▏Product Vedio

▏Plastic 315PE Drainage Water Pipe Extrusion Line

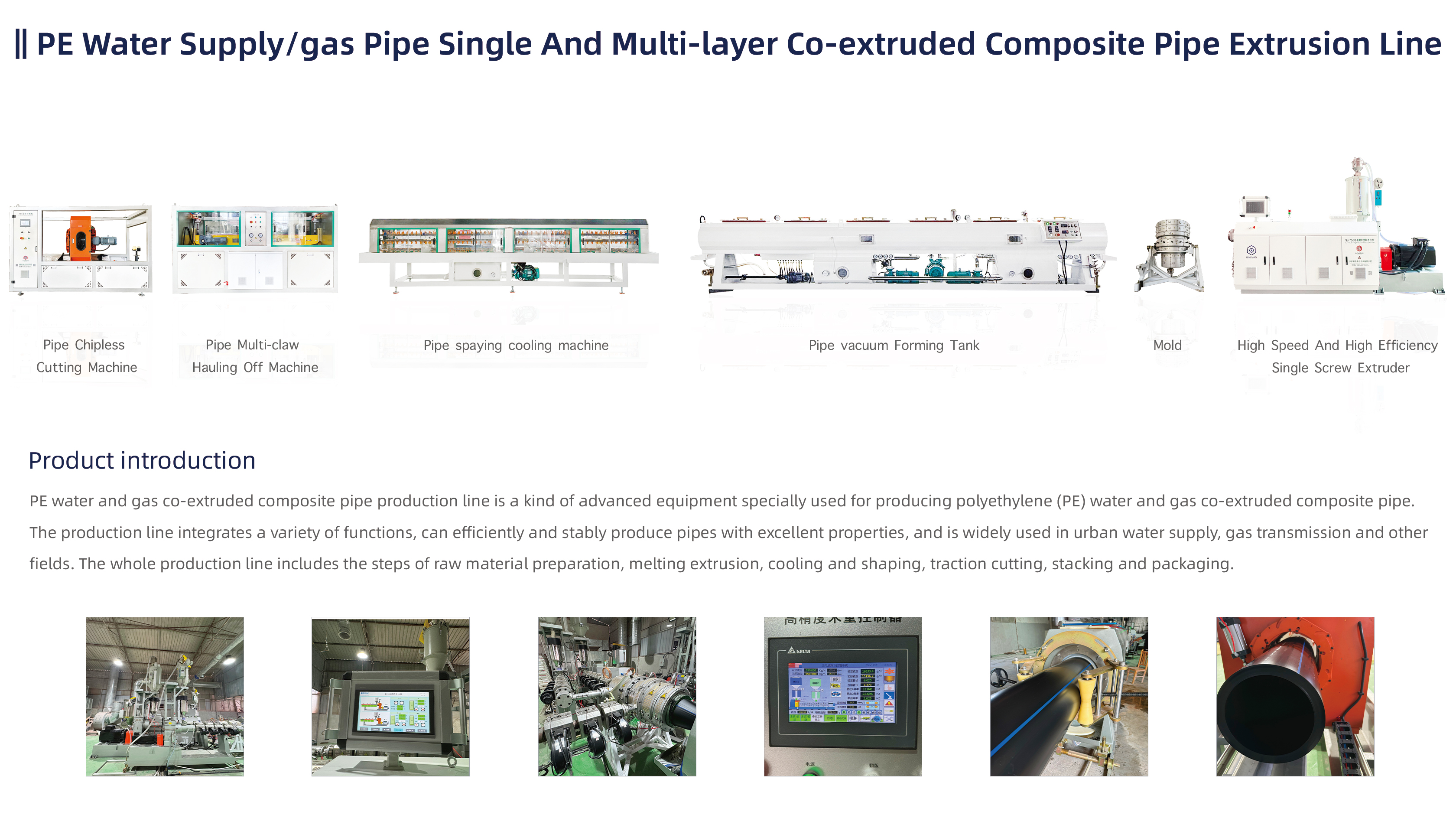

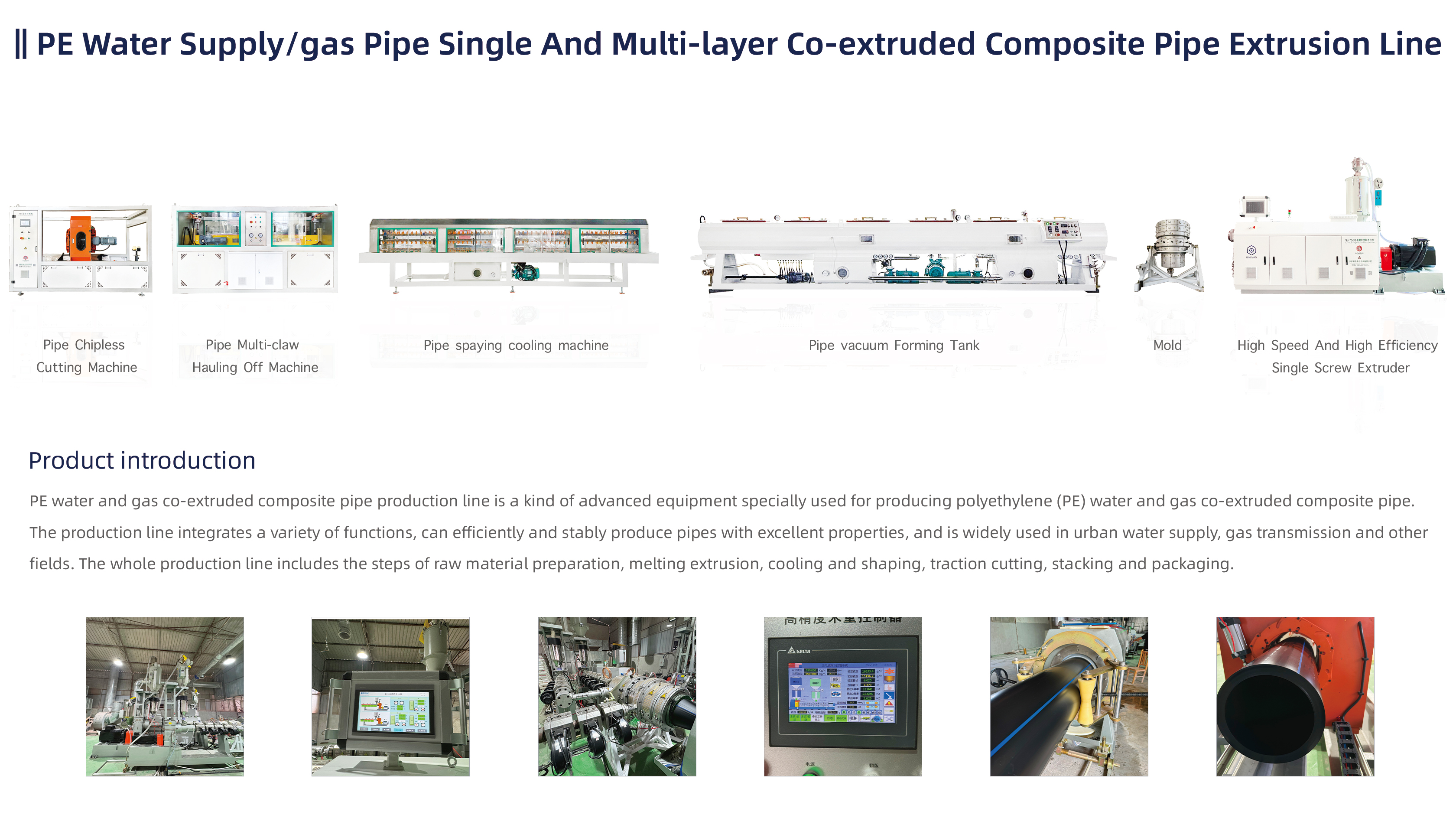

▏Introduction to the Plastic 315PE Drainage Water Pipe Extrusion Line

The Plastic 315PE Drainage Water Pipe Extrusion Line is a highly specialized and advanced manufacturing system designed for the production of durable, high-performance polyethylene (PE) drainage pipes. These pipes are used extensively in both residential and industrial drainage systems due to their resistance to corrosion, excellent flexibility, and low maintenance. With growing demand for robust drainage solutions, this extrusion line provides an efficient, cost-effective, and high-quality approach to producing pipes for wastewater management and drainage applications.

Manufacturers today need to produce large quantities of pipes that meet specific standards for pressure resistance, flexibility, and longevity. The Plastic 315PE Drainage Water Pipe Extrusion Line delivers on these needs with advanced technology that ensures superior quality, consistency, and efficient production.

▏Key Features of the Plastic 315PE Drainage Water Pipe Extrusion Line

| High-Precision Extruder for PE Materials

At the core of the Plastic 315PE Drainage Water Pipe Extrusion Line is the extruder, which plays a critical role in the production process. The extruder is designed specifically for polyethylene (PE), a widely used material in drainage systems due to its excellent resistance to environmental stress, flexibility, and ability to withstand chemical reactions. The extruder utilizes high-quality screws and barrels to melt and homogenize PE granules, ensuring a smooth and uniform flow of material. Precise temperature control during extrusion guarantees that the PE material is processed optimally, preventing degradation and ensuring the strength and durability of the final product. |

| Customizable Pipe Dimensions and Wall Thickness

The Plastic 315PE Drainage Water Pipe Extrusion Line is designed to produce pipes with varying diameters and wall thicknesses. Whether manufacturers are producing large-diameter pipes for major infrastructure projects or smaller pipes for residential use, this system can be easily adjusted to accommodate specific pipe specifications. The flexibility of the extrusion line allows manufacturers to meet specific customer needs, including requirements for pipe strength, flexibility, and pressure resistance. This customizability makes the extrusion line ideal for producing drainage pipes for diverse applications, from residential sewage systems to large-scale stormwater drainage projects. |

| Multi-Layer Extrusion Technology

Many drainage pipes require multi-layer extrusion to enhance their durability, strength, and resistance to external factors like UV radiation, chemicals, and abrasion. The Plastic 315PE Drainage Water Pipe Extrusion Line features multi-layer extrusion capabilities, which allow the creation of pipes with inner and outer layers designed for enhanced performance. These multi-layer pipes are ideal for harsh environments, as they offer greater resistance to physical stress, chemical exposure, and environmental wear. The machine ensures that each layer is uniformly applied, providing the pipe with superior protection and longevity. |

| Advanced Cooling and Calibration System

After extrusion, the pipe needs to be cooled and calibrated to maintain its shape and dimensional accuracy. The Plastic 315PE Drainage Water Pipe Extrusion Line includes a multi-stage cooling and calibration system that ensures the pipe cools evenly while retaining the correct diameter and thickness. Cooling is typically achieved through a combination of water baths and air-cooling systems. These systems help solidify the molten polyethylene, ensuring the pipe maintains its strength and shape. The calibration system ensures that each pipe is consistently shaped, preventing issues like ovality or irregularities in the final product. |

| High-Performance Haul-Off System

The Plastic 315PE Drainage Water Pipe Extrusion Line features a high-performance haul-off system designed to pull the extruded pipe through the cooling and cutting stages without causing damage. This system ensures that the pipe is pulled with the correct tension, preventing deformation or kinks during production. The haul-off unit includes rubber rollers or claws that grip the pipe securely while maintaining consistent tension. The adjustable pulling speed allows operators to fine-tune the process to suit the pipe’s diameter and material, ensuring smooth and uniform movement along the production line. |

| Automatic Cutting and Length Control

One of the most crucial components of the Plastic 315PE Drainage Water Pipe Extrusion Line is its automatic cutting system. The cutting system ensures that each pipe is cut to the required length with high precision, improving overall production efficiency. The length control system works in tandem with the haul-off system, automatically detecting when the pipe reaches the desired length and triggering the cutting process. This automation ensures that the pipes are consistently cut with minimal material waste, improving overall efficiency and reducing labor costs. |

| User-Friendly Control System

The Plastic 315PE Drainage Water Pipe Extrusion Line is equipped with an advanced, user-friendly control panel that allows operators to monitor and adjust various parameters, including temperature, pressure, speed, and cooling. This enables quick adjustments to ensure optimal performance and efficiency throughout the production process. With easy-to-use touch screen interfaces, operators can track key performance indicators and troubleshoot issues in real-time. This system reduces downtime, minimizes production errors, and ensures the smooth operation of the extrusion line. |

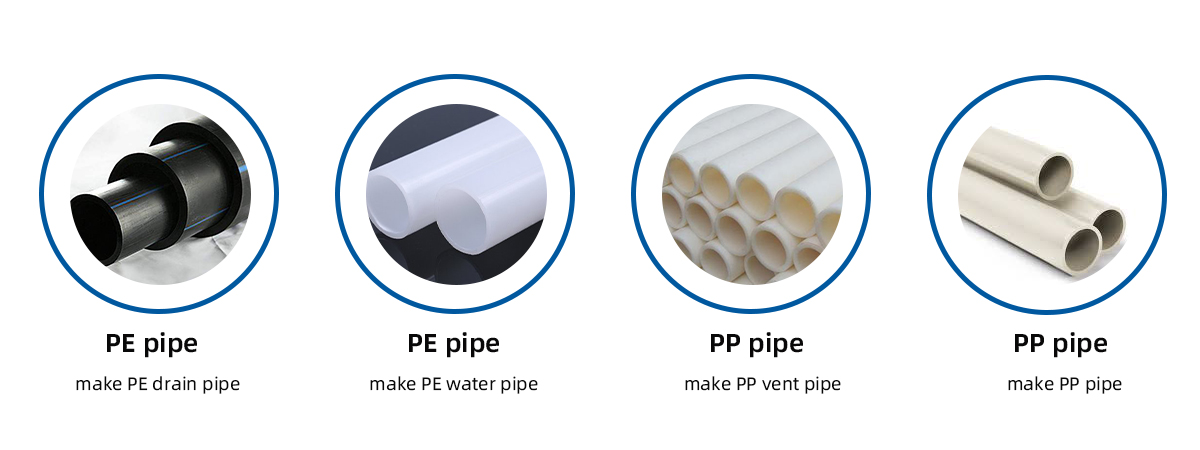

▏Range Of Application

▏Technical Parameters

Pipe outer diameter | Extruder | Maximum Capacity(kg/h) | Power(kw) |

Ø20-Ø63 | SJ60/38 | 320 | 70 |

Ø20-Ø110 | SJ60/38 | 380 | 90 |

Ø40-Ø160 | SJ60/38 | 460 | 110 |

Ø50-Ø250 | SJ75/38 | 600 | 160 |

Ø110-Ø450 | SJ90/38 | 850 | 250 |

Ø250-Ø630 | SJ90/38 | 1050 | 280 |

| Ø500-Ø800 | SJ120/38 | 1300 | 355 |

Ø710-Ø1200 | SJ75/38 SJ90/38 | 1450 | 160/250 |

Ø1000-Ø1600 | SJ90/38 SJ90/38 | 1900 | 280/280 |

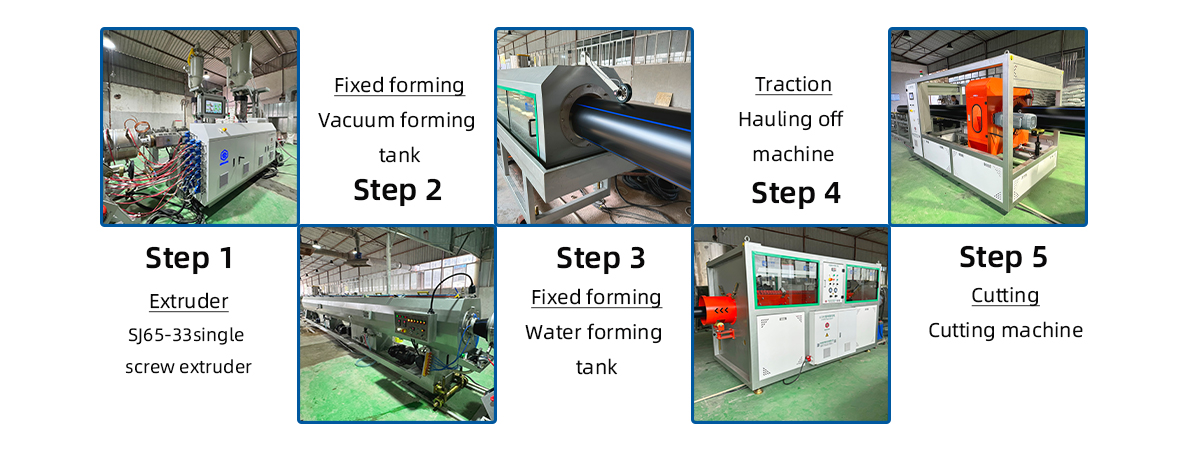

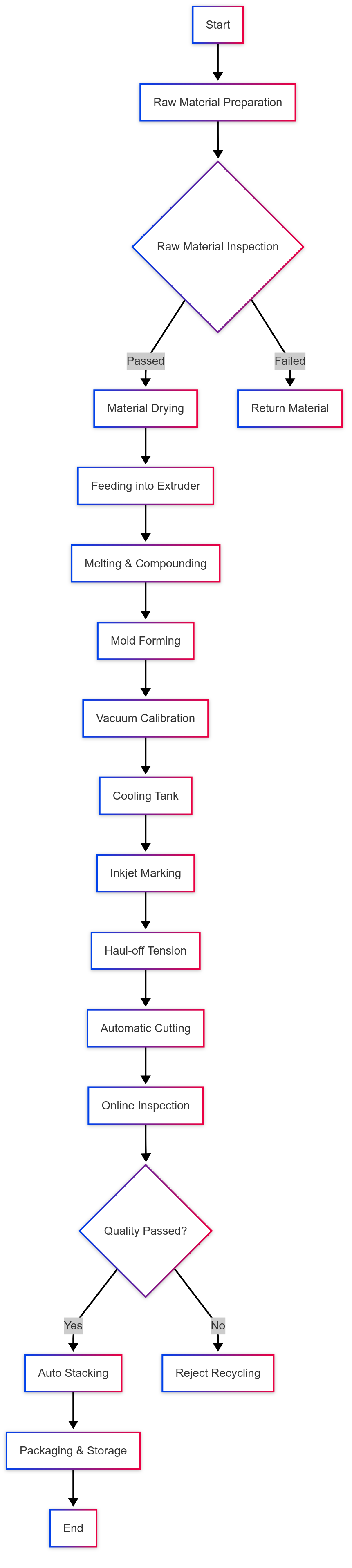

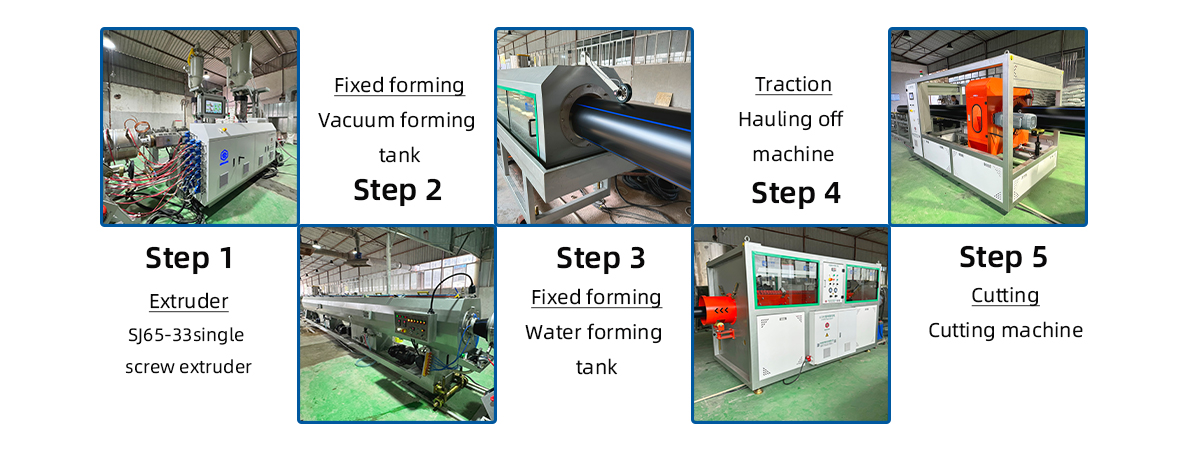

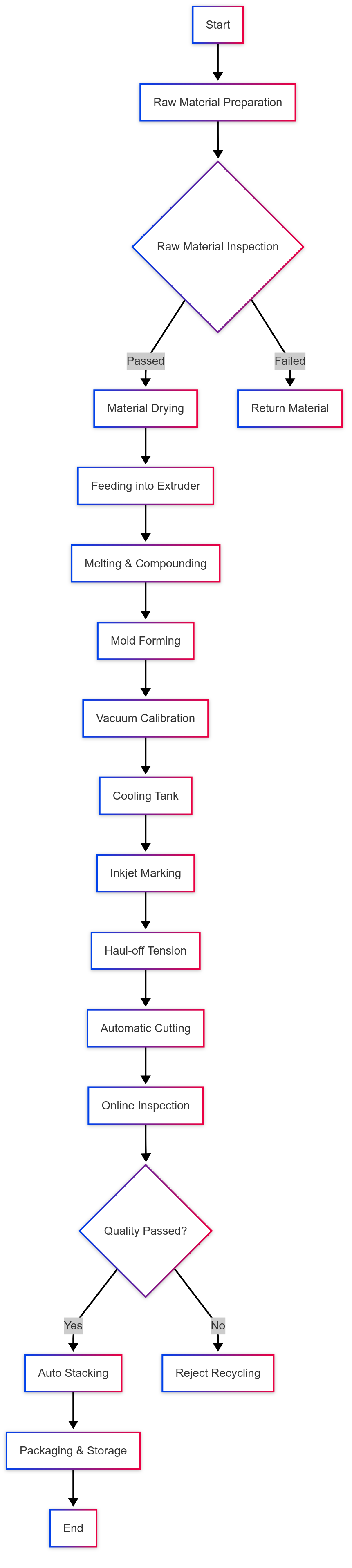

▏Production Procedure

▏Customer Case

▏How the Plastic 315PE Drainage Water Pipe Extrusion Line Works

▏Benefits of the Plastic 315PE Drainage Water Pipe Extrusion Line

| 1. High-Quality Production

The Plastic 315PE Drainage Water Pipe Extrusion Line is designed to produce pipes with consistent quality and performance. Its precise control over the extrusion, cooling, and calibration processes ensures that each pipe meets the required dimensional accuracy and performance standards. |

| 2. Flexibility and Customization

This extrusion line offers high levels of flexibility, allowing manufacturers to produce pipes in a variety of sizes, thicknesses, and materials. It can accommodate both single-layer and multi-layer extrusion, giving manufacturers the ability to create custom solutions for specific applications. |

| 3. Energy Efficiency

The Plastic 315PE Drainage Water Pipe Extrusion Line is designed to be energy-efficient, reducing energy consumption and lowering overall production costs. Optimized heating, cooling, and extrusion processes help manufacturers achieve high output while minimizing energy use. |

| 4. High Output and Efficiency

With its advanced design and automation, the extrusion line ensures high-speed production and reduced downtime. The ability to quickly switch between different pipe sizes and configurations also enhances the overall throughput of the production line. |

| 5. Minimal Maintenance

The extrusion line is built with high-quality components that require minimal maintenance. The machine is designed for continuous operation, and its easy-to-use control system allows for quick troubleshooting and minimal downtime. |

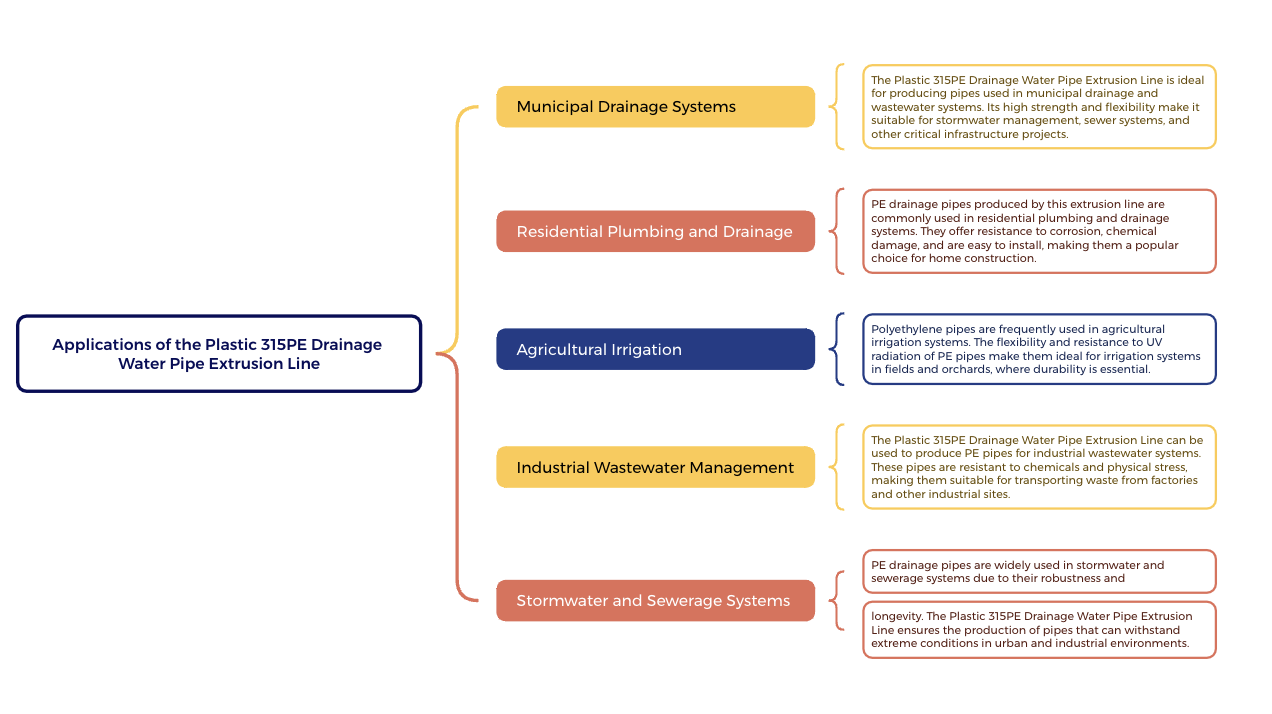

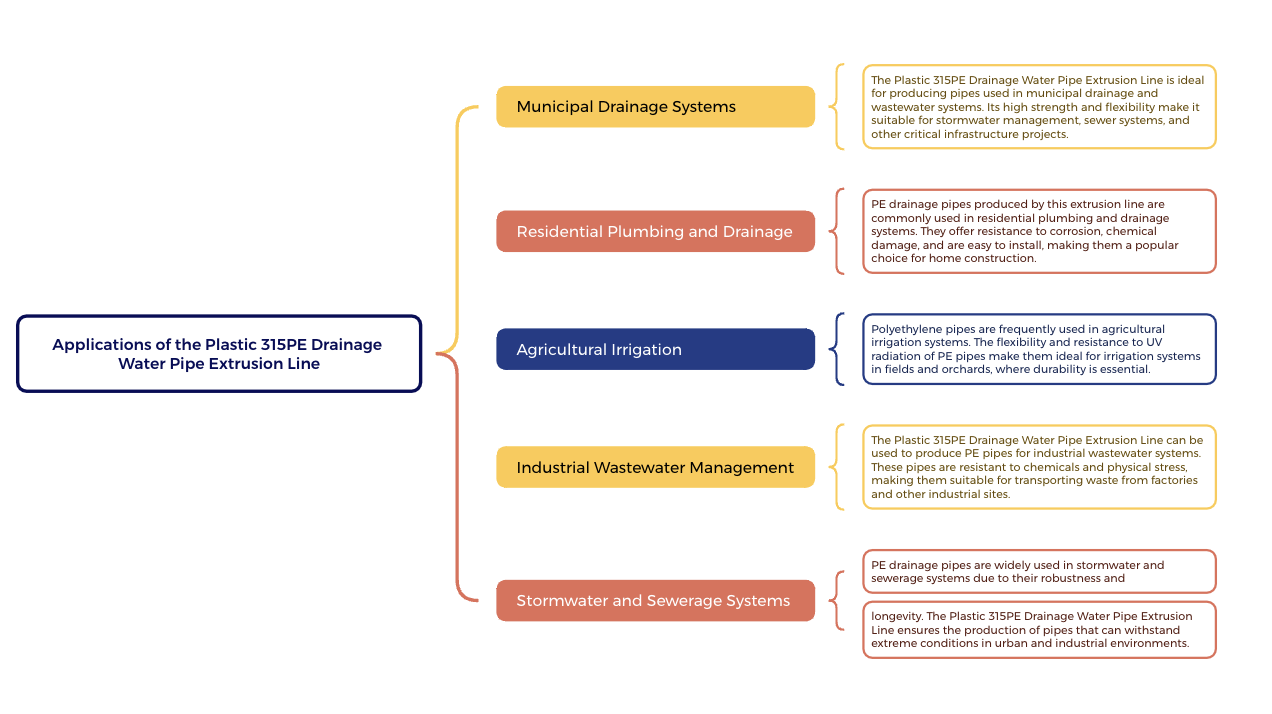

▏Applications of the Plastic 315PE Drainage Water Pipe Extrusion Line

▏Advancing the Future of Drainage Systems

The Plastic 315PE Drainage Water Pipe Extrusion Line is a cutting-edge solution for the efficient and high-quality production of polyethylene drainage pipes. With its customizable features, precise control over production parameters, and energy-efficient design, this extrusion line is ideal for manufacturers who require consistent, durable, and high-performance pipes for a wide range of applications. Whether for municipal, residential, agricultural, or industrial drainage systems, this advanced extrusion line meets the growing demand for reliable and long-lasting drainage solutions.

▏Product Advantage

| 1 | Efficient automated production |

| Plastic 315PE drainage water pipe extrusion line adopts advanced automatic control system to realize the whole process automation from raw material input to finished product output, which greatly improves the production efficiency. |

| 2 | Precise control |

| Plastic 315PE drainage water pipe extrusion line is equipped with high-precision temperature control system and speed regulation system, which can accurately control all aspects of plastic melting, extrusion, cooling and cutting to ensure the quality and performance of the pipe. |

| 3 | Continuous and stable production |

| Plastic 315PE drainage water pipe extrusion line is stable and reliable, and can be continuously produced for a long time, reducing the failure rate and downtime in the production process. |

| 4 | Excellent pipe quality |

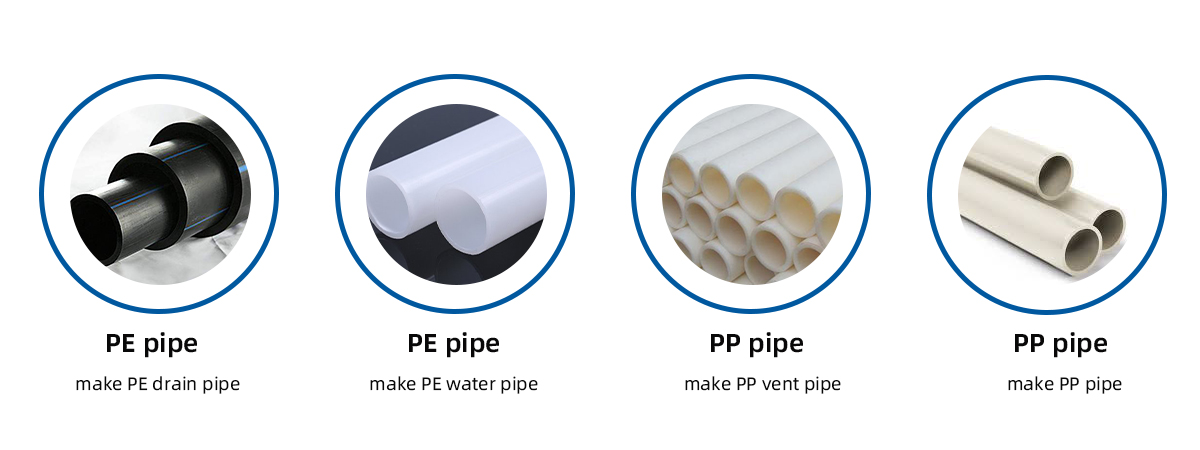

| Through precise extrusion and cooling process, the production line can produce PE/PP pipes with smooth surface, accurate size and stable performance to meet various application needs. |

| 5 | Strong adaptability |

| Plastic 315PE drainage water pipe extrusion line can be adjusted according to different raw materials and formulations to produce a variety of specifications and types of pipes to meet the diversified needs of the market. |

| 6 | Simple and flexible operation |

| The operation interface of the Plastic 315PE drainage water pipe extrusion line is friendly, the control system is easy to learn and master, and the operator can quickly adapt to the operation and management of the production line. |

| 7 | Energy saving and environmental protection |

| TPlastic 315PE drainage water pipe extrusion line pays attention to energy saving and environmental protection in the design and manufacturing process, and adopts low energy consumption drive system and emission control technology to reduce energy consumption and environmental pollution in the production process. |

| 8 | Easy maintenance |

| The structural design of the production line is reasonable, and the key components are easy to replace and maintain, reducing the maintenance cost and downtime. |

| 9 | High economic benefits |

| Due to high production efficiency, good product quality and low maintenance costs, the production line has brought significant economic benefits and market competitiveness to the enterprise. |

| 10 | Safe and reliable |

| Plastic 315PE drainage water pipe extrusion line is equipped with perfect safety protection devices and alarm systems, which can detect and deal with abnormal situations in the production process in time to ensure production safety. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping