▏Product Introduction

▏Production Details

▏Product Photos

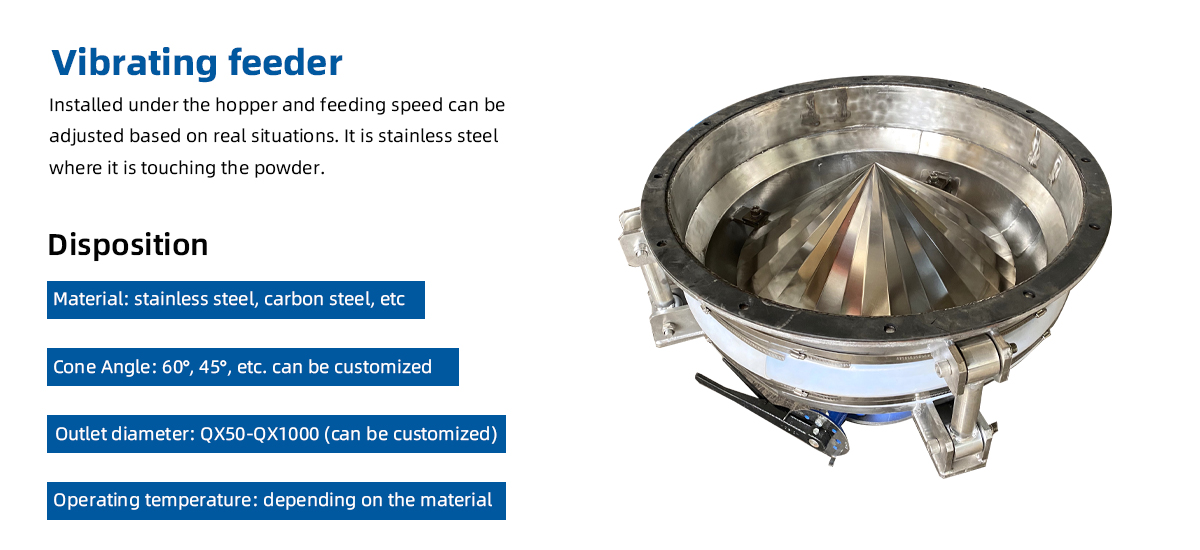

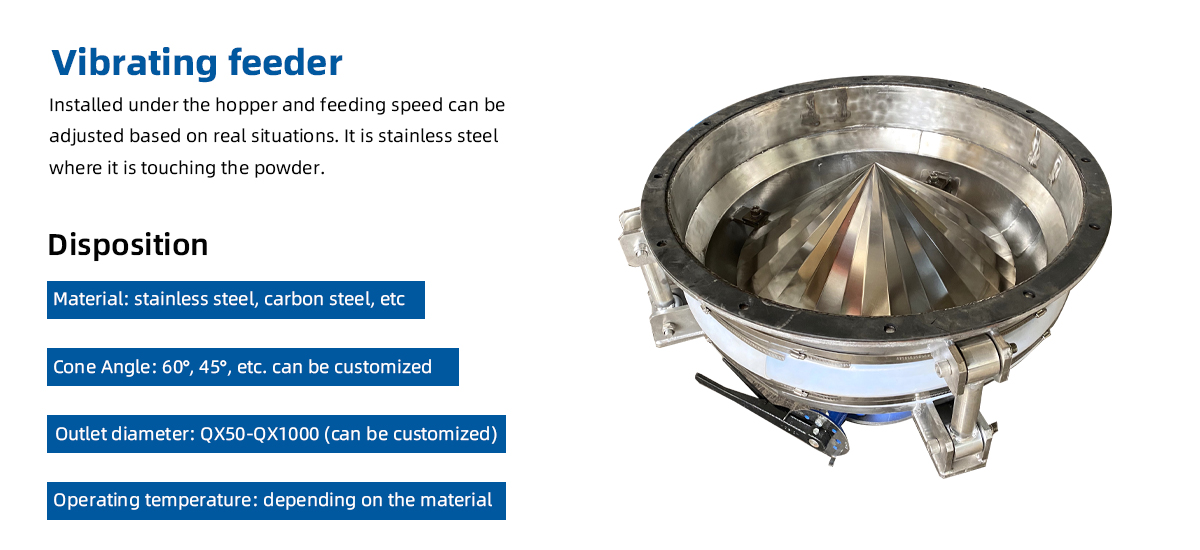

▏Silo Vibrating Feeding Hopper: The Ultimate Solution for Efficient Material Handling

The Silo Vibrating Feeding Hopper is a state-of-the-art material handling equipment designed to streamline the discharge and feeding of bulk materials from silos, bins, or storage containers. Combining advanced vibration technology with robust engineering, this hopper ensures smooth, consistent, and controlled material flow, making it an indispensable tool for industries such as food processing, pharmaceuticals, chemicals, construction, and agriculture. Whether you're handling powders, granules, or other bulk materials, the Silo Vibrating Feeding Hopper delivers unmatched efficiency, reliability, and performance.

Key Features

| 1 | Advanced Vibration Technology |

| The hopper utilizes high-frequency vibration to break material bridges, eliminate blockages, and ensure a steady flow of materials. This technology is particularly effective for handling sticky, cohesive, or irregularly shaped materials. |

| 2 | Uniform Material Discharge |

| The vibrating mechanism ensures consistent and controlled material discharge, preventing overfeeding or underfeeding and maintaining optimal process efficiency. |

| 3 | Versatile Material Compatibility |

| Designed to handle a wide range of bulk materials, including powders, granules, pellets, and flakes, the hopper is suitable for diverse industrial applications. |

| 4 | Durable and Robust Construction |

| Built with high-quality materials such as stainless steel or carbon steel, the hopper is resistant to wear, corrosion, and impact, ensuring long-term reliability even in harsh operating conditions. |

| 5 | Customizable Design |

| The hopper can be tailored to meet specific requirements, including different sizes, shapes, and discharge rates. It can also be integrated with existing silos, conveyors, or processing equipment. |

| 6 | Energy-Efficient Operation |

| The vibrating mechanism is designed to deliver high performance with low energy consumption, reducing operational costs and supporting sustainable practices. |

| 7 | User-Friendly Operation |

| The hopper features an intuitive control panel that allows operators to easily adjust vibration intensity, frequency, and discharge rate. Safety features, such as overload protection and emergency stop functions, ensure safe and reliable operation. |

| 8 | Low Maintenance |

| With minimal moving parts and a simple design, the hopper requires little maintenance, reducing downtime and operational costs. |

| 9 | Hygienic and Easy to Clean |

| The smooth surfaces and accessible design of the hopper make it easy to clean and maintain, ensuring compliance with hygiene standards in industries like food and pharmaceuticals. |

| 10 | Noise Reduction |

| The hopper is designed to operate with minimal noise, creating a quieter and more comfortable working environment. |

Applications

The Silo Vibrating Feeding Hopper is a versatile solution for a wide range of industries and applications:

- Food Processing: Discharging ingredients such as flour, sugar, spices, and grains.

- Pharmaceuticals: Feeding powders and granules for tablet production and drug formulations.

- Chemicals: Handling bulk materials like fertilizers, resins, and industrial powders.

- Construction: Discharging cement, sand, and aggregates for concrete production.

- Agriculture: Feeding animal feed, seeds, and fertilizers.

- Plastics: Discharging polymer pellets and additives for manufacturing processes.

Why Choose the Silo Vibrating Feeding Hopper?

| 1 | Enhanced Material Flow |

| The vibrating mechanism ensures smooth and consistent material discharge, eliminating blockages and improving process efficiency. |

| 2 | Increased Productivity |

| By automating the feeding process, the hopper reduces manual labor and increases production output, allowing businesses to meet growing demand. |

| 3 | Cost-Effective Solution |

| The energy-efficient operation and low maintenance requirements of the hopper reduce operational costs and maximize return on investment. |

| 4 | Superior Quality and Consistency |

| The controlled discharge ensures uniform material flow, improving product quality and reducing waste. |

| 5 | Reliability and Durability |

| Built to withstand heavy-duty use, the hopper offers unmatched reliability and a long service life, ensuring consistent performance over time. |

| 6 | Sustainability |

| By optimizing material usage and reducing waste, the hopper supports sustainable manufacturing practices. |

Technical Specifications

- Capacity: Available in various sizes to suit different material volumes.

- Material Compatibility: Suitable for powders, granules, pellets, and flakes.

- Discharge Rate: Adjustable to meet specific process requirements.

- Construction Material: High-grade stainless steel or carbon steel.

- Power Supply: Available in standard and customized power configurations.

The Silo Vibrating Feeding Hopper is the ultimate solution for industries seeking to optimize their material handling processes. With its advanced vibration technology, robust design, and user-friendly features, it delivers unmatched efficiency, reliability, and performance. Whether you're handling food ingredients, pharmaceutical powders, or industrial materials, the Silo Vibrating Feeding Hopper is the ideal choice for achieving consistent and high-quality results.

Invest in the Silo Vibrating Feeding Hopper today and experience the perfect blend of innovation, reliability, and performance in your material handling process!

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping