▏Product Vedio

▏Product Introduction

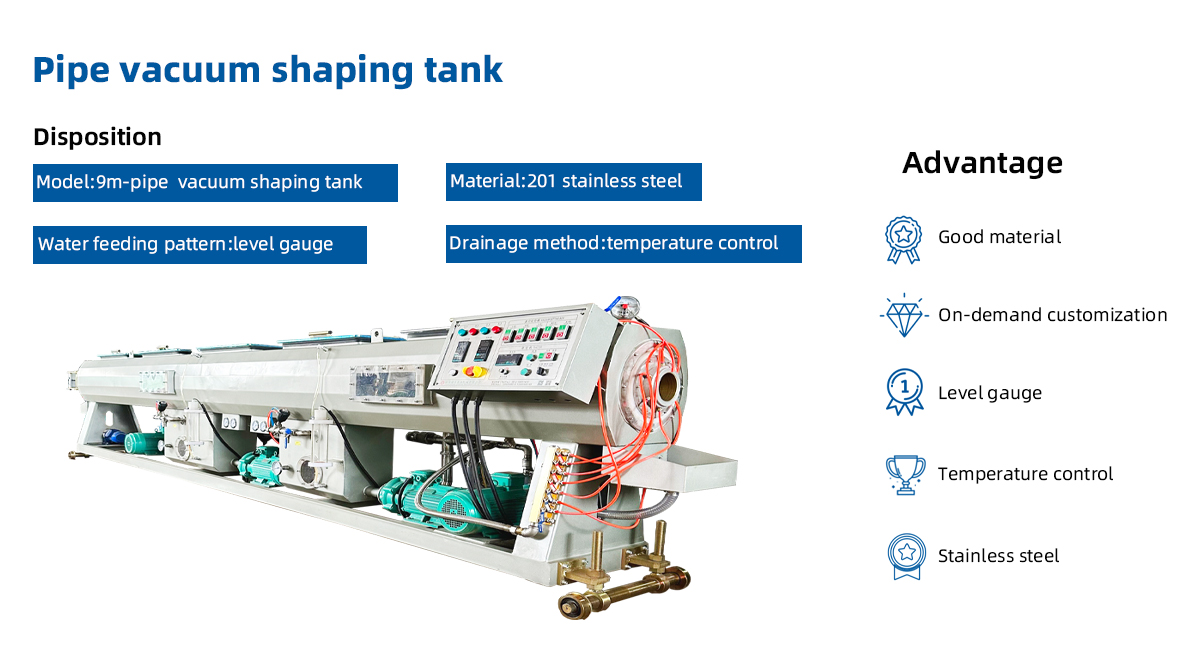

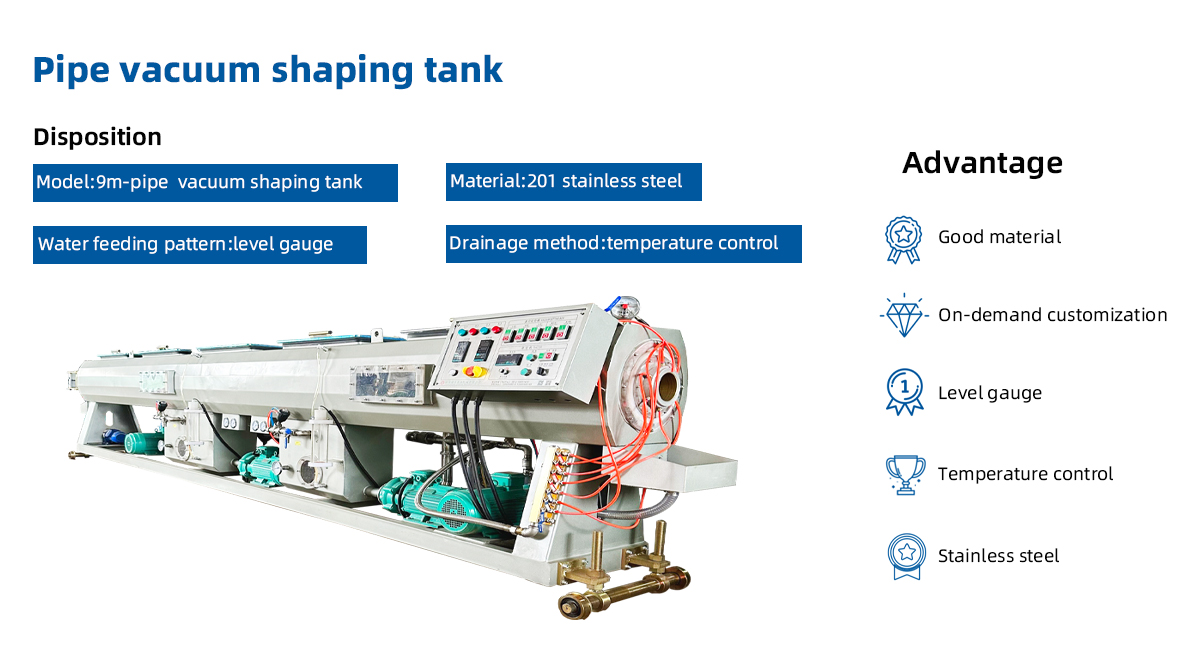

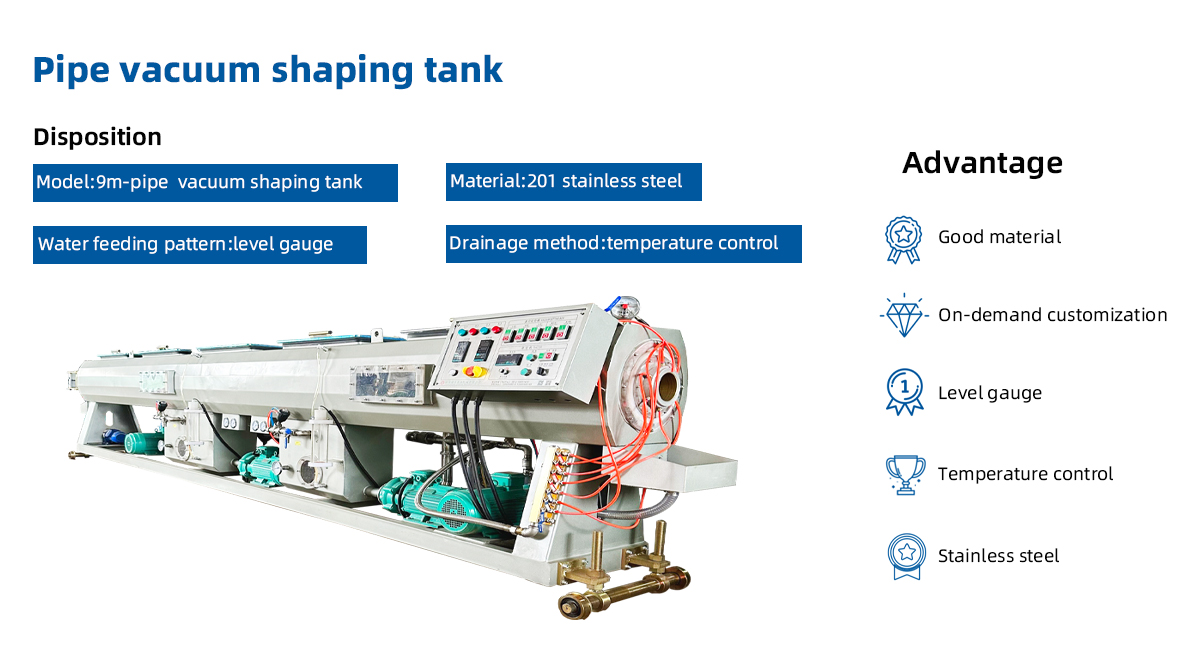

▏110-250 Pipe Vacuum Forming Cooling Tank: Optimized for Large-Diameter Pipe Production

The 110-250 Pipe Vacuum Forming Cooling Tank is a precision-engineered system designed to ensure dimensional stability, surface smoothness, and rapid cooling for PVC, HDPE, and PPR pipes with diameters ranging from 110mm to 250mm. As a critical component in modern extrusion lines, this tank integrates advanced vacuum forming technology, multi-stage cooling mechanisms, and robust construction to meet the demands of high-volume industrial, municipal, and agricultural pipe manufacturing. By delivering consistent performance across diverse materials, it minimizes production downtime and maximizes output quality.

▏Core Role in Pipe Extrusion Processes

The tank operates by applying controlled vacuum pressure to newly extruded pipes, ensuring uniform shaping and rapid solidification. Its large-capacity design accommodates thicker walls and wider diameters, making it ideal for heavy-duty applications such as sewer systems, industrial fluid transport, and underground cable conduits.

▏Key Features of the 110-250 Pipe Vacuum Forming Cooling Tank

| High-Capacity Vacuum System

Equipped with a heavy-duty vacuum pump (0.4–1.0 bar adjustable pressure), the tank maintains precise suction across extended pipe surfaces. This eliminates air pockets and ensures consistent outer diameter tolerances (±0.2mm) for pipes up to 250mm, even at high extrusion speeds. |

| Multi-Zone Cooling Technology

A segmented cooling system combines water spray jets and immersion baths to gradually reduce pipe temperature, preventing thermal stress and warping. Temperature-controlled water circulation (10°C–25°C) adapts to material-specific cooling requirements for PVC, HDPE, and PPR. |

| Durable, Corrosion-Resistant Build

Constructed from stainless steel 316L and reinforced polymer components, the tank withstands prolonged exposure to moisture, chemicals, and high temperatures. Removable sizing sleeves and replaceable seals extend operational lifespan, reducing long-term maintenance costs. |

▏Applications Across Critical Industries

The 110-250 Pipe Vacuum Forming Cooling Tank is essential for manufacturing pipes used in:

Municipal Infrastructure: Large-diameter PVC and HDPE pipes for sewage and stormwater systems.

Industrial Fluid Transport: Chemical-resistant PPR pipes for factories and processing plants.

Telecommunications: Protective HDPE conduits for fiber optic and electrical cables.

Agricultural Drainage: UV-stabilized HDPE pipes for irrigation and land reclamation.

▏Competitive Advantages Over Standard Cooling Systems

| Enhanced Production Efficiency

The tank’s optimized cooling rate enables line speeds of 1.5–4 meters per minute for large-diameter pipes, boosting output by up to 40% compared to conventional tanks. Automated water recycling reduces consumption by 30%. |

| Superior Pipe Quality

Precision vacuum control eliminates surface defects like shark skin or ovality, ensuring pipes meet ISO 4427, EN 12201, and ASTM standards. Smooth internal bores minimize friction loss in fluid transport applications. |

| Quick Changeover Capability

Modular sizing cassettes and tool-free adjustments allow rapid switching between pipe diameters (110mm–250mm) within 15–30 minutes, ideal for manufacturers producing custom orders. |

▏Technical Specifications

| Parameter | Specification |

| Pipe Diameter Range | 110–250 mm |

| Vacuum Pressure | 0.4–1.0 bar (adjustable) |

| Cooling Water Flow Rate | 1000–3000 L/h |

| Tank Dimensions | Customizable (standard: 6000mm L x 1500mm W x 1200mm H) |

| Power Requirements | 3-Phase, 380V, 7.5–15 kW |

▏Why Partner With Us?

Our 110-250 Pipe Vacuum Forming Cooling Tank combines cutting-edge engineering with unmatched reliability. We offer tailored configurations, including IoT-enabled monitoring systems for predictive maintenance and energy usage tracking. Backed by a global service network and a 3-year warranty, we ensure seamless integration into your existing extrusion line, minimizing downtime and maximizing ROI.

As demand for large-diameter plastic pipes grows in infrastructure and industrial projects, the 110-250 Pipe Vacuum Forming Cooling Tank emerges as a cornerstone of efficient, high-quality production. Its ability to deliver precision-cooled, dimensionally stable pipes at scale makes it indispensable for manufacturers aiming to lead in competitive markets. Invest in our technology to enhance your production capabilities and meet the evolving needs of global pipe applications.

▏Product Introduction

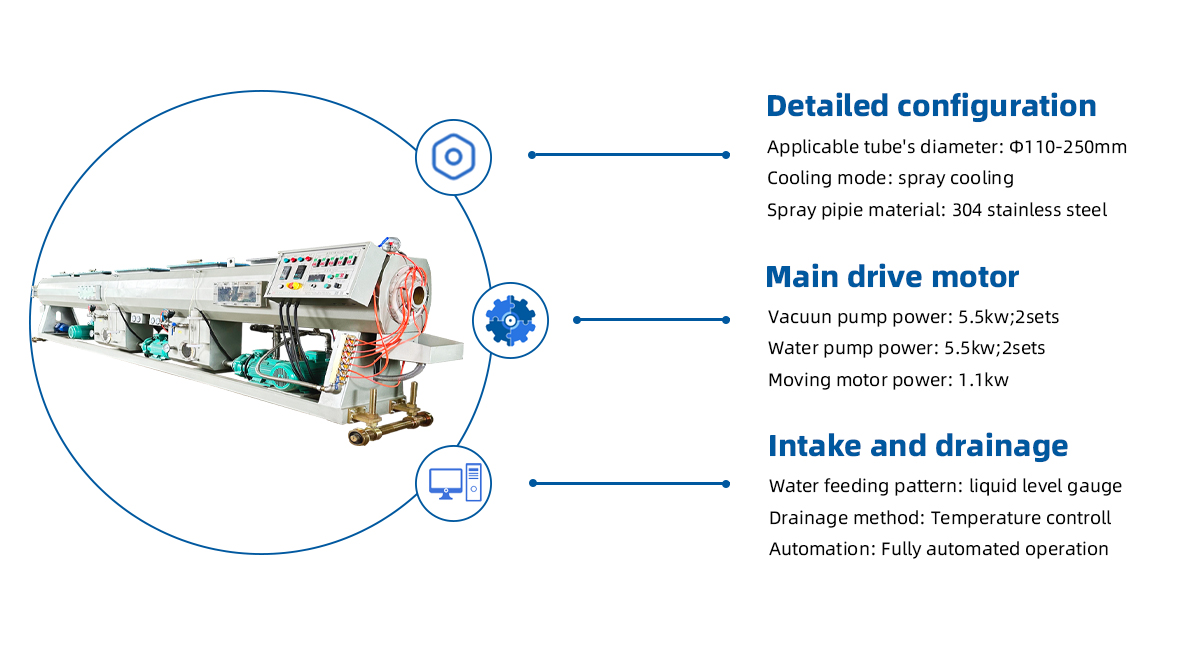

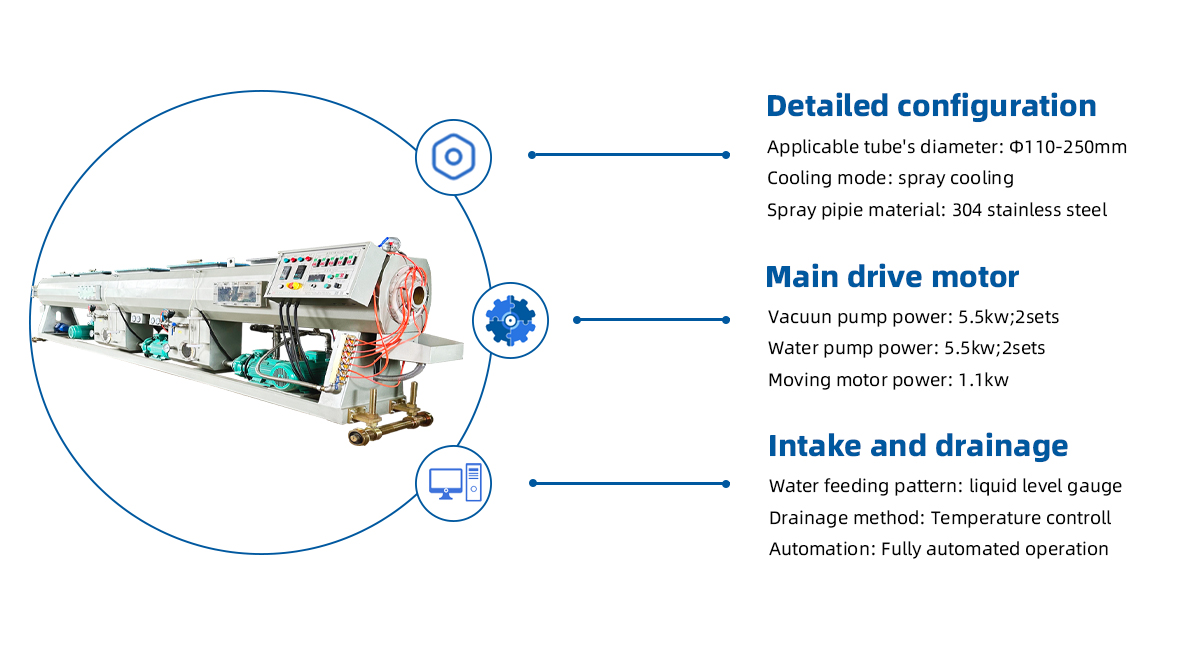

▏Technical Parameters

| Applicable tube's diameter | Φ110-250mm |

| Cooling mode | spray cooling |

| Spray pipie material | 304 stainless steel |

| Vacuun pump power | 5.5kw;2 sets |

| Water pump power | 5.5kw;2 sets |

| Moving motor power | 1.1kw |

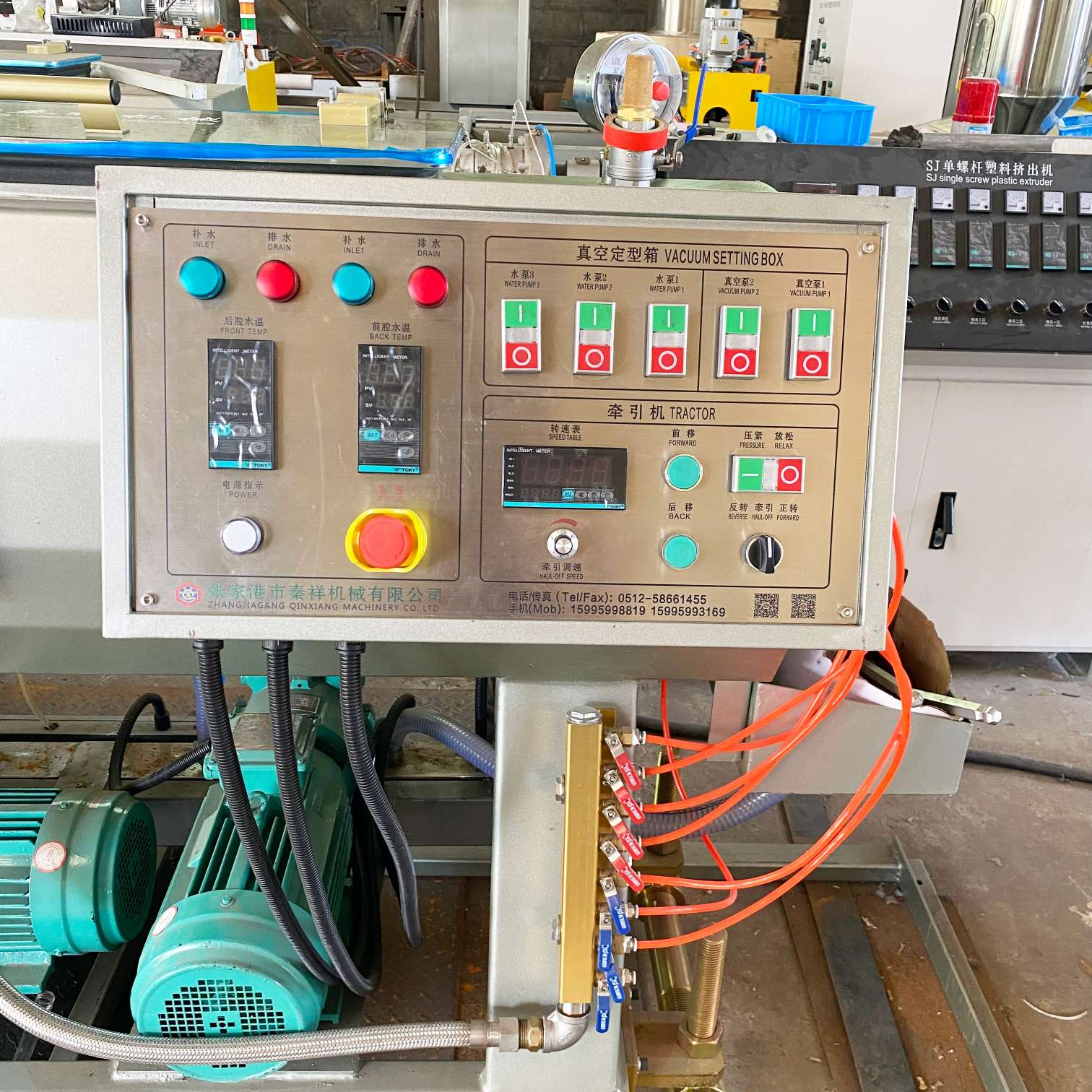

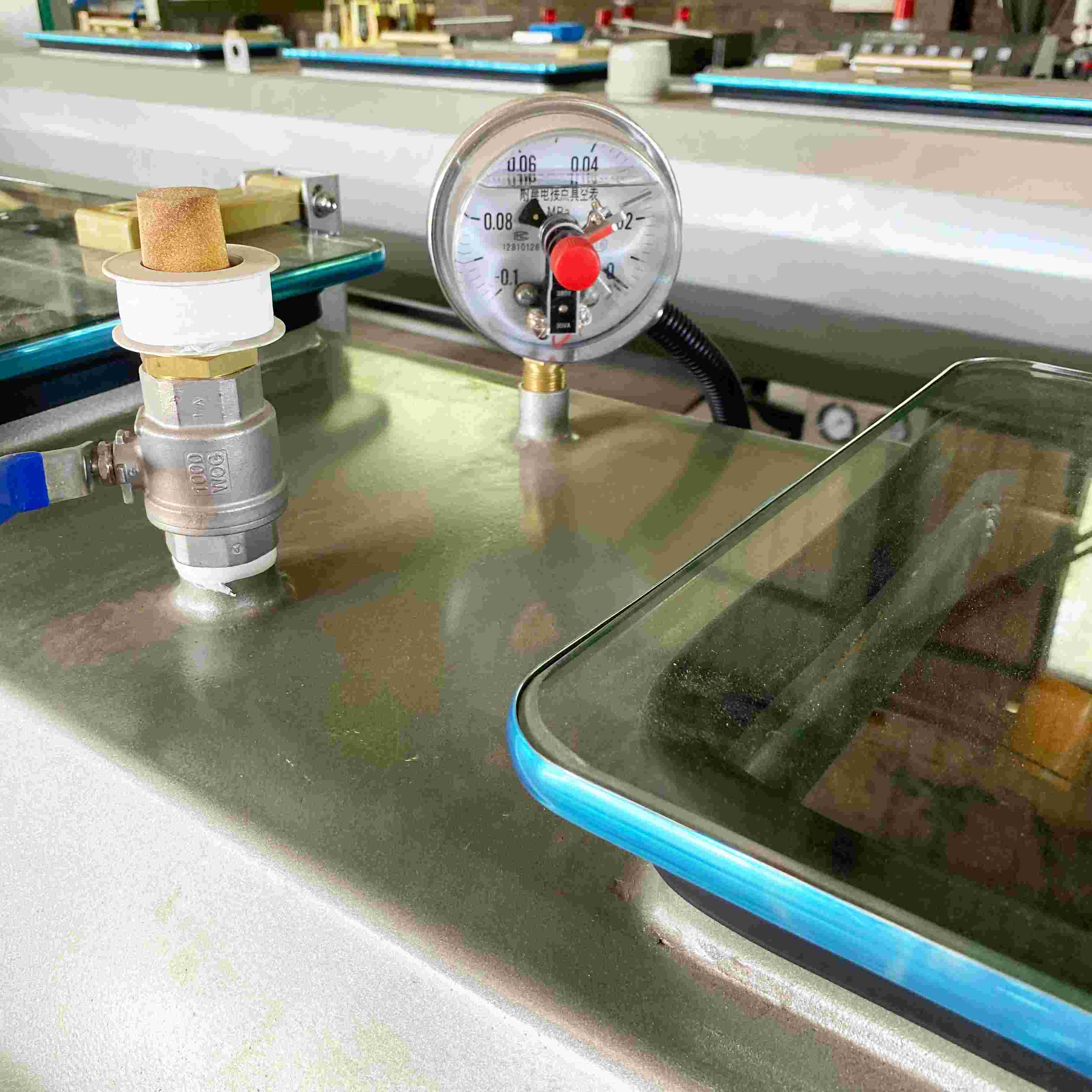

▏Main Details

▏Product Photos

110-250 vacuum forming tank

Excellent processing capacity

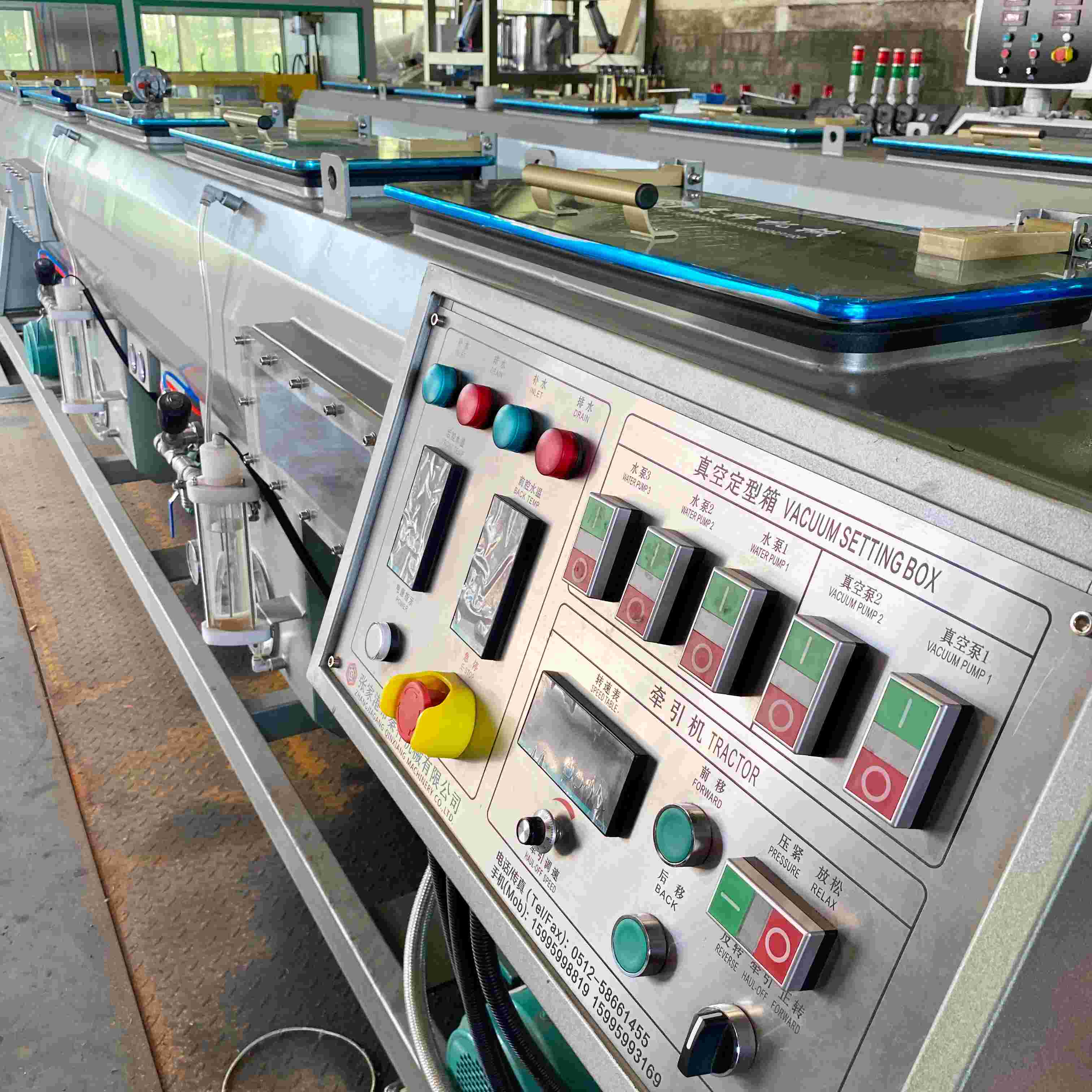

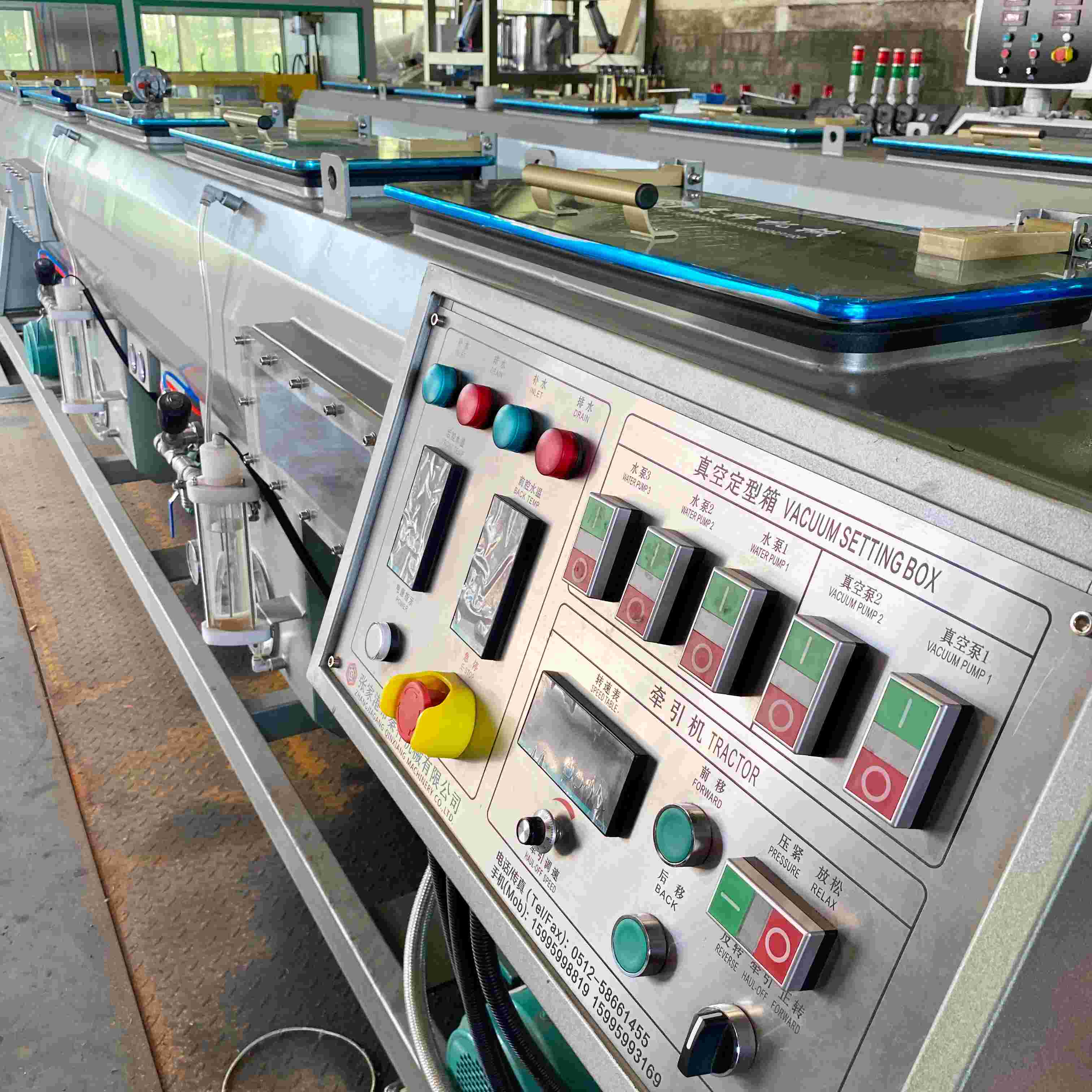

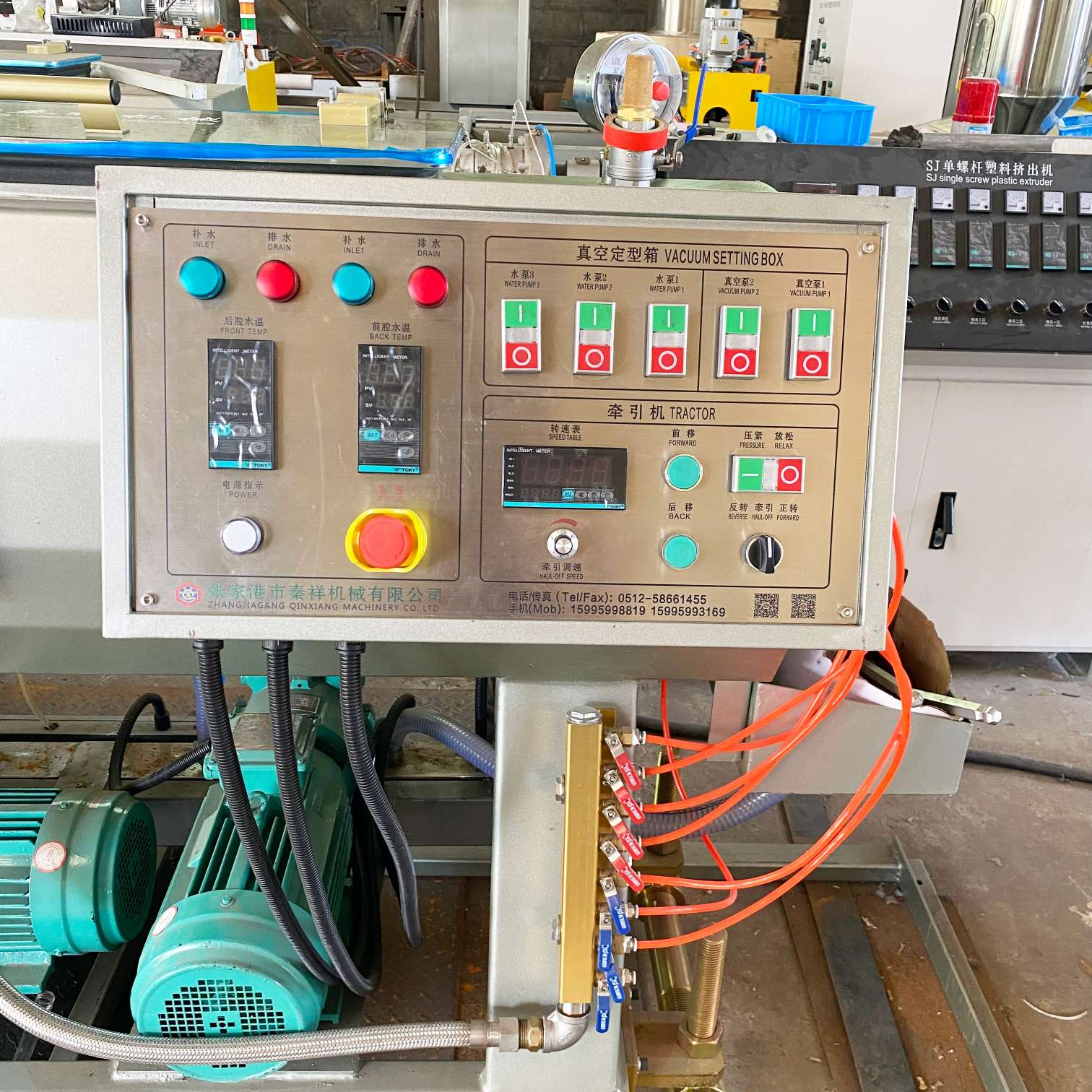

Stainless steel operating panel

Energy saving and environmental protection

Wide applicability

High precision sizing sleeve

Durable spray head

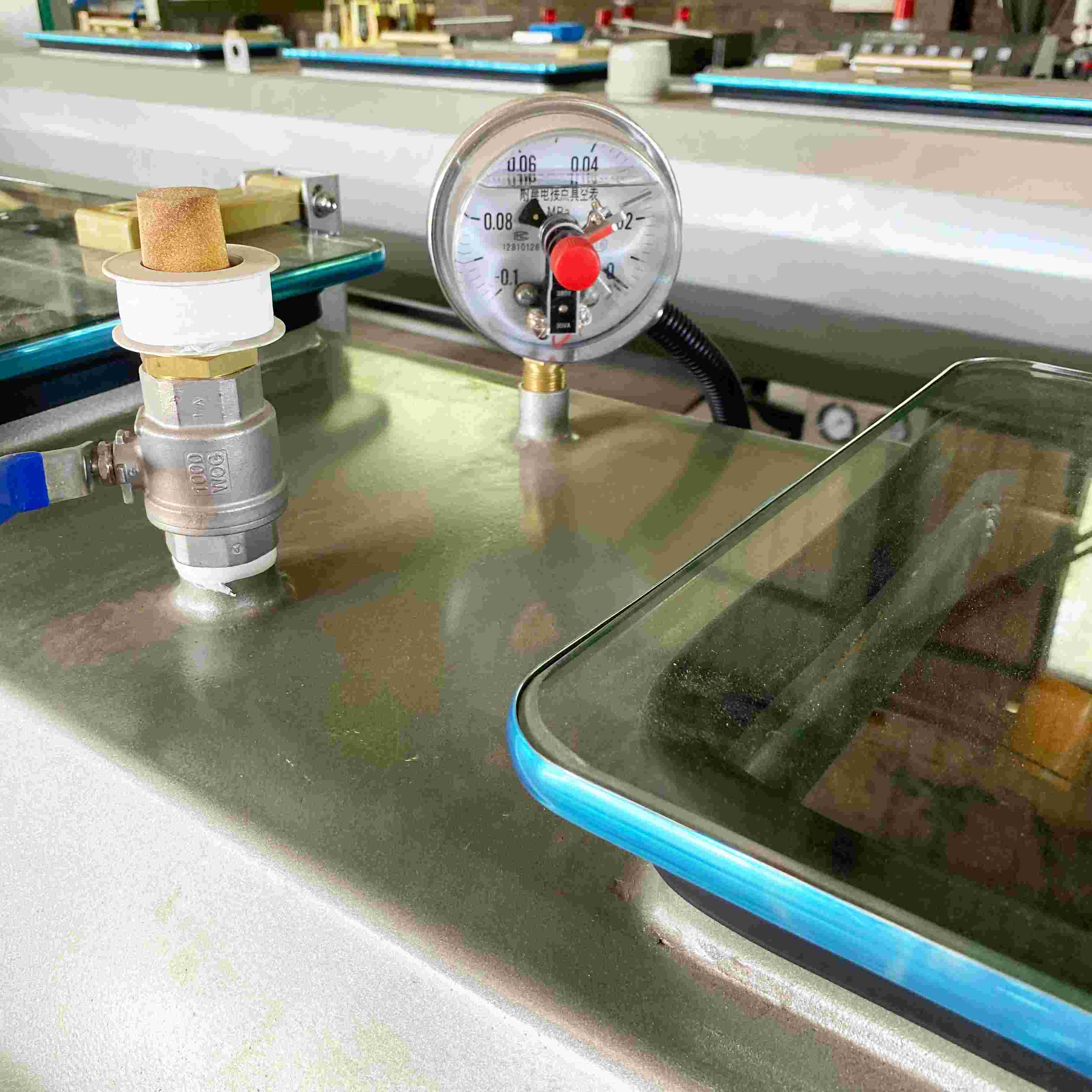

Vacuum meter

Length:9m

Stainless steel

▏Product Introduction

| 1 | Equipment structure and composition |

| The 110-250 pipe vacuum forming cooling tank is mainly composed of a vacuum tank, a vacuum system, a control system, a heating system and a cooling system. The vacuum forming cooling tank is made of high-strength materials and has good sealing performance, ensuring that a stable vacuum environment can be established during processing. The vacuum system is responsible for pumping the air out of the vacuum chamber to achieve the required vacuum degree. The control system is responsible for monitoring and adjusting the operation status of the entire equipment to ensure that the equipment can work according to the preset process parameters. |

| 2 | The working principle and advantages |

| When the pipe enters the vacuum forming cooling tank, the vacuum system begins to work, and the atmospheric components such as oxygen are removed from the vacuum chamber to establish a low-pressure vacuum environment. In this environment, the gas inside the pipe is also extracted, making the surface of the pipe produce negative pressure, and the pressure is reduced. Due to the difference in air pressure between the inside and outside of the pipe at this time, the surface stress on the pipe is also reduced, which helps to reduce deformation and stress concentration during processing. At the same time, the heating system and the cooling system begin to work, and through the precise control of the temperature of the pipe, the pipe can reach the expected processing temperature. In the vacuum room, the pipes are formed and quenched by various molds. In the vacuum, high temperature, high pressure environment, the pipe can show the best processing state, thereby improving the processing accuracy, but also can protect the pipe from deformation. |

| 3 | Application field and effect |

| 110-250 pipe vacuum forming cooling tank is widely used in the field of tube processing in construction, chemical industry, electric power and other industries. By using the equipment, the precise forming and quenching treatment of the pipe can be realized, the strength and wear resistance of the pipe can be improved, and the service life can be extended. At the same time, due to the vacuum technology used in the processing process, the oxidation and deformation of the pipe can be effectively reduced, and the product quality and pass rate can be improved. |

| 4 | Operation and maintenance |

| The operation of the equipment is simple, only through the control system to set the process parameters, the equipment can automatically complete the entire processing process. At the same time, the equipment is also equipped with a perfect maintenance system, which can monitor the operating status of the equipment in real time, discover and deal with potential problems in time, and ensure the stable operation and long life of the equipment. |

▏Product Advantages

| 1 | Firstly, its vacuum environment ensures high-quality processing, preventing oxidation and deformation of the pipe surface, thus guaranteeing precision. Secondly, the vacuum setting maintains a balanced negative pressure on the pipe surface, significantly enhancing processing speed and efficiency. |

| 2 | the vacuum system effectively reduces the presence of atmospheric components like oxygen during processing, thereby conserving energy and minimizing atmospheric pollution. The durability of the pipe materials is also prolonged, further reducing resource costs. |

| 3 | the tank's construction, often utilizing high-grade materials like stainless steel, ensures durability and longevity. The vacuum suction system, often equipped with high-precision pumps, operates with minimal noise and maintains stable vacuum levels. The cooling system, whether through water baths or spraying, achieves uniform and efficient cooling, critical for achieving desired pipe properties. |

| 4 | the 110-250 pipe vacuum forming cooling tank is designed for seamless integration with other essential equipment in the pipe production line, such as extrusion machines, forming molds, tractors, cutters, and stacking mechanisms. This integrated approach simplifies the overall production process, enhancing operational efficiency and final product quality. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping