▏Product Vedio

▏SJ25 Laboratory Extruder

▏Introduction to the SJ25 Laboratory Extruder

The SJ25 laboratory extruder is a highly efficient and precise small-scale extrusion machine designed for polymer research, development, and testing. Its compact design, advanced control features, and ability to handle various thermoplastic materials make it an indispensable tool in both academic and industrial laboratories. Whether used for material testing, prototyping, or small batch production, the SJ25 laboratory extruder provides exceptional performance and versatility.

Laboratories and R&D facilities often require machines that can simulate full-scale extrusion processes on a smaller scale. The SJ25 extruder offers the same level of precision and functionality as larger machines but in a more compact and affordable package. This extruder can process a wide variety of thermoplastics, including PVC, PE, PP, PS, and PET, making it suitable for a broad range of polymer processing applications.

▏Key Features of the SJ25 Laboratory Extruder

| Precision Control for Research and Development |

| One of the most notable features of the SJ25 laboratory extruder is its ability to offer precise control over several key parameters in the extrusion process, such as temperature, screw speed, and pressure. This precision allows researchers to fine-tune their material formulations and extrusion conditions to achieve optimal results, making it an ideal choice for experimental purposes.

The machine is equipped with advanced digital controllers that allow users to monitor and adjust each heating zone along the barrel. The precise temperature control ensures that the polymer is consistently heated to the correct processing temperature, reducing the risk of material degradation during extrusion. Furthermore, adjustable screw speeds and torque control provide the flexibility to process different materials and achieve specific material properties. |

| Compact and Space-Efficient Design |

|

The SJ25 laboratory extruder is designed to occupy minimal space, making it an excellent solution for laboratories or facilities with limited room. Despite its compact size, the machine is equipped with all the necessary components for high-quality extrusion, such as a well-engineered barrel, a powerful motor, and an efficient heating system.

The extruder’s small footprint ensures that it fits easily into a laboratory setting without compromising on performance. It also makes the machine highly portable, which is beneficial when the machine needs to be moved between different workstations or departments. |

| Versatility in Material Processing |

|

The SJ25 laboratory extruder is capable of processing a wide range of thermoplastic materials, including PVC, PE, PP, PS, PET, and other engineering plastics. This makes it a versatile tool for a variety of applications, from material testing to small-scale production. The extruder can handle materials in pellet, powder, or regrind form, which gives users the flexibility to experiment with different feedstock types.

Whether used for basic research or complex material development, the SJ25 extruder is versatile enough to meet the needs of various industries, including automotive, packaging, and medical applications. |

| Interchangeable Dies for Custom Profiles |

|

The SJ25 laboratory extruder supports interchangeable dies, allowing users to produce different profiles such as pipes, sheets, films, and rods. This die-swapping capability is especially useful for testing various product designs or producing samples for product evaluation. The ability to quickly change dies ensures that the extruder is adaptable to different projects without the need for multiple machines.

Custom profiles and geometries can be created depending on the research or production needs. This feature is particularly beneficial when working with novel or custom materials that require unique extrusions. |

| Efficient Cooling and Solidification |

|

Once the material is extruded and shaped, it needs to be cooled and solidified quickly to maintain its desired dimensions. The SJ25 laboratory extruder is equipped with an efficient cooling system that rapidly cools the extruded material, preventing deformation and ensuring dimensional accuracy.

Depending on the material being processed, the cooling system may include air cooling or water bath cooling. The cooling rate can be adjusted to suit the requirements of the specific material, enabling users to control the solidification process to achieve the desired mechanical properties in the final product. |

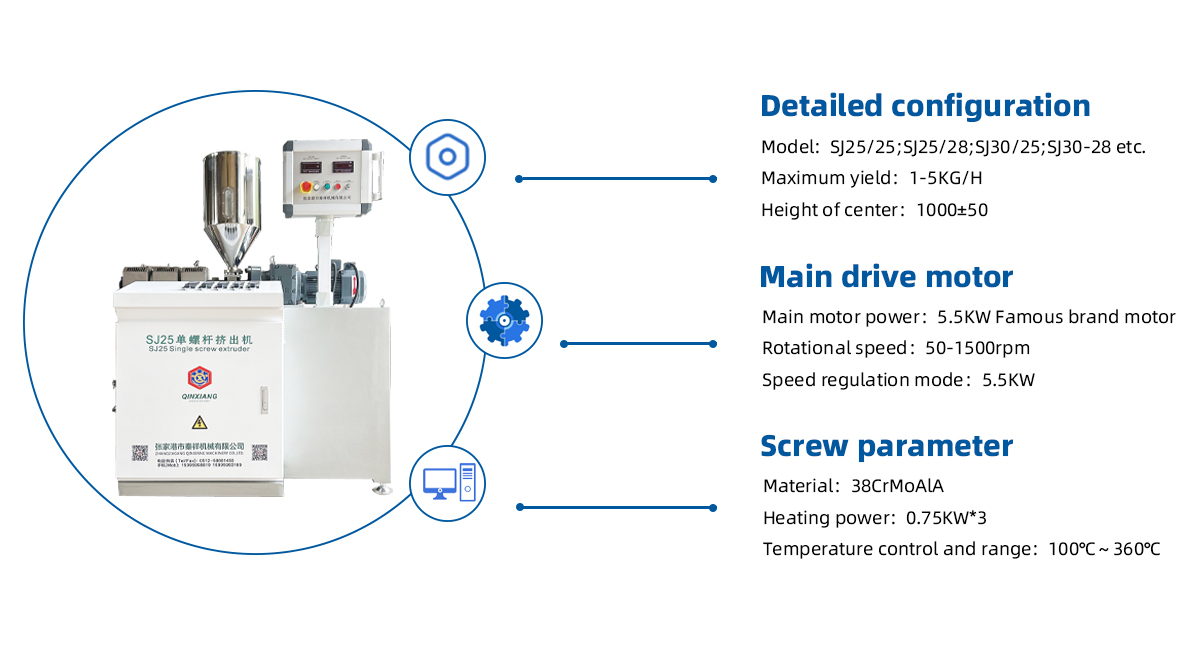

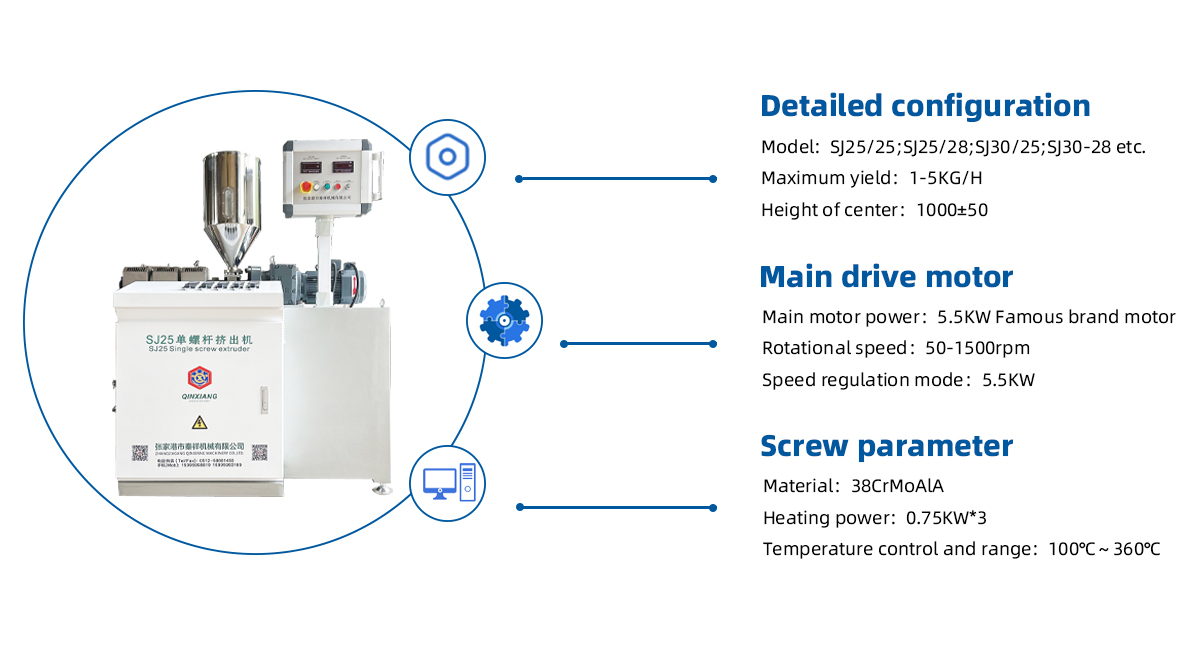

▏Technical Parameters

| Motor power | 1.1Kw |

| Heating power | 0.55Kw |

| Main engine speed regulation | frequency control |

| Screw, barrel material | 38CrMoAlA;surface nitriding |

| Electrical appliance | Siemens contactor, Dongqi temperature control meter, Delixi Electric |

| Motor speed regulation | 1.1KW inverter speed regulation |

▏Main Details

▏Product Photos

Obverse show

Side display

SJ25 single screw extruder

Automatic operation

Operation panel

Heating operation

Stainless steel hopper

Triple heating

Screw:38CrMoAlA

1.5Kw motor power

▏How the SJ25 Laboratory Extruder Works

| Feeding the Material |

| The extrusion process begins when raw material, typically in pellet form, is fed into the hopper. The material is then conveyed into the barrel through a rotating screw. The screw, which is equipped with a special design to ensure optimal material flow, compresses and melts the polymer as it moves along the barrel.

The feeding system ensures that the material is consistently supplied into the barrel, avoiding blockages or irregular flow. This is crucial for maintaining a steady extrusion rate and ensuring that the material is processed efficiently. |

| Heating and Melting |

|

Once inside the barrel, the material is heated to its desired processing temperature. The SJ25 laboratory extruder has multiple heating zones along the barrel, each of which is controlled independently to ensure even and precise temperature distribution. The digital controllers allow the operator to set the ideal temperature for each zone based on the material being processed.

The screw, which rotates and moves the material along the barrel, provides the mechanical energy needed to melt the polymer. The rotation of the screw also ensures that the material is adequately mixed, resulting in a uniform melt. This step is essential for producing high-quality extrusions and avoiding defects in the final product. |

| Extrusion and Shaping |

|

Once the polymer is melted and thoroughly mixed, it is forced through the die, which shapes the material into the desired profile. The SJ25 laboratory extruder can be equipped with a variety of dies to produce different shapes, including pipes, sheets, films, and rods.

The die is a critical component of the extruder, as it directly determines the final dimensions and surface finish of the extruded material. The ability to change dies allows users to create a variety of profiles for testing or production purposes. The extrusion speed can be adjusted based on the material and profile being produced. |

| Cooling and Solidification |

|

After the material exits the die, it is quickly cooled to solidify its shape. The SJ25 laboratory extruder features an efficient cooling system that helps to rapidly cool the extruded material, preventing warping and ensuring the material retains its dimensional integrity.

The cooling system may include air or water cooling, depending on the type of material being processed. The cooling process can be controlled to suit the specific requirements of different polymers, ensuring the extruded product maintains the desired mechanical properties. |

| Cutting and Sampling |

|

Once the material is cooled and solidified, it is cut into the desired length for testing, analysis, or further processing. The SJ25 laboratory extruder is typically equipped with an integrated cutting system that ensures precise and uniform cutting of the extruded material.

The cutting system is essential for preparing test samples, which can then be used for mechanical testing or product evaluation. The ability to produce consistently sized samples is vital for ensuring that the material meets the necessary specifications. |

▏Applications of the SJ25 Laboratory Extruder

| Material Testing and Research |

| The SJ25 laboratory extruder is an essential tool for polymer scientists and engineers involved in material testing and research. It allows users to test various polymer formulations, additives, and processing conditions to understand their effects on material properties. The ability to fine-tune extrusion parameters, such as temperature, pressure, and screw speed, provides valuable insights into how different factors influence the material's behavior during processing. |

| Prototyping and Product Development |

| The SJ25 laboratory extruder is commonly used for prototyping and small-scale product development. It enables manufacturers to create test samples and prototypes for evaluation before committing to large-scale production. This is especially useful in industries such as automotive, medical, and packaging, where product prototypes need to be tested for performance, durability, and appearance. |

| Educational Use |

| Educational institutions often use the SJ25 laboratory extruder to teach students about polymer processing and material science. It provides a hands-on opportunity for students to learn about the principles of extrusion, material behavior, and the impact of processing conditions on final product quality. The SJ25 extruder is an ideal tool for introducing students to the basics of thermoplastic processing in a controlled and practical environment. |

| Small-Scale Production |

| Small manufacturers or businesses that require low-volume production of polymer-based products can benefit from the SJ25 laboratory extruder. Whether for producing custom profiles, pipes, or sheets, this machine offers a cost-effective solution for small-scale production while maintaining high-quality standards. |

▏Advantages of the SJ25 Laboratory Extruder

| High Precision and Control |

| The SJ25 laboratory extruder provides precise control over key extrusion parameters, allowing users to experiment with various formulations and processing conditions to achieve the desired material properties. |

| Compact and Efficient |

| With its compact design, the SJ25 extruder occupies minimal space, making it ideal for laboratories with limited room. Its efficiency in processing materials ensures high-quality results without the need for a large, expensive extruder. |

| Versatility in Material Handling |

| The SJ25 laboratory extruder can process a wide range of thermoplastic materials, making it versatile for various applications, including R&D, prototyping, and small-scale production. |

| Easy Operation and Setup |

| The user-friendly interface and intuitive controls of the SJ25 laboratory extruder make it easy to set up and operate, even for those with limited extrusion experience. |

▏A Valuable Tool for Polymer Processing

The SJ25 laboratory extruder is an essential tool for anyone working in polymer research, material testing, prototyping, or small-scale production. Its precision control, compact design, and versatility make it ideal for a wide range of applications, from academic research to industrial development. With its ability to handle various thermoplastics and produce high-quality extrusions, the SJ25 laboratory extruder is a vital asset in any polymer processing laboratory.

▏Product Introduction

The SJ25 laboratory Extruder is a laboratory device designed for small batch production or research into new formulations. This equipment is suitable for formulation modification, coloring, reinforced fiber addition, fuel resistance, filling, extrusion experiments of new environmentally friendly plastics (such AS PLA, ABS, AS, PP, PE, PS, elastomer TPU, TPE, TPR, etc.) and alloy formulations.

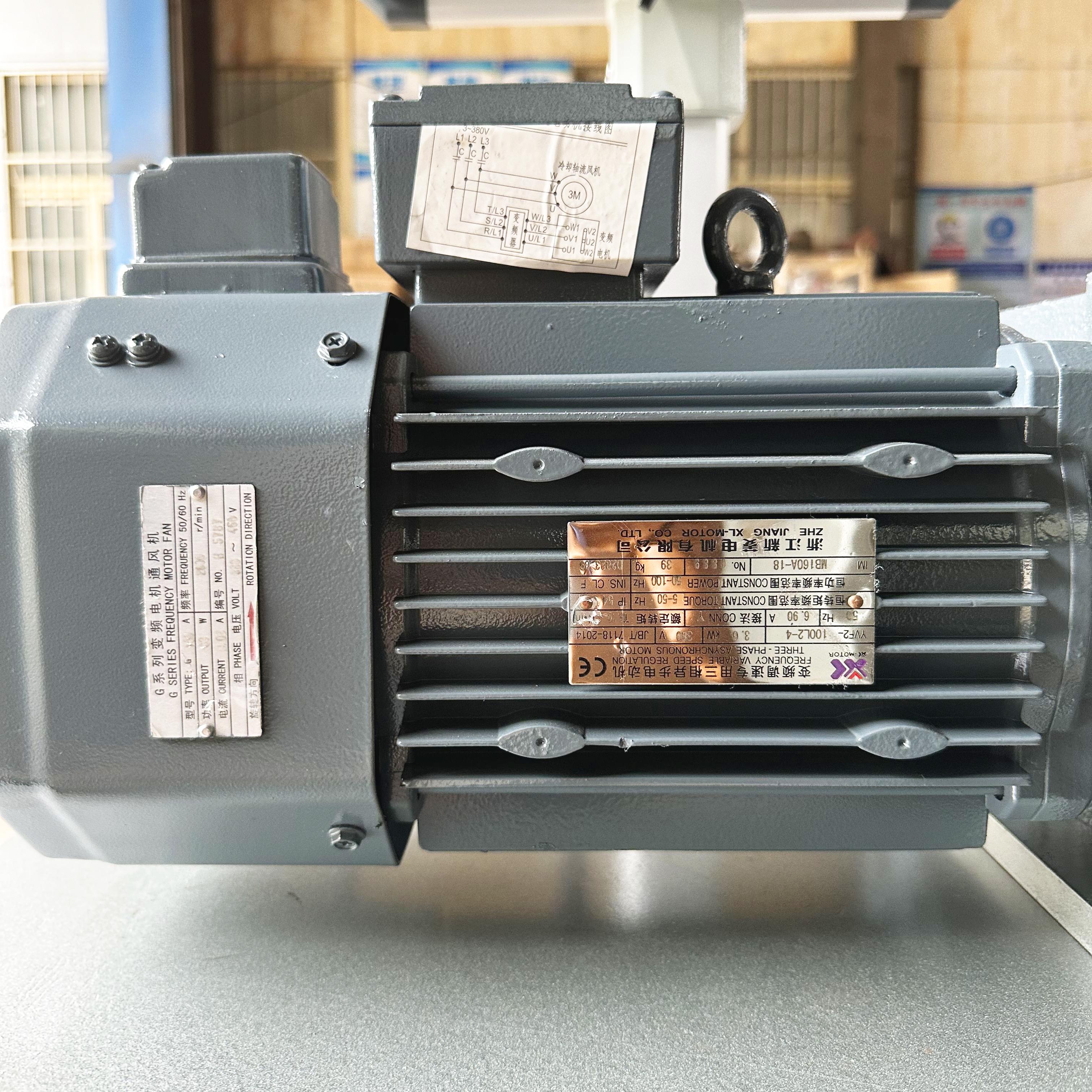

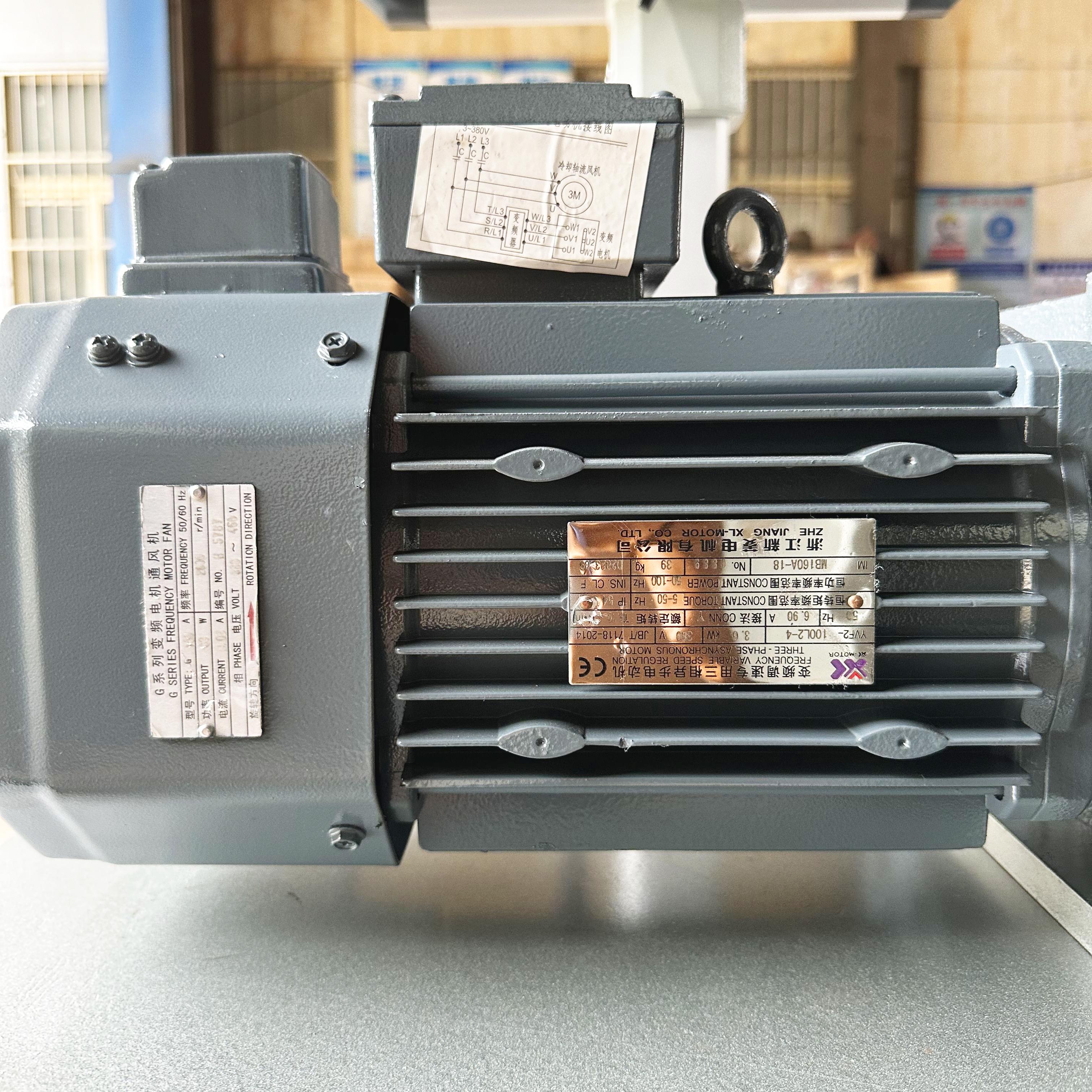

| 1 | The main parameters of SJ25 laboratory Extruder include |

| screw diameter 30mm, lengthed-diameter ratio L/D 28:1, screw speed range within 120rpm. The main machine adopts AC 5.5KW motor, and adopts frequency conversion speed regulation. In addition, the gear and shaft parts of the reducer are made of high-strength alloy steel materials, and are processed by carburizing, quenching, grinding and other processes to ensure the accuracy of the gear and the hardness of the tooth surface. |

| 2 | The equipment also includes a series of supporting components |

| such as 1.5 meters stainless steel cooling sink, blow dryer, fan, pellet cutter, pelletizer mold, as well as electrical control cabinets and variable frequency speed regulation system. Together, these components ensure the stable and efficient operation of the SJ25 laboratory Extruder . |

| 3 | Production capacity |

| In addition, SJ25 laboratory Extruder in the production capacity, usually can reach 5~10kg/h extrusion volume, very suitable for laboratory environment and small-scale production. At the same time, due to its flexibility and adjustability, it is also widely used in the research and development of new plastic extrusion processes and materials. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping