▏Product Vedio

▏Product Introduction

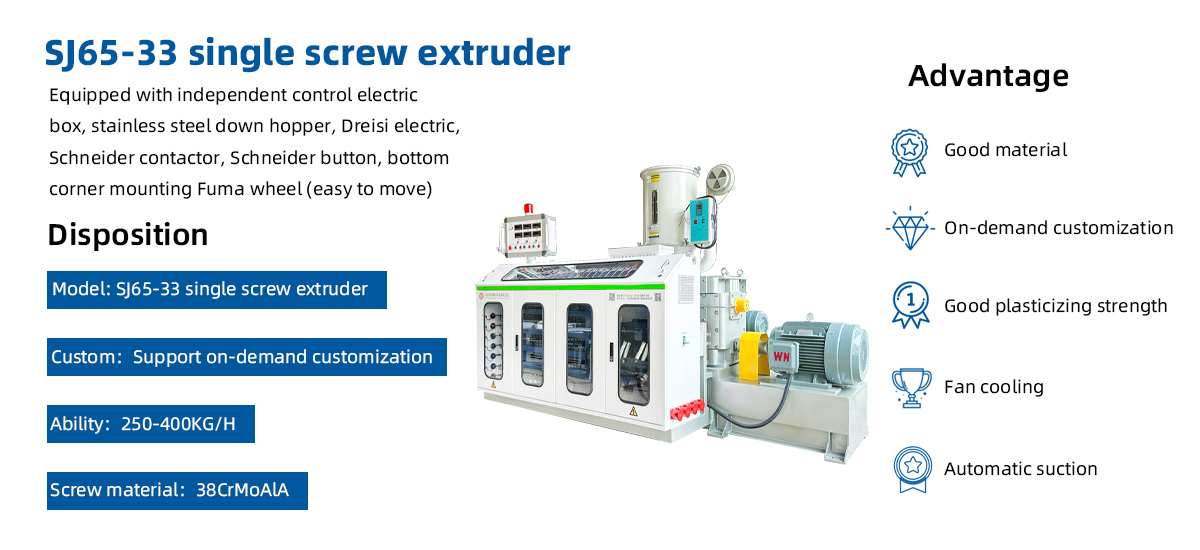

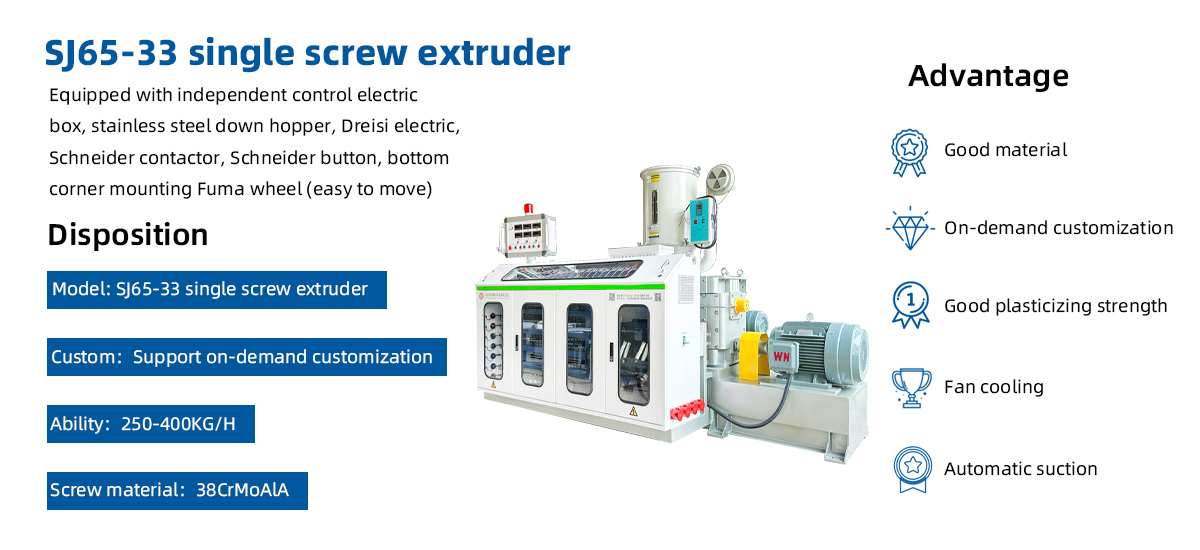

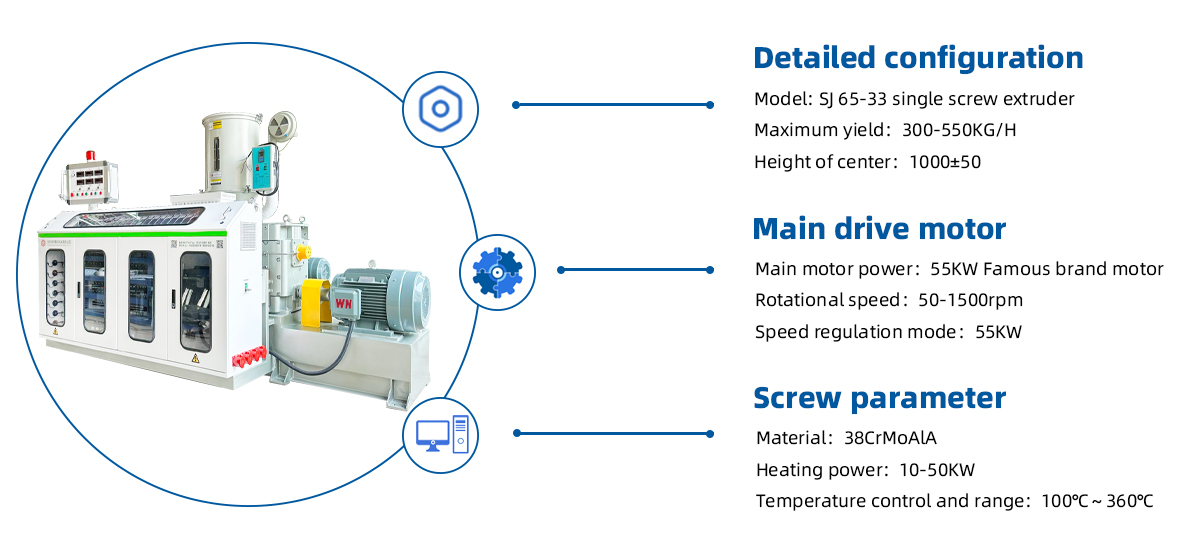

▏SJ65-33 Single Screw Extruder: Revolutionizing Polymer Processing Efficiency

The SJ65-33 Single Screw Extruder is a high-performance industrial machine engineered for precision polymer extrusion across diverse manufacturing sectors. Combining cutting-edge technology with robust construction, this extruder delivers unmatched reliability, energy efficiency, and adaptability. Below, we delve into its technical specifications, innovative features, applications, and competitive advantages.

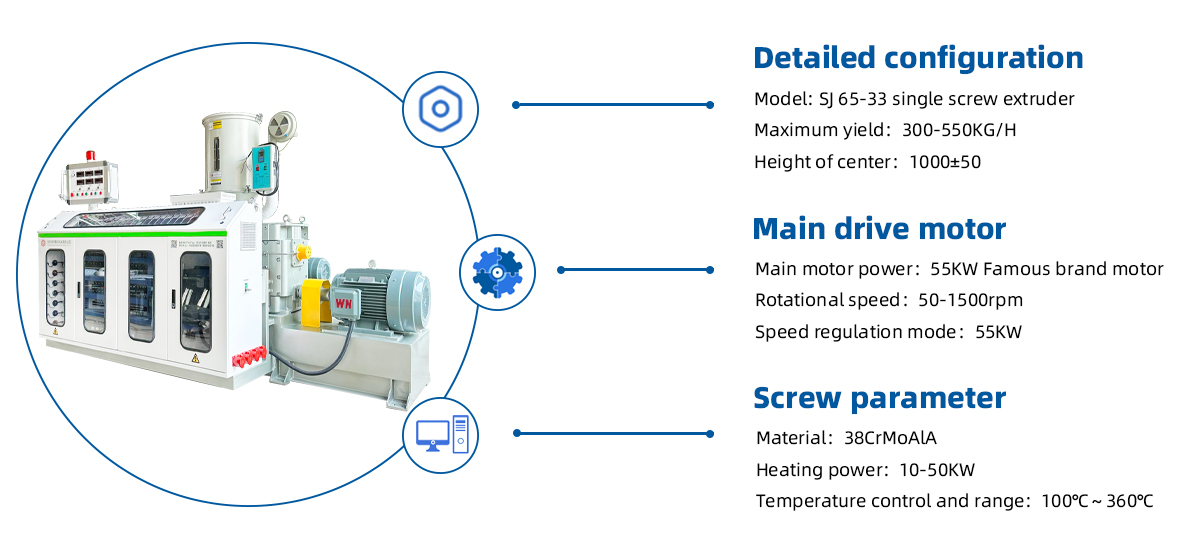

▏Technical Specifications and Engineering Excellence

The SJ65-33 single screw extruder is designed to meet the rigorous demands of modern production environments.

| Core Performance Parameters

Screw Diameter: 65 mm Length-to-Diameter Ratio (L/D): 33:1 (optimized for material homogeneity) Maximum Output: 150–350 kg/h (dependent on material viscosity) Motor Power: 55 kW with variable frequency drive (VFD) Heating Zones: 5 independently controlled zones (±1°C accuracy) Screw Speed Range: 10–120 rpm (adjustable via digital interface) |

| Advanced Design Components

High-Strength Alloy Screw: Precision-machined with dual-stage mixing zones for superior melting and dispersion. Modular Barrel System: Segmented barrels enable rapid material changeovers and simplified maintenance. Energy-Saving Thermal Management: Ceramic band heaters paired with dual cooling fans reduce power consumption by 20%. Smart Control System: An integrated PLC with touchscreen interface allows real-time monitoring of pressure, torque, and temperature. |

▏Why Invest in the SJ65-33 Single Screw Extruder?

High ROI: Achieve payback within 18 months through reduced energy and maintenance costs.

Future-Proof Design: Compatible with Industry 4.0 automation systems for smart manufacturing.

Proven Reliability: Over 500 units deployed globally in industries ranging from automotive to construction.

The SJ65-33 Single Screw Extruder sets a new benchmark in polymer processing technology. Its blend of precision engineering, energy efficiency, and versatility makes it an ideal choice for manufacturers aiming to optimize productivity while reducing environmental impact. Whether producing high-quality films, durable pipes, or recycled materials, the SJ65-33 delivers consistent performance, ensuring your operations remain competitive in a dynamic market.

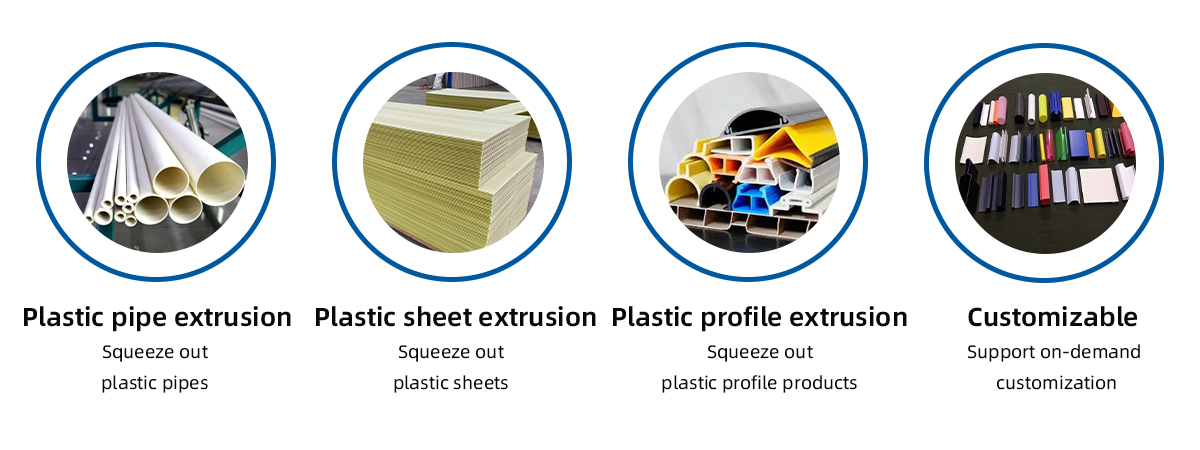

▏Range Of Application

▏Technical Parameters

Model | Diameter (mm) | L/D | Speed (rpm) | Output (kg/h) | Drive Power (kw) | Heating | Central height (mm)

|

District | Power (kw)

|

SJ-30/25 | 30 | 25 | 60 | 8 | 4 | 3 | 3 | 1000 |

SJ-45/25 | 45 | 25 | 90 | 40 | 11 | 3 | 6 | 1000 |

SJ-45/30 | 30 | 100 | 50 | 15 | 4 | 8 | 500/1000 |

SJ-50/28 | 50 | 28 | 127 | 60 | 18.5 | 3 | 8 | 500 |

SJ-55/28 | 55 | 28 | 130 | 95 | 30 | 3 | 12 | 500 |

SJ-65/25 | 65 | 25 | 60 | 55 | 22 | 3 | 10 | 1000 |

SJ-65/30 | 28 | 110 | 140 | 37 | 3 | 15 | 1000 |

SJ-75/30 | 75 | 30 | 100 | 150 | 45 | 3 | 15 | 500 |

SJ-80/30 | 80 | 30 | 100 | 180 | 55 | 4 | 25 | 1000 |

SJ-90/25 | 90 | 25 | 100 | 160 | 55 | 4 | 24 | 1000 |

SJ-90/30 | 30 | 80 | 210 | 75 | 5 | 30 | 1000 |

SJ-90/52 | 52 | 50 | 100 | 37 | 10 | 40 | 1000 |

▏Production Details

▏Product Photos

▏Product Introduction

SJ65-33 single screw extruder is a high performance plastic pipe production equipment, mainly used for the extrusion processing of thermoplastics such as HDPE (high density polyethylene). Here is a detailed description of the device:

| 1 | Basic parameters |

| Screw diameter: 65mm Screw type: Single screw Length-diameter ratio: 33:1 Motor power: According to different models and configurations, the motor power is usually in the range of 37~55kw. |

| 2 | Design features |

| High efficiency: The SJ65-33 single screw extruder is well designed to achieve an efficient and stable extrusion process and ensure product quality. High precision: With high positioning accuracy, it can ensure the precise size of the pipe production. Energy saving and environmental protection: low energy consumption design, effectively reduce production costs, while meeting the requirements of energy saving and environmental protection. |

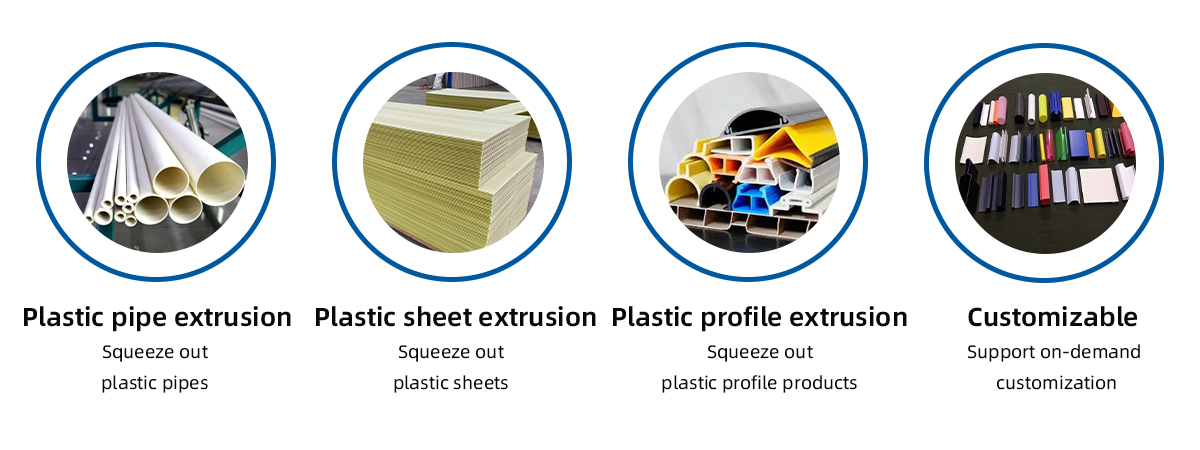

| 3 | Functions and Applications |

|

It is mainly used for pipe extrusion production of HDPE, PP, ABS and other thermoplastics, with a wide range of pipe diameters to meet different customer needs. With the corresponding auxiliary machine, it can process a variety of plastic products, such as film, rod, plate, wire, belt, cable insulation layer and hollow products. It is suitable for the processing of plastic granulation and other products, and has a wide range of applications. |

| 4 | Technical features |

|

Special design: The screw mold design makes the dissolution temperature lower, the mixing effect is good, the head pressure is low, and the output is stable. Cooling system: The use of water circulation cooling system, suitable for the cooling needs of raw materials such as HDPE. Vacuum sizing box: to ensure the stability of pipe diameter and roundness. Control system: PLC control, LCD screen control panel, easy to operate. |

| 5 | Other advantages |

|

Safety: The SJ65-33 single screw extruder is designed to be safe and has obtained CE safety certification. Brand and quality: The motor and other brands are preferred Siemens and other well-known brands, and the electrical control system is designed by professional engineers to ensure the stability and reliability of the equipment. Customized service: Customized design can be made according to the specific needs of customers to meet the special needs of different customers. |

▏Complete production line recommendation

Click the link below to view the full line description!

20-63PE Pipe Making Machine PE Pipe Production Line

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping