▏Product Vedio

▏Product Introduction

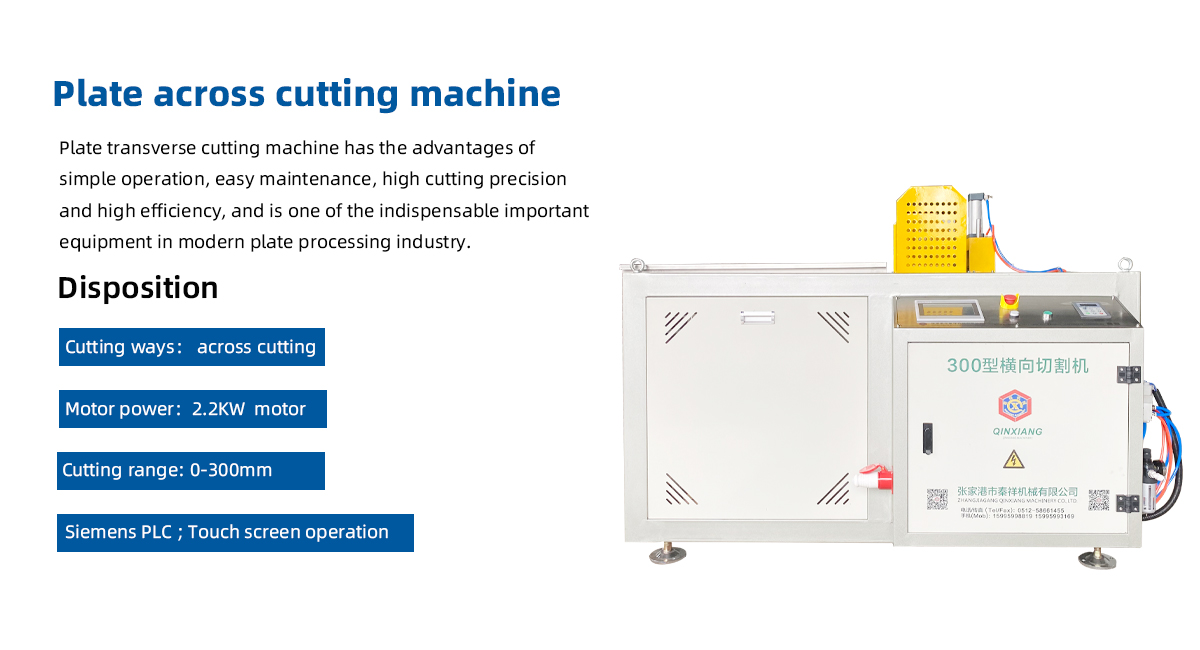

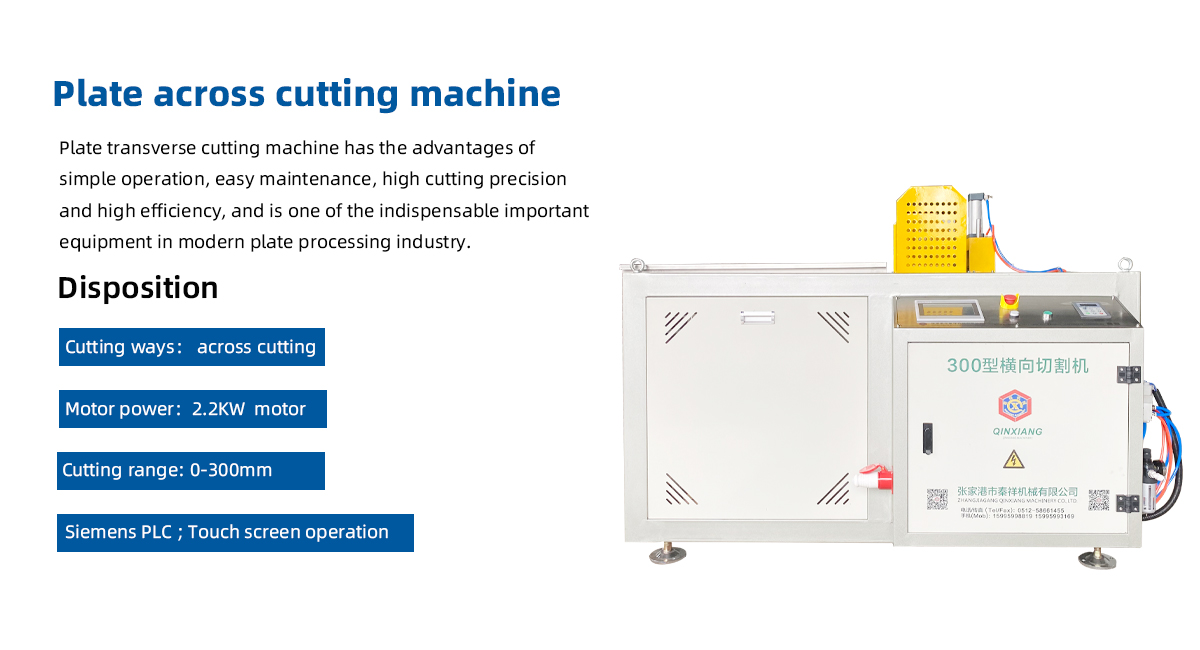

▏Plastic ABS Plate Cutting Machine: Precision and Efficiency in Sheet Cutting

The Plastic ABS plate cutting machine is a highly specialized piece of equipment designed to cut ABS (Acrylonitrile Butadiene Styrene) plastic sheets into precise sizes and shapes. ABS is a popular thermoplastic material used in various industries for its strength, impact resistance, and ease of processing. This cutting machine plays a crucial role in the plastic sheet manufacturing process, ensuring that the final products meet the required dimensional accuracy and surface quality. This product introduction explores the key features, benefits, and applications of the Plastic ABS plate cutting machine, highlighting its importance in the plastic sheet production industry.

▏What is a Plastic ABS Plate Cutting Machine?

A Plastic ABS plate cutting machine is a mechanical tool used to cut large sheets of ABS plastic into smaller, custom-sized pieces. The machine is equipped with a sharp, durable cutting blade or saw that allows for precise cuts along the length and width of the plastic sheet. These machines are essential for transforming extruded ABS plates into usable components for a wide range of industries, from automotive to electronics and packaging.

ABS plastic sheets come in various thicknesses, sizes, and formulations, and the cutting machine is designed to handle these variations efficiently. The Plastic ABS plate cutting machine ensures that the sheets are cut with high precision, minimal waste, and clean edges, ready for further processing or direct use in production.

▏Applications of the Plastic ABS Plate Cutting Machine

| 1. Automotive Industry

In the automotive industry, ABS sheets are used for components such as dashboards, interior panels, and bumpers. The Plastic ABS plate cutting machine ensures that these sheets are cut to the precise dimensions needed for manufacturing these complex parts. With its high precision, the machine helps maintain tight tolerances, which is crucial for fitting and assembly in automotive production lines. |

| 2. Electronics and Appliances

ABS plastic is commonly used for electronic enclosures, appliance covers, and other components. The cutting machine plays a critical role in producing these parts, ensuring that the ABS sheets are cut to the right size and shape for use in assembly lines. The clean cuts and minimal waste generated by the machine help reduce production costs and improve efficiency. |

| 3. Packaging

In the packaging industry, ABS sheets are often used for protective packaging materials, boxes, and containers. The Plastic ABS plate cutting machine ensures that these sheets are cut accurately to meet the specific requirements for packaging solutions, making them suitable for different product sizes and types. |

| 4. Construction and Signage

ABS sheets are used in the construction industry for applications such as wall panels, roof coverings, and signage. The cutting machine ensures that the ABS sheets are cut to the right dimensions and shapes for these applications. In signage production, for example, the machine is used to create custom-cut signs that are both durable and aesthetically appealing. |

▏Advantages of the Plastic ABS Plate Cutting Machine

| 1. High Precision and Accuracy

The cutting machine ensures that ABS sheets are cut to exact specifications, providing high-quality, consistent results with minimal material waste. The precision of the machine makes it ideal for industries where exact dimensions are crucial, such as automotive and electronics manufacturing. |

| 2. Increased Productivity

With its automated feeding system and high cutting speed, the Plastic ABS plate cutting machine enhances productivity by reducing manual labor and increasing throughput. The machine can operate continuously, cutting large volumes of ABS sheets in a short period. |

| 3. Versatility

The machine can handle a wide range of ABS sheet sizes and thicknesses, making it suitable for various applications in different industries. Whether you need to cut thin sheets for packaging or thicker, more rigid panels for construction, the cutting machine can be easily adjusted to meet the required specifications. |

| 4. Cost-Effective

By reducing material waste and improving production efficiency, the Plastic ABS plate cutting machine helps lower production costs. Its high precision minimizes the need for rework or scrap, contributing to a more cost-effective production process. |

| 5. Safety Features

The cutting machine comes with advanced safety features that protect operators from potential accidents, ensuring a safe working environment. Features like emergency stop buttons, safety shields, and sensors help prevent injuries and keep the production process running smoothly. |

The Plastic ABS plate cutting machine is an indispensable tool in the production of ABS plastic sheets, offering high precision, efficiency, and versatility. With its advanced cutting technology, adjustable settings, and durable construction, this machine ensures that ABS sheets are cut to the exact dimensions needed for various industries, including automotive, electronics, packaging, and construction. By improving productivity, reducing material waste, and providing high-quality cuts, the Plastic ABS plate cutting machine is a valuable asset for manufacturers looking to enhance their plastic sheet production processes.

▏Production Details

▏Product Photos

▏Product introduction

| 1 | Product introduction |

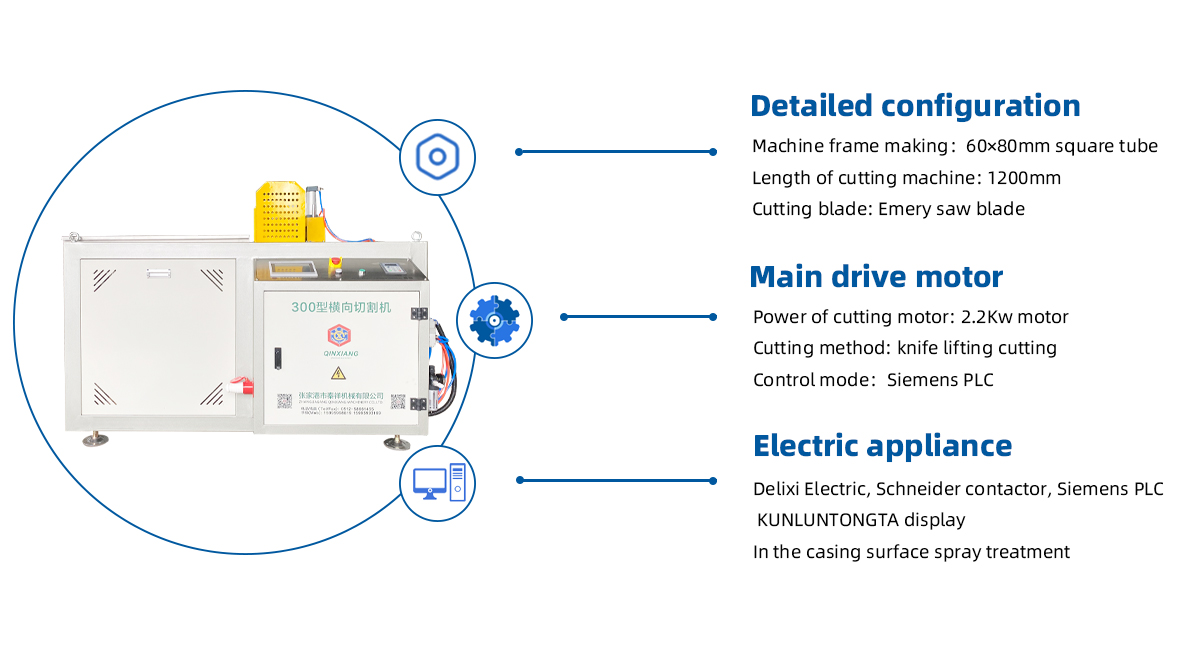

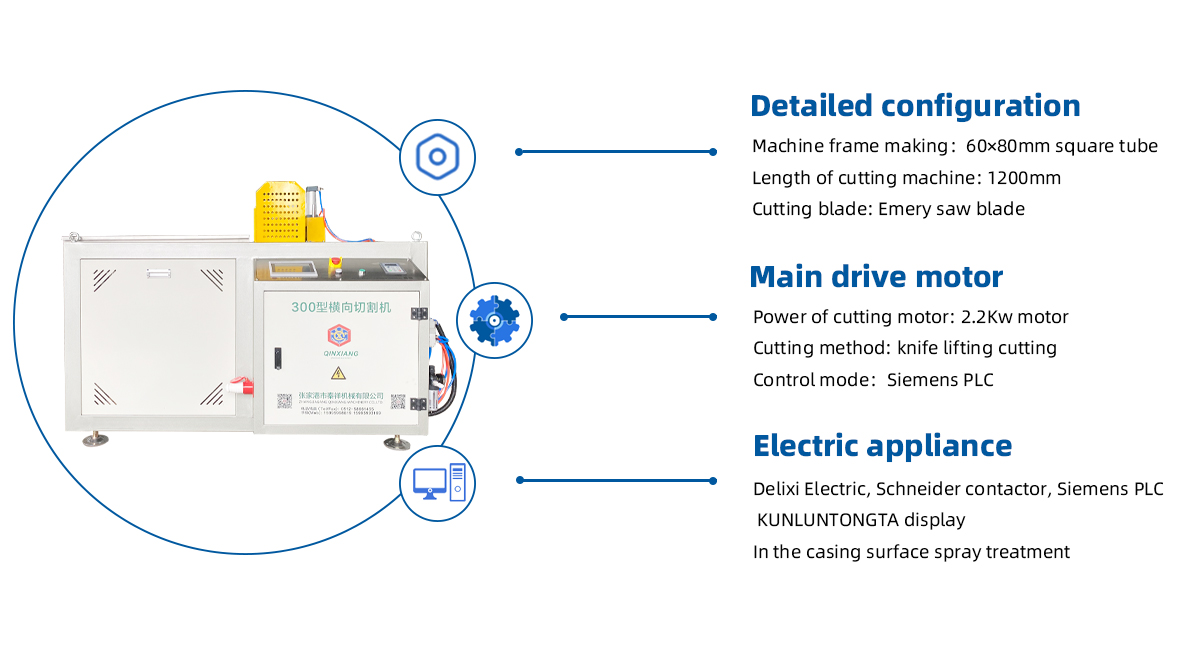

| Plastic ABS plate extrusion line cutting machine is a kind of special equipment for precise transverse cutting of various plates. The equipment adopts advanced cutting technology and control system, which can realize efficient and accurate cutting operation, and is widely used in furniture manufacturing, architectural decoration, wood processing, metal processing and other fields. Plastic ABS plate extrusion line cutting machine has the advantages of simple operation, easy maintenance, high cutting precision and high efficiency, and is one of the indispensable important equipment in modern plate processing industry. |

| 2 | Specification parameters |

| The specifications of the Plastic ABS plate extrusion line cutting machine vary according to the model and the manufacturer. The following are some common parameters: 1. Maximum cutting length: According to the model and user needs, the maximum cutting length can range from several meters to tens of meters. 2. Cutting accuracy: Using precision guide rail and servo motor control system, the cutting accuracy can reach ±0.1mm, to ensure that the cutting size of the plate is accurate. 3. Cutting thickness: Depending on the model and blade configuration, the cutting thickness can range from a few millimeters to hundreds of millimeters, to meet the cutting needs of different plates. 4. Power supply voltage: Generally three-phase AC, voltage range XXV±XX%, frequency XXHz. 5. Motor power: Depending on the model and cutting capacity, the motor power can range from several kilowatts to tens of kilowatts. |

| 3 | Equipment characteristics and application fields |

|

1. Equipment features: High efficiency: High-speed motor and precision guide rail ensure cutting speed and efficiency. Accuracy: Advanced servo control system ensures the accuracy of cutting dimensions. Stability: Strong fuselage structure and stable transmission system to ensure long-term stable operation of equipment. Easy to operate: humanized design, easy to understand operation, reduce manual error. Adaptability: Suitable for cutting plates of different materials and thicknesses. 2. Application field: Furniture manufacturing: for the production of tables, chairs, cabinets, beds and other furniture plate cutting. Architectural decoration industry: Used for cutting floor, wall panel, ceiling and other decorative materials. Wood processing industry: for the transverse cutting and processing of wood. Metal processing industry: suitable for the transverse cutting and processing of metal sheets. |

| 4 | Installation and operation methods |

|

1. Installation method: Select a smooth and stable installation position to ensure stable device placement. Install the device according to the drawings and instructions, and ensure that the components are securely and accurately connected. Turn on the power, connect and debug the electrical part. 2. Operation method: Before starting the equipment, check whether the components are installed correctly and the lubrication system is in good condition. Turn on the power switch, start the device, and conduct no-load test run to check whether the device runs normally. Place the sheet to be cut on the cutting table and adjust the cutting size and position. Start the cutting process and the machine will automatically perform the cutting operation. After cutting, power off the equipment and clean the equipment and work area. |

| 5 | Maintenance and safety precautions |

|

1. Maintenance:Clean and lubricate the equipment regularly to keep the surface and interior of the equipment clean. Check that all components of the device are securely secured. Check electrical parts and control systems regularly to ensure good wiring and no damage. The blades are regularly ground and replaced to ensure cutting quality and efficiency. 2. Safety precautions:Operators should wear labor protection products, such as safety hats, gloves, goggles, etc. Do not extend hands or other objects into the cutting area while the equipment is in operation. Ensure that there are no obstacles around the equipment to prevent collision or damage to the plate. Carry out regular safety inspection and maintenance of equipment to ensure the normal operation of equipment and personnel safety. |

▏Complete production line recommendation

Click the link below to view the full line description!

ABS hollow solid plate extrusion line Plastic Sheet Making Machine

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping