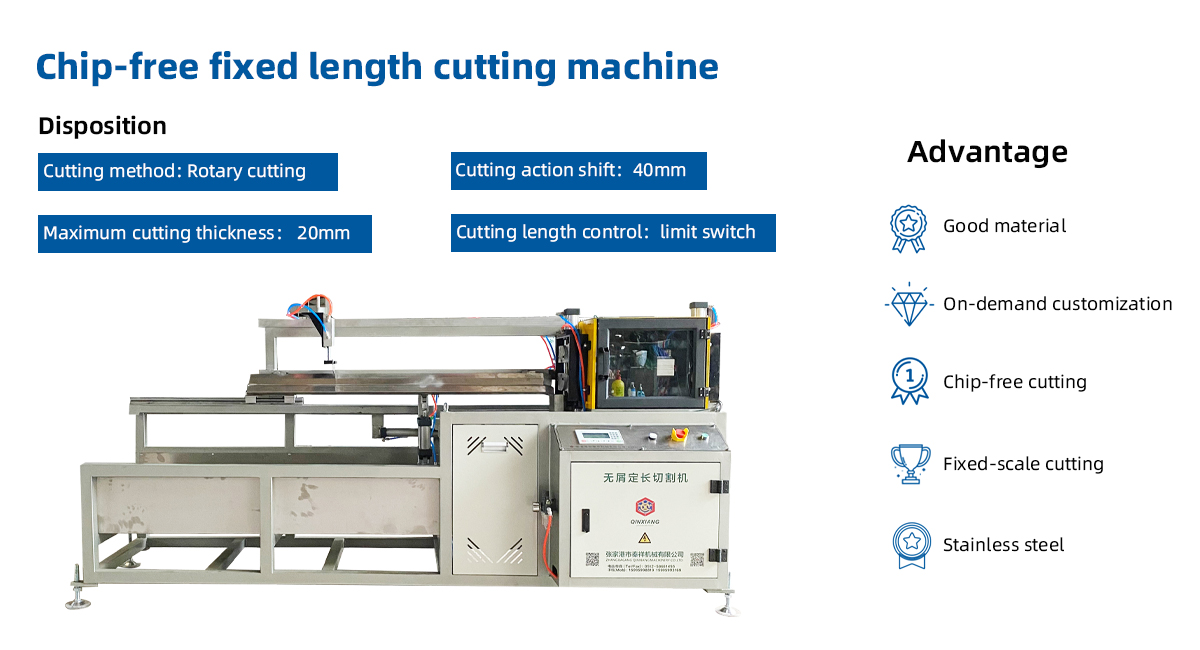

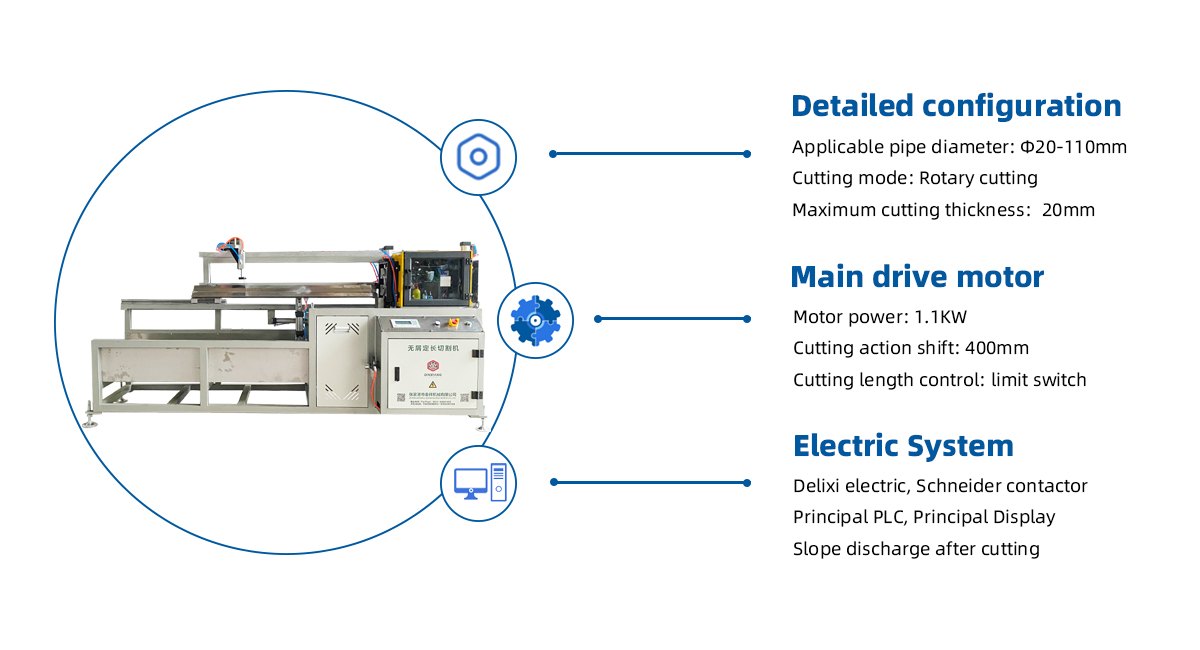

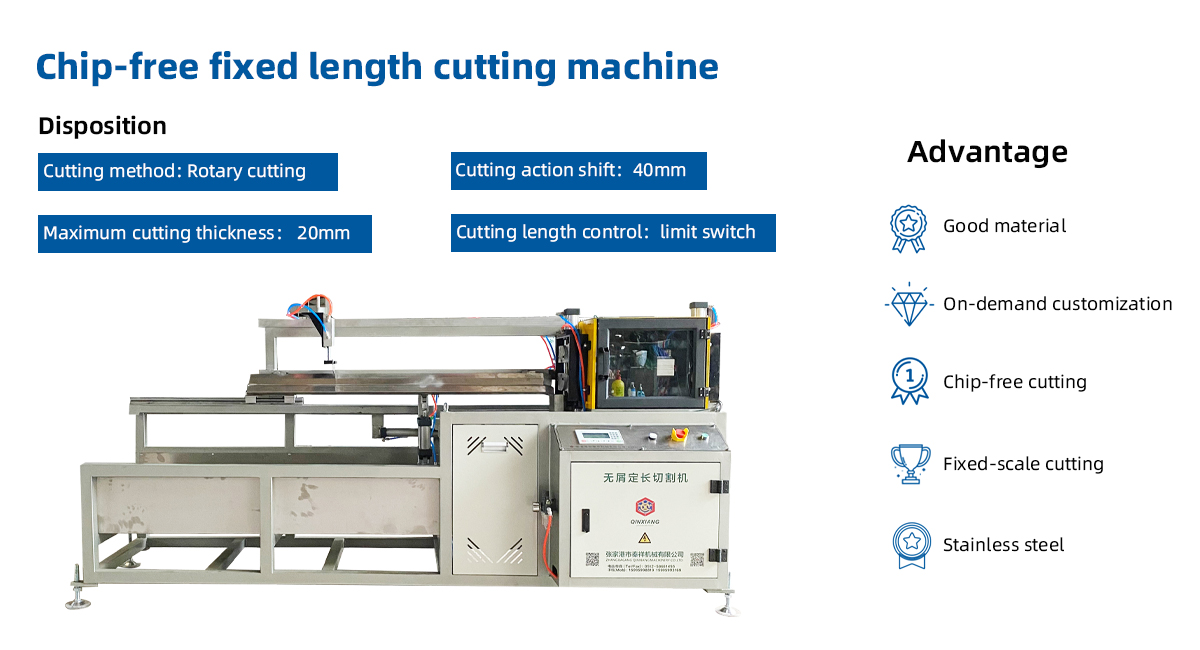

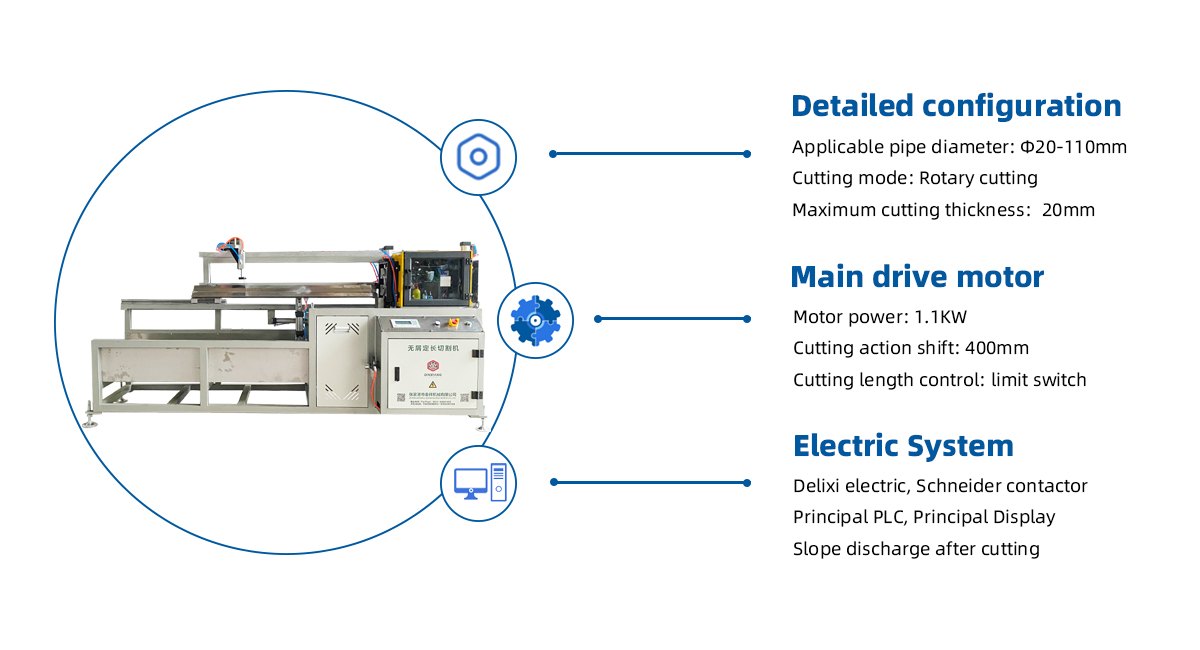

Technical Parameters

Applicable pipe diameter | Φ20-110mm |

Cutting mode | Rotary cutting |

| Maximum cutting thickness | 20mm |

Motor power | 1.1KW |

| Cutting action shift | 400mm |

| Cutting length control | limit switch |

Main Details

Product Photos

Plastic pipe fixed length cutting machine introduction

1. Equipment overview

Plastic pipe fixed length cutting machine is an efficient and accurate automatic mechanical equipment, specially used for plastic pipe fixed length cutting processing. The equipment combines advanced mechanical design and precision control technology, which can realize the rapid and stable cutting of plastic pipes of various specifications and materials, and greatly improves the efficiency and quality of pipe processing.

2. the working principle

The working principle of the fixed length cutting machine for plastic pipes is based on a high-precision measurement system and a stable cutting system. At work, the tube is fed into the device, the length is precisely measured by a sensor or encoder, and once the preset length is reached, the cutting device moves quickly to complete the cutting. Throughout the process, the equipment through the advanced control system, to achieve automatic control and operation, reduce human intervention, improve cutting accuracy and stability.

3. Technical parameters

The main technical parameters of the plastic pipe fixed length cutting machine include cutting speed, cutting accuracy, cutting range, maximum cutting pipe diameter and so on. The specific values of these parameters vary with the device model and specifications, and users should consider the actual needs when selecting the device.

4. Cutting accuracy

Cutting precision is one of the important indexes to measure the performance of the fixed length cutting machine for plastic pipes. The equipment uses an advanced measuring system and precise cutting technology to ensure the accuracy and consistency of the cutting length and meet the requirements of different industries for the cutting accuracy of pipes.

5. Scope of application

Plastic pipe fixed length cutting machine is suitable for many types of plastic pipe cutting, including but not limited to PVC pipe, PE pipe, PP pipe, etc. It is widely used in construction, water supply and drainage, agricultural irrigation, chemical and other fields, providing a convenient and efficient cutting solution for the pipe processing industry.

6. Operation steps

When using a fixed length cutting machine for plastic pipes, the user should follow the following steps:

1. Check whether the device is working properly and whether the components are correctly installed.

2. Place the pipe to be cut into the device, and adjust the position and direction of the pipe.

3. Set the cutting length and adjust cutting parameters as required.

4. Start the device and check whether the cutting process is normal.

5. After cutting, take out the pipe and check whether the cutting quality meets the requirements.

7. Security Matters

When using a fixed length cutting machine for plastic pipes, users must pay attention to the following safety matters:

(1). Do not maintain or adjust the device when it is running.

(2). The operator should wear labor protective equipment to avoid accidental injury during operation.

(3). When cleaning the equipment or replacing the tool, ensure that the equipment has been completely stopped.

(4). If the equipment is faulty or abnormal, it should be stopped immediately for inspection and contact professionals for maintenance.

Cooperative Parts Supplier

Packing And Shipping