▏Product Introduction

▏Technical Parameters

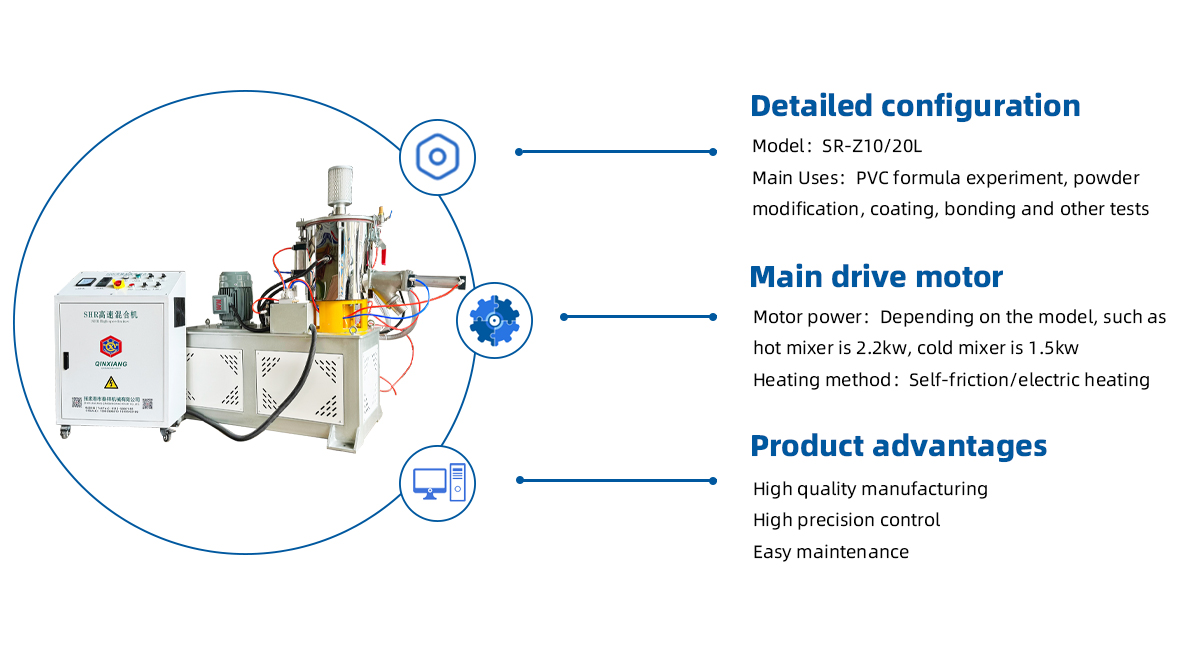

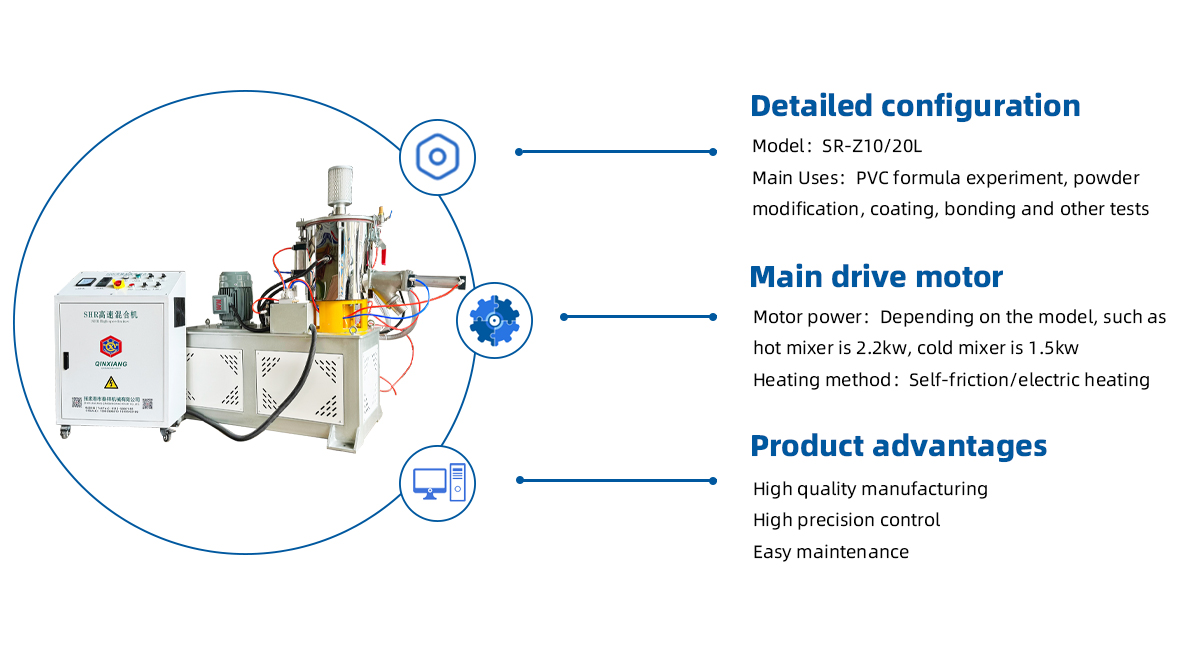

| Model | SR-Z10/20L |

| Main Uses | PVC formula experiment, powder modification, coating, bonding and other tests |

| Features | Both heating and cooling functions, automatic control, easy operation and cleaning |

| Total volume | 10L (hot mix) |

| Effective volume | 7L (hot mix) |

| Spindle speed | 0-1400/80rpm (hot mix/cold mix) |

▏Production Details

▏Product Photos

▏Product Introduction

The SRL10 Small High-Speed Mixer Unit is a compact, high-performance machine designed for efficiently mixing and blending various types of materials, particularly in the plastic processing, rubber, and chemical industries. This unit is commonly used in small to medium-scale production lines where precise mixing is required for the preparation of materials such as plastic resins, colorants, additives, and other compounds.

The SRL10 designation refers to the model’s specific capacity, with “10” typically indicating a 10-liter capacity. The unit is known for its versatility, high-speed operation, and reliability, making it ideal for both research and development (R&D) as well as smaller production batches.

Key Features of the SRL10 Small High-Speed Mixer Unit:

| 1. High-Speed Mixing:The SRL10 is equipped with a high-speed motor that ensures rapid and efficient mixing of materials. Its design allows for thorough blending of powders, liquids, resins, and additives, ensuring uniform distribution of components. This helps in achieving consistent product quality. |

| 2. Compact Design:The unit’s small footprint makes it ideal for use in limited spaces or small-scale production environments. Despite its compact size, it delivers high mixing efficiency and performance, making it suitable for applications in R&D labs, small factories, or pilot production runs. |

| 3. Precise Control:The SRL10 mixer unit features precise control over mixing speed and time. This level of control allows users to achieve optimal results depending on the specific materials being mixed. It can handle various types of materials, including plastic resins, additives, fillers, and colorants. |

| 4. Easy to Operate:The SRL10 mixer is user-friendly, with simple controls for operation. This ease of use is particularly beneficial for research environments, where operators may need to quickly adjust settings for different types of mixes. |

| 5. Efficient Heat Dissipation:The high-speed mixer is designed to prevent overheating during operation. It often comes with an integrated cooling system or efficient ventilation, ensuring that the materials do not degrade or undergo unwanted chemical reactions due to excessive heat. |

| 6. Durable and Reliable Construction:The unit is built with high-quality materials to withstand the demands of continuous mixing. Its robust construction ensures longevity and reliability, even in fast-paced environments. |

| 7. Versatile Applications:While primarily used for plastic and rubber material mixing, the SRL10 can also be applied to a wide range of other industries, such as coatings, adhesives, food processing, and pharmaceuticals, for blending and preparing formulations. |

| 8. Automatic Safety Features:The SRL10 mixer typically includes built-in safety features such as overload protection, emergency stop mechanisms, and safe guarding during operation, ensuring the safety of operators. |

Benefits:

| 1. Improved Mixing Efficiency:The high-speed motor enables rapid mixing of materials, reducing production time and increasing throughput, which is especially valuable in industries where time-to-market is critical. |

| 2. Consistent Product Quality:The precision and consistency of the mixing process ensure that the final product has uniform properties, reducing the chances of defects and variations that can occur in poorly mixed materials. |

| 3. Space-Saving:Its compact design makes it an excellent choice for businesses or laboratories with limited space. The SRL10 provides a high level of performance in a small footprint, making it ideal for small-scale operations. |

| 4. Energy-Efficient:Despite its high-speed operation, the SRL10 is designed to be energy-efficient, helping to reduce operational costs over time. It consumes minimal energy while delivering top-quality results. |

| 5. Flexibility:The SRL10 can be easily adjusted to handle different types of materials or to mix specific formulations, providing flexibility for manufacturers and researchers who work with a range of substances. |

Applications:

| 1. Plastic Industry:The SRL10 is commonly used in the plastic industry for mixing resins, colorants, and additives before extrusion or injection molding. It ensures that the materials are thoroughly blended for uniform properties in the final product. |

| 2. Rubber Processing:In rubber manufacturing, the SRL10 mixer is used to blend raw rubber compounds with chemicals, fillers, and other additives, ensuring consistent viscosity and properties in the rubber product. |

| 3. Paints and Coatings:It is used to mix pigments, binders, solvents, and other chemicals for the production of paints, coatings, and varnishes, ensuring smooth and even consistency. |

| 4. Pharmaceuticals:The mixer unit is used in pharmaceutical applications to blend active ingredients, fillers, excipients, and other compounds to create uniform formulations for tablets, capsules, and other products. |

| 5. Food and Beverage Industry:The SRL10 is useful for mixing food additives, flavors, spices, and other ingredients in small-scale food production, ensuring uniformity and consistency in the final product. |

The SRL10 Small High-Speed Mixer Unit is a versatile, efficient, and compact machine designed to meet the needs of various industries, including plastics, rubber, pharmaceuticals, and food processing. Its high-speed performance, precise control, and reliable construction make it an excellent choice for small-scale production, R&D, and pilot runs. The SRL10 mixer ensures consistent, high-quality results, increases production efficiency, and is easy to operate, making it a valuable asset in any manufacturing or research environment.

| 1 | Product Overview |

| Model : SR-Z10/20L Main Uses : PVC formula experiment, powder modification, coating, bonding and other tests Features : Both heating and cooling functions, automatic control, easy operation and cleaning |

| 2 | the main technical parameters |

|

Total volume : 10L (hot mix) Effective volume : 7L (hot mix) Spindle speed : 0-1400/80rpm (hot mix/cold mix) Heating method : Self-friction/electric heating Cold mixing method : circulating water cooling Motor power : Depending on the model, such as hot mixer is 2.2kw, cold mixer is 1.5kw Equipment weight : about 600kg |

| 3 | Product advantages |

|

1. High quality manufacturing : barrel body fine grinding and polishing, small experimental mixer barrel body all made of 5mm stainless steel plate, to ensure that the equipment is durable. 2. High precision control : stepless variable speed frequency conversion control system, all electrical components on the electric box visual operation, sensitive control accuracy. 3. Easy maintenance : The lid is sealed with double high temperature resistant rubber, the equipment is simple to operate and easy to clean. 4. Highly customized : Special customization can be made according to different processes of customers, such as the whole body to use stainless steel, special surface processing. |

| 4 | Application field |

|

SRL10 small mixer unit is widely used in various scientific research units, schools, laboratories, etc., is the ideal equipment for powder modification, coating, bonding and other tests. At the same time, it is also suitable for the production and research and development of small batch products. |

| 5 | purchase advice |

|

When purchasing SRL10 small mixer uint, the appropriate model and configuration should be selected according to the actual needs of the experiment or production.Consider the quality, performance and after-sales service of the equipment and other factors to ensure that the purchased equipment can meet the requirements of long-term use. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping