▏Product Vedio

▏Product Introduction:PVC Soft Transparent Pellet Granulation Production Line

The PVC Soft Transparent Pellet Granulation Production Line is engineered to produce high-clarity, flexible PVC pellets widely used in transparent hoses, medical tubes, footwear, and flexible films. Designed for precision and consistency, this production line guarantees high transparency, softness, and stability in the final granules, making it a preferred choice for applications where visual quality and pliability matter most.

Leveraging years of technical expertise, we provide a complete, user-friendly, and energy-efficient system tailored to meet the needs of soft and transparent PVC processing.

▏Key Highlights

| High Transparency Output: Produces clear and flexible PVC pellets with minimal yellowing. |

| Soft Material Handling: Optimized screws and temperature control ensure minimal material degradation. |

| Stabilized Plasticizing Performance: Keeps molecular structure intact during extrusion. |

| Dust-Free Granulation: Clean and accurate pelletizing systems. |

| Tailored for Flexible PVC: Excellent adaptability for plasticizers and additives. |

| Modular Design: Easy to upgrade or scale based on future production needs. |

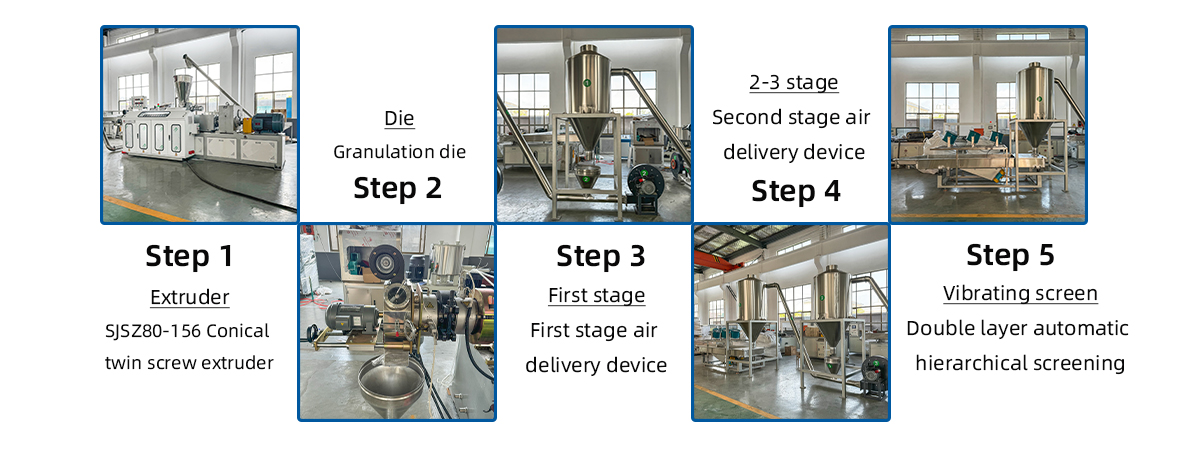

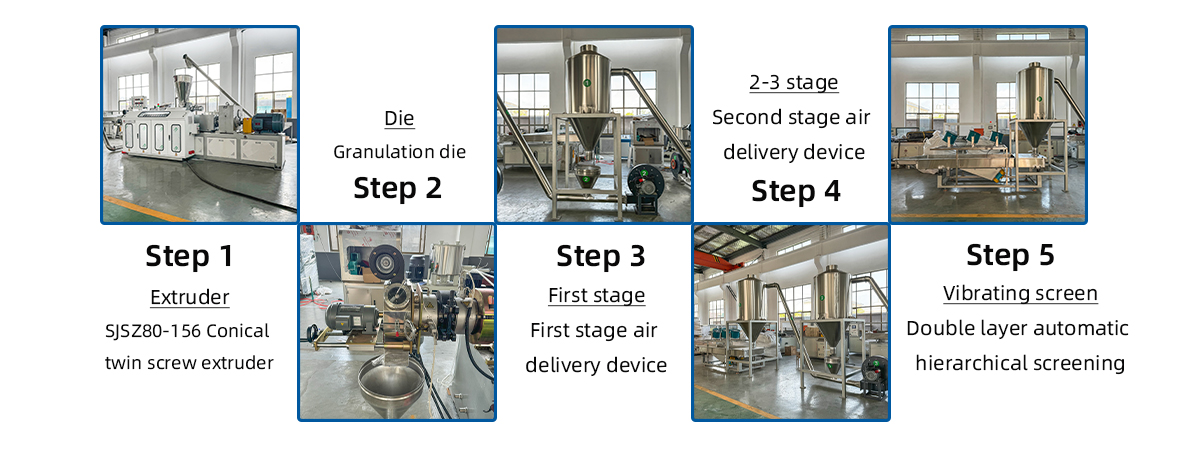

▏Product Procedure

▏Product Photos

▏Customer Case

▏Application Scope

| This PVC Granulation Equipment is specifically designed for:

Soft transparent pipe and hose manufacturing Shoe sole material production Transparent film and packaging sheet industry Medical tubing and IV bags Toy and inflatables industry |

| Industry Sector | Typical Products Produced |

| Medical Devices | Tubes, blood bags, infusion lines |

| Footwear | Transparent shoe soles, gel-like insoles |

| Packaging | Transparent films for food and pharma use |

| Industrial Tubing | Flexible clear hoses for fluids and gases |

| Consumer Goods | Toys, inflatable products, water mats |

▏Advantages of Our Soft PVC Recycling Extrusion Line

▏Core Components Configuration

| Module | Functionality Description |

| Vacuum Hopper Loader | Automatically transfers PVC raw materials |

| Soft PVC Twin-Screw Extruder | Precision extrusion designed for flexible materials |

| Temperature Controller Units | Multi-zone heating with real-time feedback |

| Underwater Pelletizer (Optional) | Ideal for sticky, soft pellets requiring gentle cutting |

| Cooling Conveyors | Air or water-cooled options based on softness |

| Centrifugal Dryer | Removes surface moisture from soft granules |

| Final Product Silo | Pellet storage with anti-stick coating |

▏Production Workflow

| Feeding of soft PVC compounds |

| Extrusion under precise temperature and shear |

| Degassing to eliminate air bubbles and moisture |

| Screen filtration to ensure purity |

| Gentle pelletizing process (strand or underwater) |

| Cooling and drying |

| Pellet classification and collection |

▏Real-World Implementations

| Case Study A: Transparent Tubing Manufacturer in Vietnam

Client Goal: Produce medical-grade soft PVC granules with ultra-high clarity.

Solution Delivered: Fully enclosed PVC Recycling Extrusion Line with underwater pelletizing.

Results: Reduced material wastage by 35% and improved pellet optical properties. |

| Case Study B: Toy Factory in Brazil

Client Goal: Convert soft PVC production scrap into reusable, colorful transparent pellets.

Customized Setup: Multi-zone heating control and air-cooling strand pelletizer.

Outcome: Achieved consistent product quality with minimal color fading. |

▏Why Choose Our PVC Soft Transparent Pellet Line?

▏Let’s Elevate Your Soft PVC Production

Need to manufacture ultra-clear, soft PVC pellets with consistent quality and performance? Connect with our team to explore the best-fit PVC Pelletizing Production Line for your requirements.

Final Keywords Mentioned: PVC Pelletizing Production Line, PVC Granulation Equipment, PVC Recycling Extrusion Line

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping