▏Product Vedio

▏Product Introduction

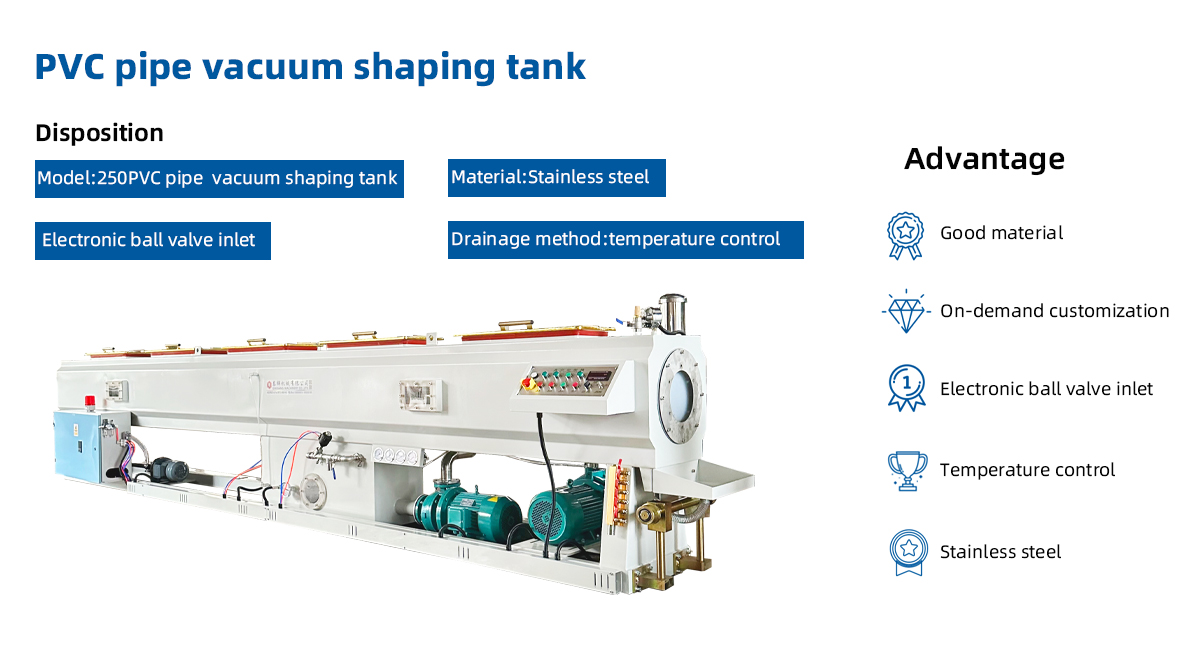

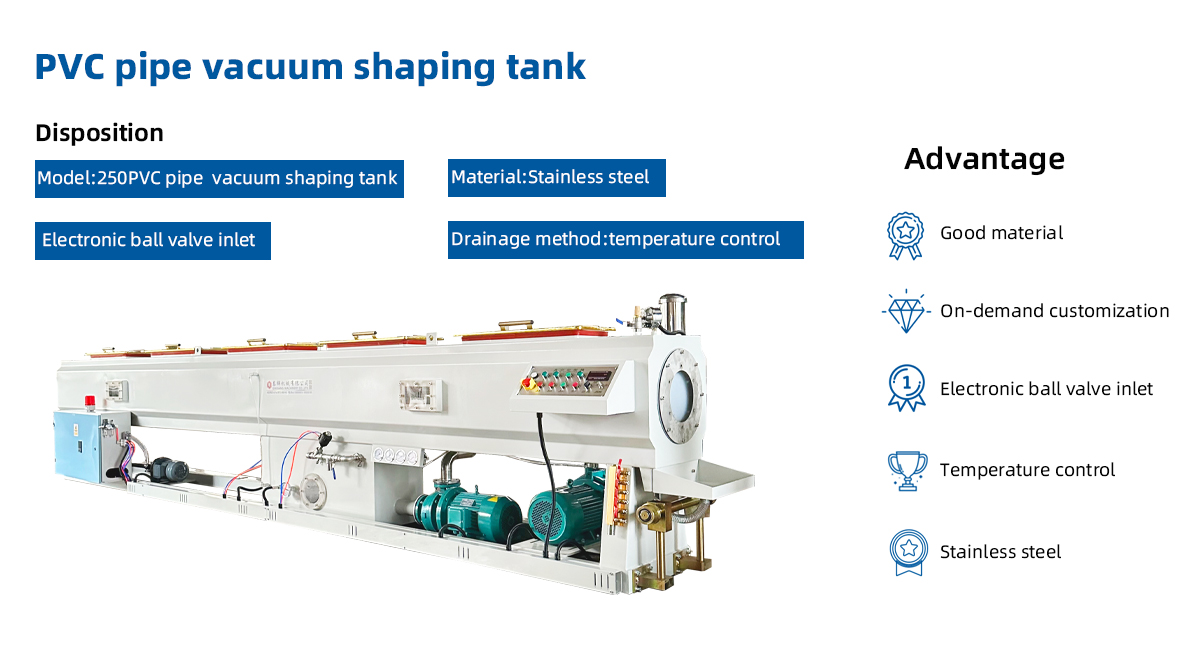

▏250 PVC Pipe Vacuum Forming Sizing Tank: Precision Cooling and Calibration for Pipe Production

The 250 PVC Pipe Vacuum Forming Sizing Tank is a highly specialized piece of equipment designed for the precise calibration, shaping, and cooling of PVC pipes. As an essential part of the pipe extrusion process, this tank ensures that PVC pipes maintain their optimal shape, size, and surface finish as they solidify. The advanced technology in the 250 PVC Pipe Vacuum Forming Sizing Tank delivers high-quality pipes suitable for a variety of industrial applications, including plumbing, drainage, and electrical conduit systems.

In this product introduction, we will explore the key features, operational principles, advantages, and common applications of the 250 PVC Pipe Vacuum Forming Sizing Tank, showcasing its vital role in the modern pipe manufacturing industry.

▏Key Features of the 250 PVC Pipe Vacuum Forming Sizing Tank

| 1. Vacuum Calibration System

The 250 PVC Pipe Vacuum Forming Sizing Tank features a high-performance vacuum calibration system. This system works by applying vacuum pressure to the outer surface of the pipe as it moves through the tank. The vacuum pulls the pipe into a calibrated mold, ensuring that the pipe maintains its shape and meets the required dimensional standards. This step is essential for achieving uniform pipe diameter, roundness, and structural integrity. |

| 2. Efficient Water Cooling System

A key feature of the tank is its water cooling system, which is responsible for rapidly cooling the hot extruded PVC pipe. As the pipe passes through the tank, the cooling water ensures that the pipe solidifies uniformly. The even distribution of water across the pipe’s surface prevents warping, deformation, or internal stress, ensuring the final product has optimal mechanical properties and a smooth surface. |

| 3. Adjustable Calibration and Vacuum Pressure

The 250 PVC Pipe Vacuum Forming Sizing Tank is equipped with adjustable settings for calibration and vacuum pressure. These adjustable parameters allow operators to customize the machine to suit different pipe diameters, thicknesses, and material properties. This flexibility is crucial for manufacturers producing a variety of pipe sizes and ensures that each pipe is calibrated according to its specific requirements. |

| 4. Stainless Steel Construction

Constructed from high-quality stainless steel, the 250 PVC Pipe Vacuum Forming Sizing Tank offers durability, resistance to corrosion, and long-term reliability. Stainless steel is an ideal material for this type of equipment as it can withstand the constant exposure to water, high temperatures, and pressure during the pipe formation process. The robust construction ensures minimal maintenance and maximum uptime. |

| 5. Automatic Temperature Control

The 250 PVC Pipe Vacuum Forming Sizing Tank is equipped with an automatic water temperature control system, which ensures that the cooling water is maintained at the ideal temperature for effective cooling. This system helps prevent temperature fluctuations, which could lead to inconsistent cooling rates and poor-quality pipe production. By maintaining consistent cooling, the system guarantees uniform pipe properties. |

| 6. User-Friendly Control Panel

The tank is designed with a user-friendly control panel that allows operators to easily monitor and adjust key parameters such as vacuum pressure, water temperature, and calibration settings. The intuitive interface enhances operational efficiency and reduces the risk of errors, ensuring that the pipe production process runs smoothly. |

| 7. Energy Efficiency

The 250 PVC Pipe Vacuum Forming Sizing Tank is designed with energy efficiency in mind. The efficient vacuum pump and water cooling system help minimize energy consumption, reducing operational costs while maintaining high-quality production standards. The machine’s design is optimized to ensure that the cooling and calibration processes are both effective and energy-efficient. |

▏Advantages of the 250 PVC Pipe Vacuum Forming Sizing Tank

| 1. High Precision and Consistency

The 250 PVC Pipe Vacuum Forming Sizing Tank ensures that each pipe is calibrated and cooled to exact specifications, resulting in high-quality, consistent products. The vacuum calibration system ensures that the pipes maintain their roundness and dimensional accuracy. |

| 2. Increased Production Efficiency

The efficient vacuum and cooling systems enable rapid production of high-quality pipes, increasing overall production efficiency. Manufacturers can produce large quantities of pipes with minimal downtime and reduced operational costs. |

| 3. Energy Efficiency

The machine is designed to operate with minimal energy consumption, making it a cost-effective solution for manufacturers. The efficient vacuum and cooling systems help reduce electricity usage, lowering overall operating costs. |

| 4. Durability and Longevity

Built from stainless steel, the 250 PVC Pipe Vacuum Forming Sizing Tank is highly durable and resistant to wear and corrosion. This robust construction ensures long-term reliability and reduces maintenance requirements. |

| 5. Flexibility for Various Applications

The 250 PVC Pipe Vacuum Forming Sizing Tank is highly versatile and can handle a wide range of PVC pipe sizes and applications. Its adjustable settings make it suitable for manufacturers producing a variety of pipe types, from plumbing to industrial applications. |

The 250 PVC Pipe Vacuum Forming Sizing Tank is an essential component in the PVC pipe extrusion process, providing precise calibration, shaping, and cooling for high-quality pipes. With its advanced vacuum calibration system, efficient water cooling, and durable construction, the tank ensures that PVC pipes meet the required standards for a variety of applications, including plumbing, drainage, electrical conduits, and more. By incorporating this tank into their production lines, manufacturers can enhance product quality, increase production efficiency, and reduce operational costs, making it a valuable investment for modern pipe manufacturing facilities.

▏Technical Parameters

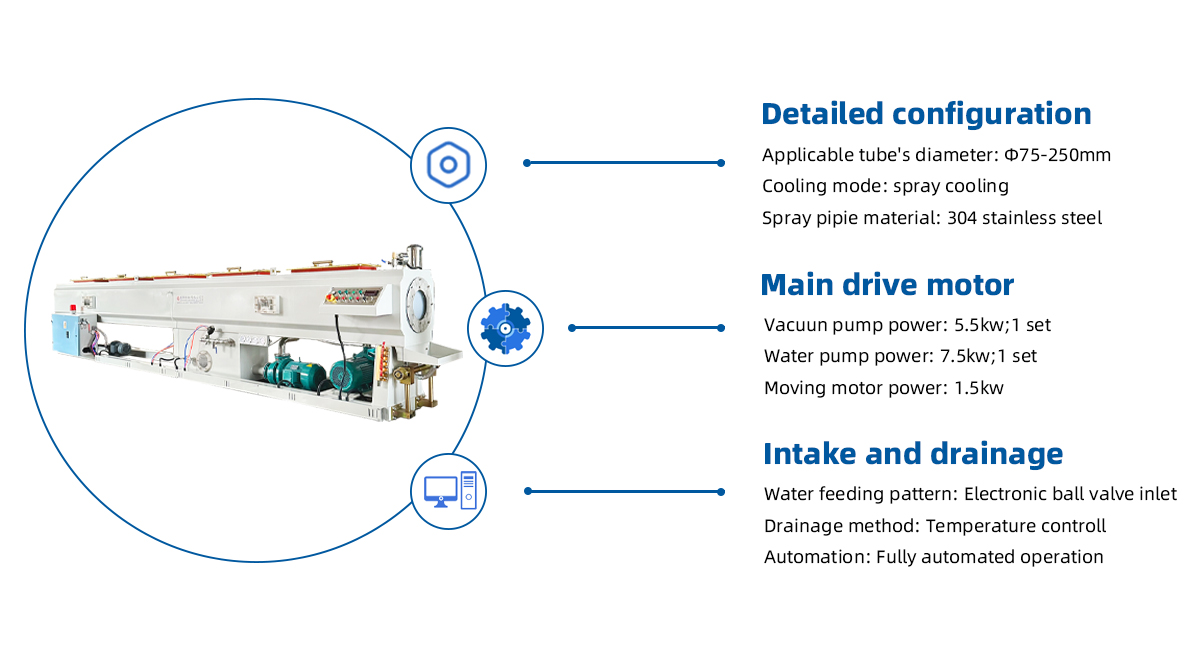

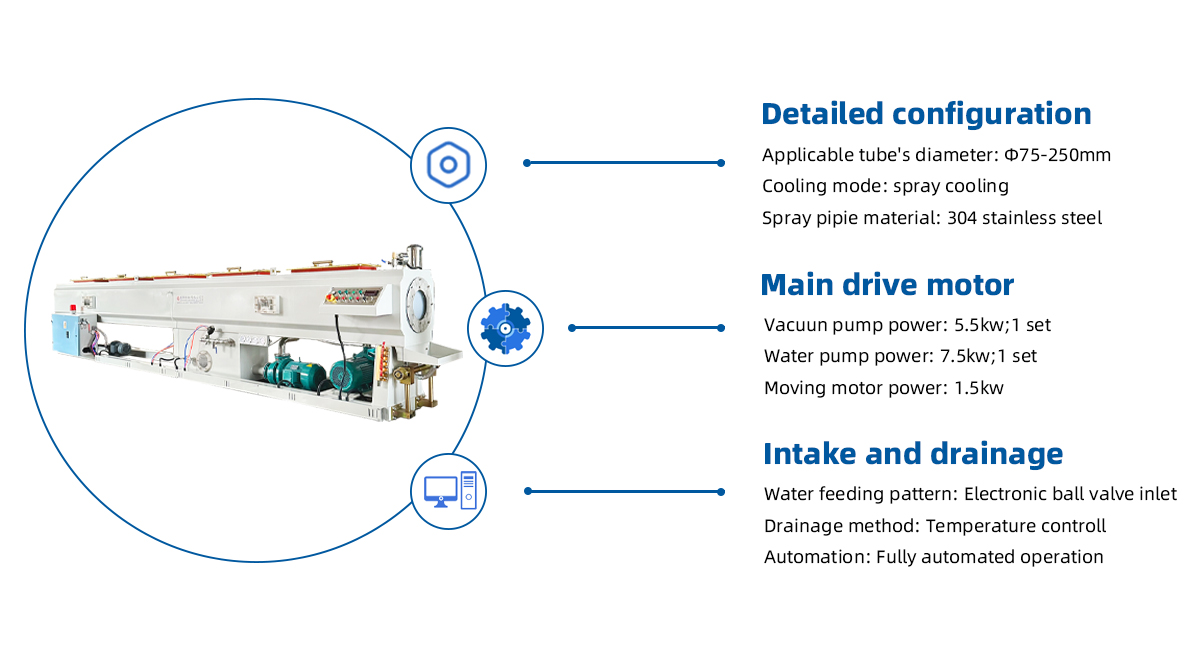

| Applicable tube's diameter | Φ75-250mm |

| Cooling mode: | spray cooling |

| Spray pipie material | 304 stainless steel |

| Vacuun pump power | 5.5kw;1 set |

| Water pump power | 7.5kw;1 set |

| Moving motor power | 1.5kw |

▏Main Details

▏Product Photos

▏Product Application

| 1 | The application principle |

| The application principle of vacuum forming sizing tank is mainly to form a negative pressure environment inside the pipe by vacuuming, so as to achieve rapid cooling and shaping of the pipe. In the vacuum state, the air inside the pipe is quickly extracted, and water and other volatile substances are also discharged, which helps to improve the uniformity and density of the internal structure of the pipe. At the same time, vacuum cooling can also effectively reduce the residual stress and deformation of the pipe, and improve the precision and strength of the pipe. |

| 2 | Pipe processing advantages |

| 1、the hollow tank can quickly realize the cooling and shaping of the pipe and improve production efficiency. 2、 vacuum cooling helps to eliminate bubbles and impurities inside the pipe and improve the quality of the pipe. 3、because the vacuum tank can precisely control the cooling temperature and time, it can effectively reduce the thermal deformation and shrinkage rate of the pipe, and ensure the dimensional accuracy and stability of the pipe. |

| 3 | Quality control and efficiency |

| In the production process of PVC pipes, the application of vacuum forming sizing tank not only helps to improve the quality of pipes, but also improves production efficiency. Precise control of vacuum and cooling time ensures that each tube meets predetermined quality standards. At the same time, the automation and intelligence level of the vacuum forming tank continues to improve, making the production process more efficient and stable. |

| 4 | Industry application fields |

| At present, PVC pipe vacuum forming sizing tank has been widely used in many fields. In building drainage systems, PVC pipes are favored because of their excellent corrosion resistance and aging resistance. In the field of agricultural irrigation, the lightweight and easy installation characteristics of PVC pipe make it an ideal choice; In the urban water supply system, the high strength and sealing performance of PVC pipes ensure the safety of water supply. In addition, empty boxes also play an important role in chemical industry, environmental protection and other fields. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping