▏Product Vedio

▏Product Introduction

▏Technical Parameters

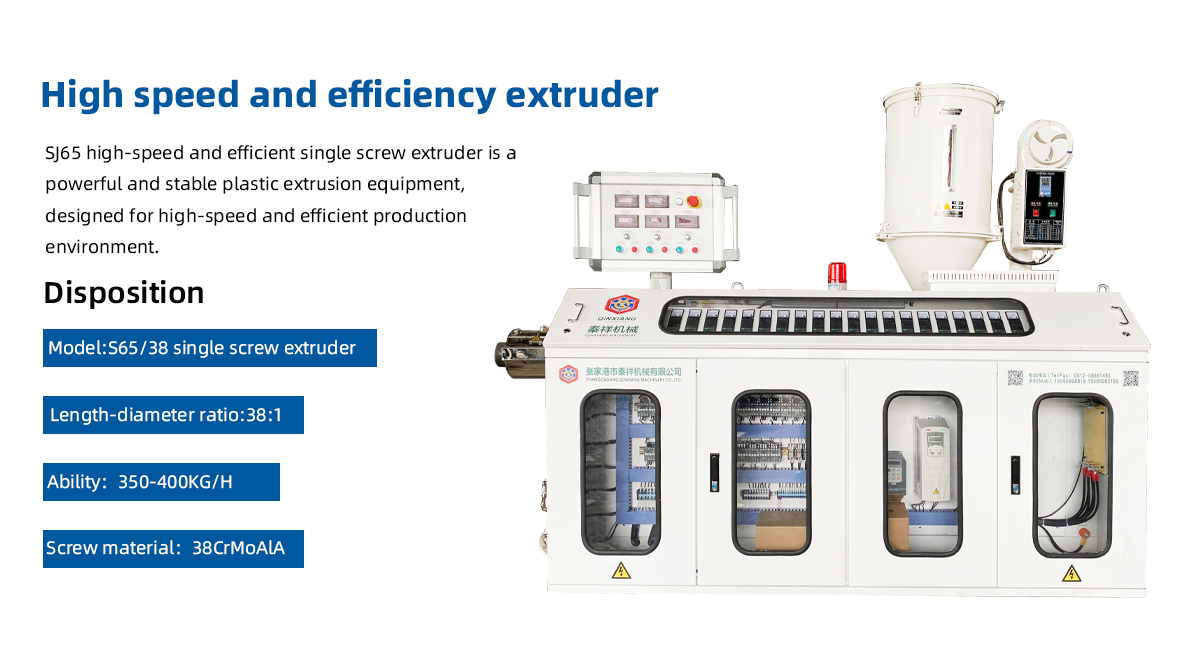

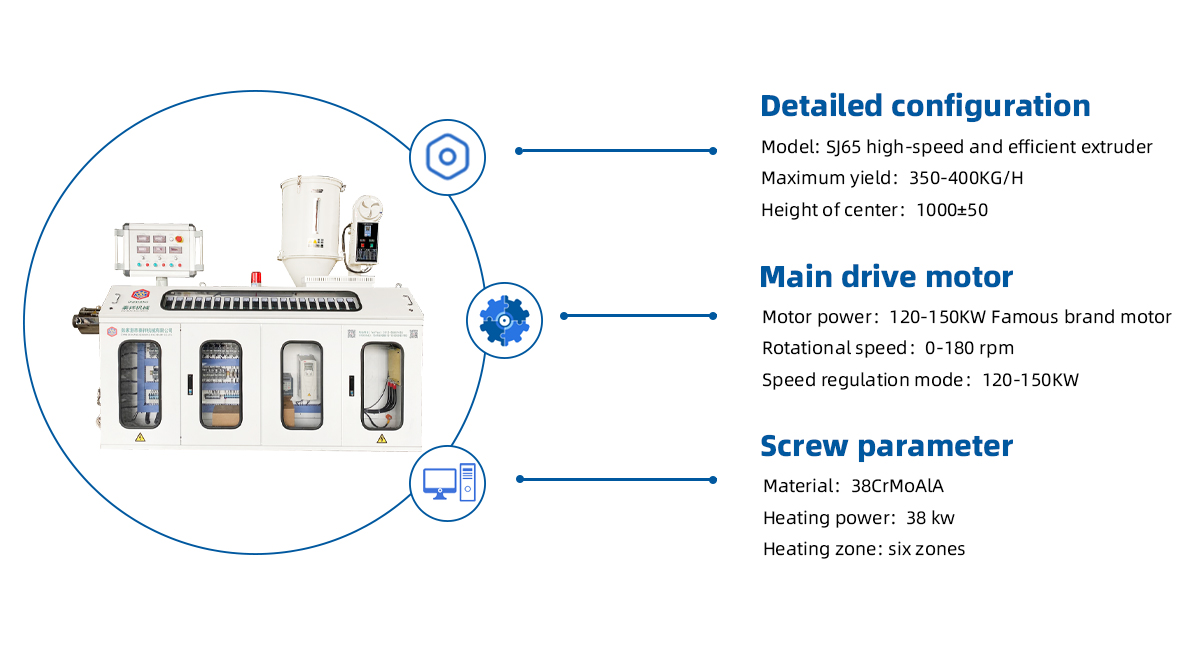

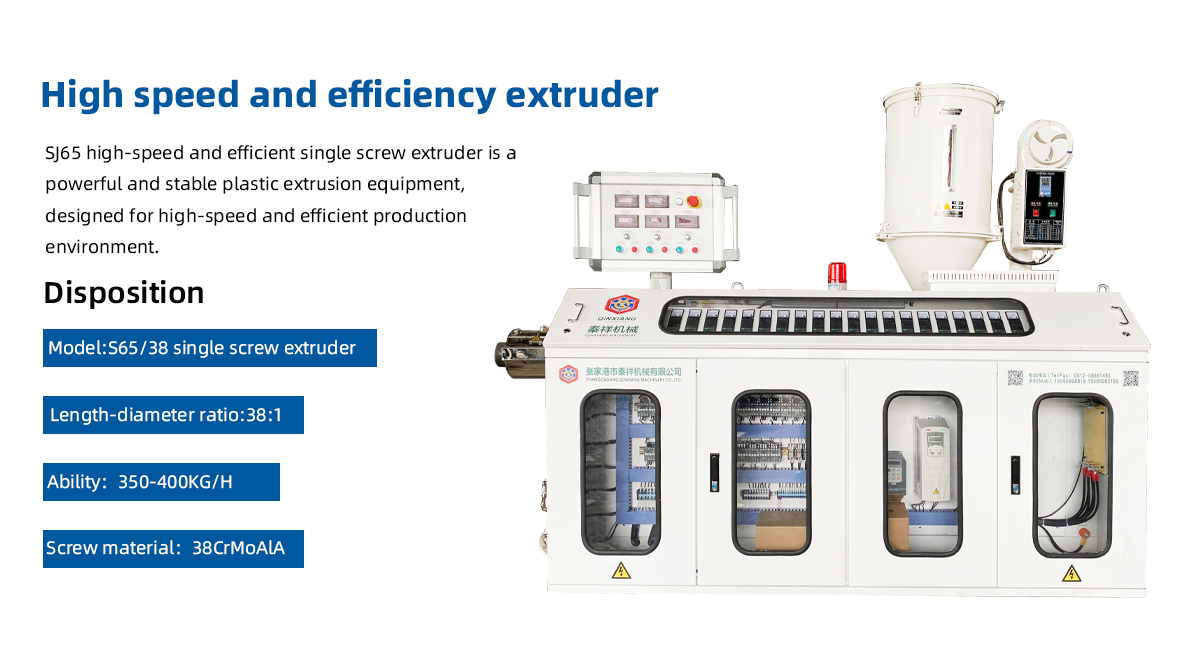

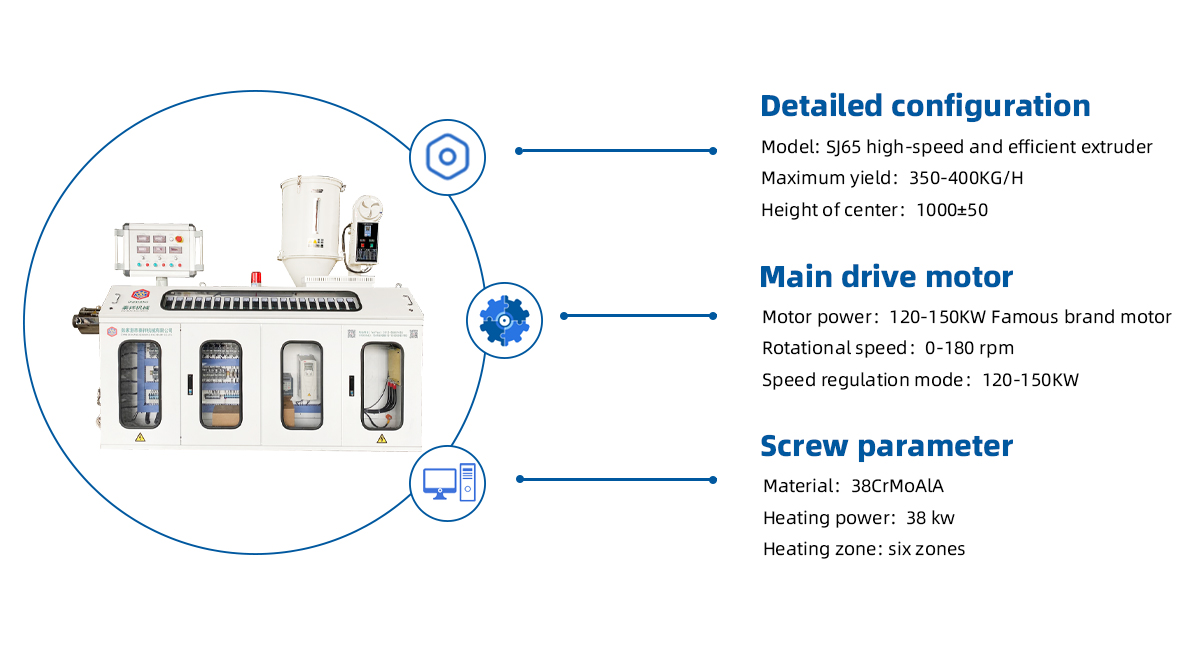

| Model | SJ65 high-speed and efficient single screw extruder |

| Length-diameter ratio | 38:1 |

| Screw diameter | 65mm |

| Motor power | 120-150Kw |

▏Main Details

▏Product Photos

SJ65 high-speed and efficient single screw extruder

SJ65 high-speed and efficient single screw extruder

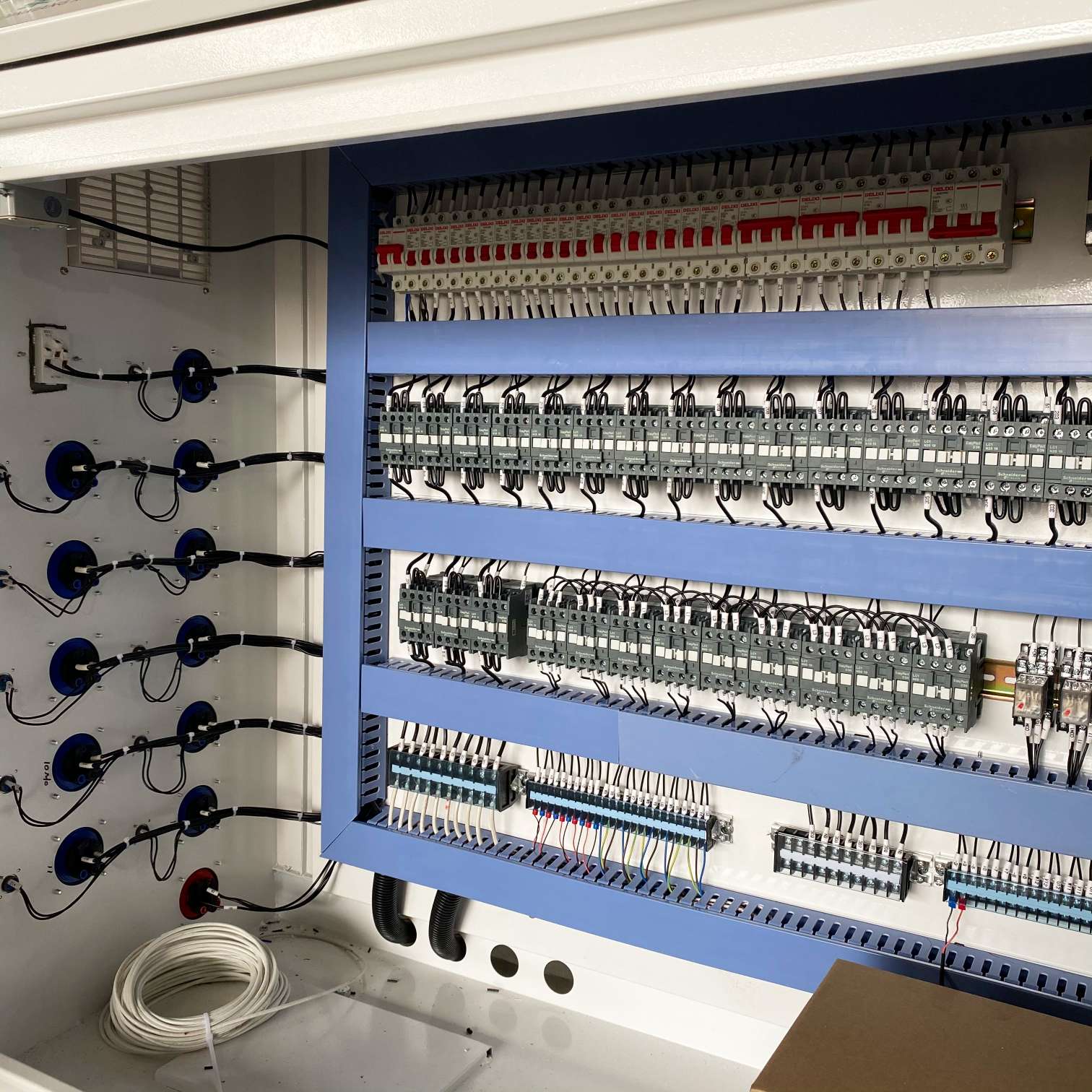

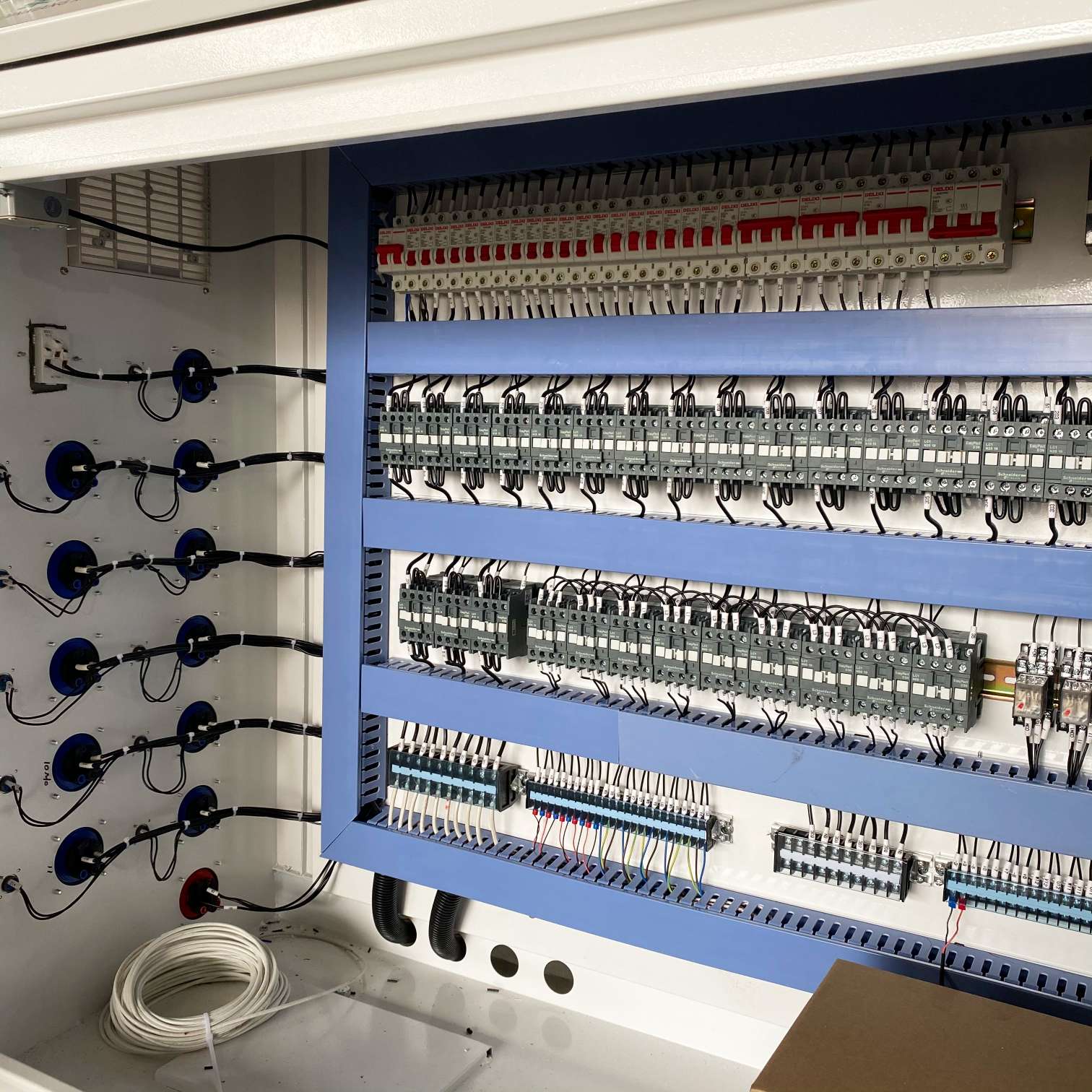

Large electric cabinet control

Aeronautical plug-in

Side display

Heating control area

Automatic drying suction machine

Full automatic control

Oscillating cabinet

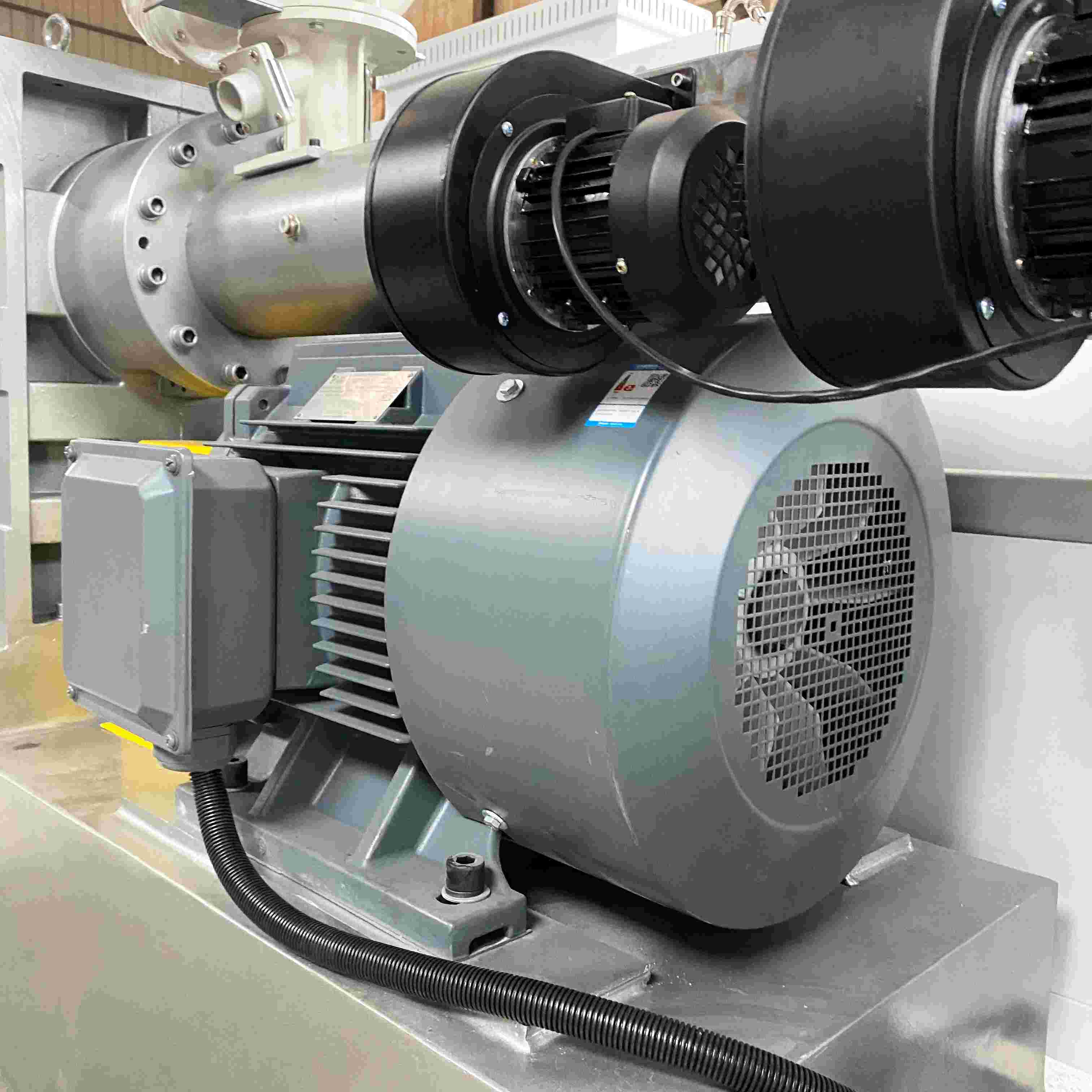

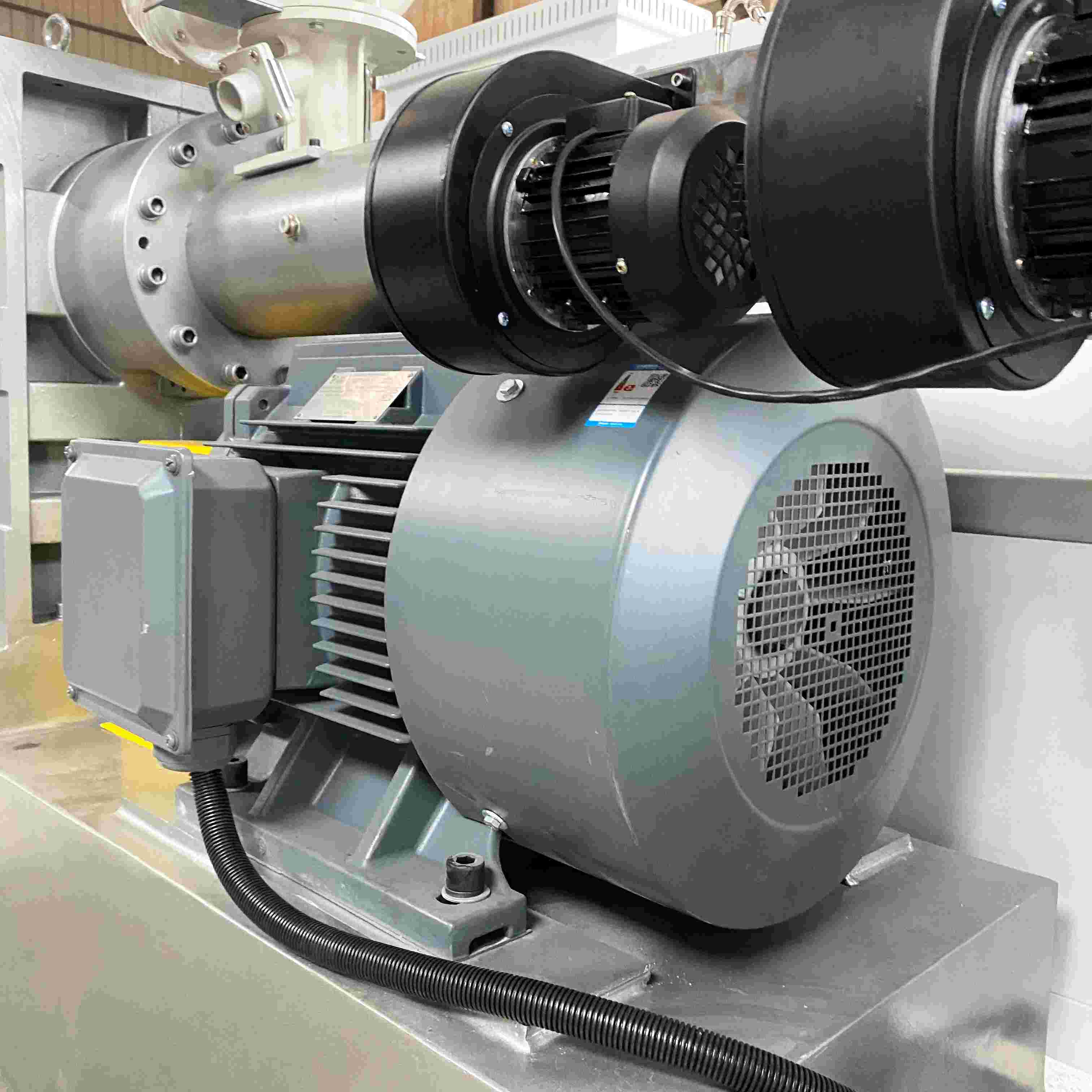

Motor

Screw

▏Product Introduction

The SJ65/38 High-Speed and Efficient Single Screw Extruder is a specialized piece of equipment used in the plastic extrusion industry to process a wide range of materials, typically for the production of plastic products such as pipes, profiles, sheets, films, and granules. The machine is particularly known for its efficiency, speed, and versatility, making it an essential part of many manufacturing lines.

The SJ65/38 designation refers to the specific size and specifications of the extruder. The “65” refers to the diameter of the screw (65 mm), while the “38” indicates the length-to-diameter ratio of the screw, which is 38:1. This ratio plays a significant role in the efficiency of the extrusion process, allowing for better material melting and mixing.

The high-speed and efficient nature of this extruder makes it ideal for processing thermoplastic materials such as PVC, PE, PP, and ABS, as well as others like nylon and PET. This makes it suitable for applications in industries such as packaging, automotive, construction, and electronics.

Key Features of the SJ65/38 High-Speed and Efficient Single Screw Extruder:

| 1. High-Speed Performance:The SJ65/38 extruder is designed for high-speed operation, which significantly improves production efficiency. The faster processing speed allows manufacturers to produce large quantities of extruded materials within a short period, which is crucial for high-volume production. |

| 2. Single-Screw Design:The machine uses a single screw mechanism, which is simple, cost-effective, and reliable. The screw is designed to provide uniform melting, mixing, and extrusion of materials, making it suitable for a wide range of plastic products. |

| 3. Efficient Material Processing:The screw geometry and length-to-diameter ratio of 38:1 allow for excellent plasticizing, mixing, and homogenizing of the material before it is forced through the die. This results in consistent product quality with minimal waste. |

| 4. Versatile Applications:The extruder can process a variety of thermoplastics, including PVC, PE, PP, and other common plastics. This makes it a versatile solution for manufacturers who produce a range of products, from pipes to films and sheets. |

| 5. Energy-Efficient Design:The high-speed design and optimized screw profile reduce energy consumption during the extrusion process. The machine’s energy efficiency helps manufacturers lower operational costs while maintaining high productivity. |

| 6. Temperature Control:Precise temperature control is essential for the extrusion of thermoplastics. The SJ65/38 extruder is equipped with advanced temperature regulation systems for the barrel and screw, ensuring that the material is processed at the optimal temperature for melting and extrusion. |

| 7. Automatic Control System:The extruder is typically integrated with an advanced automatic control system that monitors parameters such as screw speed, temperature, and pressure. This system helps ensure consistency and quality in the final product and minimizes the need for manual adjustments. |

| 8. Durability and Reliability:The SJ65/38 extruder is built with high-quality materials and precision engineering, ensuring long-lasting durability and reliable performance under continuous operation. This makes it a great investment for high-demand production environments. |

Applications:

| 1. Pipe and Profile Production:The SJ65/38 extruder is ideal for producing various types of plastic pipes (such as PVC pipes for plumbing and electrical conduit) and plastic profiles used in windows, doors, and decorative trims. |

| 2. Sheet and Film Production:The extruder is used to produce plastic sheets and films, which can be used in packaging, signage, and even in medical and food industries. |

| 3. Granules Production:The extruder is also commonly used for compounding and the production of plastic granules, which are then used in other plastic manufacturing processes. |

| 4. Packaging Materials:It can be used in the production of flexible films and bags, which are commonly used in the packaging industry. |

| 5. Automotive and Electrical Components:Plastic materials processed through this extruder are used in making automotive parts, insulation materials, and other electrical components that require durability and precision. |

Advantages:

| 1. Increased Productivity:The high-speed operation of the SJ65/38 extruder allows for faster processing and higher throughput, making it ideal for large-scale production lines. |

| 2. Consistency and Quality:The extruder produces high-quality, consistent plastic products with minimal variation, reducing the need for rework or material waste. |

| 3. Reduced Energy Consumption:Thanks to its efficient design, the SJ65/38 extruder minimizes energy consumption, leading to reduced operational costs. |

| 4. Flexibility:With the ability to process different types of thermoplastics and produce a wide variety of products, this extruder offers great flexibility to manufacturers. |

| 5. Easy Maintenance:The design of the SJ65/38 extruder makes it relatively easy to maintain and service, ensuring minimal downtime during production. |

The SJ65/38 High-Speed and Efficient Single Screw Extruder is a powerful and reliable solution for plastic processing in industries that demand high throughput, versatility, and precision. Its ability to handle a range of thermoplastic materials while providing consistent, high-quality results makes it an invaluable asset in the production of pipes, profiles, sheets, films, and granules. With features like high-speed performance, energy efficiency, and an advanced control system, this extruder helps manufacturers increase productivity and reduce operational costs, ensuring they can meet the demands of a competitive market.

| 1 | Screw design |

| The screw diameter of SJ65 extruder reaches 65mm, and its design fully considers the material handling, mixing and extrusion efficiency. By optimizing the geometry of the screw and the ratio of length to diameter, the material can be efficiently transported and evenly mixed in the extrusion process. |

| 2 | High efficiency extrusion |

| The equipment realizes high speed and high yield extrusion process on the basis of high quality. By using an advanced temperature control system and precise drive control, the plastic is evenly heated and flowed during the extrusion process, thus achieving high extrusion efficiency. |

| 3 | Low Temperature Plasticization |

| SJ65 extruder adopts the design concept of low temperature plasticization, which helps to maintain the high quality of materials and reduce energy consumption. This design makes the extrusion process more stable, while reducing the problem of material degradation or performance degradation that can occur due to high temperatures. |

| 4 | High torque output |

| The equipment is equipped with large thrust bearings with high torque output to ensure the stable operation of the screw under high load conditions. This design not only improves the reliability and durability of the equipment, but also helps achieve higher extrusion speeds and yields. |

| 5 | Gear and shaft design |

| gear and shaft are made of high-strength alloy steel material, which is processed by carburizing, grinding and other processes, with high hardness and high finish. This design not only improves the wear resistance and service life of the gear, but also helps to reduce noise and improve the overall performance of the equipment. |

| 6 | Intelligent control |

| SJ65 extruder is equipped with automatic PLC intelligent control system, which can realize linkage control between main and auxiliary machines. This intelligent control method not only simplifies the operation process, but also helps to improve the operating accuracy and stability of the equipment. |

| 7 | Application and adaptability |

| SJ65 high speed and high efficiency single screw extruder is suitable for extrusion processing of various plastic materials, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and so on. At the same time, due to its efficient and stable characteristics, it is also suitable for large-scale production and continuous operation scenarios. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping