▏Product Vedio

▏Product Introduction

▏Technical Parameters

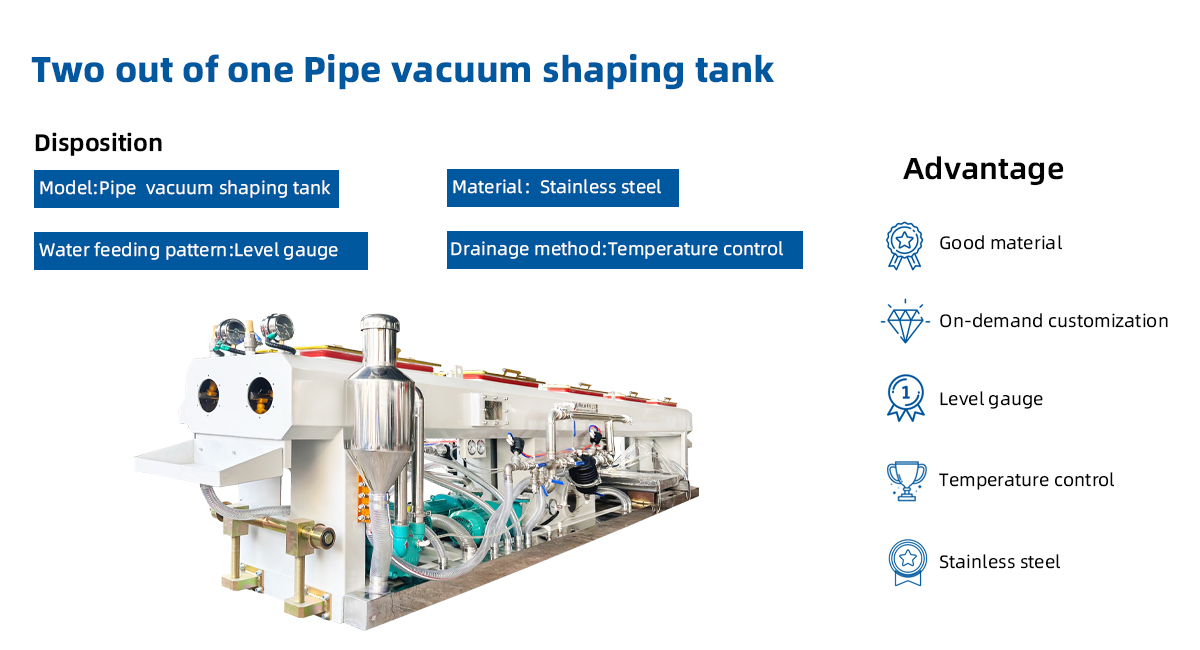

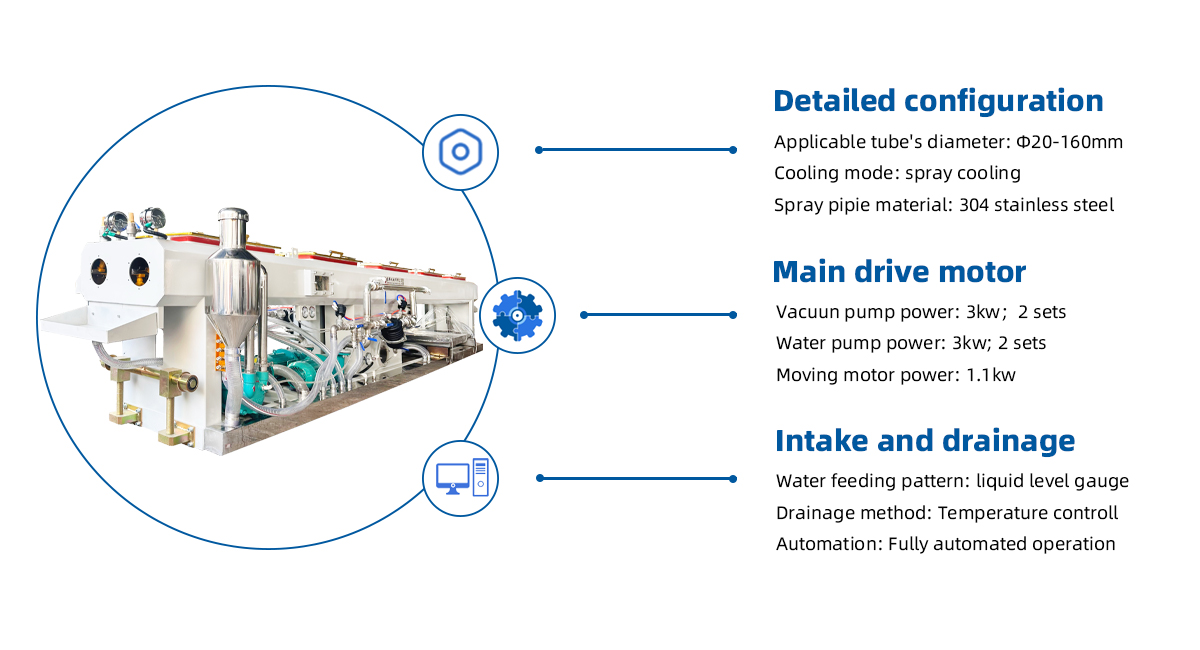

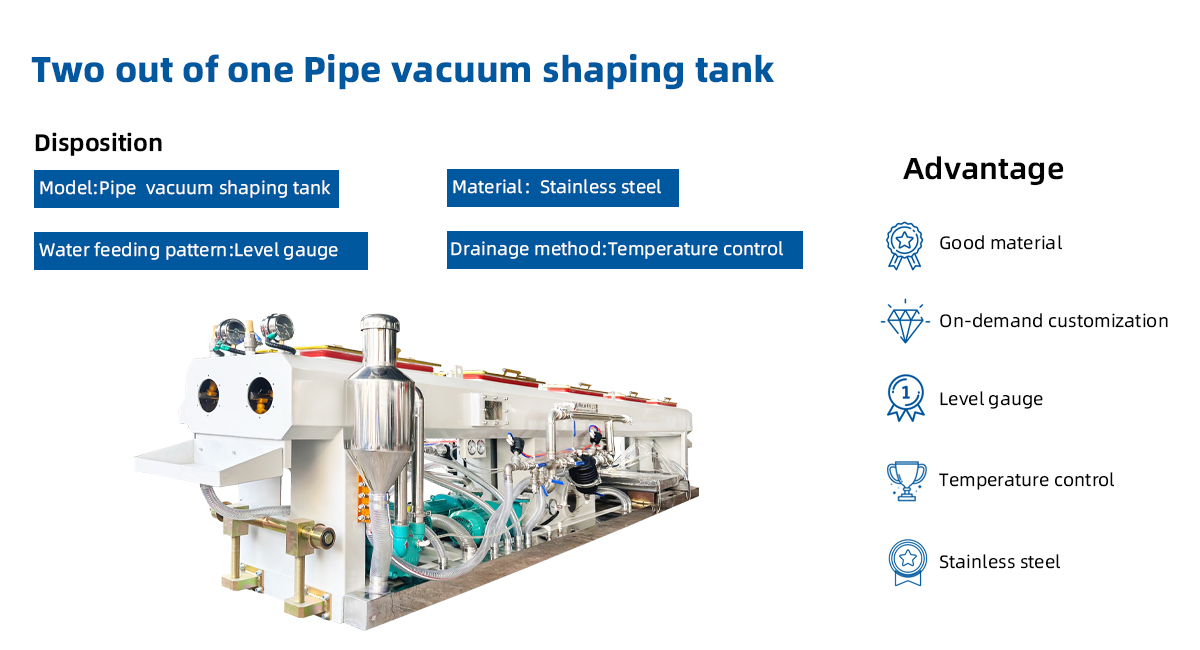

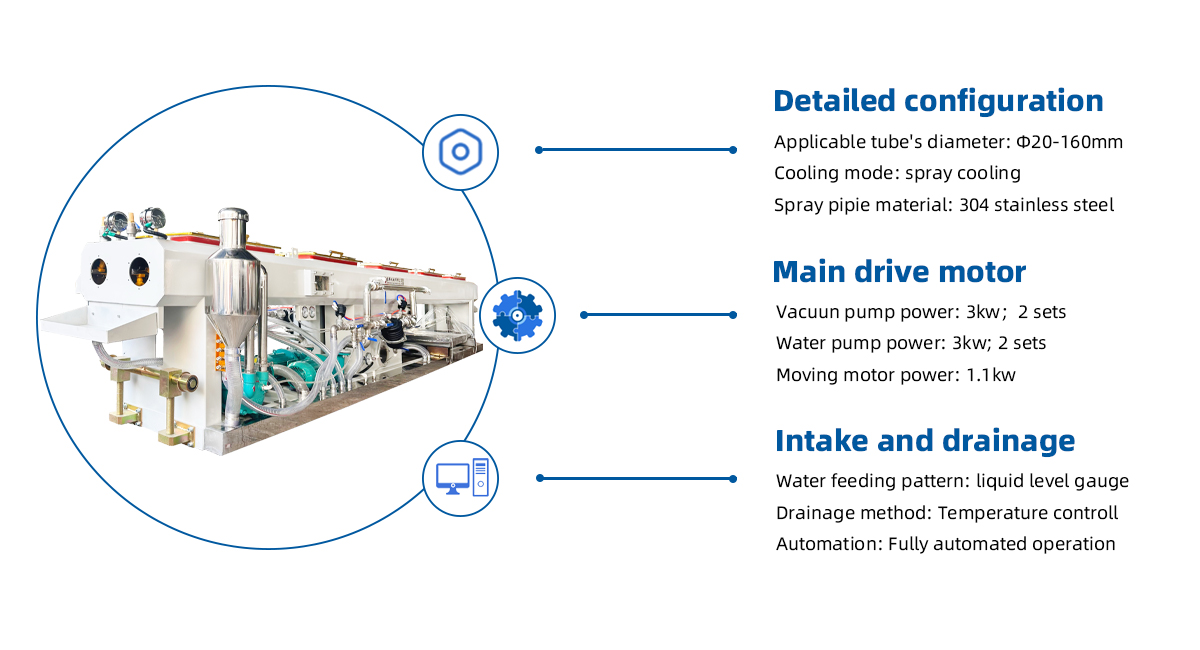

| Applicable tube's diameter | Φ20-160mm |

| Cooling mode | spray cooling |

| Spray pipie material | 304 stainless steel |

| Vacuun pump power | 3kw;2 sets |

| Water pump power | 3kw; 2 sets |

| Moving motor power | 1.1kw |

▏Production Procedure

▏Product Photos

▏Production Introduction

The 16-63mm Plastic PVC Pipe Vacuum Calibration Forming Tank is an essential piece of equipment in the manufacturing process of PVC pipes, specifically designed for pipes with diameters ranging from 16 mm to 63 mm. This tank plays a crucial role in the cooling and calibration of the extruded PVC pipes, ensuring they achieve the desired shape, size, and surface quality.

Once the PVC material has been melted and extruded through the die, it is still in a hot, soft state. The vacuum calibration forming tank uses both vacuum pressure and cooling water to solidify the pipe, maintain its dimensional accuracy, and ensure that it meets the required specifications. The vacuum ensures that the pipe retains its shape, while the cooling system helps to quickly solidify the pipe.

Key Features of the 16-63mm PVC Pipe Vacuum Calibration Forming Tank:

| 1. Vacuum Calibration:The vacuum calibration process involves applying controlled vacuum pressure around the extruded pipe as it moves through the tank. This pressure pulls the pipe tightly against the mold, ensuring that the pipe retains its correct diameter and smooth surface. This process is essential for maintaining the precision and quality of the pipe. |

| 2. Water Cooling System:The tank contains a water bath that cools the extruded PVC pipe quickly. The cooling process solidifies the material while preventing deformations, warping, or shrinkage. The temperature of the water is regulated to ensure optimal cooling conditions for the PVC. |

| 3. Adjustable Calibration:The calibration tank is designed to accommodate PVC pipes with diameters ranging from 16 mm to 63 mm, with adjustable settings to accommodate different pipe sizes. This flexibility allows manufacturers to produce a variety of pipe sizes with consistent quality. |

| 4. Dimensional Accuracy:The vacuum forming tank ensures that the PVC pipes maintain precise wall thickness and diameter, eliminating variations in size that could lead to product defects or poor performance in the final application. |

| 5. High Efficiency:The system is designed for high production efficiency. The continuous cooling and vacuum calibration processes work in tandem to rapidly cool and form the pipes without compromising on quality. This increases the overall throughput of the production line. |

| 6. Durable Construction:The tank is typically made from corrosion-resistant materials to withstand exposure to water and the conditions of continuous production. It is built to last and requires minimal maintenance. |

| 7. Automated Control System:Many modern PVC pipe vacuum calibration forming tanks are equipped with PLC-based control systems, which allow for precise monitoring and adjustment of parameters like vacuum pressure, water temperature, and pipe speed. This ensures that the calibration process is consistent and accurate for every batch of pipes. |

Benefits:

| 1. Enhanced Pipe Quality:The vacuum calibration and cooling process ensures that the extruded PVC pipes have consistent wall thickness, smooth surfaces, and accurate dimensions. This results in a high-quality finished product that meets industry standards. |

| 2. Increased Production Speed:The tank is designed for high-speed operation, allowing for quick cooling and solidifying of the pipes. This enhances production efficiency and enables manufacturers to meet high-volume production demands. |

| 3. Energy Efficiency:The advanced cooling and vacuum systems are designed to minimize energy consumption while maximizing cooling efficiency, leading to reduced operational costs. |

| 4. Reduced Defects:The precision calibration and cooling process reduces the likelihood of defects such as deformation, uneven wall thickness, or dimensional inaccuracies, ensuring that the final pipes are of superior quality. |

| 5. Adaptability:The ability to process pipes with a range of diameters (16 mm to 63 mm) makes the system highly versatile. Manufacturers can produce various sizes of PVC pipes without needing significant adjustments or additional equipment. |

| 6. Environmentally Friendly:The use of a closed-loop water system in many vacuum calibration tanks helps minimize water wastage and reduces the environmental impact of the production process. |

Applications:

| 1. Plumbing and Water Supply:PVC pipes produced using this calibration tank are widely used in plumbing systems for water distribution and drainage. The precise dimensional control ensures the pipes are leak-proof and meet regulatory standards. |

| 2. Electrical Conduit:PVC pipes are commonly used as conduits for electrical wiring due to their durability and resistance to corrosion. The calibration tank ensures that these pipes meet the required standards for protection and safety. |

| 3. Irrigation Systems:PVC pipes are extensively used in irrigation systems, where the pipes must maintain their shape and durability under various environmental conditions. The vacuum calibration tank ensures that pipes maintain their integrity during installation and operation. |

| 4. Gas Piping:The system is also used to produce PVC pipes for low-pressure gas piping, ensuring that the pipes are strong, consistent, and resistant to external pressures. |

| 5. Telecommunication:PVC pipes are used for protecting underground cables in telecommunications networks. The consistent dimensions and smooth surfaces produced by the calibration tank reduce the risk of damage to the cables. |

The 16-63mm Plastic PVC Pipe Vacuum Calibration Forming Tank is an essential piece of equipment in the production of high-quality PVC pipes. By using vacuum calibration and efficient water cooling, it ensures that the extruded pipes maintain accurate dimensions, smooth surfaces, and uniform wall thickness, making them ideal for applications in plumbing, irrigation, gas piping, and electrical conduits. Its high efficiency, adaptability, and ability to produce consistent results make it a crucial part of any PVC pipe extrusion line, helping manufacturers meet the growing demand for reliable, high-performance pipes.

▏Range Of Application

16-63mm plastic PVC pipe Vacuum Calibration Forming Tank is a kind of equipment used in the plastic pipe production line, mainly used for the cooling and shaping of the threaded pipe. Its main features and advantages are as follows:

| 1. The internal structure and parts are made of stainless steel to ensure the durability and stability of the equipment.

2. The water inlet and outlet are equipped with valves, which can be exchanged according to the water temperature or actual production needs, so as to ensure the best cooling and shaping effect. 3. A pressure gauge is also installed at the water inlet to facilitate the user to check the pressure in the box at any time and adjust it accordingly. 4. The device has beautiful appearance, simple structural design and convenient operation, so that users can easily get started in the use process and improve production efficiency. |

In addition, 16-63mm plastic PVC pipe Vacuum Calibration Forming Tank also uses a special roller and base design, when the vacuum pump is working normally, to ensure the stable operation of the equipment; When the vacuum pump fails and needs to be repaired, the design can easily pull out the vacuum pump, providing more operating space for the maintenance personnel, making the maintenance work more convenient.

Please note that for the specific use and maintenance of a two-out vacuum molding box, refer to the equipment's manual and operating procedures to ensure its normal operation and extend its service life. At the same time, according to the specific production needs and process requirements, the equipment may need to be properly adjusted and optimized to achieve the best production results.

▏Product Advantage

16-63mm plastic PVC pipe Vacuum Calibration Forming Tank has significant advantages in the plastic pipe production line, which are reflected in the following aspects:

| 1 | High efficiency production |

| The design of 16-63mm plastic PVC pipe Vacuum Calibration Forming Tank can realize the simultaneous processing of pipes on two production lines, which greatly improves the production efficiency. Compared with the traditional single forming tank, it can complete more work tasks in the same time, making the entire production process more efficient and fast. |

| 2 | Accurate setting effect |

| The 16-63mm plastic PVC pipe Vacuum Calibration Forming Tank uses vacuum technology to provide uniform and stable pressure distribution during pipe cooling and setting. This ensures the precise size and shape of the tube and improves product quality by reducing product defects due to uneven cooling or insufficient pressure. |

| 3 | Easy to operate and maintain |

| The structural design of the 16-63mm plastic PVC pipe Vacuum Calibration Forming Tank is simple and clear, so that the operator can easily get started. At the same time, all parts of the equipment are made of high-quality materials and manufacturing processes, making equipment maintenance more convenient. In addition, the valve design of the inlet and outlet and the installation of the pressure gauge facilitate the user to carry out daily inspection and maintenance of the equipment. |

| 4 | Highstability and durability |

| The interior of the tank is made of stainless steel to ensure that the equipment can operate stably in harsh production environments and is not susceptible to corrosion or damage. At the same time, the design of the roller and the base can also ensure that the equipment remains stable when the vacuum pump is working, reducing the equipment failure and loss of accuracy due to vibration. |

| 5 | Energy saving and environmental protection |

| Through reasonable water quality exchange and cooling system design, 16-63mm plastic PVC pipe Vacuum Calibration Forming Tank can ensure product quality at the same time, achieve the effective use of energy and reduce waste. This not only helps to reduce production costs, but also meets the requirements of modern industrial production for environmental protection and sustainable development. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping