▏Product Vedio

▏Vacuum Suction Machine: Advanced Solution for Efficient Material Handling

▏Introduction to the Vacuum Suction Machine

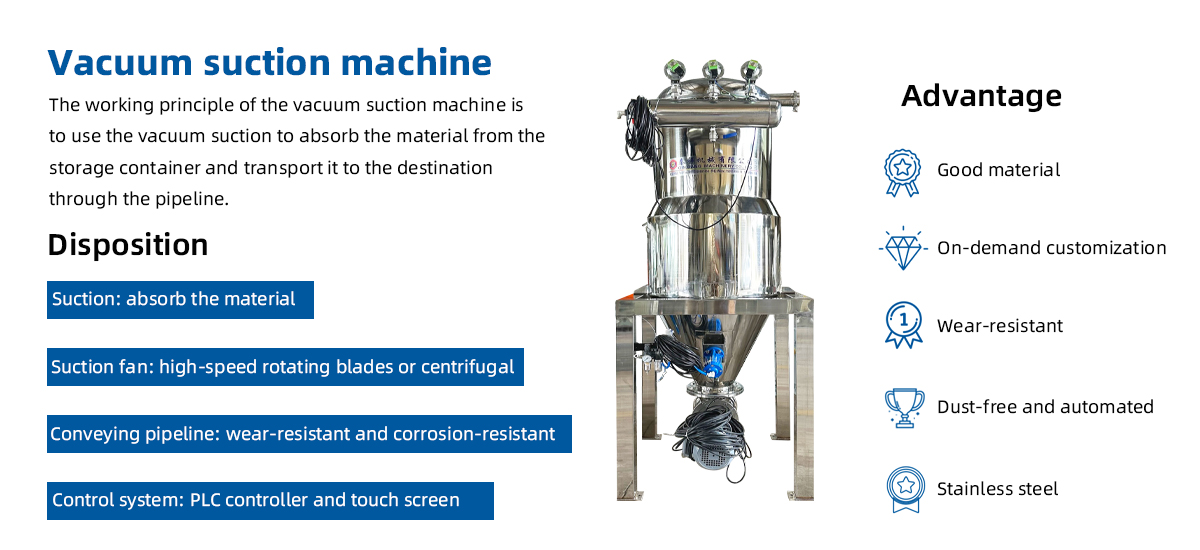

The Vacuum Suction Machine is an advanced material handling system designed to efficiently lift, transport, and place materials using the power of vacuum suction. This technology is widely used across various industries, including packaging, automotive, food processing, pharmaceuticals, and logistics. The vacuum suction machine utilizes the principle of vacuum pressure to create a strong grip on objects, allowing them to be moved and manipulated with ease.

Whether you're dealing with delicate items like glass, paper, and thin films, or heavier materials such as wood panels and metal sheets, the Vacuum Suction Machine offers a versatile and reliable solution. Its gentle yet powerful suction mechanism ensures the secure handling of materials without causing damage, making it an invaluable tool for improving productivity, reducing manual labor, and enhancing workplace safety.

▏Key Features of the Vacuum Suction Machine

| Powerful and Adjustable Suction Capacity

One of the standout features of a Vacuum Suction Machine is its adjustable suction power. The machine uses a vacuum pump to create suction, which can be tailored to suit different materials and sizes. Whether handling small, lightweight objects or heavy, bulky items, the suction capacity can be adjusted to provide optimal handling power. This feature ensures versatility, as the same machine can be used for a wide range of applications and materials. |

| Flexible and Efficient Handling System

A key benefit of the Vacuum Suction Machine is its flexible handling system. Equipped with suction cups or pads, the machine can securely grip materials of varying shapes and sizes. The suction cups are designed to adapt to the contours of the material, providing a stable grip without causing deformation or damage. These cups can be customized in size, shape, and material to suit specific handling requirements, allowing the machine to work efficiently with diverse types of products. |

| User-Friendly Controls and Automation

The Vacuum Suction Machine is often designed with easy-to-use controls, making it simple for operators to adjust suction levels, movement speed, and other settings. Many models are also integrated with automated features such as programmable controls, touchscreens, and robotic arms, enhancing precision and reducing the need for manual intervention. Automation allows for faster cycle times, fewer errors, and reduced labor costs. |

| Compact and Ergonomic Design

Designed with both functionality and ergonomics in mind, the Vacuum Suction Machine often features a compact form factor that can be easily integrated into existing workflows. Its small footprint ensures that it can fit into confined spaces or be mounted on existing equipment, maximizing available space in the production area. Additionally, the ergonomic design minimizes operator fatigue, making it easier for workers to handle and manipulate materials over long periods without strain. |

| Durability and Low Maintenance

The Vacuum Suction Machine is built for durability. Constructed from high-quality materials, such as stainless steel and durable polymers, it is designed to withstand heavy use and exposure to different environmental conditions. Moreover, these machines are low-maintenance, with easily accessible components for cleaning and service. Many models also include self-diagnostic features to identify issues early, reducing the need for costly repairs and downtime. |

▏Production Details

▏Product Photos

▏How the Vacuum Suction Machine Works

The Vacuum Suction Machine operates by creating a vacuum within its suction cups or pads. The machine is typically equipped with a vacuum pump that generates suction pressure. The suction cup is placed on the surface of the material, and the pump creates a vacuum that securely grips the material. Once the material is held in place, the machine’s movement system (often a robotic arm, conveyor, or lifting mechanism) transports the material to its next destination.

| Vacuum Generation: The vacuum pump is activated to create a vacuum inside the suction cups. This creates negative pressure, which allows the machine to grip the material securely. Material Handling: Once the material is held by the suction cups, the machine’s arm or conveyor system lifts and transports the material to the desired location. Release Mechanism: Once the material reaches its destination, the vacuum suction is released by either turning off the vacuum pump or using a valve to allow air into the system. This releases the grip on the material, allowing it to be placed accurately in its new location. |

The Vacuum Suction Machine can be programmed to handle multiple materials in quick succession, ensuring that production lines continue to run smoothly and efficiently.

▏Benefits of the Vacuum Suction Machine

| Improved Efficiency and Productivity

The Vacuum Suction Machine significantly boosts operational efficiency by automating material handling tasks that would otherwise be performed manually. With its ability to move materials quickly and precisely, the machine reduces cycle times and increases throughput. The automation also ensures that materials are consistently handled in the same manner, improving overall process consistency and reducing the risk of errors. |

| Enhanced Worker Safety

Manual material handling can pose a range of risks, including lifting injuries, repetitive strain, and exposure to hazardous materials. The Vacuum Suction Machine reduces the need for human intervention in heavy lifting tasks, minimizing the risk of workplace accidents. Operators are no longer required to manually lift heavy or awkward materials, which improves overall safety in the workplace. |

| Reduced Material Damage

One of the key advantages of using a Vacuum Suction Machine is that it provides a gentle grip on materials, reducing the likelihood of damage. For delicate items such as glass, metal sheets, or plastic components, the machine's suction cups provide a secure hold without causing scratches, dents, or deformities. This makes it an ideal solution for industries that require precision handling of sensitive materials. |

| Versatility Across Industries

The Vacuum Suction Machine can be used in a wide range of industries, making it a versatile tool for material handling. In the automotive industry, it can be used to handle heavy parts and components, while in food processing, it can be used to lift fragile food products without contamination. The pharmaceutical industry also benefits from the precision and hygiene offered by vacuum suction systems for handling tablets, vials, and packaging materials. |

| Cost Savings

By automating material handling tasks, the Vacuum Suction Machine reduces the need for manual labor, leading to cost savings in terms of staffing. The increased speed and accuracy also reduce material waste, as products are handled more carefully and efficiently. Additionally, by preventing damage to materials, companies can avoid costly replacements and rework. |

▏Applications of the Vacuum Suction Machine

| Automotive Industry

In the automotive industry, the Vacuum Suction Machine is used to handle a variety of parts, from glass panels to heavy engine components. It allows for precise placement and safe transport of materials, reducing the risk of damage during assembly. |

| Food Processing

The Vacuum Suction Machine is essential in food processing plants where fragile items, such as fruits, vegetables, and packaged goods, need to be moved efficiently without causing damage. The system also prevents contamination by ensuring that the materials are handled in a controlled and hygienic environment. |

| Electronics Manufacturing

In electronics manufacturing, delicate components such as circuit boards, displays, and semiconductor wafers are often handled using vacuum suction technology. The gentle yet secure grip ensures that these sensitive items are transported safely without risk of static or physical damage. |

| Logistics and Packaging

In the logistics and packaging industries, vacuum suction systems are used to automate the picking and placing of items in boxes, crates, or pallets. The machines help increase speed in packaging operations while reducing labor costs and errors associated with manual handling. |

▏The Future of Material Handling

The Vacuum Suction Machine is a revolutionary solution for material handling that offers numerous benefits across various industries. By automating tasks such as lifting, transporting, and placing materials, it enhances productivity, reduces manual labor, improves safety, and minimizes material damage. Its versatility, precision, and low maintenance requirements make it an essential tool for modern production lines.

As industries continue to evolve and demand more efficient and cost-effective solutions, the Vacuum Suction Machine will remain a key component of advanced material handling systems. Whether it’s for fragile items, heavy components, or sensitive products, the Vacuum Suction Machine ensures that materials are handled safely, efficiently, and with minimal waste.

▏Product Introduction

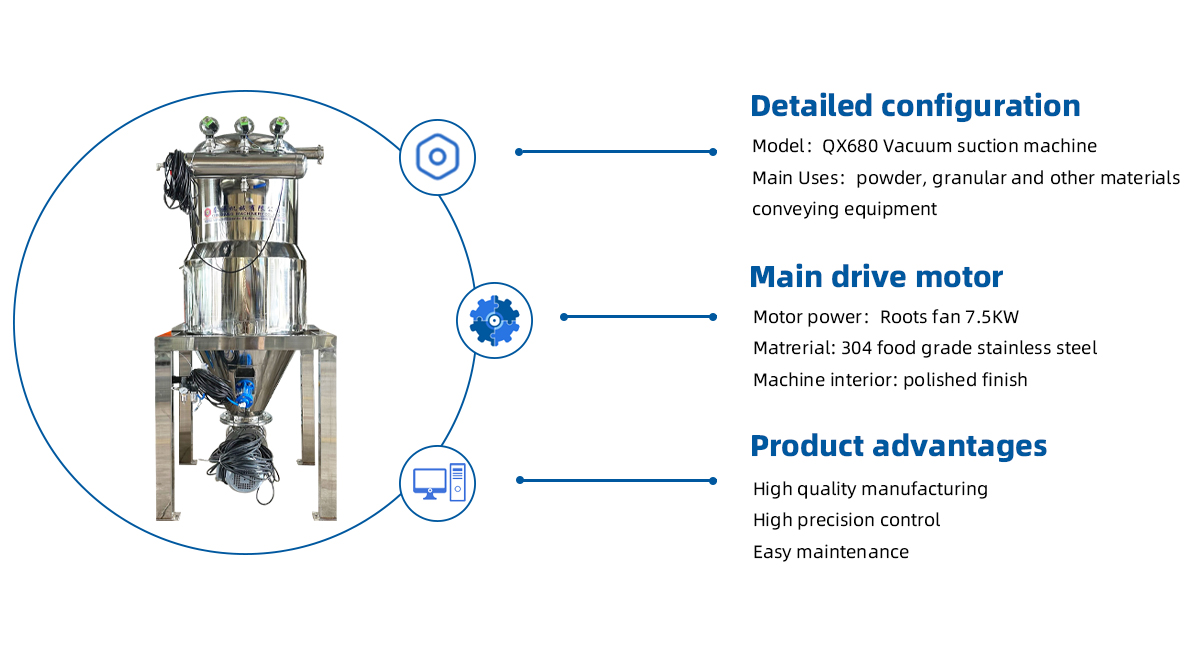

| 1 | Overview |

| Vacuum suction machine is mainly used for powder, granular and other materials conveying equipment, it absorbs materials through negative pressure, the material is extracted from the storage container, and transported to the destination. The equipment has a wide range of applications in modern chemical, pharmaceutical, food, metallurgy, building materials and other industries, especially in the need for efficient, automated, dust-free material handling scenarios. |

| 2 | the working principle |

| The working principle of the vacuum suction machine is to use the vacuum suction to absorb the material from the storage container and transport it to the destination through the pipeline. Specifically, the workflow is as follows: 1. The vacuum pump produces negative pressure and draws out the air in the tank to form a vacuum state. 2. The motor drives the suction device to operate, and the powder material is sucked into the tank. 3. The conveying pipe will transport the material in the tank to the designated position. |

| 3 | structure composition |

|

The main structural components of the vacuum suction machine include: 1. Suction: the important part of the material is absorbed, and the size and shape can be designed according to different material characteristics. 2. Suction fan: The key component to produce negative pressure, using high-speed rotating blades or centrifugal fans. 3. Filter: Filter the material to ensure that the material is clean and free of impurities. 4. Conveying pipeline: The channel for conveying materials to the destination, made of wear-resistant and corrosion-resistant materials. 5. Control system: The key components for controlling and adjusting the vacuum suction machine, using PLC controller and touch screen for automatic control and adjustment. |

| 4 | Technical parameters |

|

The main technical parameters of the vacuum suction machine include: 1. Suction capacity: refers to the ability to transport materials within a specified time, usually in kg/h. 2. Pressure: refers to the pressure difference generated by the vacuum suction machine when extracting gas, usually in Pa (PASCAL) as a unit. 3. Power: refers to the power required by the vacuum suction machine, usually in kW. 4. Operating temperature: refers to the highest temperature that the vacuum suction machine equipment can withstand during operation, usually in degrees Celsius (° C). 5. Vacuum degree: refers to the maximum vacuum degree produced by the vacuum suction machine, usually in Pa or mmHg. 6. Noise: refers to the size of the sound generated by the vacuum suction machine equipment during work, usually in dB units. |

| 5 | Advantages and characteristics |

|

1. Fully closed conveying, avoid dust, and eliminate the influence of the outside world on the material. 2. Simple structure, easy to disassemble and clean. 3. Smooth inside without dead corners, no material residue, in line with the requirements of medicine, food, military and other industries. 4. High degree of automation, easy to form automatic production process with upstream and downstream equipment. 5. Power diversification, vacuum pump or air compressor can be used as power source. 6. The production noise is low, the vibration is small, and the impact on upstream and downstream equipment is small. |

| 6 | Safe operation and maintenance |

|

When using vacuum suction machine, it is necessary to strictly observe the safety operation procedures, including wearing good work clothes and safety shoes, wearing protective glasses and masks when operating equipment, and avoiding fingers and other objects from entering the suction machine. At the same time, the equipment needs regular cleaning, inspection and maintenance, including checking the connection of the power socket and transmission mechanism of the equipment, replacing the worn parts, and checking the lubrication of the transmission chain of the equipment. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping