▏Product Vedio

▏Product Introduction

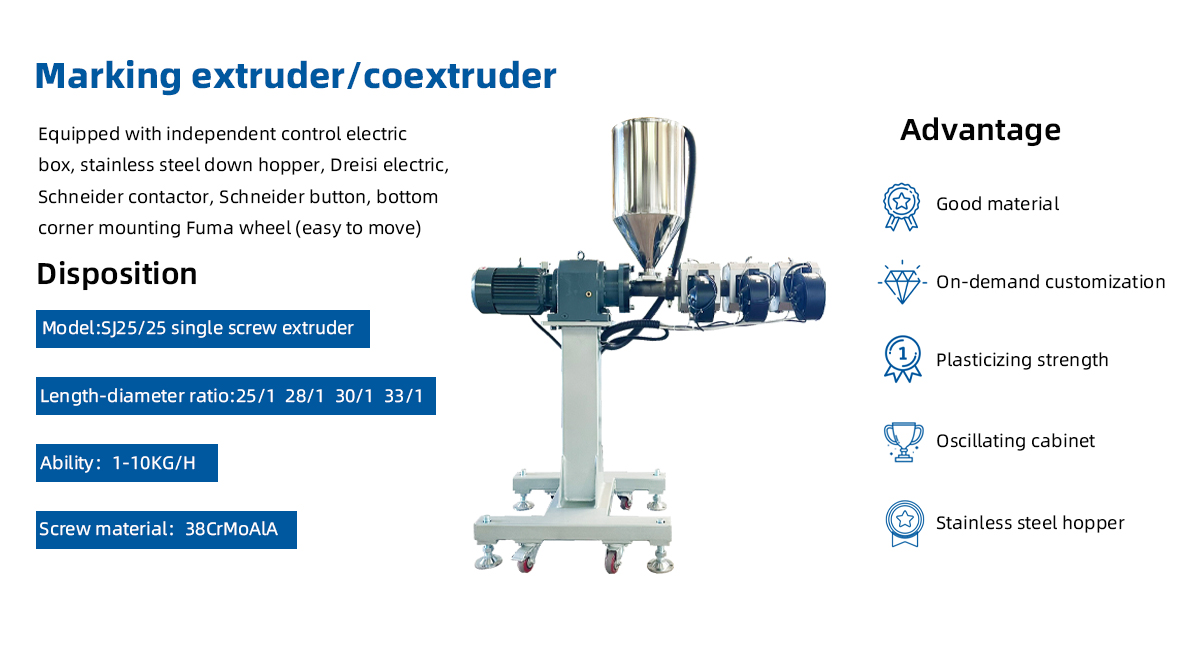

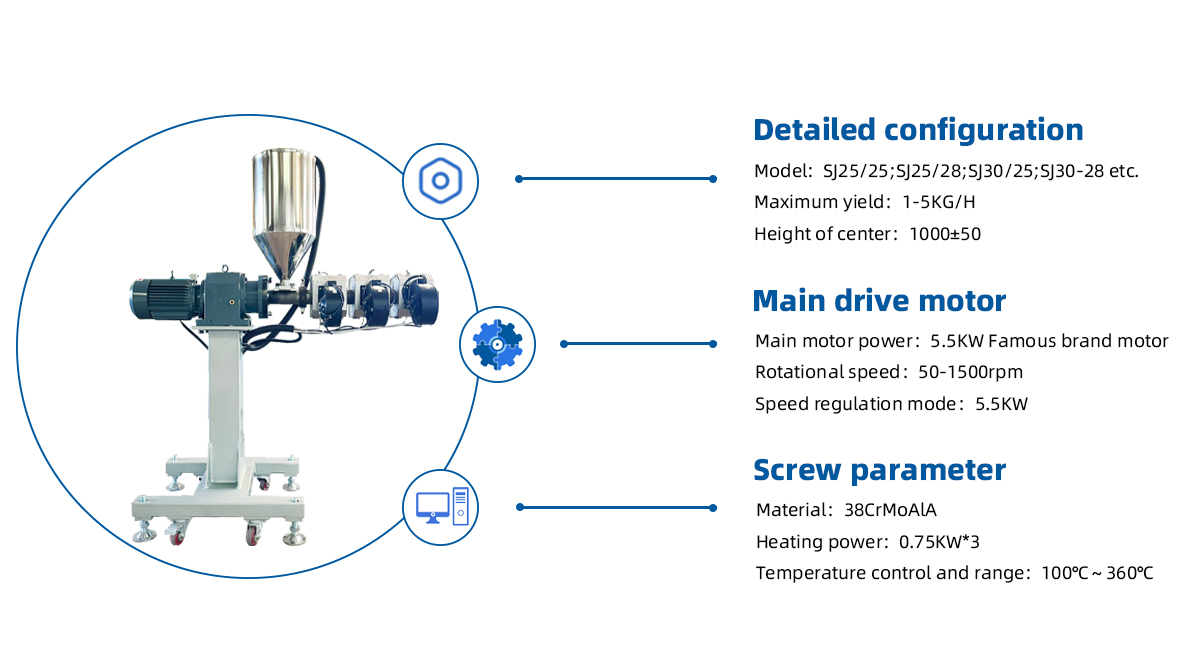

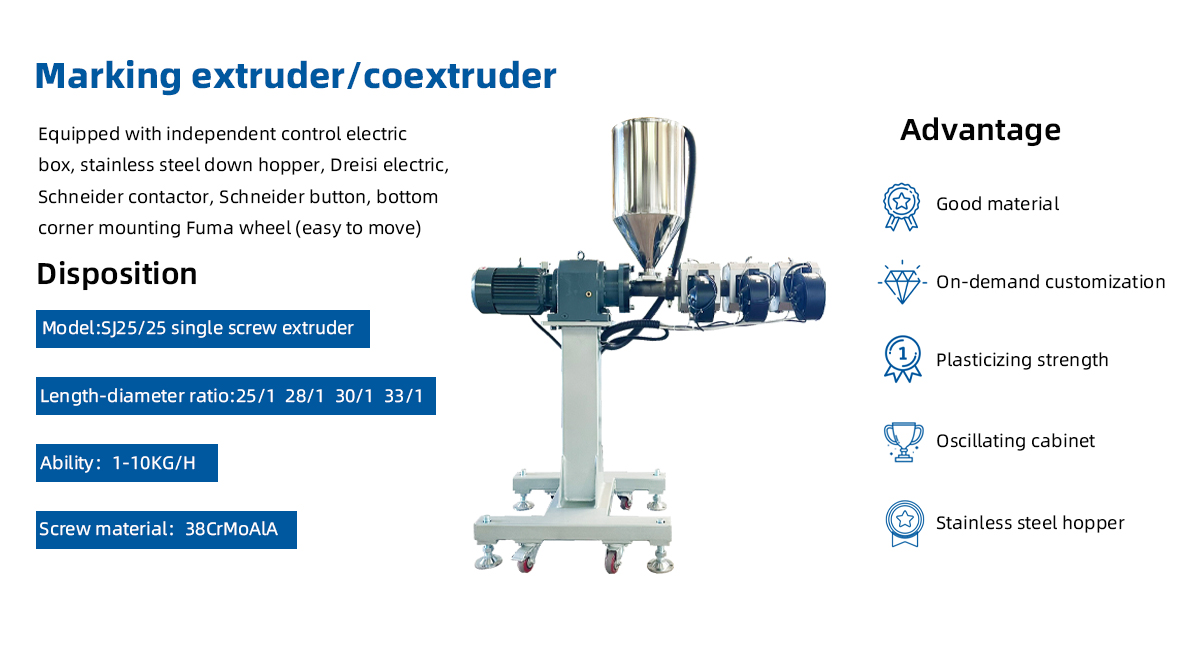

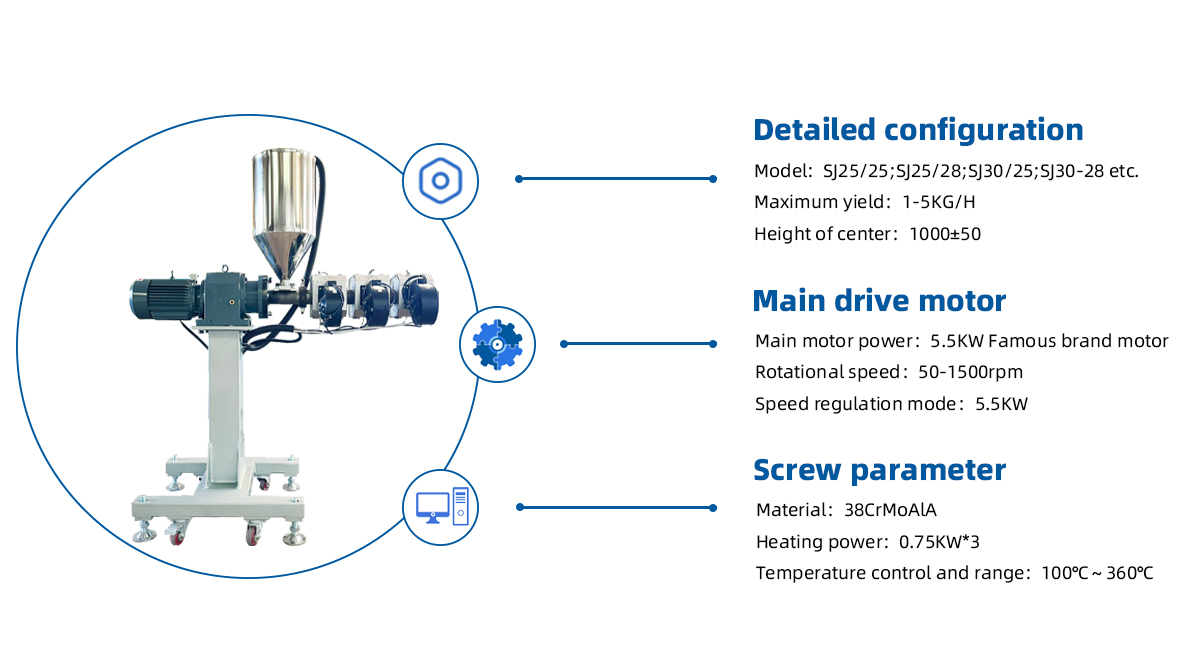

▏SJ25 Single Screw Extruder: Reliable Performance for Small-Scale Plastic Processing

The SJ25 single screw extruder is a highly efficient and versatile piece of machinery designed for small-scale plastic extrusion applications. Its compact design, reliable performance, and ability to process a wide range of materials make it an ideal solution for small to medium-sized manufacturers or for use in research and development environments. The SJ25 extruder is commonly employed in the production of profiles, small pipes, pellets, and a variety of other plastic products, offering excellent precision and control over the extrusion process.

In this product introduction, we will explore the key features, operational principles, and advantages of the SJ25 single screw extruder, highlighting why it is a top choice for manufacturers seeking reliable and cost-effective plastic extrusion equipment.

▏Key Features of the SJ25 Single Screw Extruder

| 1. Compact Design and Space Efficiency

The SJ25 single screw extruder is designed with a compact size that makes it ideal for small-scale production lines, research and development applications, and laboratories. Its small footprint allows it to be installed in spaces where larger extruders may not fit, without sacrificing performance or capabilities. |

| 2. Precision and Control

One of the standout features of the SJ25 extruder is its high level of precision and control over the extrusion process. The screw speed, temperature, and pressure are all adjustable, allowing operators to fine-tune the process to meet specific requirements. This precise control ensures that the extruded products are of consistent quality and dimension. |

| 3. Efficient Plasticizing and Mixing

The screw design of the SJ25 single screw extruder is optimized for efficient plasticizing and mixing. The extruder’s screw geometry promotes the even melting of plastic materials and the uniform dispersion of additives, fillers, or colorants. This results in high-quality, homogenous melts with minimal risk of degradation or inconsistency. |

| 4. Advanced Temperature Control System

The SJ25 extruder features an advanced temperature control system that allows for accurate regulation of the heating zones along the barrel. This is critical to ensure that the plastic is processed at the correct temperature, avoiding issues such as overheating, degradation, or poor flowability. The precise temperature control helps maintain the viscosity of the material for optimal extrusion results. |

| 5. Durable and Reliable Construction

Built to last, the SJ25 single screw extruder is constructed with high-quality materials that ensure durability and long service life. The screw and barrel are made from wear-resistant alloys, which are designed to handle high temperatures and abrasive materials. This robust construction helps to minimize downtime and maintenance costs, ensuring reliable operation over time. |

| 6. Energy-Efficient Operation

The SJ25 extruder is designed to operate with high energy efficiency. The combination of optimized screw design, efficient heating elements, and intelligent control systems helps reduce energy consumption while maintaining excellent performance. This makes the SJ25 a cost-effective choice for small-scale manufacturers looking to minimize operational expenses. |

| 7. Versatile Applications

The SJ25 single screw extruder is highly versatile and can process a wide range of thermoplastic materials, such as PVC, PE, PP, ABS, and more. This makes it suitable for a variety of applications, including pipe production, profile extrusion, film extrusion, and pelletizing. Its flexibility allows manufacturers to experiment with different formulations and materials to meet specific production needs. |

▏Advantages of the SJ25 Single Screw Extruder

| 1. Space-Efficient Design

The compact size of the SJ25 extruder makes it an excellent choice for operations with limited space. Its small footprint allows it to be installed in small-scale production lines or R&D facilities without requiring significant space. |

| 2. Precision and Customization

The ability to adjust key parameters such as temperature, screw speed, and pressure provides manufacturers with precise control over the extrusion process, ensuring that each product meets the desired specifications. |

| 3. Cost-Effective Operation

The SJ25 single screw extruder is energy-efficient and requires minimal maintenance, making it a cost-effective option for small-scale manufacturers and laboratories. |

| 4. Durability and Long Service Life

With its high-quality construction and durable materials, the SJ25 extruder is built to withstand the demands of continuous operation, minimizing downtime and maintenance costs. |

| 5. Versatility

The SJ25 extruder can process a wide variety of thermoplastic materials, making it suitable for a broad range of applications, including pipe, profile, and sheet extrusion, as well as pelletizing and compounding. |

The SJ25 single screw extruder is an excellent solution for small-scale plastic processing. Its compact design, precise control, and versatility make it ideal for a variety of applications, including pipe production, profile extrusion, sheet manufacturing, and pelletizing. With its efficient operation, durable construction, and energy-saving features, the SJ25 extruder offers an affordable and reliable option for small manufacturers, laboratories, and research facilities looking to produce high-quality plastic products with minimal space requirements.

▏Production Details

▏Product Photos

▏Product Introduction

25 Co-extruder is an extrusion equipment specially designed to adapt to the small co-extruder flow and can be interfacing with different forms of the main machine. The following is a detailed introduction to the 25 co-extruder:

| 1 | Basic concepts |

| Name: 25 co-extruder, sometimes referred to as 25/25 color line extruder or 25 model co-extruder single screw extruder. Usage: Mainly used for plastic pipe (such as PE, PPR pipe) co-extrusion production, also suitable for laboratory and other occasions |

| 2 | The main characteristics |

| 2.1. Compact structure: small footprint, easy to arrange and operate in a limited space. 2.2. Easy operation: equipped with a small control system, making the operation more simple and fast. 2.3. Strong versatility: easy runner interface design, so that it can be used with other types of extruders, the production of multi-layer structure of products. 2.4. Easy disassembly and maintenance: The mobile rack design is convenient for disassembly and maintenance when needed. |

| 3 | Technical parameters (Taking a certain model as an example) |

|

Screw diameter: Φ25mm Screw length to diameter ratio: Generally 25:1 (specific ratio may vary by model) Drive motor power: Depending on the model and configuration, the drive motor power varies, such as a model may be 0.75KW or higher. Production capacity: Depending on the raw material and process, production capacity will vary, but generally can meet the needs of laboratory or small-scale production. |

| 4 | The working principle |

|

25 Co-extruder adopts melt co-extrusion technology to mix and homogenize different plastic materials through the same extruder, and then extrude them through the co-extruder die head. In the die head, different plastic materials pass in turn according to the multi-layer structure required by the product, and finally form a product with a multi-layer structure. |

| 5 | Application fields |

|

Plastic pipe production: mainly used for the co-extrusion production of PE, PPR and other plastic pipes, which can produce multi-layer composite materials with a variety of functions and characteristics. Laboratory research: It is also suitable for laboratory and other occasions to carry out co-extrusion experimental research of plastic materials. |

| 6 | Precautions |

|

When using 25 co-extruder, the operation procedures should be strictly followed to avoid safety accidents. Check and maintain the equipment regularly to ensure the normal operation and service life of the equipment. Select the right model and configuration according to the production needs to achieve the best production results and economic benefits. |

▏Complete production line recommendation

Click the link below to view the full line description!

315PE drainage water pipe making machine

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping