▏Product Vedio

▏Product Introduction

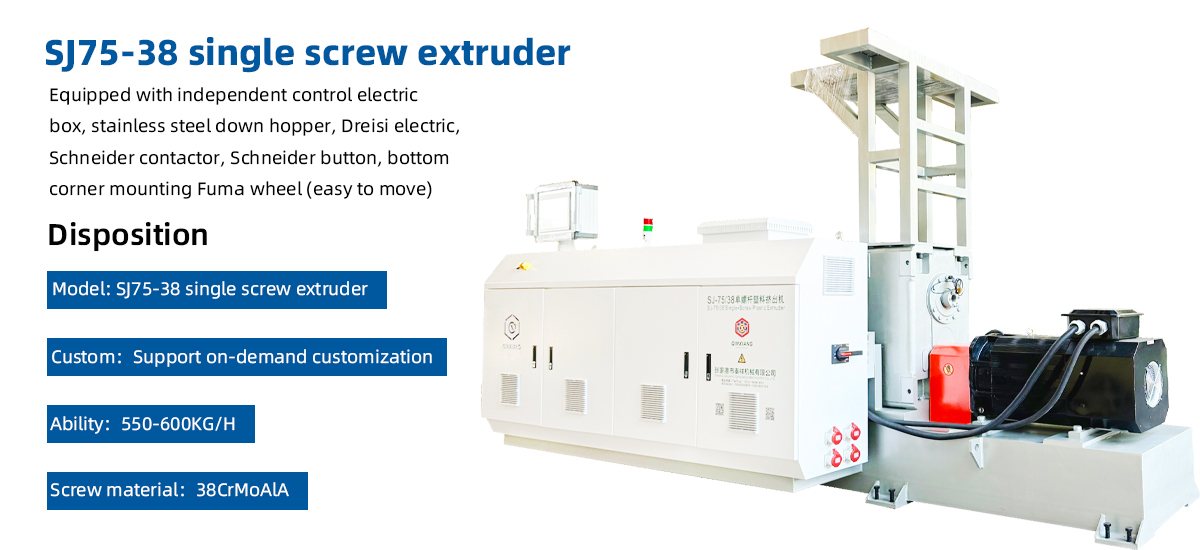

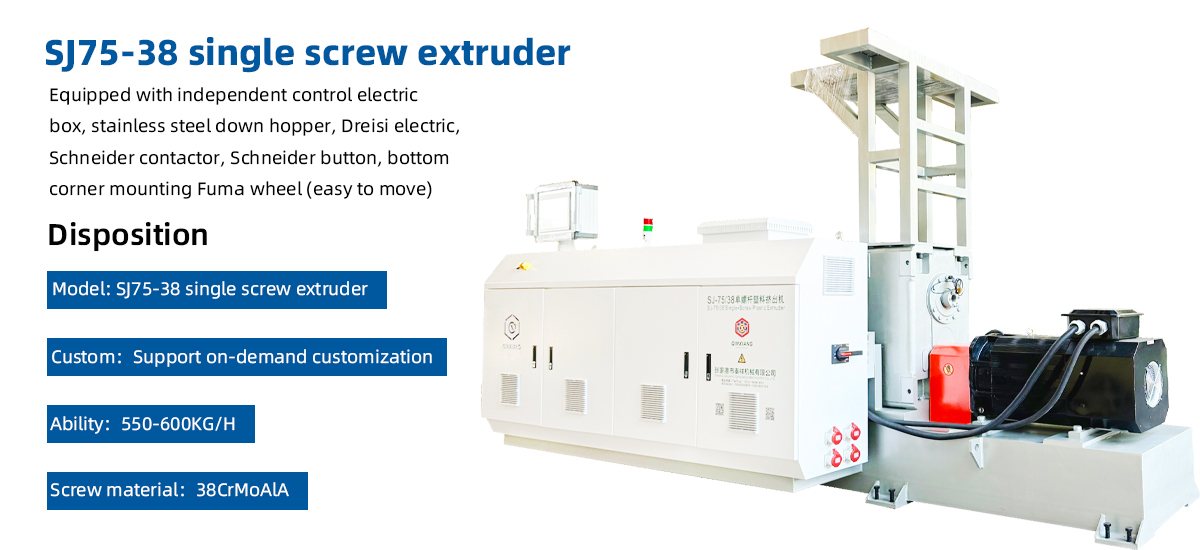

▏SJ75-38 Single Screw Extruder: Precision and Efficiency in Plastic Processing

The SJ75-38 single screw extruder is a high-performance machine widely used in the plastic extrusion industry. Known for its precision, durability, and versatile applications, this extruder is an essential tool for the production of a variety of plastic products, including pipes, sheets, profiles, and films. Designed to deliver consistent, high-quality results, the SJ75-38 extruder offers manufacturers a reliable solution for efficient plastic processing.

In this product introduction, we will delve into the key features, working principles, and applications of the SJ75-38 single screw extruder, along with its advantages in modern plastic extrusion.

▏What is the SJ75-38 Single Screw Extruder?

The SJ75-38 single screw extruder is a mechanical device used to process thermoplastic materials by forcing them through a heated barrel via a rotating single screw. The "75" in the model number refers to the screw diameter (75mm), while "38" represents the screw length-to-diameter ratio (38:1), which is a standard configuration designed for general-purpose extrusion applications.

This type of extruder is ideal for processing materials such as PVC, PE, PP, ABS, and other thermoplastics, making it versatile for various industries. The SJ75-38 extruder is well-suited for producing products such as pipes, sheets, and profiles, as well as for compounding operations.

▏Applications of the SJ75-38 Single Screw Extruder

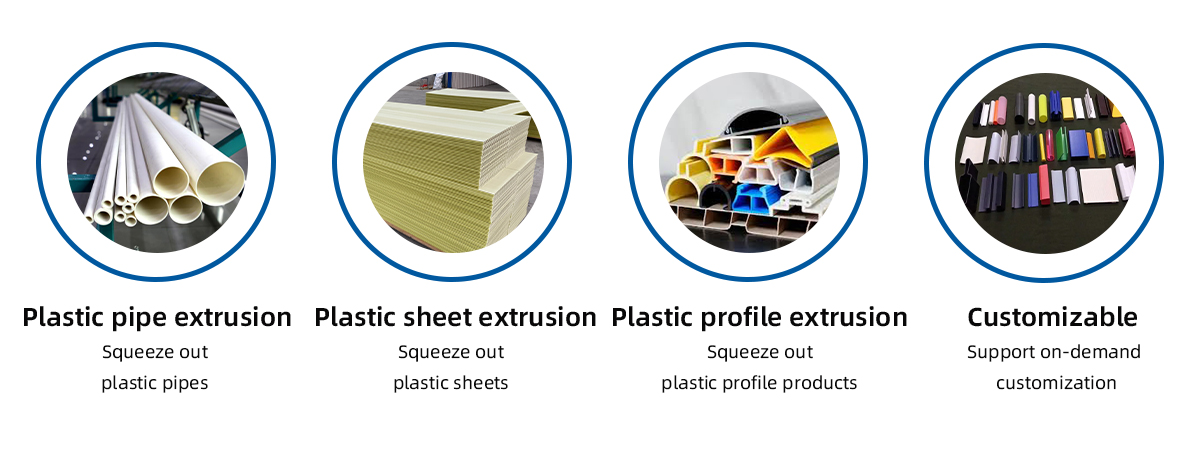

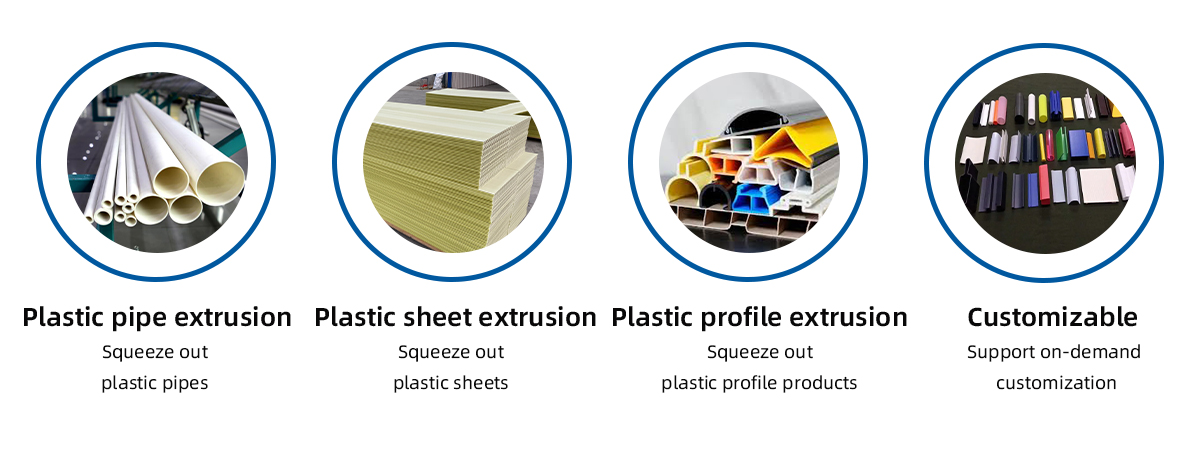

The SJ75-38 single screw extruder is versatile and can be used for a wide variety of applications, including:

| 1. Pipe Extrusion

The SJ75-38 extruder is widely used in the production of pipes made from materials such as PVC, PE, and PP. The extruder’s ability to maintain consistent melt quality and precise temperature control ensures that the produced pipes meet the required standards for strength, durability, and dimensional accuracy. |

| 2. Profile Extrusion

The SJ75-38 single screw extruder is also commonly used for profile extrusion, where plastic is formed into custom shapes such as window frames, door frames, and other architectural profiles. The extruder’s excellent mixing and homogenizing capabilities ensure that the profiles are uniform in color, texture, and strength. |

| 3. Sheet and Film Extrusion

For the production of plastic sheets and films, the SJ75-38 extruder provides the necessary control over melt viscosity and material flow, resulting in a consistent and high-quality product. Plastic sheets and films are used in various industries, including packaging, construction, and signage, and require precise control to achieve the desired thickness and surface finish. |

| 4. Compounding

In addition to extrusion, the SJ75-38 extruder can be used for compounding various materials. This includes blending different polymers or adding fillers, colorants, or stabilizers to the base material. The machine’s excellent mixing and melting capabilities ensure a uniform and homogenous compound, which is critical for high-quality plastic products. |

▏Range Of Application

▏Technical Parameters

Model | Diameter (mm) | L/D | Speed (rpm) | Output (kg/h) | Drive Power (kw) | Heating | Central height (mm)

|

District | Power (kw)

|

SJ-30/25 | 30 | 25 | 60 | 8 | 4 | 3 | 3 | 1000 |

SJ-45/25 | 45 | 25 | 90 | 40 | 11 | 3 | 6 | 1000 |

SJ-45/30 | 30 | 100 | 50 | 15 | 4 | 8 | 500/1000 |

SJ-50/28 | 50 | 28 | 127 | 60 | 18.5 | 3 | 8 | 500 |

SJ-55/28 | 55 | 28 | 130 | 95 | 30 | 3 | 12 | 500 |

SJ-65/25 | 65 | 25 | 60 | 55 | 22 | 3 | 10 | 1000 |

SJ-65/30 | 28 | 110 | 200 | 37 | 3 | 15 | 1000 |

SJ-75/30 | 75 | 30 | 100 | 300 | 45 | 3 | 15 | 500 |

SJ-80/30 | 80 | 30 | 100 | 450 | 55 | 4 | 25 | 1000 |

SJ-90/25 | 90 | 25 | 100 | 550 | 55 | 4 | 24 | 1000 |

SJ-90/30 | 30 | 80 | 600 | 75 | 5 | 30 | 1000 |

SJ-90/52 | 52 | 50 | 650 | 37 | 10 | 40 | 1000 |

▏Production Details

▏Product Photos

▏Product Introduction

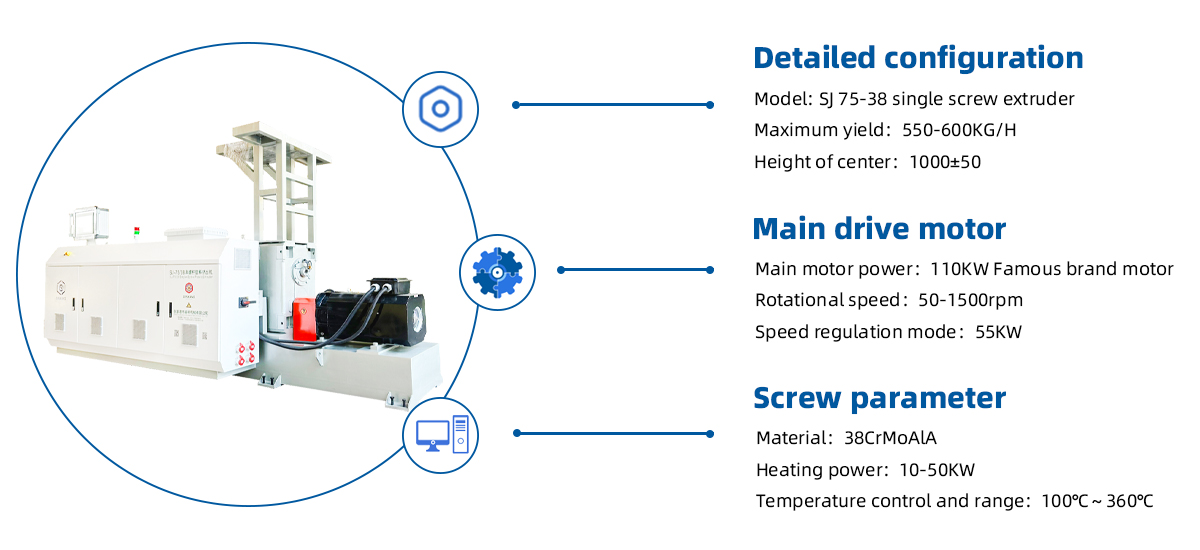

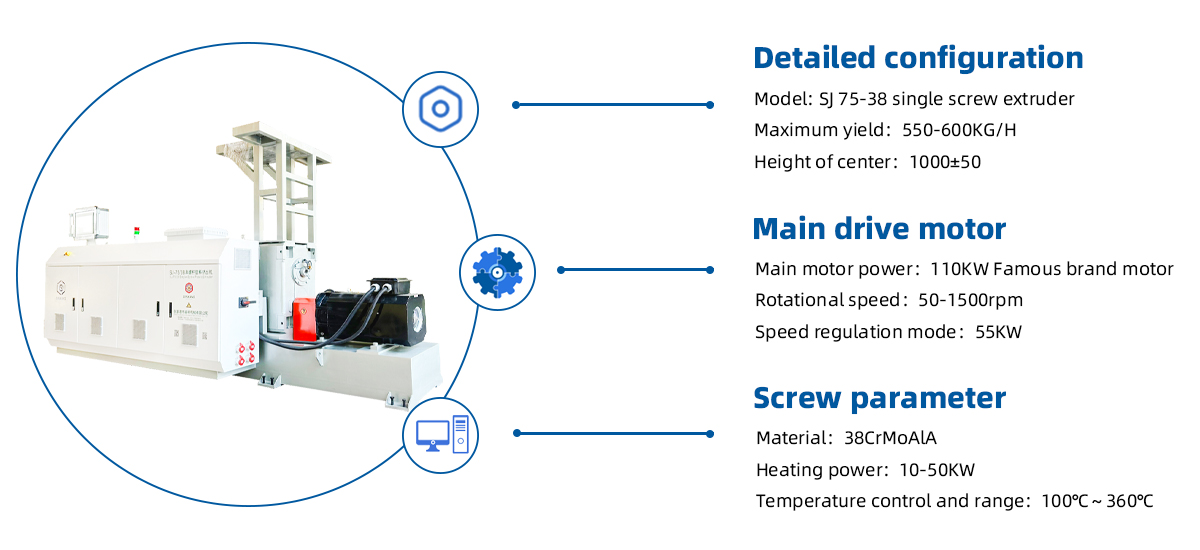

SJ75-38 single screw extruder is a special equipment for plastic processing, mainly used for the production of profile, pipe, plate and other plastic products or granulation operation. Here is a detailed description of the device:

| 1 | Basic specifications |

| 1.1. Model: SJ75-38 1.2. screw diameter: 75 mm 1.3. screw speed range: according to different configurations, usually can be adjusted within a certain range 1.4. production capacity: 550kg/h to 600kg/h or higher |

| 2 | Technical characteristics |

| 2.1. Applicable materials: Mainly used for PP, PE, ABS and other plastics processing, can be adapted to a variety of plastic materials. 2.2. Production flexibility: With various auxiliary machines, it can directly produce plastic products or granulation such as profiles, pipes, sheets, etc., with simple production process, high output, stable quality and low cost. 2.3. Efficient and durable: screw and barrel material is excellent, usually using high-performance alloy steel, such as 38CrMoAlA nitride steel, and after special treatment, with wear resistance, corrosion resistance, high strength and other advantages. 2.4. Electrical control: Advanced electrical control system, can be configured according to user needs, such as PLC touch screen control, variable frequency speed control stepless speed control, easy to operate, accurate control. |

| 3 | Structure composition |

|

3.1. the main part: including screw, barrel, reducer, motor and other key components, is the main part of plastic melting extrusion. 3.2. auxiliary parts: according to the production needs to configure different auxiliary machines, such as feeders, heads, cooling devices, granulators, etc., in order to achieve plastic processing and molding. 3.3. electrical control cabinet: responsible for the electrical control of the entire equipment, including temperature control system, drive system, interlocking control system, etc. |

| 4 | Application field |

|

SJ75-38 single screw extruder is widely used in the plastic processing industry, such as the production of pipes, profiles, sheets, and plastic recycling and granulation fields. |

| 5 | Precautions |

|

5.1. in the use of SJ75-38 single screw extruder, should be strictly in accordance with the equipment operating rules to operate, to ensure safe production. 5.2. regular maintenance of the equipment, to maintain the good condition of the equipment, extend the service life of the equipment. 5.3. according to the production needs to choose the appropriate formula and process parameters to ensure product quality and production efficiency. |

▏Complete production line recommendation

Click the link below to view the full line description!

315PE drainage water pipe making machine

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping