costs, and stay ahead of the competition in the growing global market for small-diameter plastic tubes.

▏Product Introduction

| 1 | Raw Material Selection |

| The process begins with the selection of appropriate raw materials, typically metals such as stainless steel, copper, or aluminum, depending on the application requirements. |

| 2 | Tube Drawing |

| The raw material is drawn through a series of dies to reduce its diameter and increase its length. This process is known as tube drawing and can be done either by dry drawing or wet drawing, depending on the desired surface finish and dimensional accuracy. |

| 3 | Annealing |

| After drawing, the tubes may undergo an annealing process to relieve internal stresses and improve ductility. This step is crucial for maintaining the integrity of the tubes during further processing. |

| 4 | Sizing and Shaping |

| The tubes are then sized and shaped to the exact specifications required. This may involve additional drawing, sinking, or pilgering processes to achieve the precise diameter and wall thickness. |

| 5 | Cutting |

| Once the tubes are sized correctly, they are cut to the desired lengths using precision cutting tools. |

| 6 | Cleaning |

| The tubes are thoroughly cleaned to remove any lubricants, debris, or contaminants that may have accumulated during the manufacturing process. This step is critical for applications where cleanliness and purity are essential. |

| 7 | Inspection |

| The capillary tubes are inspected for defects such as cracks, leaks, or dimensional inaccuracies. This can be done using visual inspection, automated optical inspection systems, or other non-destructive testing methods. |

| 8 | Packaging |

| After passing inspection, the capillary tubes are packaged to protect them from damage and contamination during transportation and storage. |

| 9 | Quality Control |

| Throughout the production line, quality control measures are in place to ensure that the capillary tubes meet the required specifications and standards. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping