▏Product Vedio

▏Product Introduction

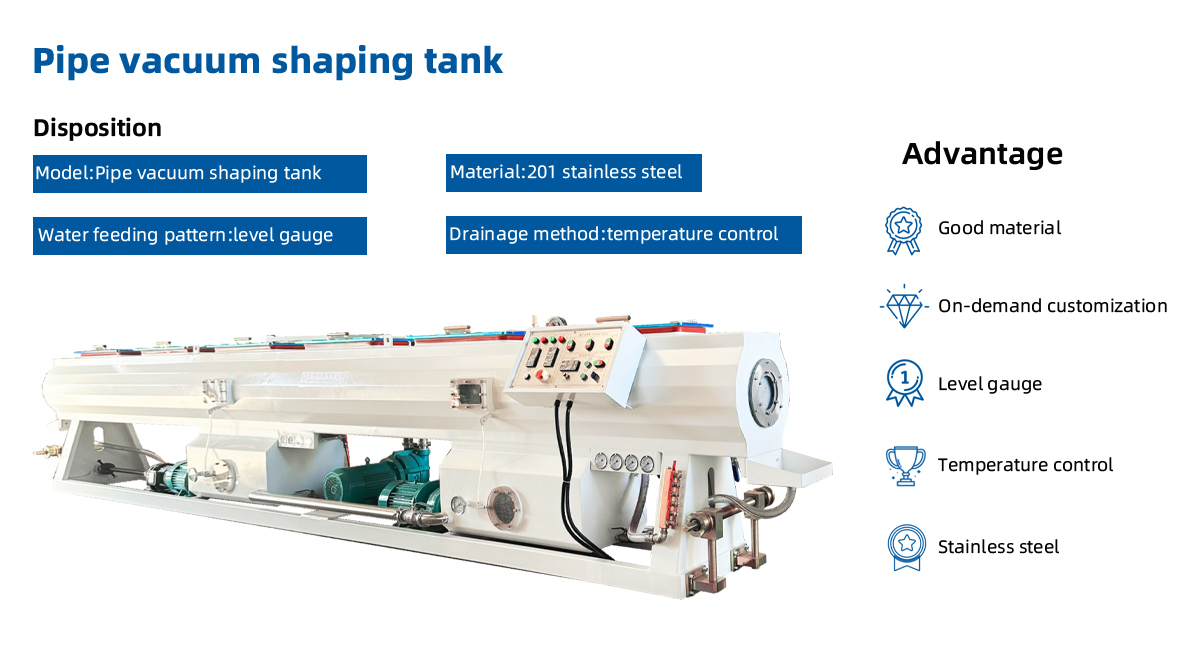

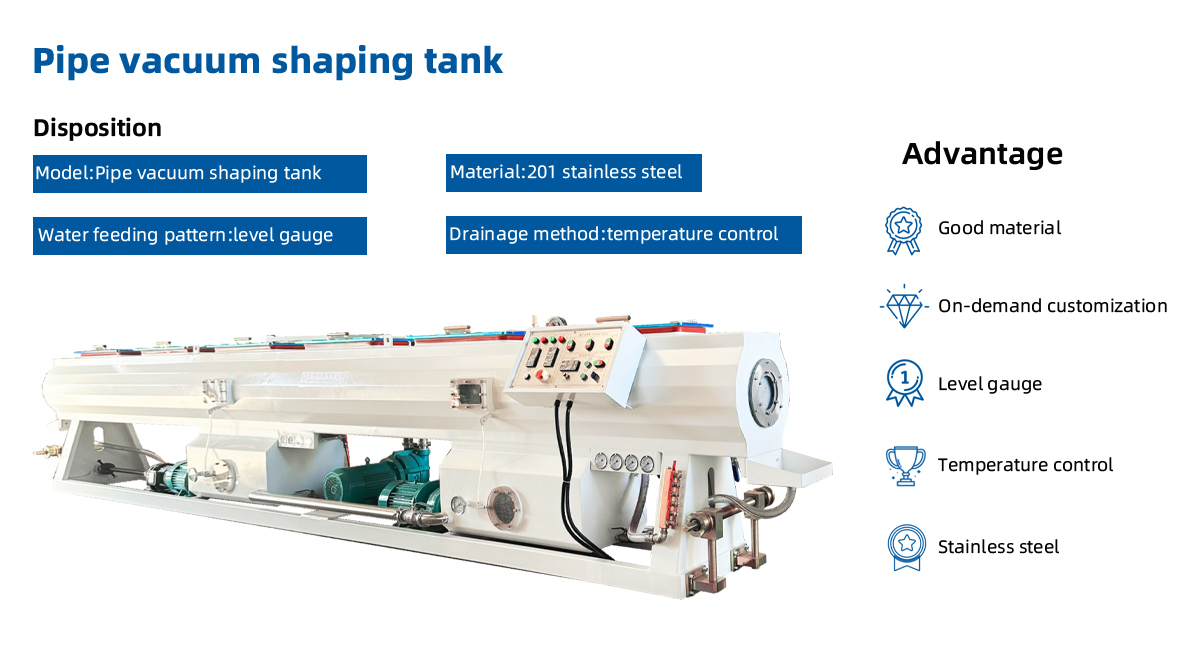

▏20-110 Pipe Vacuum Calibration Forming Tank: Precision in Pipe Shaping and Cooling

The 20-110 Pipe Vacuum Calibration Forming Tank is a highly efficient machine designed for the precise calibration and shaping of pipes made from various materials, including PVC, PE, and other thermoplastics. This advanced equipment plays a crucial role in the production process of pipes, ensuring their perfect roundness, dimensional accuracy, and smooth surface finish. As a vital component in pipe manufacturing lines, the 20-110 Pipe Vacuum Calibration Forming Tank enhances the quality of finished products, while also increasing productivity and reducing operational costs.

In this product introduction, we will delve into the key features, benefits, and applications of the 20-110 Pipe Vacuum Calibration Forming Tank, providing a comprehensive overview of its role in modern pipe extrusion processes.

▏How Does the 20-110 Pipe Vacuum Calibration Forming Tank Work?

The operation of the 20-110 Pipe Vacuum Calibration Forming Tank is straightforward, yet crucial for achieving high-quality pipes. Below is a step-by-step guide on how the system works:

| 1. Pipe Entry

Once the plastic pipe exits the extruder, it enters the 20-110 Pipe Vacuum Calibration Forming Tank. The pipe is typically hot and still in a semi-molten state when it enters the tank. |

| 2. Vacuum Calibration

As the pipe moves through the tank, a vacuum system is applied to the outer surface of the pipe. The vacuum pressure pulls the pipe into a calibrated mold, forcing it to take on the desired shape and size. The vacuum ensures that the pipe is round and has the correct dimensional tolerance. |

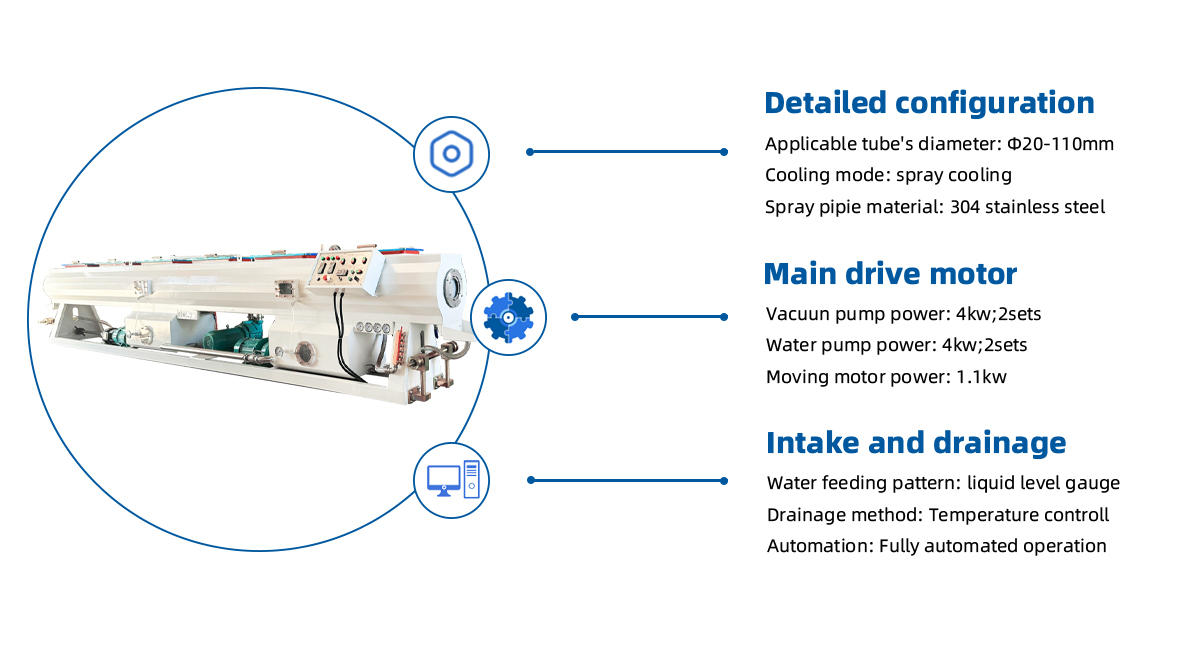

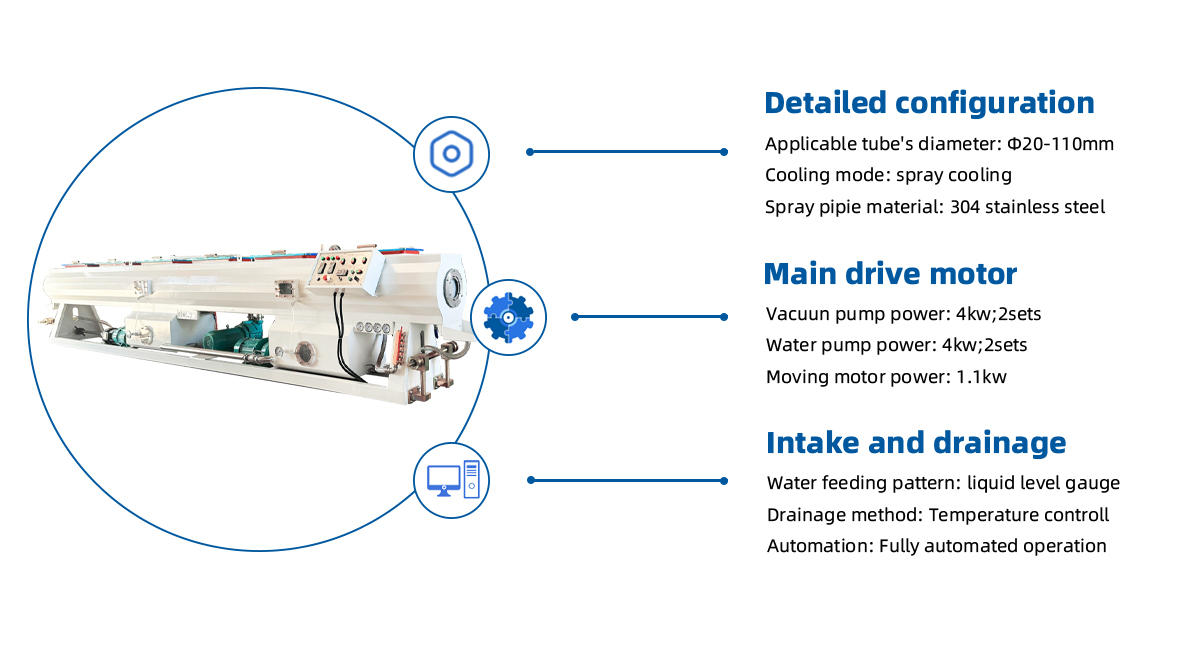

| 3. Water Cooling

Simultaneously, water flows through the tank, cooling the pipe as it passes through. The cooling process solidifies the plastic, turning it into a rigid pipe with the required physical properties. The even distribution of cooling water ensures uniform temperature control, preventing any warping or deformation. |

| 4. Shaping and Sizing

The combination of vacuum calibration and water cooling ensures that the pipe maintains its intended shape and size throughout the cooling process. The pipe exits the forming tank with the exact dimensions required for its intended application. |

| 5. Pipe Ejection

Once the pipe has cooled and solidified, it is ejected from the tank and can be directed to downstream equipment for further processing. Depending on the application, the pipe may be cut to the desired length, coiled, or packaged for shipment. |

▏Applications of the 20-110 Pipe Vacuum Calibration Forming Tank

The 20-110 Pipe Vacuum Calibration Forming Tank is widely used in the production of various types of plastic pipes. Some of the most common applications include:

| 1. Plumbing Pipes

The 20-110 Pipe Vacuum Calibration Forming Tank is commonly used in the production of plumbing pipes made from PVC or PE. These pipes are used in both residential and commercial applications for water supply, drainage, and other plumbing systems. |

| 2. Drainage Pipes

Plastic pipes produced using the 20-110 forming tank are ideal for drainage systems. Their smooth surface finish and precise dimensions make them suitable for effective water flow in both residential and industrial drainage applications. |

| 3. Electrical Conduits

The tank is also used in the production of plastic electrical conduits, which are essential for protecting wiring systems in buildings and infrastructure projects. The uniform dimensions and strength of the pipes ensure that they meet safety and performance standards. |

| 4. Irrigation Systems

Irrigation pipes, which are commonly made from PE, benefit from the use of the 20-110 Pipe Vacuum Calibration Forming Tank. The tank ensures that the pipes are produced with precise measurements and a smooth surface, contributing to the efficiency and longevity of irrigation systems. |

| 5. Industrial Applications

In addition to plumbing and drainage, the 20-110 Pipe Vacuum Calibration Forming Tank is used in various industrial applications where pipes are needed for transporting fluids, gases, or other materials. The tank ensures that pipes used in demanding conditions meet strict dimensional and performance standards. |

▏Technical Parameters

▏Product Photos

▏Product Introduction

| 1 | Product overview |

| The 20-110 pipe vacuum calibration forming tank is an important auxiliary equipment specially designed for the plastic pipe production line, which is mainly used for sizing and cooling the molten pipe billet extruded from the mold. Through vacuum and spray technology, the equipment ensures that the pipe maintains a stable size and shape during the molding process, while effectively removing the waste heat inside the pipe, preventing deformation, and improving the yield and quality of the pipe. |

| 2 | The main role |

| The main functions of the 20-110 pipe vacuum calibration forming tank for plastic pipes include: 2.1. Sizing: Through vacuum adsorption and spray cooling, the pipe is stably formed under a specific size to ensure that the diameter and wall thickness of the pipe meet the design requirements. 2.2 Cooling: The spray system is used to quickly cool the pipe, reduce the temperature of the pipe, and prevent deformation or dimensional change caused by waste heat. 2.3. Improve the yield: By precisely controlling the sizing and cooling process, reduce waste products and improve production efficiency and yield. |

| 3 | Technical characteristics |

| 3.1. High precision: Advanced vacuum and spray technology is used to ensure the precision of pipe sizing and cooling. 3.2. Good stability: equipment structure design is reasonable, material selection of high-quality stainless steel, to ensure long-term stable operation. 3.3. High degree of automation: equipped with automatic control system to achieve automatic adjustment of water level, water temperature and other parameters, reducing the difficulty of manual operation. 3.4 Energy saving and environmental protection: The spray cooling system adopts circulating water design to reduce water waste and reduce energy consumption. |

| 4 | Application field |

| Plastic pipe vacuum calibration forming tank is widely used in PE, PPR, PVC and other plastic pipe production line, is an indispensable important equipment for plastic pipe production. It is suitable for industrial plants, construction and other fields, and provides strong support for the manufacturing of various plastic pipes. |

| 5 | Functional segmentation |

|

Plastic pipe vacuum calibration forming tank is usually divided into two sections: 5.1. The front section (vacuum, spray cooling section) : mainly responsible for the preliminary sizing and cooling of the pipe, through vacuum adsorption and spray cooling technology, so that the pipe in the vacuum state of rapid cooling and shaping. 5.2. The latter section (spray cooling section) : Continue to spray and cool the pipe to ensure that the pipe temperature drops to room temperature to prevent subsequent deformation. |

| 6 | Supporting equipment |

|

Plastic pipe vacuum calibration forming tank is mainly used with the following equipment: 6.1. Plastic extruder: provide molten tube billets. 6.2. Forming die: The extruded pipe is preliminarily formed. 6.3. Traction machine: Pull the formed pipe from the mold and send it into the vacuum setting box. 6.4. Cutting machine: The shaped pipe is cut to form the required length of the finished product. 6.5. Turning stacking device: turning and stacking the cut pipe to facilitate subsequent treatment. |

▏Complete production line recommendation

Click the link below to view the full line description!

High-speed Energy-saving MPP Pipe Extrusion Line

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping