▏Product Vedio

▏Product Introduction

▏The 20-110PE Pipe Cutting Machine: Essential Technology for Pipe Manufacturing

The 20-110PE pipe cutting machine is an advanced tool used in the production of Polyethylene (PE) pipes, particularly those ranging from 20mm to 110mm in diameter. These machines play a crucial role in the post-production process by ensuring that the pipes are cut accurately and efficiently to meet the specific lengths required for various applications. With the increasing demand for reliable, high-quality PE pipes, the importance of the cutting machine in modern manufacturing cannot be overstated. This article explores the features, working mechanism, and advantages of the 20-110PE pipe cutting machine and its significance in the pipe production industry.

▏How Does the 20-110PE Pipe Cutting Machine Work?

The operation of the 20-110PE pipe cutting machine involves several well-coordinated stages that result in precise, clean cuts for PE pipes.

| 1. Pipe Feeding and Alignment

Once the PE pipes are extruded and cooled, they are fed into the cutting machine. The feeding system aligns the pipes correctly to ensure they are in the proper position for cutting. This alignment is essential for achieving uniform lengths and avoiding any operational errors. |

| 2. Cutting Process

The cutting blades, powered by a high-speed motor, are activated to make precise cuts. The blades are typically designed for optimal cutting performance, using high-quality materials that can withstand the wear and tear of cutting through PE pipes. The cutting process may involve a rotary blade or a guillotine-style blade depending on the machine design, both of which offer smooth and consistent cuts. |

| 3. Automatic Length Adjustment

The machine allows for easy adjustment of pipe length based on user specifications. The length adjustment can be done automatically via the control system, ensuring that all pipes are cut to the desired dimensions. The system also tracks and adjusts the cutting cycle in real-time to maintain consistency. |

| 4. Pipe Discharge

After the pipes are cut to the required length, they are discharged from the machine and sent to the next stage of the production process. Typically, the pipes are either bundled together for packaging or sent directly to storage. The machine is designed to handle a high volume of pipes, allowing for rapid movement through the manufacturing line. |

▏Advantages of the 20-110PE Pipe Cutting Machine

| 1. High Production Efficiency

By automating the cutting process, the machine significantly improves production efficiency. The rapid cutting cycle allows manufacturers to meet higher demand without increasing operational costs. The ability to produce large volumes of pipes in a short time frame is crucial for industries that rely on timely deliveries. |

| 2. Cost-Effective

The 20-110PE pipe cutting machine helps manufacturers reduce costs associated with labor and waste. Automated adjustments and precise cutting minimize the need for rework and scrap material, contributing to cost savings in the long run. The machine’s high efficiency also reduces energy consumption during production. |

| 3. Enhanced Pipe Quality

The precision and consistency achieved through the cutting process enhance the overall quality of the pipes. This is particularly important for applications in sensitive infrastructure projects, where the integrity of each pipe is vital. The smooth edges and uniform lengths produced by the cutting machine contribute to the overall strength and durability of the final product. |

| 4. Durability and Low Maintenance

The 20-110PE pipe cutting machine is built to last, with high-quality components that are designed to withstand the rigors of continuous operation. The machine requires minimal maintenance, ensuring consistent performance over time. Regular maintenance schedules can help prolong the lifespan of the machine and ensure that it continues to operate at peak efficiency. |

The 20-110PE pipe cutting machine is an essential piece of equipment in the PE pipe manufacturing process, offering precision, efficiency, and versatility for producing high-quality pipes. Whether used for water supply systems, sewage, gas distribution, or industrial applications, the machine ensures that PE pipes are cut to the required length with minimal waste and maximum speed. With its ability to handle varying pipe sizes, automated control systems, and low-maintenance design, the 20-110PE pipe cutting machine plays a vital role in streamlining production and maintaining high standards in the pipe manufacturing industry.

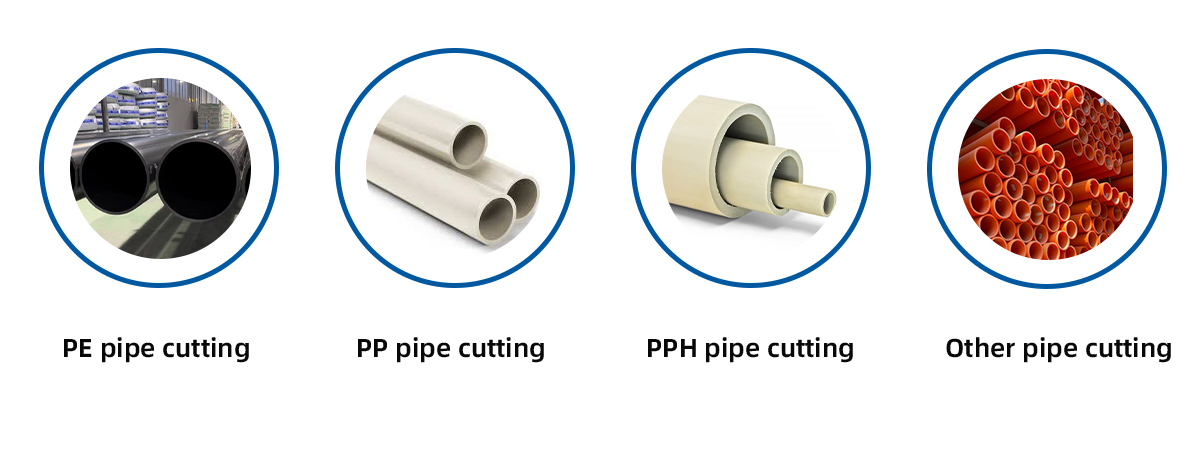

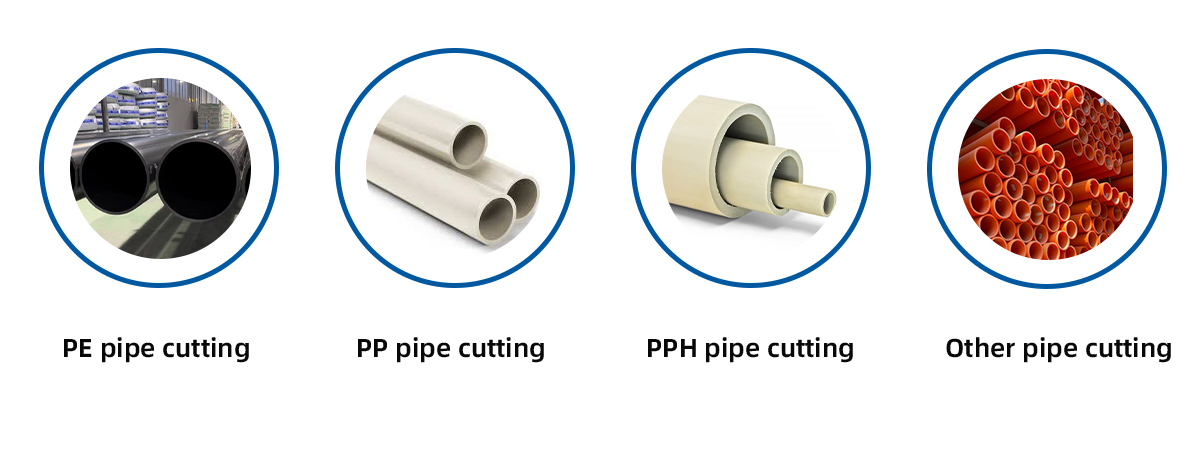

▏Production Application

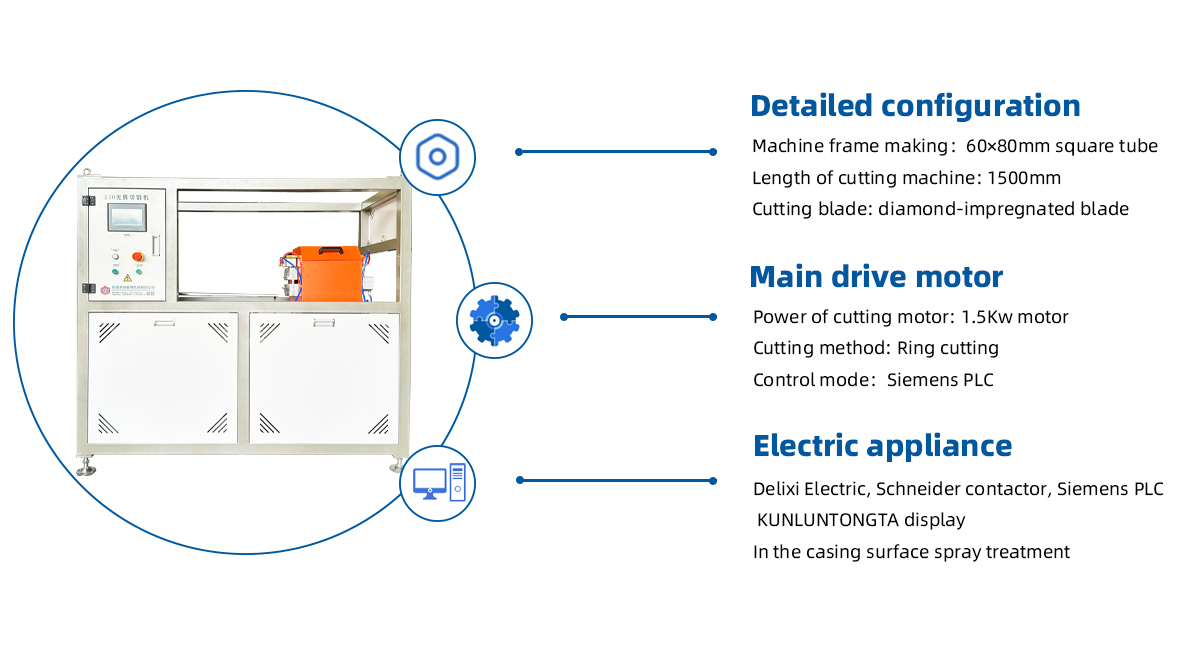

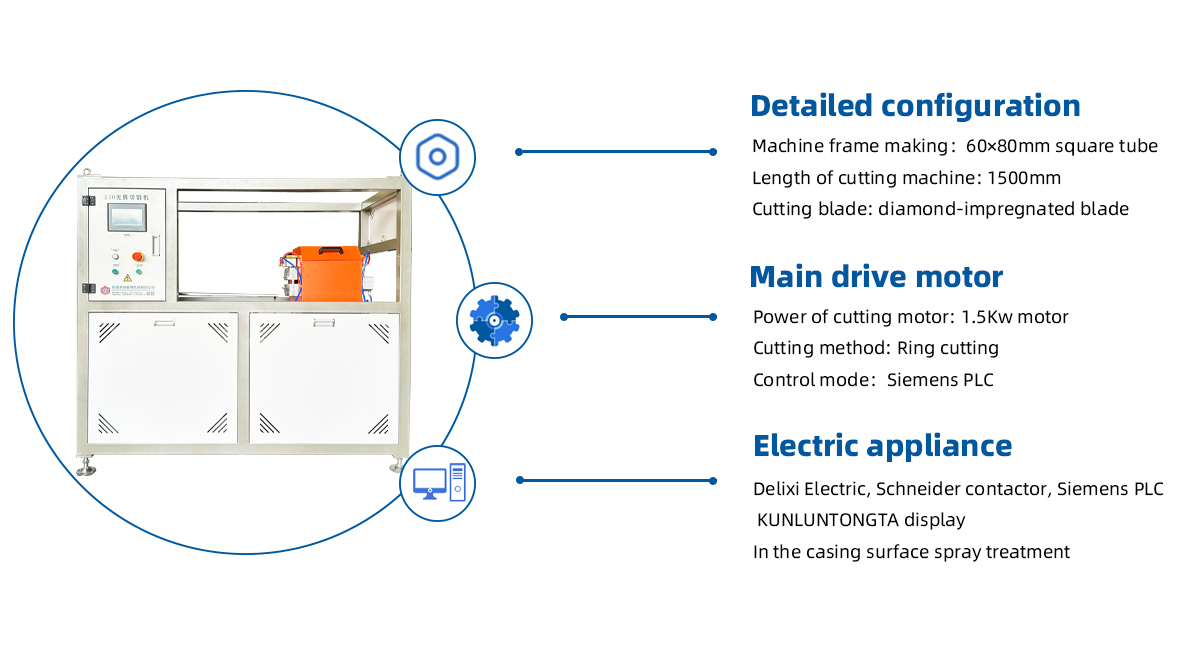

▏Production Details

▏Product Photos

▏Product Advantages

| 1 | Precision Cutting |

| The Automatic PE Pipe Cutting Machine is designed to provide clean, precise cuts, which are essential for creating a tight seal when joining pipes. This precision helps to prevent leaks and ensures the integrity of the piping system. |

| 2 | Efficiency |

| The 20-110PE pipe cutting machine can cut through PE pipes quickly and efficiently, saving time compared to manual cutting methods. This is particularly beneficial when working on large projects or when a large number of cuts are required. |

| 3 | Consistency |

| The Automatic PE Pipe Cutting Machine ensures consistent cutting angles and lengths, which is important for maintaining uniformity in the piping system. This consistency can be difficult to achieve with hand tools. |

| 4 | Reduced Effort |

| Cutting PE pipes manually can be physically demanding. A 20-110PE pipe cutting machine reduces the physical effort required, making the job easier for the operator and potentially reducing the risk of repetitive strain injuries. |

| 5 | Versatility |

| The machine can handle a range of pipe sizes, from 20mm to 110mm, which makes it a versatile tool for various applications. This eliminates the need for multiple cutting tools for different pipe sizes. |

| 6 | Durability |

| These Automatic PE Pipe Cutting Machines are typically built to withstand the rigors of construction and industrial use, meaning they can last a long time with proper maintenance. |

| 7 | Safety |

| Using a machine to cut pipes can be safer than manual methods, as it reduces the risk of injury from sharp tools or from the pipe itself during cutting. |

| 8 | Portability |

| Many pipe cutting machines are designed to be portable, allowing for easy transportation to different job sites. This is particularly useful for contractors and technicians who need to work in various locations. |

| 9 | Cost-Effectiveness |

| While the initial investment in a pipe cutting machine may be higher than that of manual tools, the increased efficiency and precision can save time and material in the long run, making it a cost-effective option for frequent users. |

| 10 | Easy to Use |

| These machines are generally user-friendly, with simple controls and operations that can be learned quickly, even by those with limited experience. |

▏Complete production line recommendation

Click the link below to view the full line description!

20-63PE Pipe Making Machine PE Pipe Production Line

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping