▏Product Vedio

▏Product Introduction

▏Vacuum Water Cooling Tank: A Key to High-Quality Extrusion Cooling

The Vacuum Water Cooling Tank is a critical component in the extrusion industry, especially for cooling and solidifying extruded materials like pipes, profiles, and other plastic or metal products. This machine uses a combination of vacuum calibration and water cooling techniques to ensure precise dimensional control, uniform temperature distribution, and high-quality finishes. The system is designed to prevent defects such as warping, dimensional distortion, and surface imperfections that often arise during the cooling phase of extruded products.

In this article, we will discuss the various features, advantages, applications, and the working mechanism of the Vacuum Water Cooling Tank to highlight its importance in modern manufacturing processes.

▏What is a Vacuum Water Cooling Tank?

A Vacuum Water Cooling Tank is an advanced machine used to cool and calibrate materials immediately after the extrusion process. Extruded products, such as plastic pipes, profiles, and other items, are initially hot and need to undergo rapid cooling to solidify into their final forms. This tank utilizes a combination of water cooling and vacuum pressure to ensure that the extruded materials retain the desired shape, size, and surface quality as they cool.

The machine consists of a water-filled chamber that uses vacuum calibration to maintain the precise dimensions of the extruded product while cooling it uniformly. It prevents dimensional distortion and ensures the extruded material cools at a controlled rate, which is essential for producing high-quality final products.

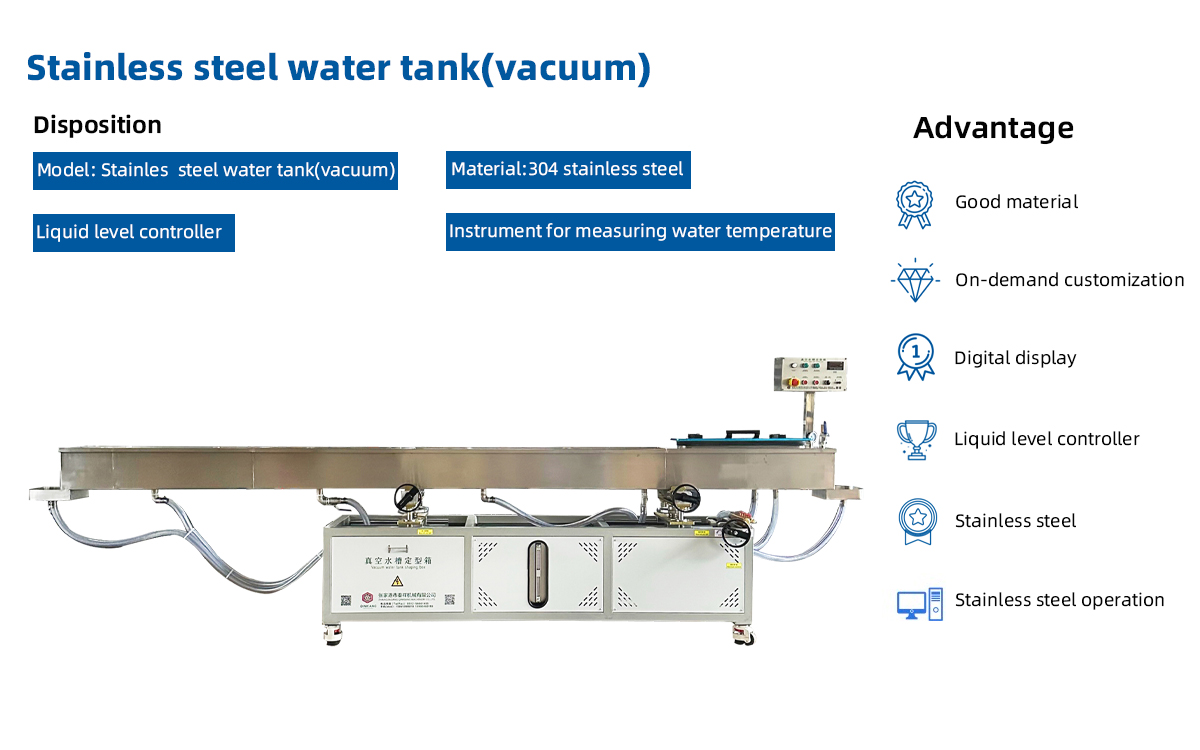

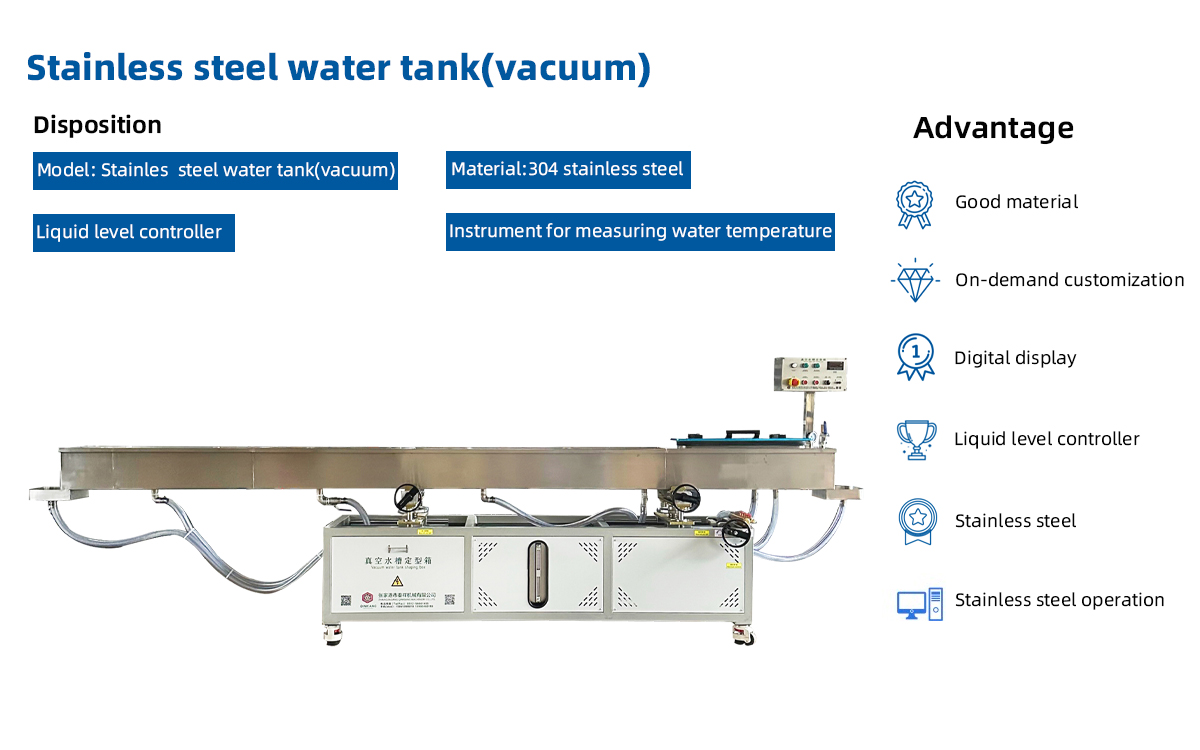

▏Key Features of the Vacuum Water Cooling Tank

| 1. Vacuum Calibration for Dimensional Accuracy

One of the primary features of the Vacuum Water Cooling Tank is its ability to calibrate the dimensions of the extruded material with the help of a vacuum system. After the material is extruded, it enters the tank, where the vacuum calibration system pulls the material into a mold or die. This process ensures that the extruded product retains its intended diameter, thickness, and shape throughout the cooling process. The vacuum helps prevent common issues like ovality or non-uniform dimensions that could compromise the quality of the final product. |

| 2. Efficient Water Cooling System

The cooling tank uses an efficient water circulation system to maintain a uniform and controlled cooling process. Water is sprayed or circulated around the extruded product to ensure it cools evenly and rapidly. The constant flow of water removes excess heat from the material, solidifying it while maintaining dimensional accuracy. The even temperature distribution also helps prevent issues like warping or cracking that might otherwise occur with improper cooling. |

| 3. Stainless Steel Construction for Durability

The Vacuum Water Cooling Tank is typically made from high-quality stainless steel, ensuring that it is both durable and resistant to corrosion. The material can withstand the constant exposure to water and high temperatures in industrial environments. Stainless steel construction also makes the tank easier to clean and maintain, extending its lifespan and ensuring reliable performance over time. |

| 4. Adjustable Parameters for Customization

The cooling process needs to be adjusted based on the specific material being processed. The Vacuum Water Cooling Tank comes with adjustable parameters such as water flow rate, vacuum pressure, and water temperature. This flexibility allows manufacturers to tailor the cooling process to meet the needs of different materials, whether they are plastic, rubber, or metal. Customization ensures that the product's cooling process remains efficient and effective for a wide range of extruded materials. |

| 5. Automated Temperature Control

An automated temperature control system is often integrated into the Vacuum Water Cooling Tank. This system continuously monitors the temperature of the water and adjusts it to maintain the ideal cooling conditions. By maintaining a consistent water temperature, the cooling process remains stable, reducing the risk of thermal shock or inconsistent cooling, which can lead to defects or dimensional errors in the final product. |

| 6. Low Water and Energy Consumption

The Vacuum Water Cooling Tank is designed to be energy-efficient, using minimal water and power to achieve effective cooling. The system’s advanced circulation mechanisms ensure that water is reused efficiently, making the process more sustainable and reducing operational costs. Energy-efficient features make it an eco-friendly option for large-scale manufacturers looking to reduce their environmental footprint. |

| 7. Easy-to-Use Control Panel

The Vacuum Water Cooling Tank is equipped with a user-friendly control panel that allows operators to monitor and control key parameters such as water flow, vacuum pressure, and temperature. This interface makes it easy for operators to adjust settings and optimize the cooling process, leading to higher productivity and fewer errors during production. |

▏Technical Parameters

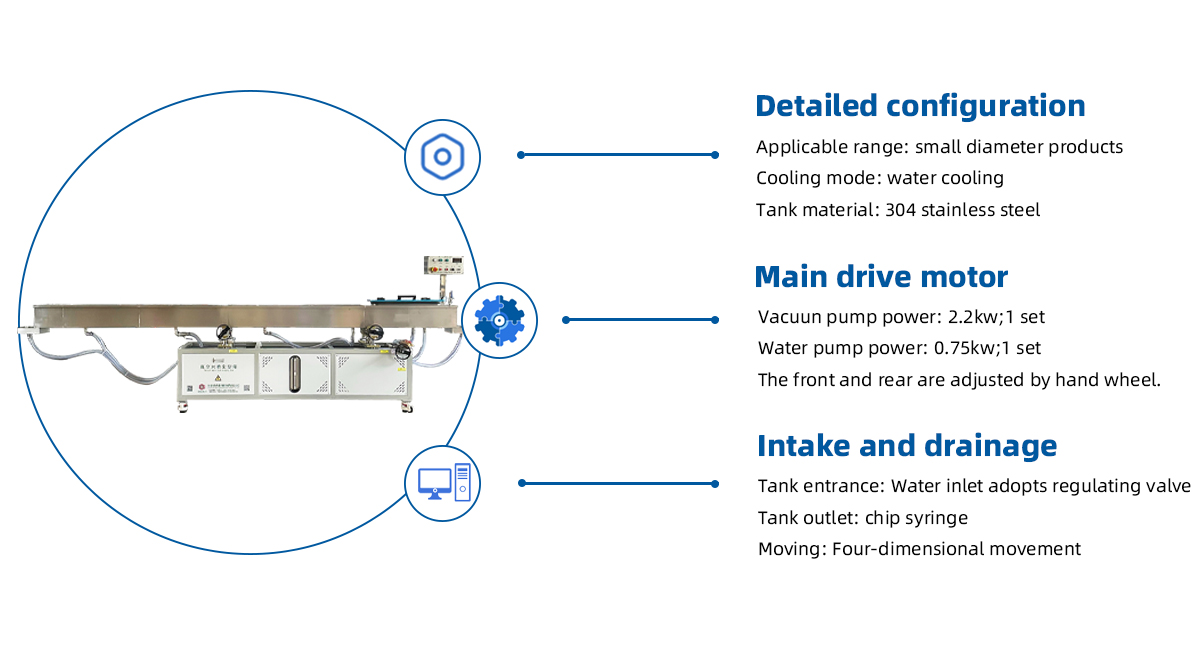

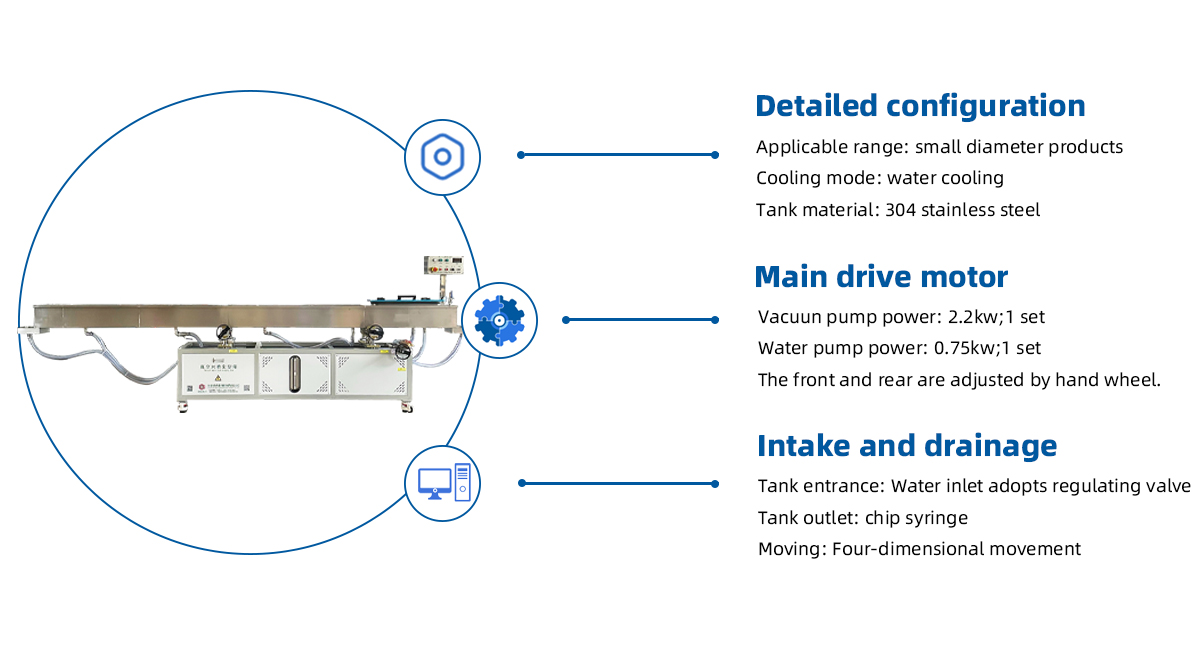

Applicable range | small diameter products |

Cooling mode | water cooling |

| Tank material | 304 stainless steel |

Moving

| Four-dimensional movement |

| Tank entrance: | Water inlet adopts regulating valve |

| Tank outlet | chip syringe |

▏Main Details

▏Product Photos

▏Product Application

| 1 | Vacuum type tank overview |

| Vacuum Water Cooling Tank for plastic pipe is one of the most important equipment in plastic pipe production line. The design concept is based on vacuum adsorption and efficient cooling technology to provide accurate sizing and dimensional control of the pipe, ensuring high quality and stability of the product. The structure design of vacuum shaped water tank is reasonable, the material is strong and durable, and it can meet the needs of continuous and large-scale production, which is an indispensable key link in modern pipe production. |

| 2 | Vacuum adsorption help forming |

| One of the core functions of Vacuum Water Cooling Tank is to help pipe forming through vacuum adsorption. After the tube is extruded, the vacuum system inside the tank is quickly activated to hold the surface of the tube close to the mold, ensuring that the shape and size of the tube are as expected. This vacuum adsorption technology not only improves the accuracy of the pipe, but also greatly reduces the scrap rate caused by irregular shape or dimensional errors. |

| 3 | Water cooling to ensure quality |

| One of the core functions of Vacuum Water Cooling Tank is to help pipe forming through vacuum adsorption. After the tube is extruded, the vacuum system inside the tank is quickly activated to hold the surface of the tube close to the mold, ensuring that the shape and size of the tube are as expected. This vacuum adsorption technology not only improves the accuracy of the pipe, but also greatly reduces the scrap rate caused by irregular shape or dimensional errors. |

| 4 | Efficient cooling to improve efficiency |

| The efficient cooling capacity of Vacuum Water Cooling Tank greatly improves the production efficiency of pipes. The faster the cooling rate, the shorter the curing time of the pipe, thus shortening the overall production cycle. At the same time, the efficient cooling system also helps to reduce energy consumption, reduce production costs, and improve the competitiveness of enterprises. |

| 5 | Accurately adjust to the needs |

| In order to meet the needs of different types and specifications of pipe production, the Vacuum Water Cooling Tank is equipped with a precision adjustment system. By adjusting the vacuum degree, water temperature, cooling time and other parameters, the tank can adapt to the characteristics of different materials and production requirements, to ensure that the quality and performance of the product meet the expectations. |

| 6 | Wide range of applications |

| Vacuum Water Cooling Tank is widely used in various fields. Whether it is building water supply and drainage, agricultural irrigation, or industrial transportation and other fields, high-quality plastic pipes are needed as infrastructure. With its precise shaping capacity and efficient production efficiency, vacuum molding flume meets the demand for pipe quality and quantity in these fields. |

| 7 | Obvious advantages in environmental protection and energy saving |

| In today's social background of environmental protection and energy saving, the environmental protection and energy saving advantages of special Vacuum Water Cooling Tank for plastic pipes are particularly prominent. By optimizing the cooling system and reducing energy consumption, the water tank reduces waste heat and wastewater discharge during the production process, reducing environmental pollution. At the same time, the efficient production process also reduces the waste of raw materials and realizes the effective use of resources. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping