▏Product Vedio

▏Product Introduction

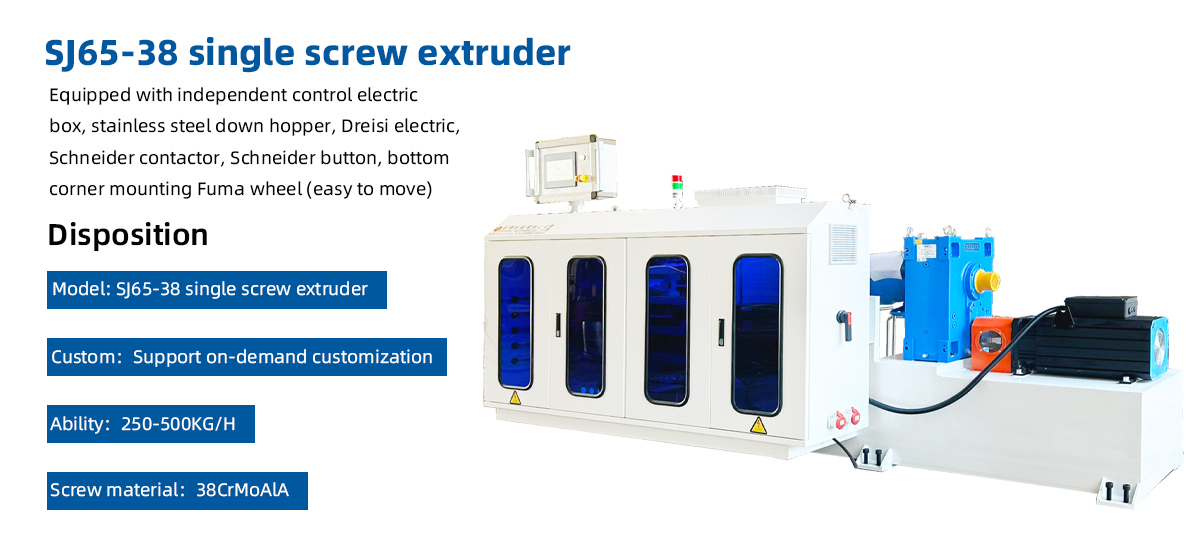

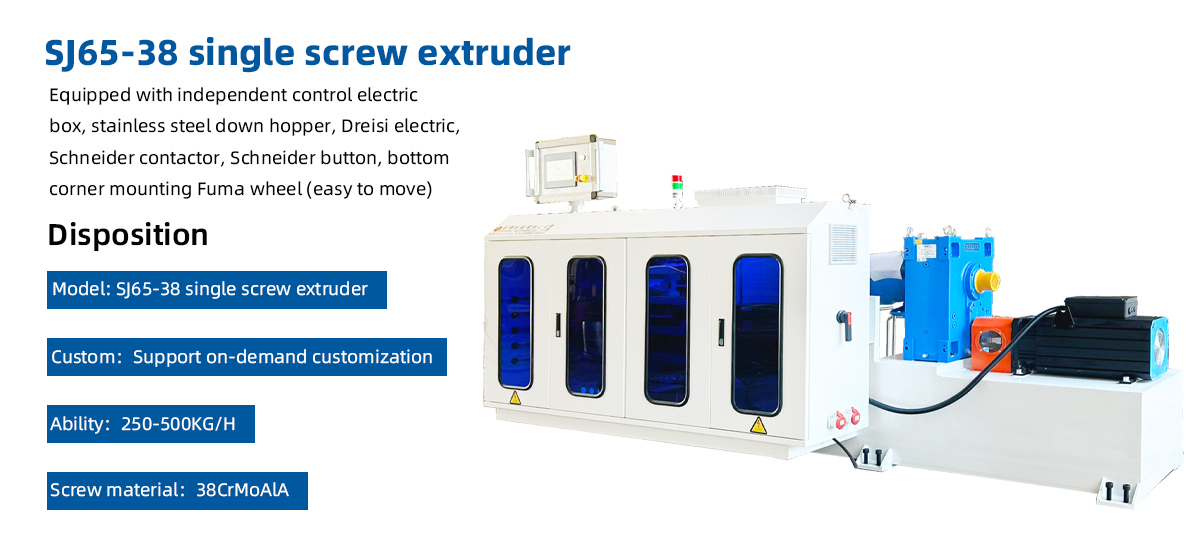

▏SJ65-38 Single Screw Extruder: Advanced Solution for Plastic Processing

The SJ65-38 single screw extruder is a versatile and high-performance machine designed for efficient plastic extrusion. It is ideal for a wide range of applications, from the production of pipes and profiles to sheets, films, and other thermoplastic products. Known for its reliability and superior output, the SJ65-38 extruder provides optimal performance in both small and medium-scale production environments.

In this product introduction, we will explore the key features, operational principles, and advantages of the SJ65-38 single screw extruder, demonstrating why it is an essential piece of equipment for modern plastic processing.

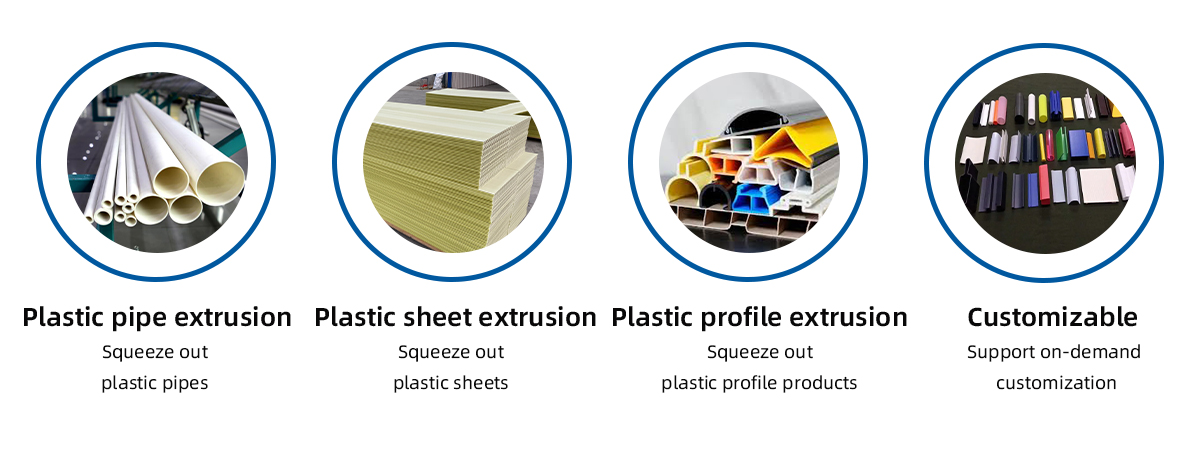

▏Applications of the SJ65-38 Single Screw Extruder

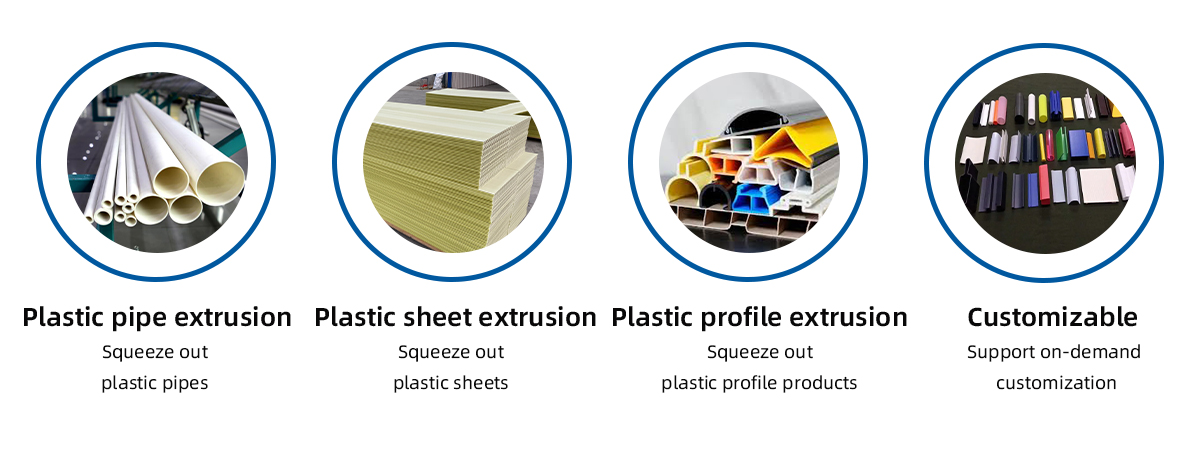

The SJ65-38 single screw extruder is highly versatile and can be used in various applications across multiple industries. Some of the most common uses include:

| 1. Pipe Production

The SJ65-38 extruder is widely used in the production of plastic pipes, including water supply pipes, drainage pipes, and sewerage pipes. Its ability to handle large quantities of material and produce high-quality pipes with precise dimensions makes it an excellent choice for pipe extrusion. |

| 2. Profile Extrusion

The extruder is also used to manufacture plastic profiles, such as trim, molding, window frames, and door frames. The SJ65-38 extruder provides precise control over the extrusion process, ensuring that the profiles meet the required specifications. |

| 3. Sheet and Film Extrusion

For applications that require plastic sheets or films, the SJ65-38 single screw extruder offers consistent quality and dimensional accuracy. It is commonly used in the production of packaging materials, protective films, and other thin plastic products. |

| 4. Pelletizing

In pelletizing applications, the SJ65-38 extruder is used to produce plastic pellets from raw materials. These pellets can then be used in further processing or as raw material for other extrusion processes. |

▏Advantages of the SJ65-38 Single Screw Extruder

| 1. High-Quality Extrusion

The SJ65-38 extruder is designed to produce high-quality products with consistent dimensions and properties. Its precise control over temperature, pressure, and screw speed ensures that the extruded materials meet the highest standards. |

| 2. Versatility

With its ability to process a wide range of thermoplastic materials, the SJ65-38 single screw extruder is highly versatile. It can be used for producing pipes, profiles, sheets, films, and pellets, making it suitable for a broad range of applications. |

| 3. Improved Productivity

The high processing capacity and fast extrusion speeds of the SJ65-38 extruder improve overall production efficiency, reducing the time required to produce large quantities of plastic products. |

| 4. Energy Efficiency

Thanks to its energy-efficient design, the SJ65-38 extruder helps reduce energy consumption, lowering operating costs and making it a more environmentally friendly option. |

| 5. Durability

Built with high-quality materials and components, the SJ65-38 extruder is durable and long-lasting, ensuring a reliable performance throughout its lifespan. |

The SJ65-38 single screw extruder is a powerful, efficient, and versatile machine that is essential for various plastic extrusion applications. Its precise temperature control, efficient plasticizing capabilities, and high processing capacity make it an ideal choice for producing high-quality pipes, profiles, sheets, films, and pellets. Whether used in small-scale or large-scale production, the SJ65-38 extruder ensures consistent, reliable performance, making it an indispensable tool for manufacturers in the plastic processing industry. With its durable construction, energy-efficient operation, and user-friendly controls, the SJ65-38 extruder is an excellent investment for businesses looking to improve their extrusion capabilities.

▏Range Of Application

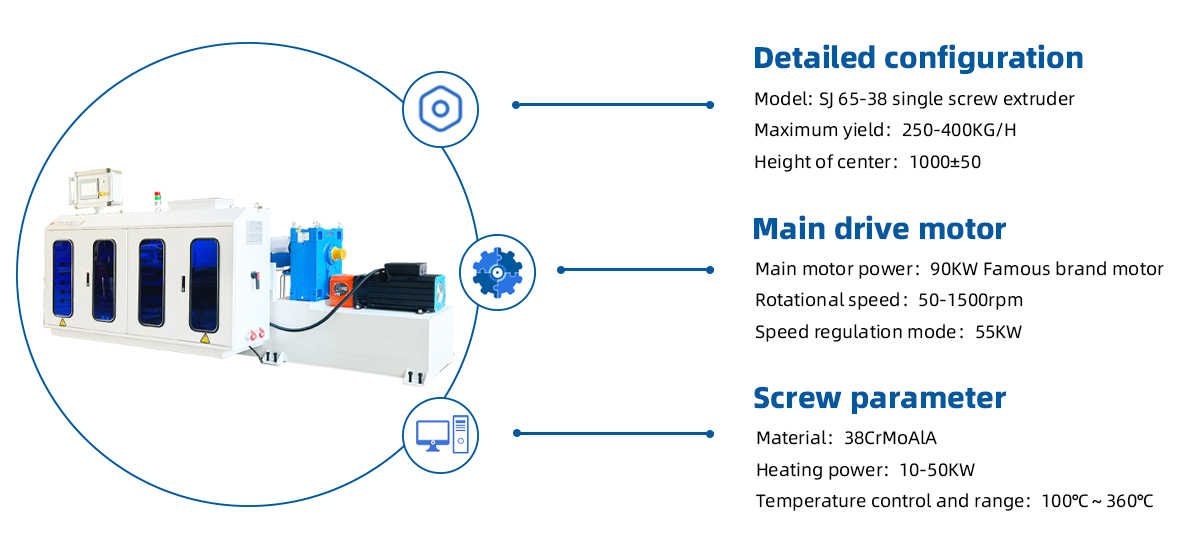

▏Technical Parameters

Model | Diameter (mm) | L/D | Speed (rpm) | Output (kg/h) | Drive Power (kw) | Heating | Central height (mm)

|

District | Power (kw)

|

SJ-30/25 | 30 | 25 | 60 | 8 | 4 | 3 | 3 | 1000 |

SJ-45/25 | 45 | 25 | 90 | 40 | 11 | 3 | 6 | 1000 |

SJ-45/30 | 30 | 100 | 50 | 15 | 4 | 8 | 500/1000 |

SJ-50/28 | 50 | 28 | 127 | 60 | 18.5 | 3 | 8 | 500 |

SJ-55/28 | 55 | 28 | 130 | 95 | 30 | 3 | 12 | 500 |

SJ-65/25 | 65 | 25 | 60 | 55 | 22 | 3 | 10 | 1000 |

SJ-65/30 | 28 | 110 | 200 | 37 | 3 | 15 | 1000 |

SJ-75/30 | 75 | 30 | 100 | 300 | 45 | 3 | 15 | 500 |

SJ-80/30 | 80 | 30 | 100 | 450 | 55 | 4 | 25 | 1000 |

SJ-90/25 | 90 | 25 | 100 | 550 | 55 | 4 | 24 | 1000 |

SJ-90/30 | 30 | 80 | 600 | 75 | 5 | 30 | 1000 |

SJ-90/52 | 52 | 50 | 650 | 37 | 10 | 40 | 1000 |

▏Production Details

▏Product Photos

▏Product Introduction

Plastic MPP/PE pipe extrusion line main extruder machine is a kind of extrusion equipment with high efficiency and high speed, which is widely used in plastic processing industry. The following is a detailed introduction to the extruder:

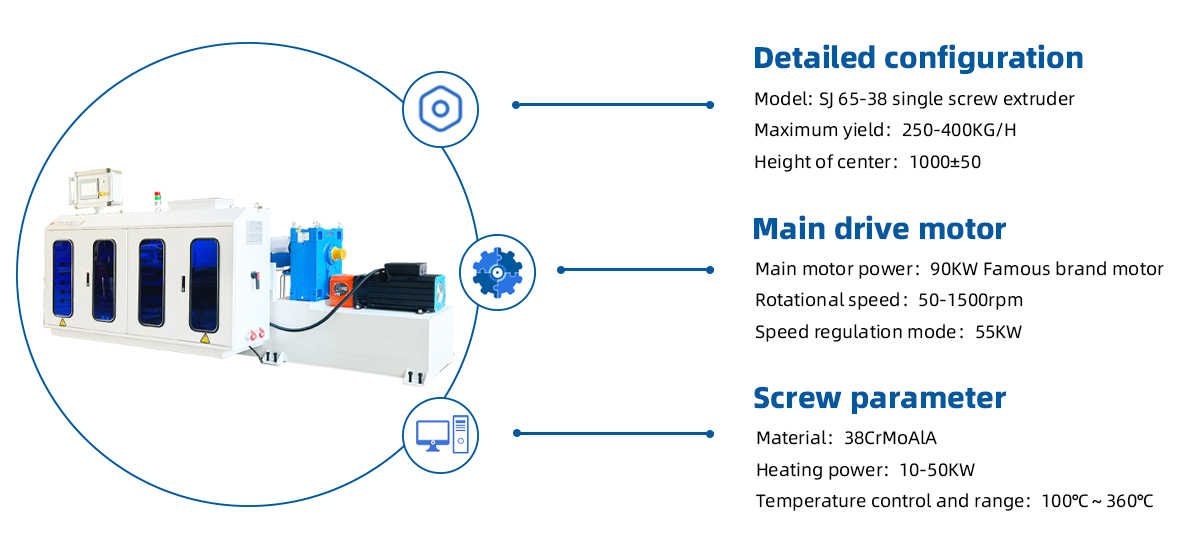

| 1 | Basic parameters |

| 1.1. Model: SJ65-38 1.2. screw diameter: 65mm (usually used to represent the main specifications of the extruder) 1.3. Screw length-diameter ratio: Although the specific value may vary according to the manufacturer's design, the length-diameter ratio usually affects the output and extrusion effect of the extruder. For the SJ65-38 model, the aspect ratio can be expected to be more like 1.1.4. Screw speed: High speed is an important feature of high-speed extruders, SJ65-38 screw speed is usually higher to achieve rapid melting and extrusion effect. The speed may vary according to the device configuration and actual application requirements. |

| 2 | Technical characteristics |

| 2.1 Efficient extrusion: The extruder adopts advanced design concept and manufacturing process, and has the ability of efficient extrusion. Whether dealing with soft or hard plastic materials, it can maintain a stable extrusion speed and product quality. 2.2. High-speed melting: Through the optimized screw structure and heating system, SJ65-38 can quickly melt the plastic raw material into a uniform melt, providing a stable supply of raw materials for the subsequent extrusion process. 2.3 Stability performance: It is very important for the extruder to maintain stability and reliability during operation. SJ65-38 uses high-quality materials and advanced manufacturing technology to ensure good performance and stability during long operation. 2.4. Flexibility: The extruder has high flexibility and can be configured and adjusted according to different production needs. For example, screws and heads of different specifications can be replaced to produce plastic products of different sizes and shapes. |

| 3 | Application fields |

|

Plastic MPP/PE pipe extrusion line main extruder machine are widely used in the plastic processing industry, including but not limited to the following aspects: 3.1. Pipe extrusion: Plastic pipes of various specifications and materials can be produced, such as PVC pipes, PE pipes, etc. 3.2. Sheet extrusion: suitable for the production of plastic sheets, such as PVC sheets, PP sheets, etc. 3.3 Profile extrusion: By replacing different shapes of the head, can produce a variety of profile products. 3.4. Granulation: In a specific configuration, the extruder can also be used in the plastic granulation process. |

| 4 | Precautions |

|

4.1. When using Plastic MPP/PE pipe extrusion line main extruder machine, it should be operated in strict accordance with the equipment operating rules to ensure safe production. 4.2. Maintain and maintain the equipment regularly to maintain the good performance and stability of the equipment. 4.3. Select the right screw and head configuration according to the production demand to achieve the best production effect. |

▏Complete production line recommendation

Click the link below to view the full line description!

High-speed Energy-saving MPP Pipe Extrusion Line

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping