▏Product Vedio

▏Plastic ABS Plate Production Line: Revolutionizing Industrial Manufacturing

The Plastic ABS Plate Production Line is a specialized industrial system engineered to manufacture high-performance Acrylonitrile Butadiene Styrene (ABS) sheets and boards with unmatched precision. Designed for industries requiring durable, impact-resistant, and thermally stable plastic products, this fully automated line integrates cutting-edge extrusion technology, intelligent controls, and energy-efficient processes. Ideal for automotive, electronics, and construction sectors, it ensures consistent quality while optimizing production costs.

Core Components of the ABS Plate Production Line

The production line features a meticulously designed workflow, including a high-torque extruder, vacuum calibration unit, multi-stage cooling system, precision haul-off machinery, and programmable cutting devices. Each component is tailored to handle ABS resin’s unique properties, ensuring smooth processing from raw material input to finished board output.

▏Key Features of the Plastic ABS Plate Production Line

| High-Efficiency Twin-Screw Extruder

At the heart of the line lies a twin-screw extruder, optimized for ABS polymer processing. Its advanced screw geometry ensures thorough melting, homogenization, and degassing of ABS pellets, eliminating impurities and enhancing mechanical strength in the final product. The system supports a broad temperature range (180°C–240°C) to accommodate varying ABS grades. |

| Intelligent Temperature and Speed Control

An integrated PLC and touch-screen HMI (Human-Machine Interface) allow real-time adjustments to extrusion speed, temperature zones, and cooling rates. Automated feedback loops maintain stability, ensuring uniform thickness (±0.1mm tolerance) and surface finish, even during high-speed production. |

| Energy-Saving Design

Equipped with regenerative drives and heat-exchange cooling systems, the line reduces energy consumption by up to 30% compared to traditional models. Insulated barrels and servo-driven motors further minimize power waste, aligning with global sustainability standards. |

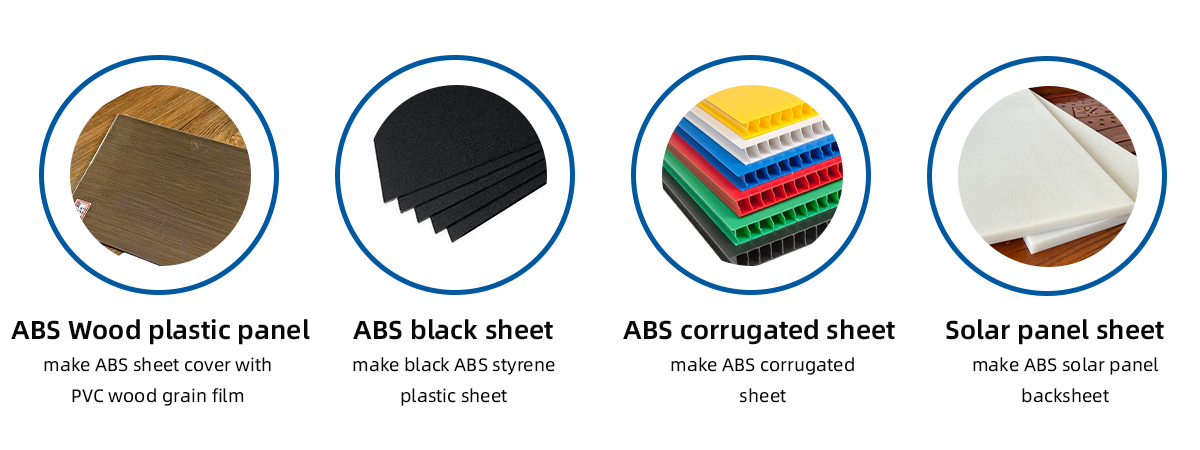

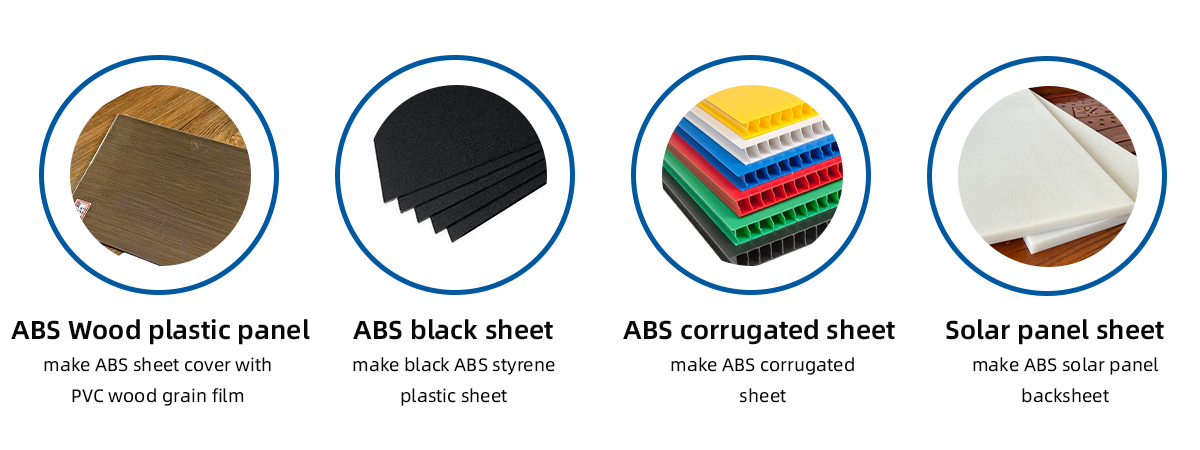

▏Applications of ABS Plates

| ABS boards produced by this line are widely utilized in:

Automotive: Interior trim panels, dashboards, and impact-resistant components. Electronics: Housings for appliances, machinery guards, and insulating parts. Construction: Lightweight partitions, signage, and corrosion-resistant cladding. Consumer Goods: Luggage shells, toy components, and ergonomic handles. |

▏Advantages of Choosing Our ABS Plate Production Line

| Superior Product Quality

The line’s precision calibration and cooling systems prevent warping or shrinkage, delivering ABS boards with exceptional dimensional stability and surface smoothness (Ra ≤ 0.8μm). |

| High Output & Flexibility

With a production capacity of 300–1500 kg/h, the system supports 24/7 operation. Quick-change dies and adjustable rollers enable seamless transitions between board thicknesses (2mm–30mm) and widths (500mm–2000mm). |

| Low Operational Costs

Durable, wear-resistant components and automated lubrication systems reduce maintenance downtime by 40%. Predictive maintenance alerts via IoT-enabled sensors further enhance operational efficiency. |

▏Technical Specifications

| Parameter | Specification |

| Extruder Type | Co-rotating Twin-Screw |

| Max Output | 1500 kg/h |

| Power Consumption | 200–450 kW |

| Board Thickness Range | 2–30 mm |

| Cooling System | 3-Stage Vacuum Calibration + Water Cooling |

▏Why Partner With Us?

Our Plastic ABS Plate Production Line combines decades of engineering expertise with innovative automation. We offer comprehensive support, including on-site installation, operator training, and a 3-year warranty. By prioritizing energy efficiency and customization, we empower manufacturers to meet evolving market demands while reducing their carbon footprint.

In an era where high-performance plastics dominate industrial applications, the Plastic ABS Plate Production Line stands as a cornerstone of modern manufacturing. Its ability to produce robust, versatile ABS boards with precision and efficiency makes it indispensable for businesses aiming to lead in quality and innovation. Invest in our technology to elevate your production capabilities and capitalize on the growing ABS market.

▏Product Introduction

‖ ABS hollow solid plate extrusion line/Plastic plate Making Machine

The ABS (Acrylonitrile Butadiene Styrene) Hollow Solid Plate Extrusion Line is a specialized manufacturing system designed to produce high-quality, durable ABS plates with either hollow or solid structures. These plates are widely used in various industries, including automotive, construction, and electronics, due to their excellent mechanical properties, impact resistance, and thermal stability.

▏Range Of Application

▏Technical Parameters

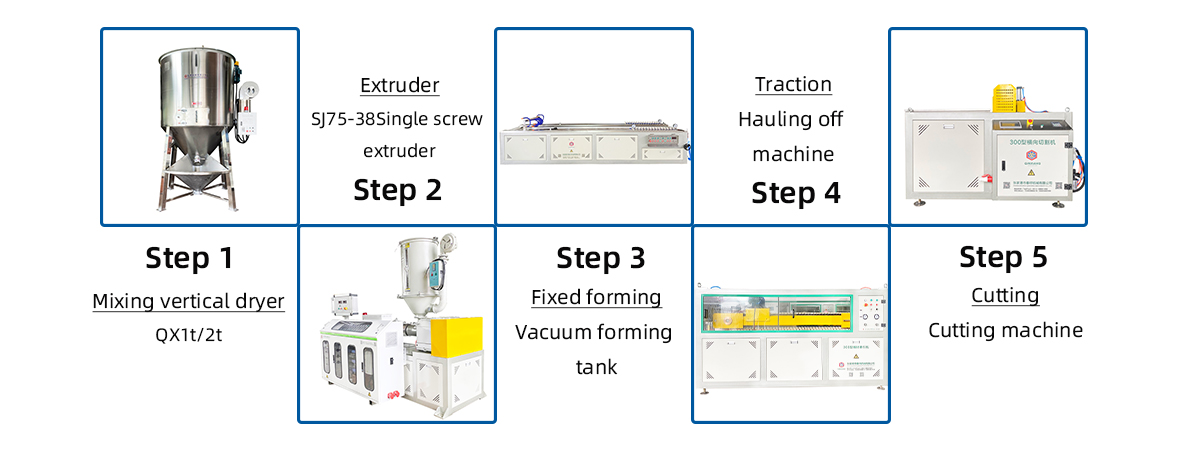

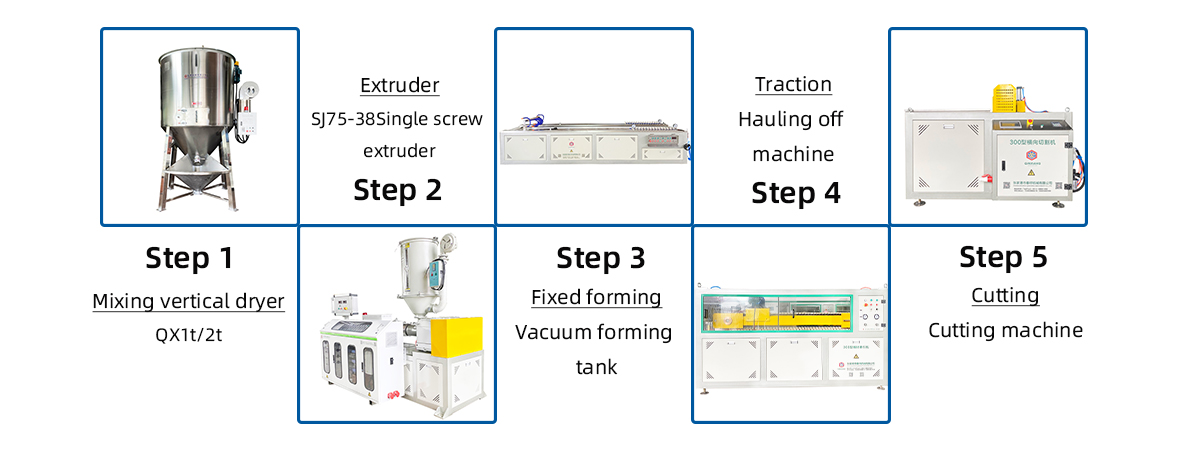

Production line configuration | Detail |

Mixing vertical dryer |

QX-2T |

SJ80/30 single screw extruder | 80-150 kg/h |

Vacuum forming tank | 4.5m |

Hauling off machine | 2700mm |

Cutting machine | Transverse cutting |

QX-800 automatic vacuum feeding system | 450KG/H |

▏Production Procedure

▏Product Photos

ABS plate production line

ABS sheet production line

Mixing vertical dryer

QX-2T

stainless steel

SJ80/30 single screw extruder

QX-800 automatic vacuum feeding system

QX-75 hopper dryer

screw and barrel

Efficient automated production

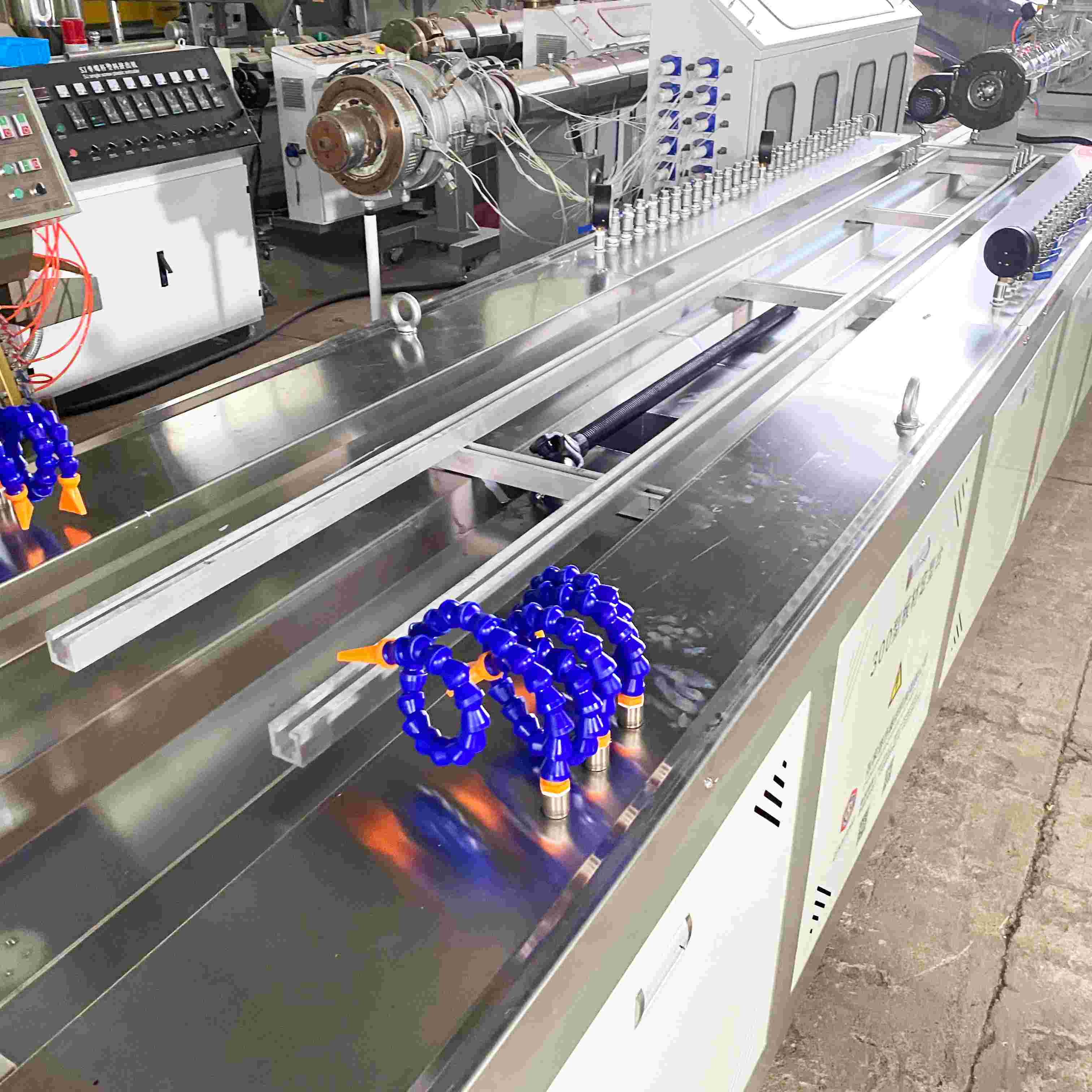

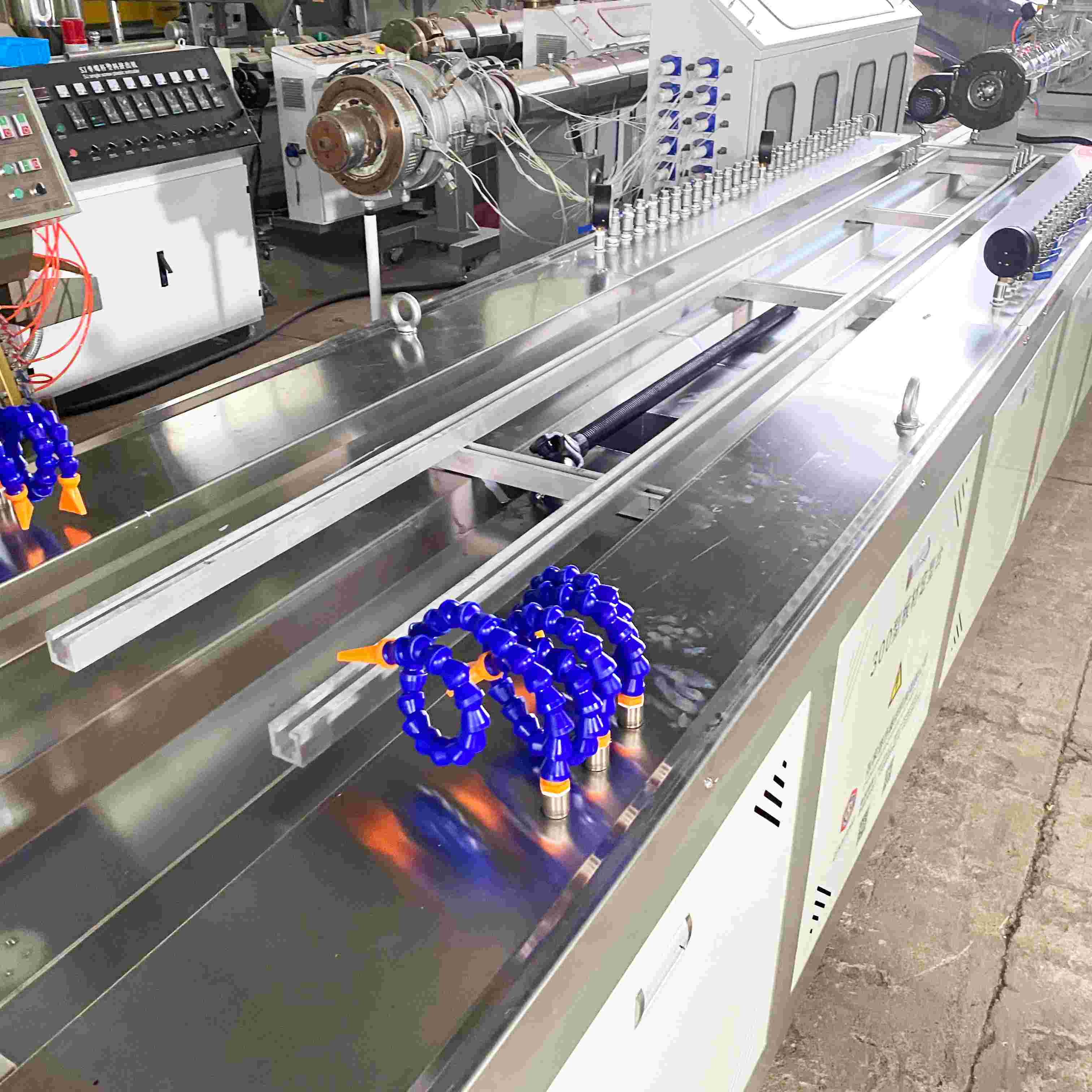

Vacuum forming tank

Precise control

Excellent plate quality

Good thickness uniformity

Simple and flexible operation

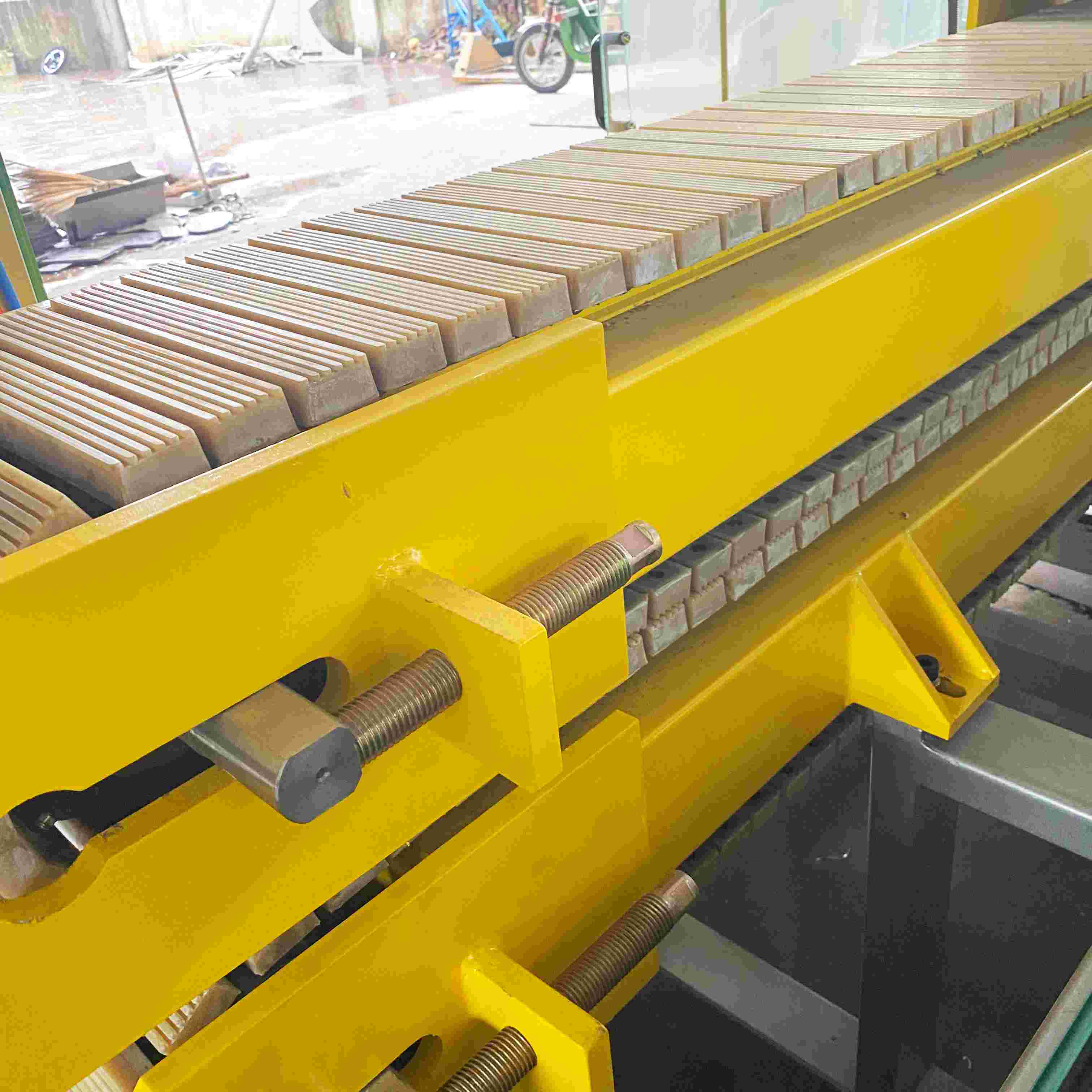

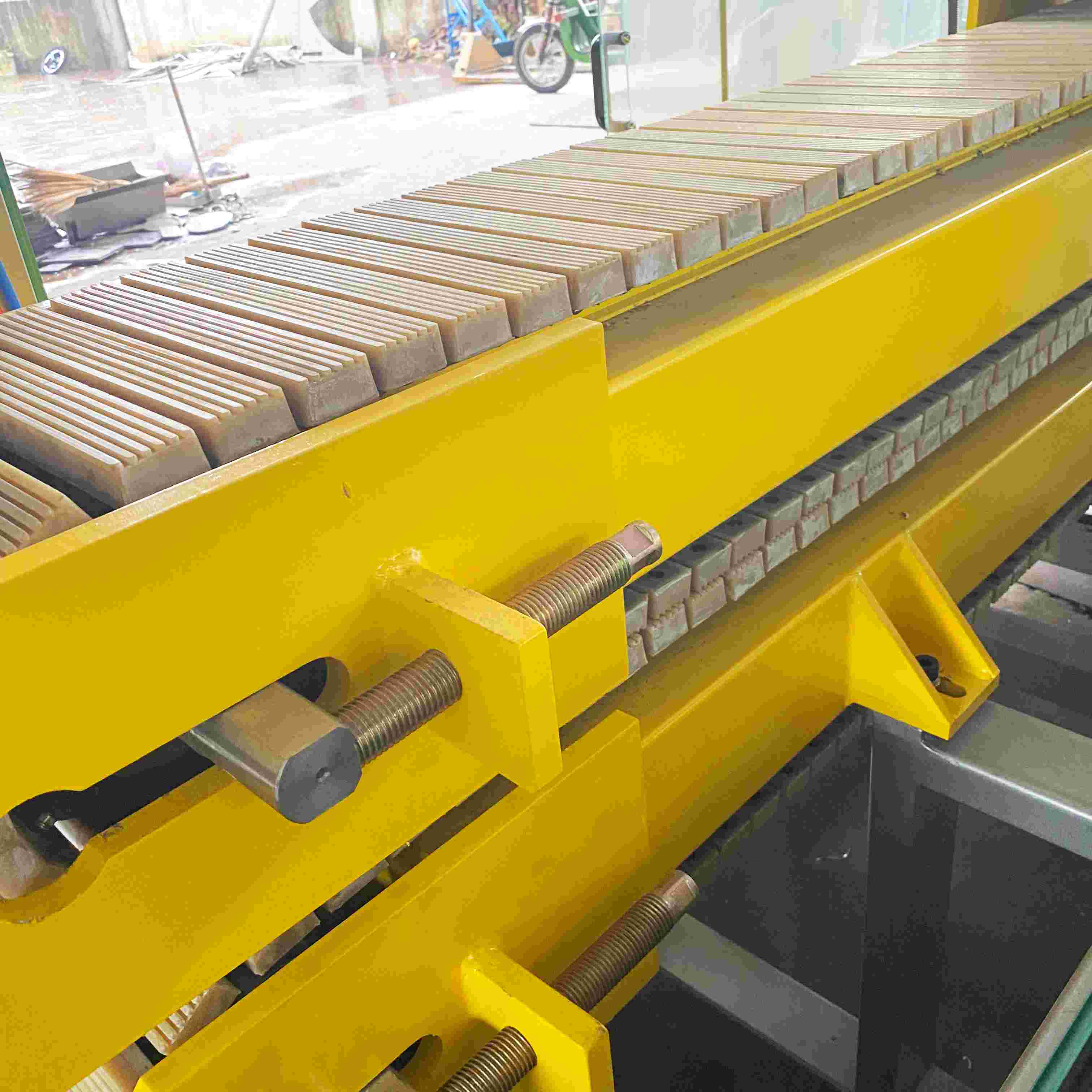

Hauling off machine

Strong adaptability

Energy saving and environmental protection

Easy maintenance

Safe and reliable

Cutting machine

Cutting precision

Chip-free cutting

Fixed-scale cutting

Fixed-scale cutting

High economic benefits

▏Product Details

| 1 | Key Components and Process |

| Extruder: The extrusion line starts with a high-performance extruder, typically a single-screw or twin-screw extruder, designed to melt and process ABS granules efficiently. The extruder's screw and barrel are engineered to ensure proper melting and mixing of the ABS material. Die: The melted ABS is then forced through a specially designed die to form the hollow or solid plate profile. The die shape and size can be customized to produce plates of various thicknesses and widths. Vacuum Sizing and Cooling: After exiting the die, the ABS plate enters a vacuum sizing and cooling tank. The vacuum sizing ensures the plate maintains its precise dimensions, while the cooling process solidifies the material. Calibration and Haul-off: The calibrated plate then passes through a series of rollers for further cooling and calibration. A haul-off unit pulls the plate through the line at a consistent speed, ensuring uniform thickness and surface quality. Cutting: Finally, the ABS plate is cut to the desired length by a cutting device. The cutting process can be automated for precise and efficient production. |

| 2 | Applications |

| ABS plates produced by this extrusion line are used in numerous applications, including: Automotive: For interior and exterior components, such as dashboards, door panels, and body parts. Construction: For wall panels, partitions, and other building materials. Electronics: For housings, enclosures, and other structural components. Furniture: For chair backs, tabletops, and other furniture parts. |

| 3 | Advantages |

|

Versatility: The line can produce both hollow and solid ABS plates, offering flexibility in production. Efficiency: High-volume production capabilities make it suitable for large-scale manufacturing. Quality Control: The extrusion process ensures consistent quality and performance of the plates. Customization: The line can be customized to produce plates of different sizes, thicknesses, and profiles to meet specific customer requirements. |

| 4 | Technical Specifications |

|

Extruder Types: Single-screw and twin-screw extruders are commonly used, with twin-screw extruders often preferred for their better mixing and melting capabilities. Temperature Settings: Melt temperatures typically range from 220°C to 270°C for ABS. Screw Design: Screws with high compression ratios are used to ensure thorough melting and mixing of the ABS material. Die Design: Custom dies are designed to produce hollow or solid plates with specific dimensions and profiles. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping

▏FAQ

1.Are you a factory or trading company?

Qinxiang:We are a factory.

2.Can we visit your machine operation in your factory?

Qinxiang:You can see machine operation in our factory.

3.Can the machine be customized?

Qinxiang:Yes,it can.

4.How many electric, water, air need for the machines?

Qinxiang: technical department supply the whole layout for workshop details.

5.Can I operate machine if don’t have experienced engineers?

Qinxiang: (1) short-time engineers to customer company (5-15days) (2) Year-time working as requirements

6.Any quality checking before shipment?

Qinxiang: 100% confirm, run and test machines before shipment with quality certificate.

7.How long is the guarantee?

Qinxiang: 12 months since the first day customer operates (except wear parts).

8.How can u help us when face some technical problem?

Qinxiang: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

9.Where can we get spare part?

Qinxiang: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Fixed-scale cutting

Fixed-scale cutting