▏Product Vedio

▏Product Introduction

▏Pipe Vacuum Spray Water Cooling Tank: Optimizing Cooling for Precision Extrusion

The Pipe Vacuum Spray Water Cooling Tank is an essential piece of machinery in the manufacturing process of pipes, profiles, and other extruded materials. This tank is designed to rapidly cool down freshly extruded pipes, ensuring they maintain their shape, size, and quality during the solidification process. The combination of vacuum calibration and a spray water cooling system helps achieve precise dimensional control and surface quality, which are critical in industries such as plumbing, drainage, construction, and manufacturing.

In this product introduction, we will explore the features, operation, applications, and advantages of the Pipe Vacuum Spray Water Cooling Tank and explain why it’s indispensable in modern extrusion processes.

▏How the Pipe Vacuum Spray Water Cooling Tank Works

The operation of the Pipe Vacuum Spray Water Cooling Tank can be broken down into the following key steps:

| 1. Extrusion and Entry into the Tank

After the pipe is extruded, it is fed into the Pipe Vacuum Spray Water Cooling Tank while still hot and malleable. The material may still be in a flexible state, requiring immediate cooling to maintain its shape. |

| 2. Vacuum Calibration

Upon entering the tank, the pipe is subjected to a vacuum calibration process. The vacuum gently pulls the pipe into a mold or die, ensuring that it maintains its correct shape and diameter. This prevents the pipe from becoming oval or distorted during the cooling process. |

| 3. Spray Water Cooling

Once calibrated, the pipe moves through a series of spray nozzles, where a fine mist of water is sprayed evenly across its surface. This rapid cooling helps to solidify the material quickly and evenly. The cooling water absorbs the heat from the pipe, lowering its temperature uniformly and preventing warping or cracking. |

| 4. Exit and Solidification

Once the pipe has cooled to the desired temperature, it exits the tank in its final form, solidified and dimensionally stable. The product is now ready for further processing, whether it involves cutting, coiling, or packaging. |

▏Applications of the Pipe Vacuum Spray Water Cooling Tank

The Pipe Vacuum Spray Water Cooling Tank is versatile and can be used in various industries where precision cooling and calibration of extruded materials are required. Some of the common applications include:

| 1. Plastic Pipe Production

The most common use for the Pipe Vacuum Spray Water Cooling Tank is in the production of plastic pipes, such as PVC, PE, and HDPE pipes. The tank ensures that the pipes maintain the required diameter and wall thickness during the cooling process, resulting in high-quality pipes for plumbing, drainage, and industrial applications. |

| 2. Profile Extrusion

Extruded plastic or metal profiles used in construction, automotive, and electronics manufacturing also benefit from the cooling process provided by this tank. The uniform cooling ensures that the profiles retain their structural integrity and meet dimensional specifications. |

| 3. Wire and Cable Coating

In the wire and cable industry, the Pipe Vacuum Spray Water Cooling Tank is used to cool coated wires. The tank helps ensure that the coating solidifies evenly and adheres properly to the wire, providing protection against moisture, heat, and other environmental factors. |

| 4. Medical Tubing Production

Medical-grade tubing made from plastic or rubber can also be cooled effectively in a Pipe Vacuum Spray Water Cooling Tank. The precise calibration and cooling are essential for producing tubing with the right dimensions and surface quality for medical applications. |

| 5. Flexible Hose Manufacturing

The tank can be used in the production of flexible hoses, ensuring that the hoses maintain their desired diameter and flexibility without any distortion or surface defects. |

▏Technical Parameters

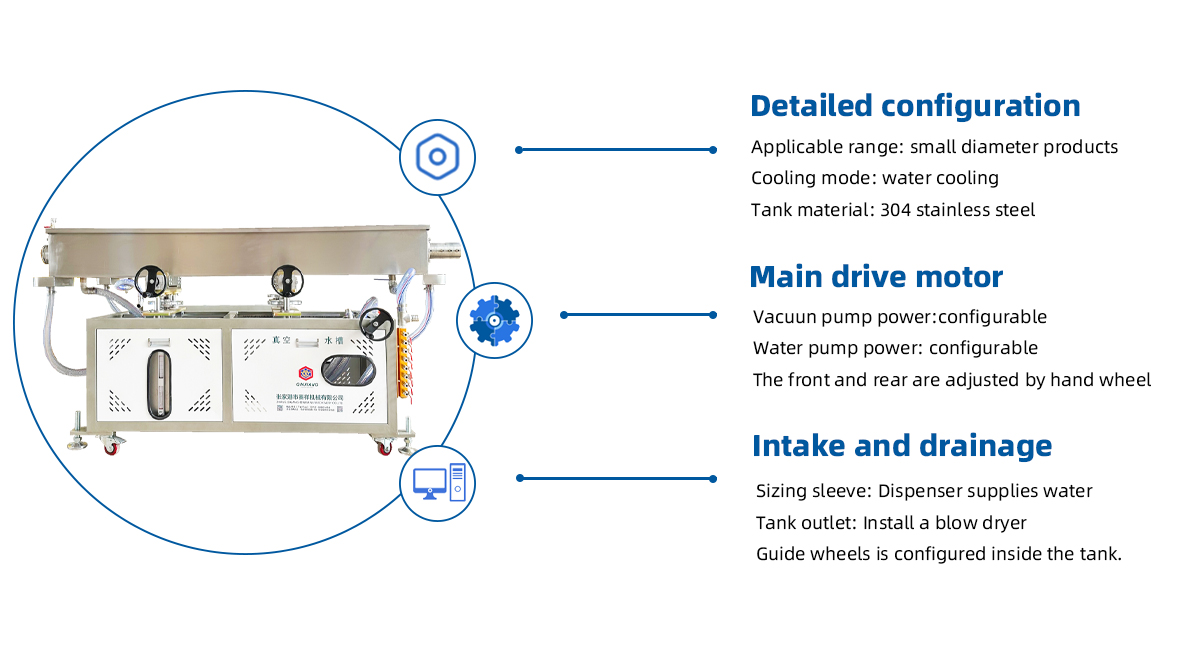

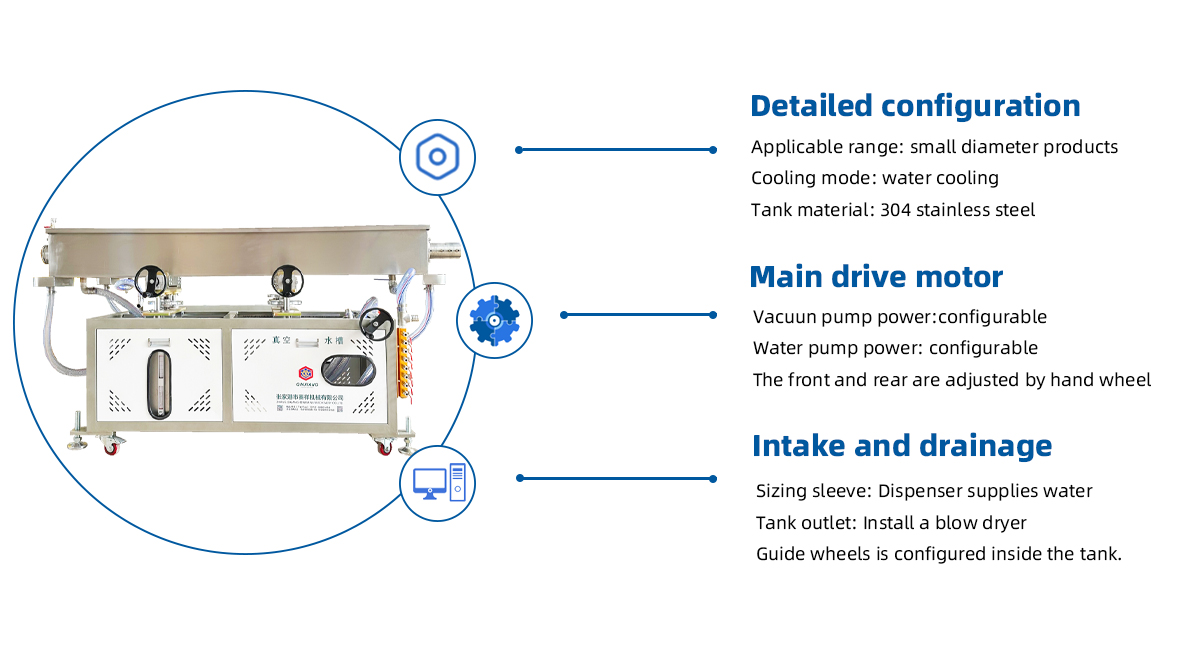

Applicable range | small diameter plastic products |

| Cooling mode | water cooling |

| Tank material | 304 stainless steel |

Vacuun pump power | 1.5KW;1 set |

| Water pump power | 0.75kw; 1 set |

| The front and rear are adjusted by hand wheel |

▏Main Details

▏Product Photos

▏Product Application

With the continuous progress and development of modern industrial technology, the demand for plastic pipes in production and application is increasing day by day. In order to meet this demand, the 2-meter Vacuum Spray Water Cooling Tank for plastic pipes came into being and became the key equipment on the plastic pipe production line. This paper will discuss in detail the application of this device and its important role in the production process.

| 1 | The basic characteristics |

| This tank uses advanced vacuum shaping technology and is designed for 2-meter long plastic tubing. Its compact structure and simple operation can ensure that the pipe can be accurately shaped and size controlled during the extrusion process. At the same time, the material of the Vacuum Spray Water Cooling Tank has been carefully selected to have excellent corrosion resistance and durability, which can ensure long-term stable operation. |

| 2 | The production process |

| First, its vacuum adsorption function allows the molten plastic to fit tightly onto the mold, thus ensuring that the shape and size of the tube are stable. This precise molding method greatly improves the accuracy and consistency of the pipe and reduces the reject rate. Secondly, the water cooling setting function of the sink is crucial to ensure the quality of the pipe.

The pipe is cooled rapidly by circulating cooling water, so that the pipe reaches a stable state in a short time, so as to maintain the stability of its shape and size. This water-cooled shaping method can not only improve the physical properties of the pipe, but also reduce the risk of deformation during subsequent processing and transportation. |

| 3 | Characteristics of efficient cooling |

| First, its vacuum adsorption function allows the molten plastic to fit tightly onto the mold, thus ensuring that the shape and size of the tube are stable. This precise molding method greatly improves the accuracy and consistency of the pipe and reduces the reject rate. Secondly, the water cooling setting function of the sink is crucial to ensure the quality of the pipe.

The pipe is cooled rapidly by circulating cooling water, so that the pipe reaches a stable state in a short time, so as to maintain the stability of its shape and size. This water-cooled shaping method can not only improve the physical properties of the pipe, but also reduce the risk of deformation during subsequent processing and transportation. |

| 4 | Applications |

| Its cooling system can quickly reduce the temperature of the pipe and shorten the curing time, thus improving production efficiency. At the same time, the water temperature, flow and other parameters in the tank can be accurately adjusted according to the production needs to adapt to different types and specifications of pipe production. Not only for traditional fields such as building water supply and drainage, agricultural irrigation, but also gradually expanded to high-end fields such as industrial transportation and chemical pipelines. In these areas, the 2-meter custom plastic pipe is favored for its precise size, excellent performance and stable quality. |

| 5 | Environmental protection and energy saving |

|

In addition, with the promotion of environmental awareness and the demand for green production, this Vacuum Spray Water Cooling Tank is also fully considered in the design of environmental protection and energy saving factors.By optimizing the cooling system and reducing energy consumption, the Vacuum Spray Water Cooling Tank effectively reduces the discharge of waste heat and wastewater during the production process, reducing the pollution to the environment. At the same time, its efficient cooling performance also reduces energy consumption and saves production costs for enterprises. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping