▏Product Vedio

▏Product Production

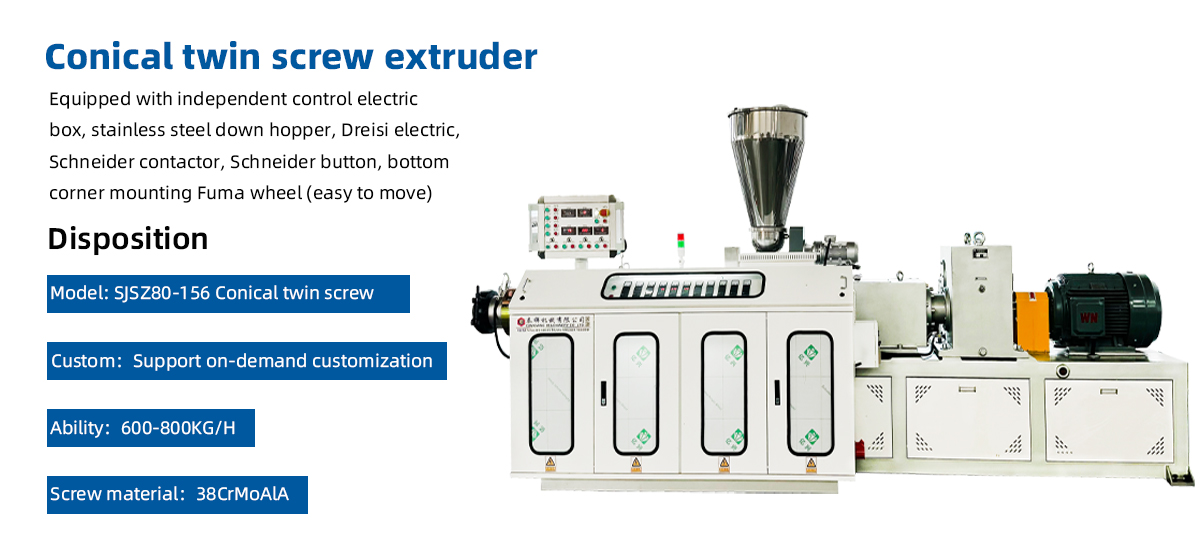

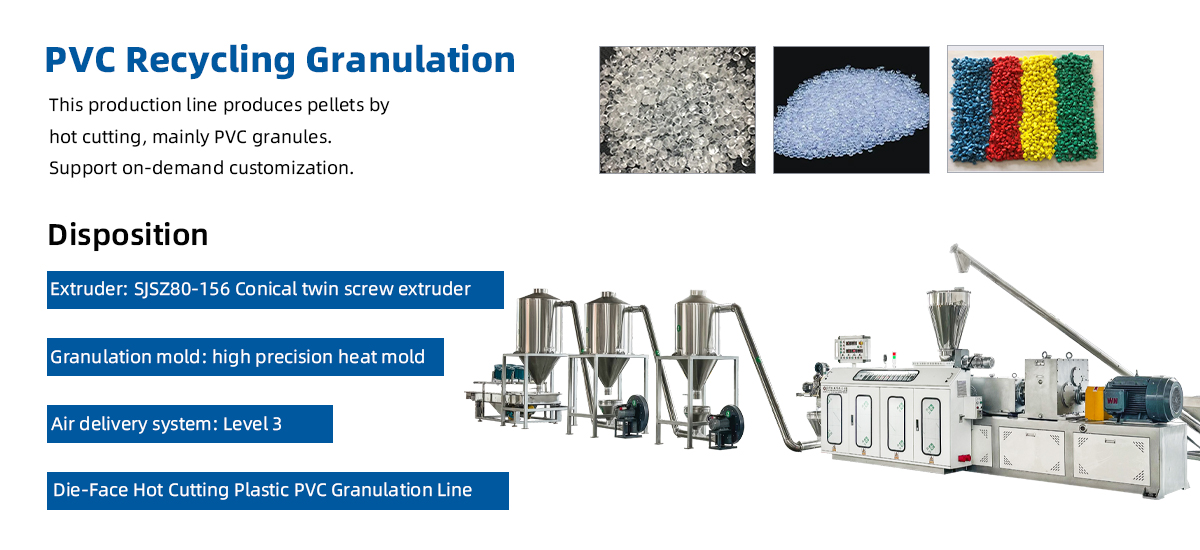

▏SJSZ80-156 Conical Twin Screw Extruder: High-Performance Solution for Plastic Processing

The SJSZ80-156 conical twin screw extruder is an advanced piece of equipment specifically designed for the processing of thermoplastic materials. Known for its high efficiency and precision, this extruder is used in a variety of industries to produce products such as pipes, profiles, sheets, and compounds. The SJSZ80-156 model stands out in its class for its exceptional performance, durable construction, and versatility, making it an ideal solution for manufacturers seeking superior processing of plastics.

In this product introduction, we will explore the key features, benefits, and applications of the SJSZ80-156 conical twin screw extruder, highlighting how this machine can boost production efficiency and product quality.

▏Key Features of the SJSZ80-156 Conical Twin Screw Extruder

| 1. High Torque and Excellent Plasticization

The SJSZ80-156 conical twin screw extruder is engineered for high torque and efficient plasticization. The conical screw design ensures that the plastic material is consistently melted and evenly distributed. This results in high-quality extruded products with smooth surfaces and precise dimensions. The high torque also allows for the processing of high-viscosity materials, ensuring the ability to handle complex compounds and demanding formulations. |

| 2. Efficient Mixing and Homogenization

One of the standout features of the SJSZ80-156 extruder is its ability to deliver excellent mixing and homogenization. The intermeshing, counter-rotating screws create a dynamic shear force that blends materials effectively, ensuring a uniform melt. This is particularly beneficial when working with multi-component materials, such as polymer blends or compounds that require precise color dispersion and additive distribution. |

| 3. Precise Temperature Control

Temperature management is crucial in extrusion processes to prevent material degradation and ensure consistent product quality. The SJSZ80-156 conical twin screw extruder is equipped with a multi-zone temperature control system, which precisely regulates the temperature along the barrel and screws. This ensures that the material is processed at the optimal temperature, reducing the risk of overheating, discoloration, and material breakdown. |

| 4. Advanced Screw Design

The screw design of the SJSZ80-156 extruder is highly advanced and tailored to enhance both processing efficiency and material quality. The screws are specifically designed to optimize the flow and mixing characteristics of the material. Additionally, the use of a conical barrel allows for gradual compression and excellent heat transfer, resulting in efficient energy use and consistent melt quality. |

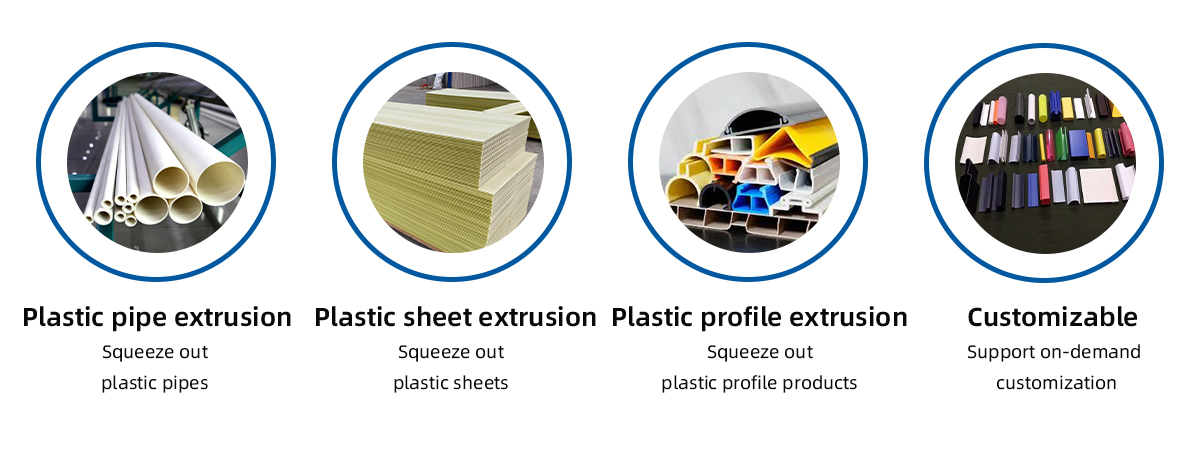

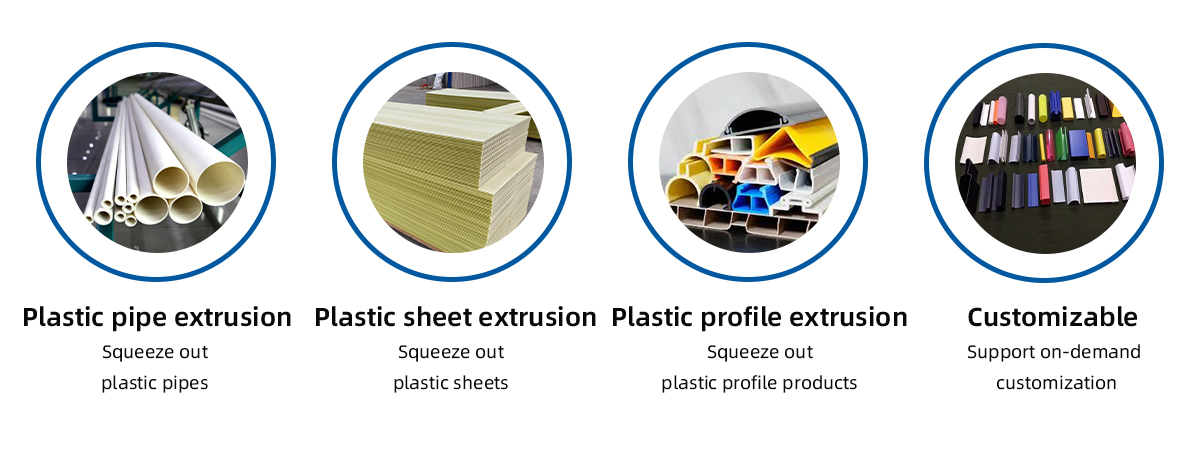

| 5. Flexible and Versatile Applications

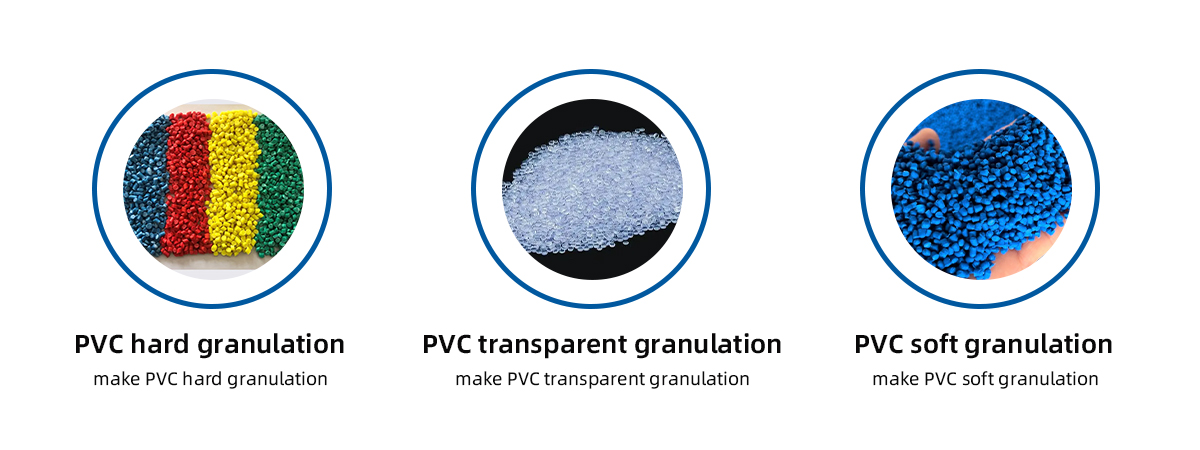

The SJSZ80-156 conical twin screw extruder is designed to handle a wide range of thermoplastic materials, including PVC, PE, PP, ABS, and more. This versatility allows manufacturers to process a variety of plastics for different applications, such as pipe extrusion, profile manufacturing, sheet production, and compounding. The machine can also handle materials with varying additives and fillers, further increasing its flexibility. |

| 6. User-Friendly Control System

The extruder is equipped with an advanced control panel and PLC (Programmable Logic Controller) system, which simplifies operation and monitoring. The intuitive control interface allows operators to easily adjust parameters such as screw speed, temperature, and pressure, ensuring smooth and efficient operation. The system also provides real-time monitoring of key performance indicators, reducing the likelihood of errors and ensuring process consistency. |

| 7. Durability and Long Service Life

The SJSZ80-156 extruder is built with high-quality materials designed to withstand the stresses of continuous operation. The screws are made from hardened steel, providing excellent wear resistance and extending the life of the machine. The barrel is constructed from durable, corrosion-resistant alloys, ensuring that the extruder can handle high temperatures and abrasive materials over time. |

▏How Does the SJSZ80-156 Conical Twin Screw Extruder Work?

The SJSZ80-156 conical twin screw extruder works through a multi-step process that involves feeding, melting, mixing, and shaping the plastic material. Here’s a basic breakdown of the process:

| 1. Material Feeding

Plastic pellets or powder are fed into the extruder’s hopper, where they are directed into the barrel. The hopper is designed to ensure a consistent feed rate, preventing material blockages or inconsistencies that could affect the extrusion process. |

| 2. Melting and Plasticizing

As the material moves along the barrel, the rotating screws begin to melt it through a combination of mechanical shear and heat. The conical screw design promotes gradual compression, which helps to evenly distribute the heat and ensures that the material is plasticized uniformly. The screws are engineered to maintain a consistent flow and minimize melt degradation. |

| 3. Mixing and Homogenization

The intermeshing screws work to mix the molten material, ensuring uniform dispersion of any additives, colorants, or fillers. This is particularly important when producing compounds or colored plastics, as it ensures that the end product has consistent properties throughout. |

| 4. Shaping and Forming

After the material is melted and homogenized, it is forced through a die that shapes it into the desired product, such as a pipe, profile, sheet, or film. The die determines the final shape and dimensions of the extruded material, and the SJSZ80-156 extruder is capable of working with a wide range of dies for different product types. |

| 5. Cooling and Solidifying

After leaving the die, the extruded product is cooled to solidify it. For most applications, this is achieved by passing the extruded material through a cooling bath or using air cooling systems. The cooling process helps to maintain the shape and size of the product, ensuring dimensional accuracy. |

| 6. Cutting or Winding

Finally, the cooled, solidified product may be cut into specific lengths or wound into coils, depending on the type of product being produced. In some cases, additional downstream equipment such as cutting machines or winders are used to further process the extruded material. |

▏Range Of Application

▏Production Details

▏Product Photos

▏Product Introduction

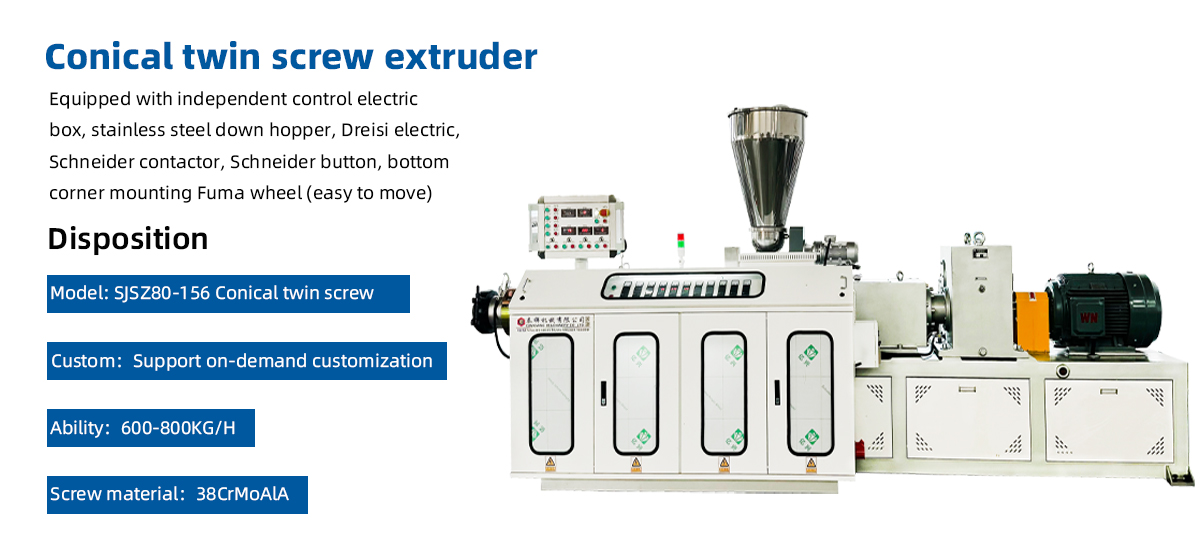

SJSZ80-156 conical twin screw extruder is a kind of efficient and multi-functional plastic processing equipment, mainly used for PVC and other thermoplastics mixing, extrusion molding. The following is a detailed introduction to the extruder:

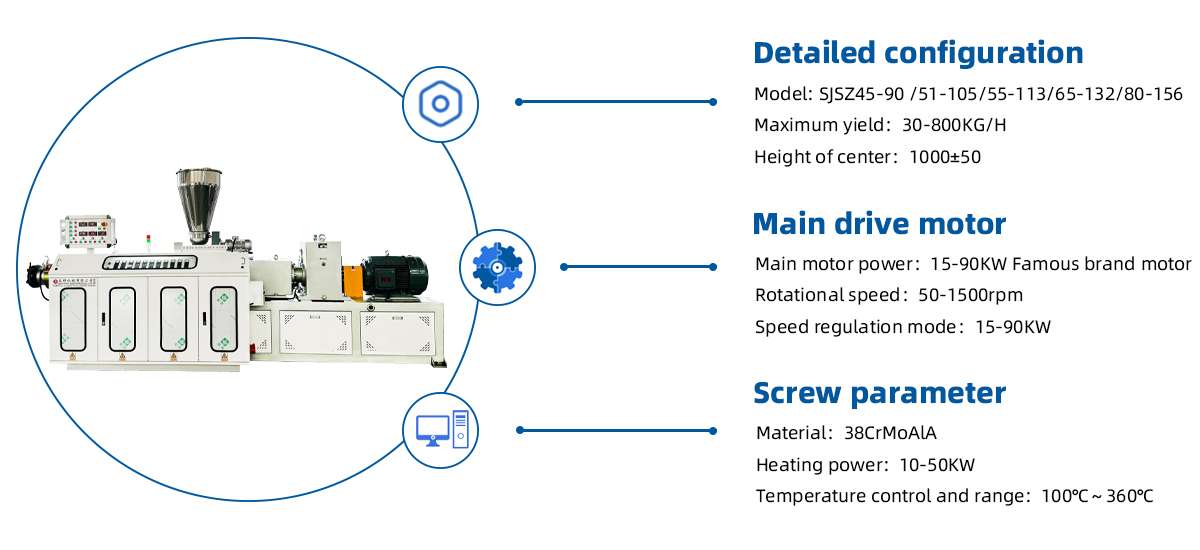

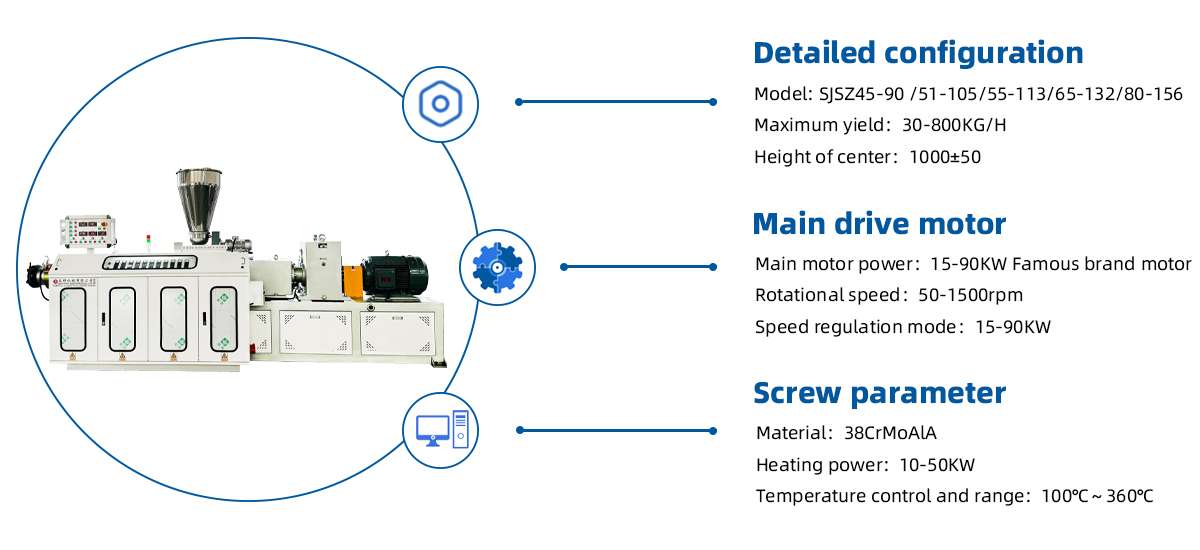

| 1 | Basic parameters |

| Model: SJSZ80-156 Number of screws: twin screws Screw diameter: small head 80mm, big head 156mm Maximum extrusion diameter: Depending on the configuration and mold, the maximum extrusion diameter can be up to 400mm Production capacity: When PVC material is extruded, the production capacity can reach 350\~380Kg/h Motor power: 55KW (also use 75KW configuration, according to the specific model and customer demand) Overall size: According to the overall layout and design of the equipment, the size is usually larger. |

| 2 | Structure composition |

| SJSZ80-156 conical twin screw extruder is mainly composed of the following parts: Forced feeding system: to ensure that the raw material evenly and stably into the screw barrel. Screw barrel: Made of high-strength, high-wear-resistant materials, such as 38CrMoAlA high-quality nitride steel, with a long service life. High precision gear box: provides stable power transmission for the screw to ensure the stability and accuracy of the extrusion process. Vacuum exhaust system: effectively remove moisture and volatiles in raw materials to improve the quality of extruded products. Heating and cooling system: the barrel is heated by casting aluminum heating ring, wrapped by stainless steel cover, beautiful and safe; At the same time, it is equipped with air cooling or water cooling devices to ensure accurate temperature control of the barrel and screw. Electrical control cabinet: including frequency conversion governor, temperature controller and other key control components to achieve automatic control of equipment. |

| 3 | Product characteristics |

|

Uniform mixing: The tapered screw structure helps to improve the plasticization and mixing quality of the material. Strong plasticizing ability: It can efficiently handle all kinds of thermoplastics, especially PVC powder. Stable operation: High-precision gear box and reliable electrical control system ensure the stable operation of the equipment. High output: Under reasonable operation and maintenance, the equipment can achieve high production efficiency. Easy maintenance: equipment structure design is reasonable, easy to daily maintenance and overhaul. |

| 4 | Application field |

|

SJSZ80-156 conical twin screw extruder is widely used in the extrusion production of PVC drainage pipe,water supply pipe, power pipe, profiles, plates, sheets, etc. By replacing different molds and auxiliary machines, other types of plastic products can also be produced. |

▏Complete production line recommendation

Click the link below to view the full line description!

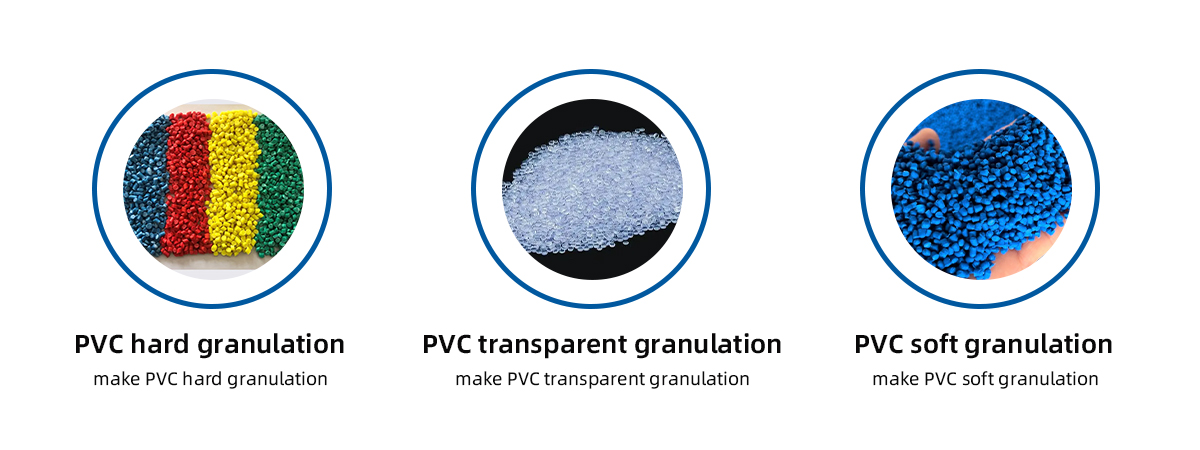

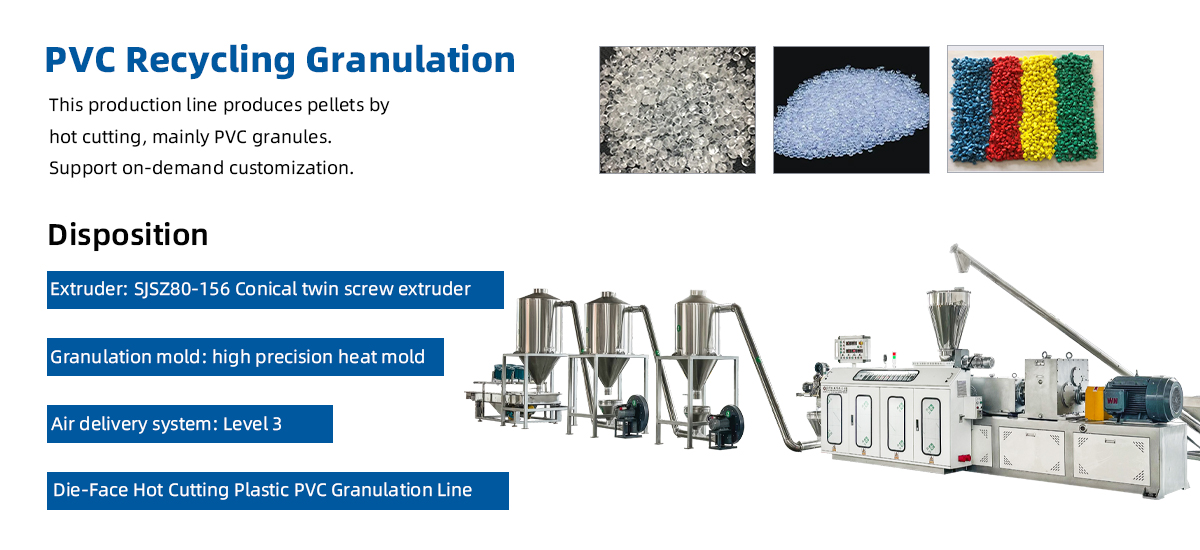

PVC Plastic Pellet Granulation Extrusion Granulators Production Line

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping