▏Product Vedio

▏Product Introduction

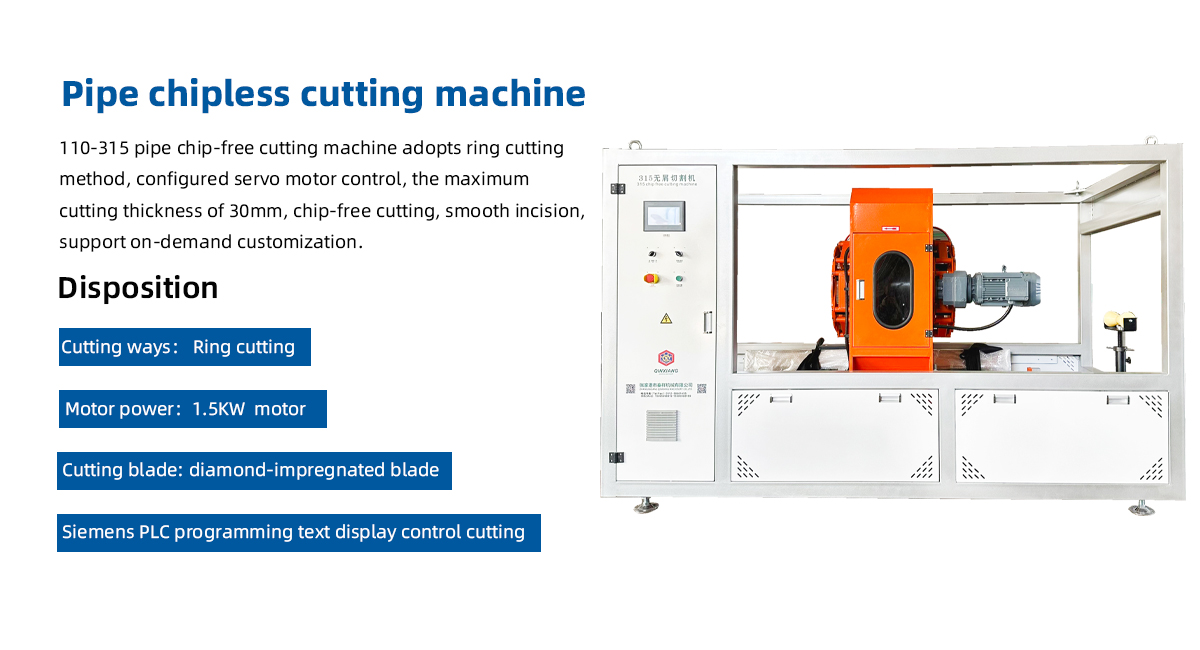

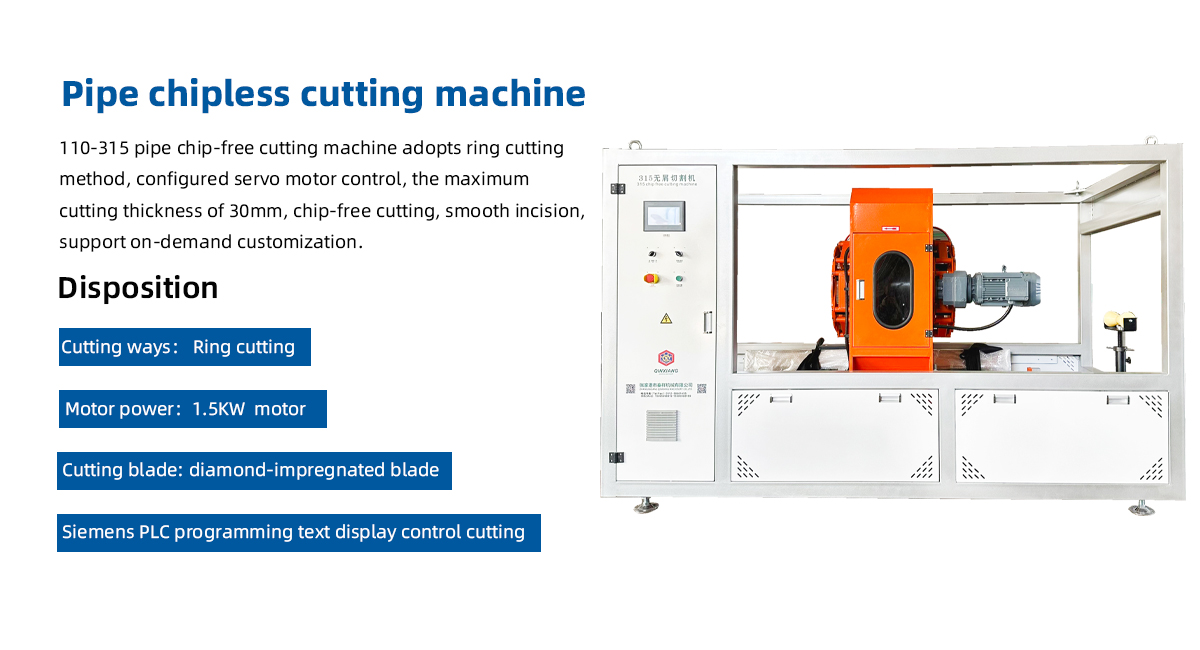

▏Plastic 315PE Drainage Water Pipe Cutting Machine: Precision and Efficiency in Pipe Cutting

The Plastic 315PE drainage water pipe cutting machine is an advanced piece of equipment designed for the precise and efficient cutting of large polyethylene (PE) pipes used in drainage systems. With its robust features and high-performance capabilities, this cutting machine ensures that pipes are cut to the required length and quality for a wide range of drainage applications. This machine is an essential tool for manufacturers and contractors involved in the production and installation of drainage systems, offering optimal results in both small-scale and large-scale operations.

In this product introduction, we will explore the features, benefits, and applications of the Plastic 315PE drainage water pipe cutting machine, providing an in-depth understanding of its functionality and advantages in modern pipe cutting processes.

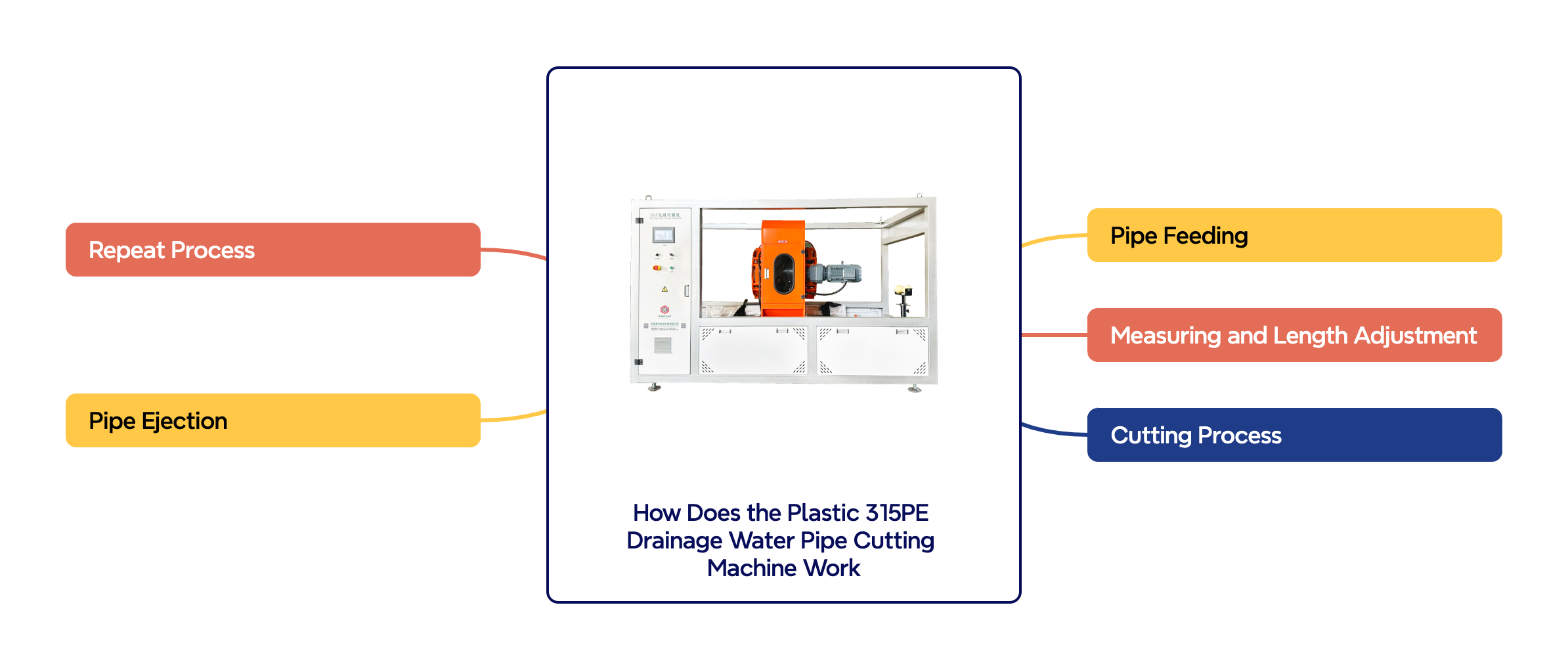

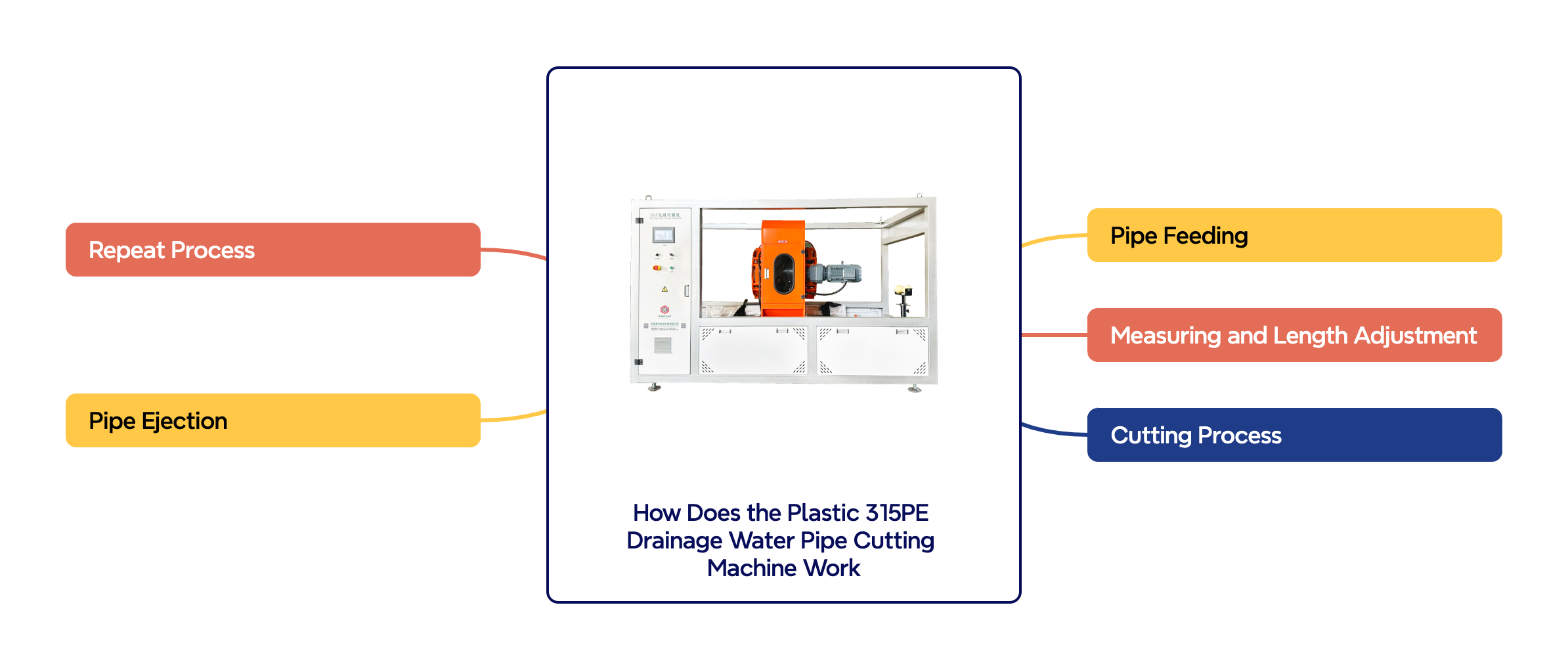

▏How Does the Plastic 315PE Drainage Water Pipe Cutting Machine Work?

The Plastic 315PE drainage water pipe cutting machine works through a straightforward but highly effective process. Below is a step-by-step overview of how the machine operates:

| 1. Pipe Feeding

The operator feeds the polyethylene pipe into the machine’s cutting chamber. The machine is typically equipped with a conveyor system to ensure smooth and controlled movement of the pipe through the machine. Some models also feature an automatic feeding system, which helps to reduce manual labor and improve efficiency. |

| 2. Measuring and Length Adjustment

Once the pipe is in position, the machine measures the length of the pipe and adjusts the cutting mechanism accordingly. The adjustable settings allow operators to program the desired pipe length, whether it is for short or long pieces, depending on the specific project needs. |

| 3. Cutting Process

With the pipe properly aligned and measured, the cutting mechanism begins the process. The Plastic 315PE drainage water pipe cutting machine uses a rotating blade or saw to cut through the polyethylene material with precision. The machine is designed to provide a smooth and clean cut, minimizing burrs or damage to the pipe during the cutting process. |

| 4. Pipe Ejection

After the pipe has been cut, it is ejected from the machine. Some models may include an automatic ejection system to push the cut pipe pieces out of the cutting area and onto a conveyor or collection area for further processing. This step helps to maintain a continuous production flow and reduces handling time. |

| 5. Repeat Process

The machine can then repeat the process, cutting additional pipes to the same length or different lengths as per the programmed settings. Depending on the model, the machine may be capable of cutting multiple pipes at once, enhancing productivity. |

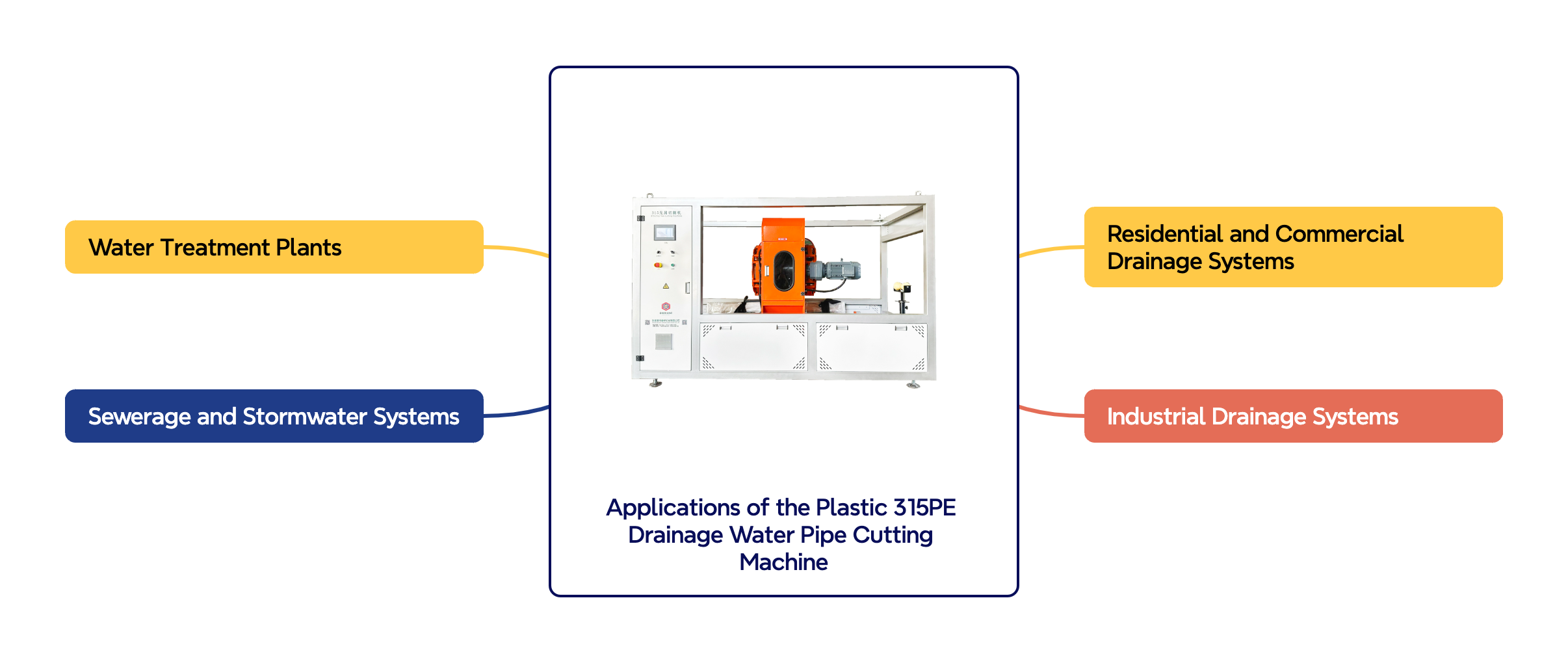

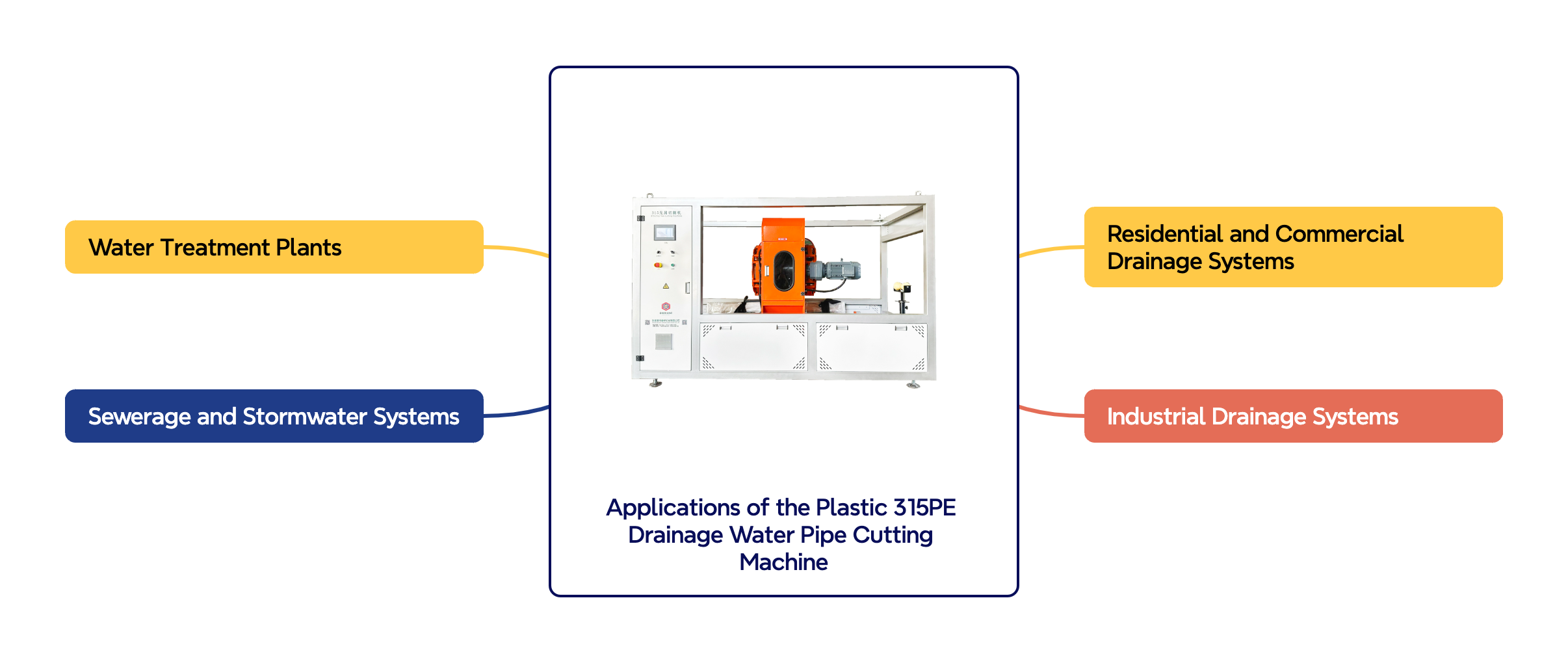

▏Applications of the Plastic 315PE Drainage Water Pipe Cutting Machine

The Plastic 315PE drainage water pipe cutting machine is used in various applications related to the manufacturing and distribution of drainage systems. Its primary application is in the cutting of polyethylene drainage pipes, but it is also used in other areas such as:

| 1. Residential and Commercial Drainage Systems

The Plastic 315PE cutting machine plays a vital role in the production of pipes used in residential and commercial drainage systems. Accurate and reliable cuts are crucial for the proper installation of drainage pipes, and the 315PE cutting machine ensures that pipes are cut to the correct length and dimensions for seamless installation. |

| 2. Industrial Drainage Systems

In industrial settings, the need for larger-diameter pipes is common. The 315PE cutting machine is specifically designed to handle large polyethylene pipes, making it ideal for industrial drainage applications where durability and high throughput are required. |

| 3. Sewerage and Stormwater Systems

For municipal applications such as sewerage and stormwater systems, accurate and efficient pipe cutting is essential. The Plastic 315PE cutting machine ensures that pipes are cut to size for optimal installation and long-term performance in these critical systems. |

| 4. Water Treatment Plants

In water treatment plants, polyethylene pipes are often used for conveying wastewater or clean water. The 315PE cutting machine ensures that pipes are cut accurately and efficiently to meet the exact requirements of these important infrastructure systems. |

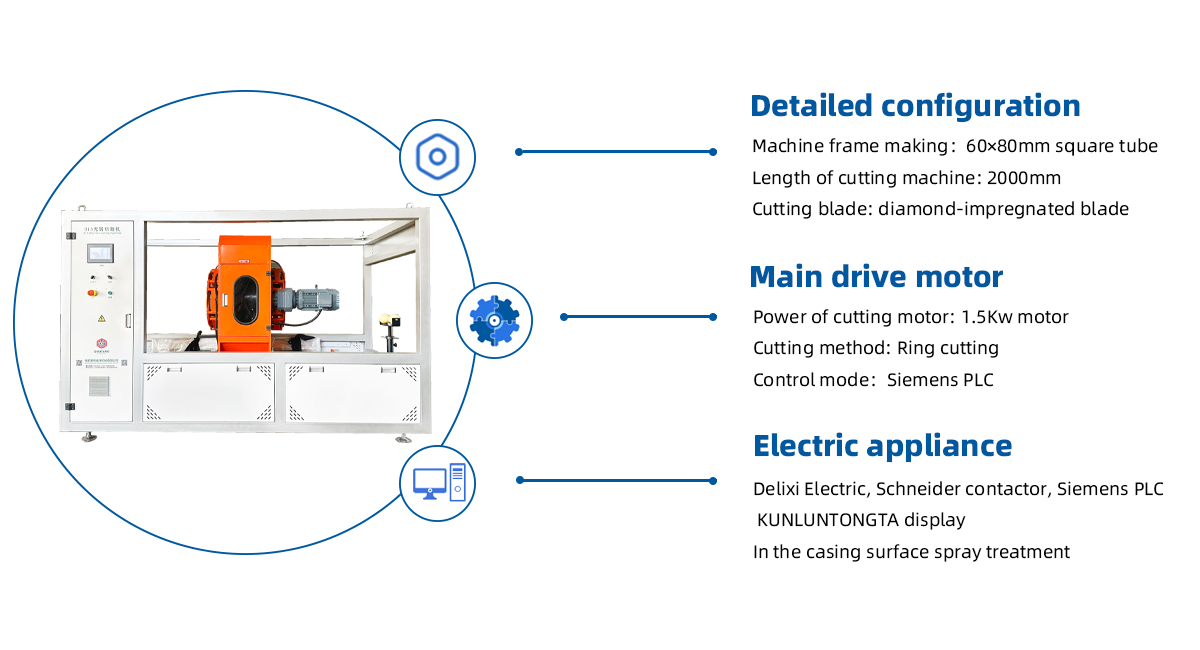

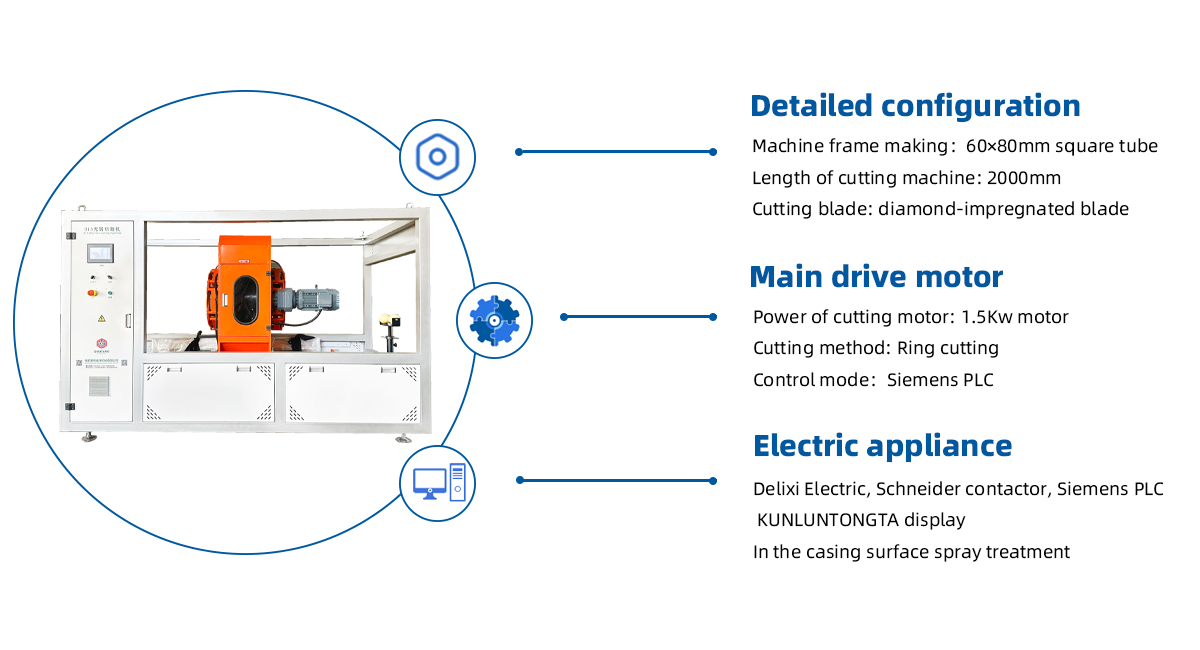

▏Technical Parameters

▏Product Photos

▏Complete production line recommendation

Click the link below to view the full line description!

315PE drainage water pipe making machine

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping