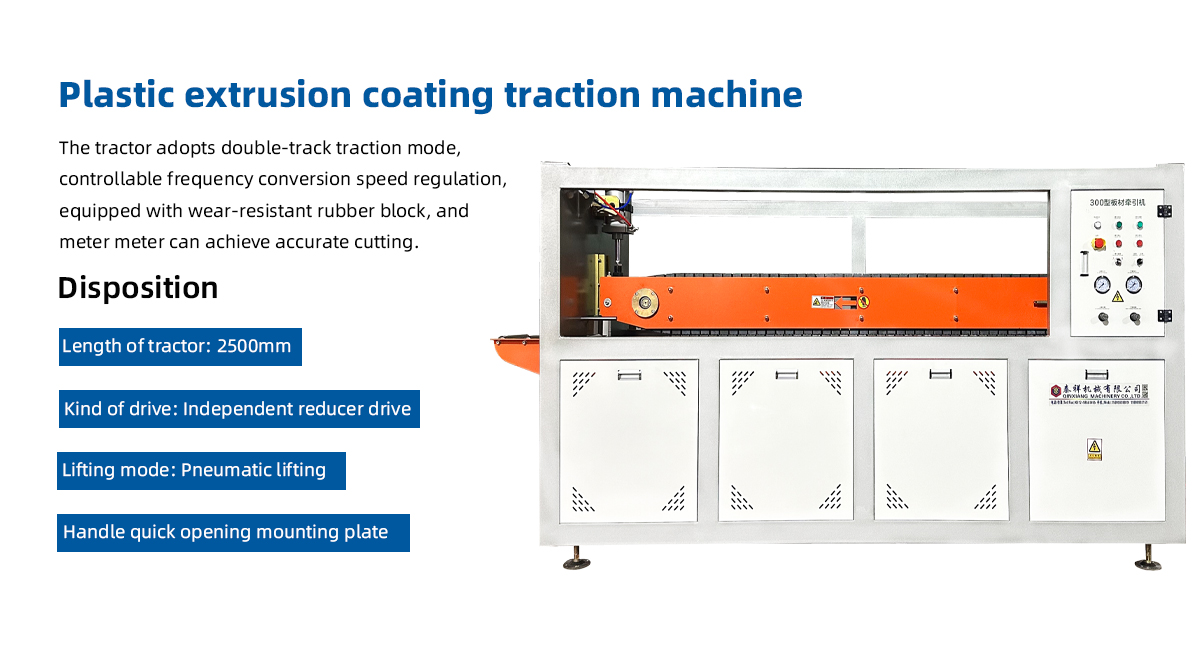

▏Product Introduction

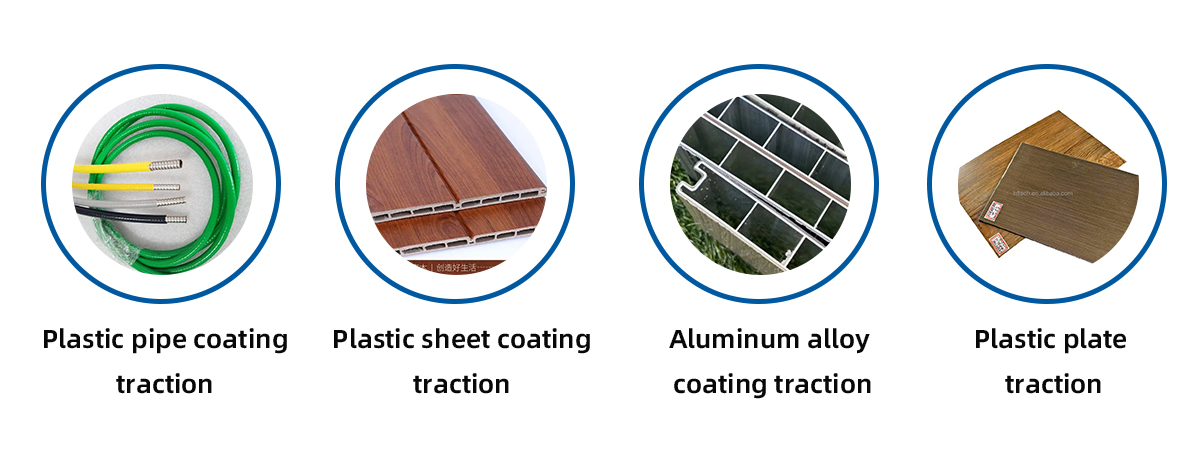

▏Range Of Application

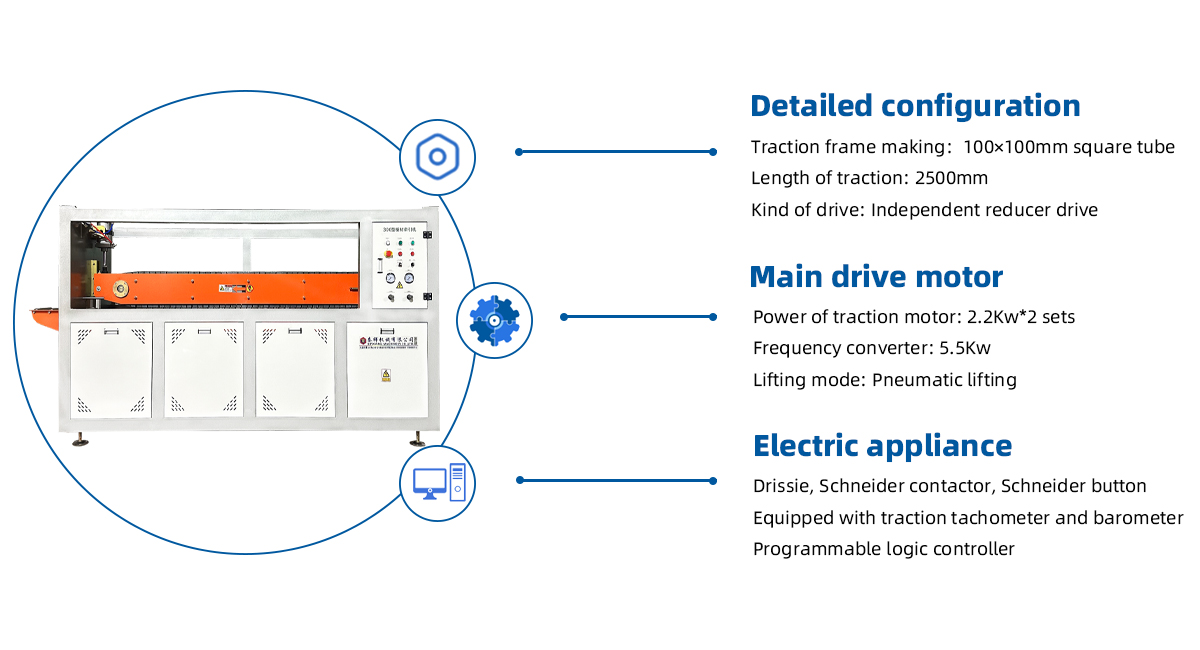

▏Production Details

▏Product Photos

▏Product Introduction

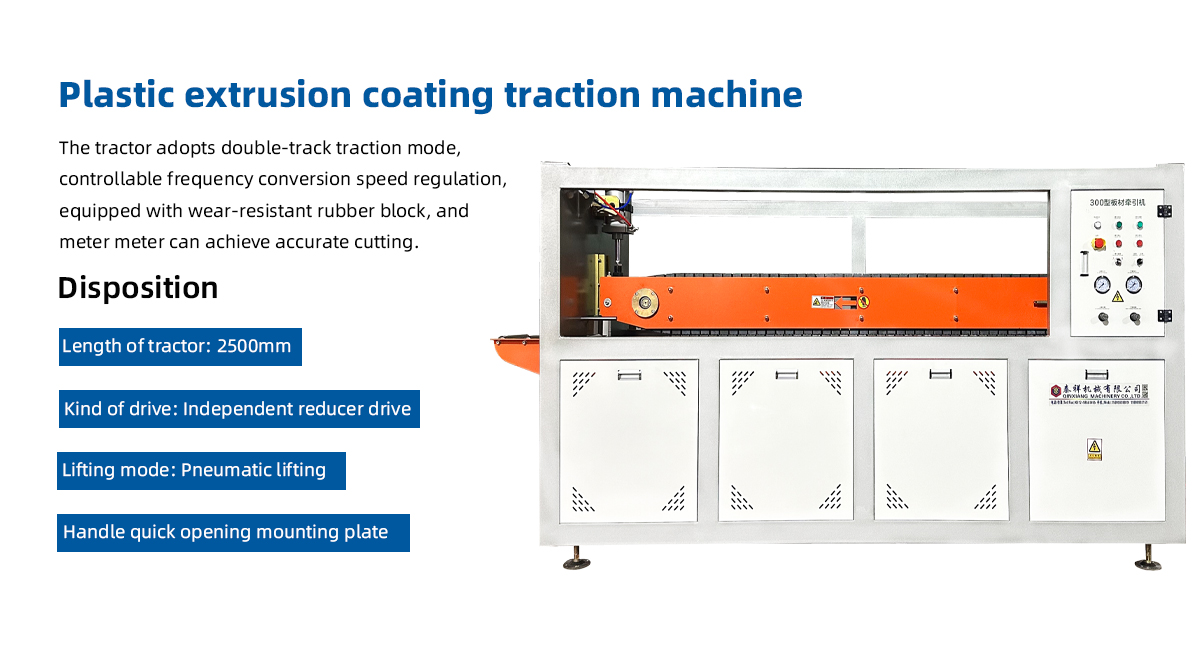

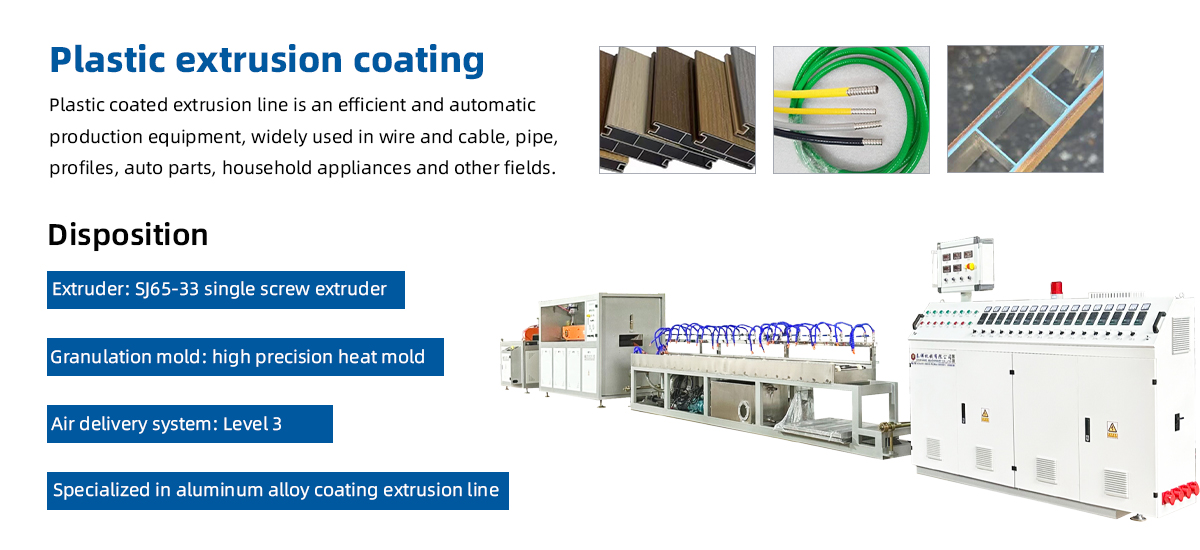

In the plastic coating extrusion line, the tractor is one of the indispensable key equipment, which is responsible for the smooth and continuous forward traction of the coated product to ensure the smooth transmission and subsequent processing of the product on the production line. The following is a detailed introduction to the tractor in the plastic coated extrusion line:

1.the role of the tractor

The main function of the tractor is to carry out stable and continuous traction on the coated semi-finished product during the plastic coating extrusion process to ensure that the shape, size and surface quality of the product are not affected. At the same time, the traction machine can also adjust the traction speed according to the production demand to adapt to the production of different specifications and materials.

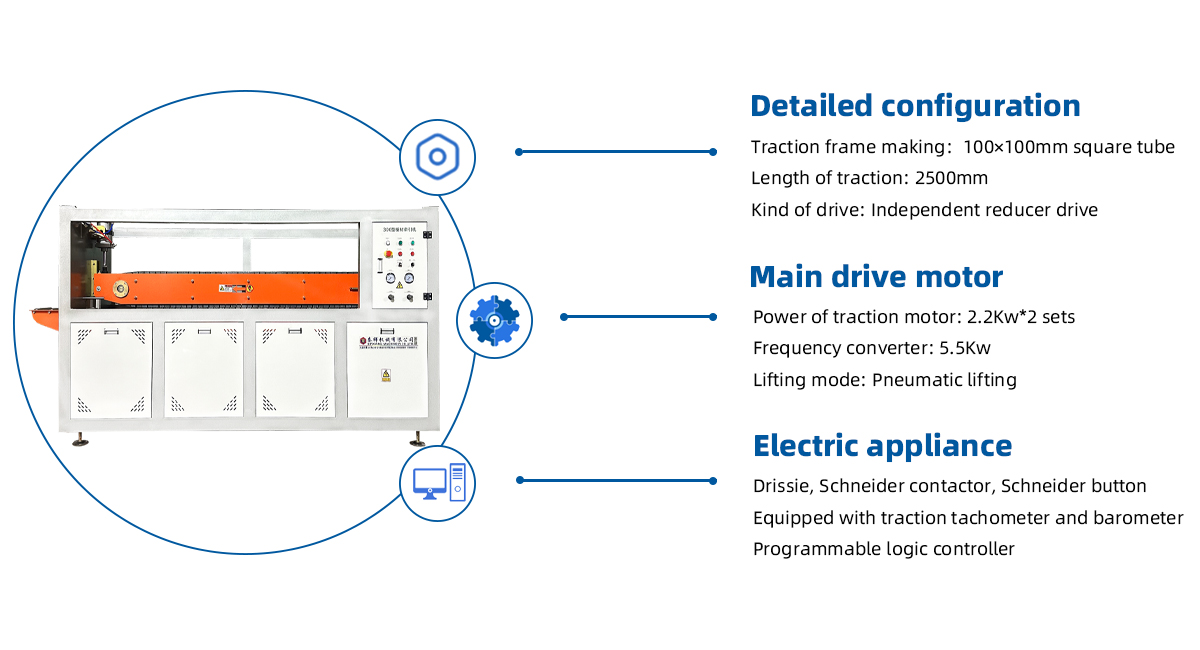

2. the structural characteristics of the tractor

The tractor usually includes a frame, a transmission system, a traction track or traction wheel, and a speed regulating device. Among them, the frame is the support structure of the tractor, and the transmission system transmits power to the traction track or traction wheel through the motor, reducer, gear and other components to drive its rotation. Traction tracks or traction wheels are in contact with the product surface through friction to achieve traction of the product. The speed regulating device is used to adjust the traction speed to meet the production demand.

3.the performance requirements of the tractor

3.1. Stability: The tractor should be kept running smoothly during the working process to avoid excessive vibration and noise to ensure the shape and dimensional accuracy of the product.

3.2. Adjustability: the traction speed should be adjusted according to the production needs to adapt to the production of different specifications and materials.

3.3. Wear resistance: Traction tracks or traction wheels should be made of wear-resistant materials to improve their service life and reduce maintenance costs.

3.4. Synchronicity: On the production line of multi-unit joint operation, good synchronicity should be maintained between each tractor to ensure the overall quality and production efficiency of the product.

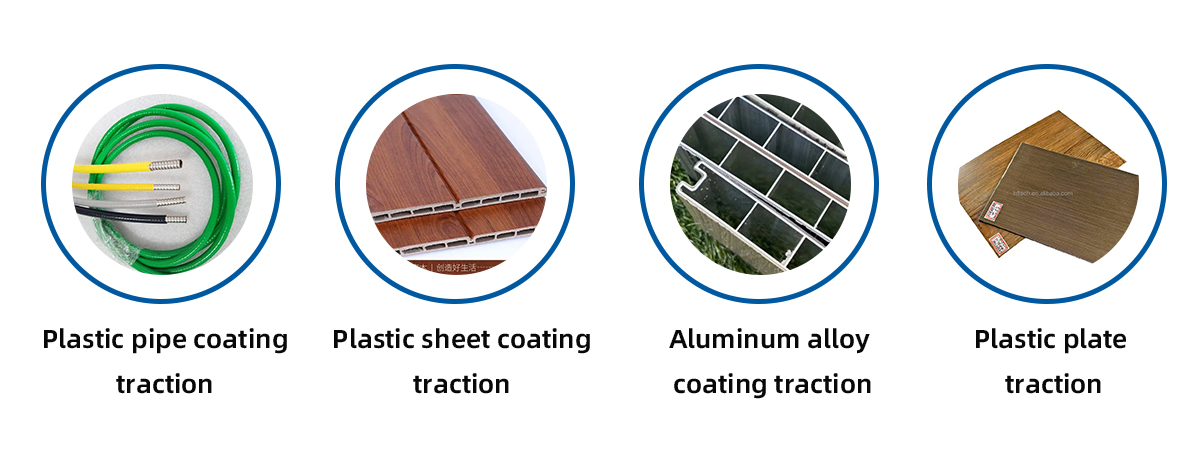

4. Application examples of tractor

In the plastic coating extrusion line, the tractor is usually used in conjunction with the extruder, the coating mold, the cooling water tank and other equipment. For example, in the production process of wire and cable, the tractor pulls the coated wire and cable smoothly out of the mold, and cools and solidifies through the cooling water tank, and finally obtains qualified wire and cable products.

5.Maintenance and maintenance

In order to ensure the normal operation of the tractor and extend its service life, regular maintenance and maintenance work are required. The details include:

5.1. Cleaning and maintenance: Regularly clean the dust and dirt on the surface of the traction track or traction wheel to keep it clean and smooth.

5.2. Lubrication maintenance: lubrication and maintenance of each part of the transmission system to reduce wear and reduce noise.

5.3. Check and adjust: Regularly check whether the parts of the tractor are loose or seriously worn, and tighten or replace them if necessary. At the same time, the traction speed is adjusted to ensure that it matches the production needs.

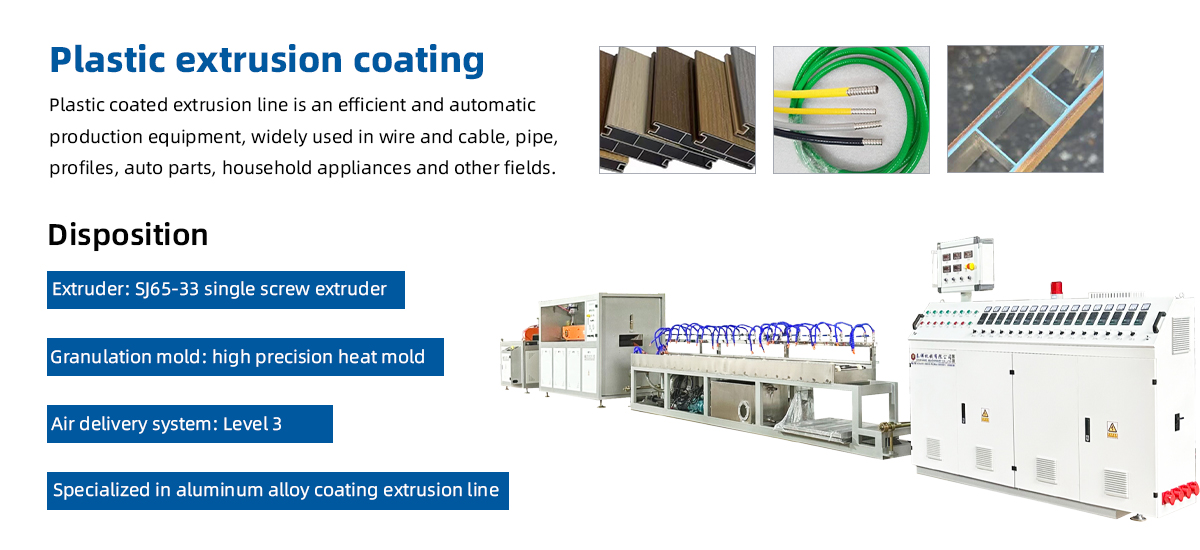

▏Complete production line recommendation

Click the link below to view the full line description!

plastic extrusion coating machine

▏About Us

▏Why Choose Us

▏Corporate Culture

▏Our Advantages

▏Cooperative Parts Supplier

▏Packing And Shipping