▏Product Introduction

▏Production Details

▏Product Photos

▏Plastic Raw Material Silo: The Ultimate Storage Solution for Plastic Manufacturing

The Plastic Raw Material Silo is a state-of-the-art storage system designed to meet the unique needs of the plastics manufacturing industry. Engineered for efficiency, durability, and reliability, this silo provides an optimal solution for storing and managing plastic raw materials such as pellets, granules, and powders. Whether you're producing injection-molded parts, extruded products, or blow-molded containers, the Plastic Raw Material Silo ensures consistent material quality, reduces waste, and enhances overall production efficiency.

Key Features

| 1 | High-Capacity Storage |

| The silo is available in a range of sizes, from small units for limited spaces to large-capacity systems for high-volume production. It can store tons of plastic raw materials, ensuring a steady supply for continuous manufacturing processes. |

| 2 | Durable and Robust Construction |

| Built with high-quality materials such as stainless steel or carbon steel, the silo is resistant to corrosion, wear, and environmental factors. Its robust design ensures long-term durability and reliability. |

| 3 | Material Preservation |

| The silo is designed to protect plastic raw materials from moisture, dust, and contamination. Optional features such as airtight seals, desiccant breathers, and humidity control systems ensure material integrity and quality. |

| 4 | Efficient Material Discharge |

| Equipped with advanced discharge systems, such as cone bottoms, vibratory feeders, or screw conveyors, the silo ensures smooth and consistent material flow, preventing blockages and bridging. |

| 5 | Customizable Design |

| The silo can be tailored to meet specific production needs, including different sizes, shapes, and material compatibility. It can also be integrated with existing material handling systems, such as conveyors, blenders, or drying units. |

| 6 | User-Friendly Operation |

| The silo features an intuitive control panel that allows operators to monitor material levels, control discharge rates, and manage inventory. Automated systems can be added for enhanced efficiency and reduced manual labor. |

| 7 | Hygienic and Easy to Clean |

| With smooth surfaces and accessible interiors, the silo is easy to clean and maintain, ensuring compliance with hygiene standards in industries like food-grade plastics manufacturing. |

| 8 | Energy Efficiency |

| The silo is designed to minimize energy consumption during material storage and discharge, supporting sustainable manufacturing practices. |

| 9 | Safety Features |

| The silo includes safety mechanisms such as level sensors, pressure relief valves, and explosion-proof options to ensure safe operation in hazardous environments. |

| 10 | Scalability |

| The modular design of the silo allows for easy expansion, making it a future-proof investment for growing businesses. |

The Plastic Raw Material Silo is a versatile solution for a wide range of industries and applications:

- Injection Molding: Storing plastic pellets for the production of molded parts.

- Extrusion: Supplying raw materials for the manufacture of pipes, sheets, and profiles.

- Blow Molding: Storing granules for the production of bottles, containers, and other hollow products.

- 3D Printing: Managing plastic powders and filaments for additive manufacturing.

- Recycling: Storing recycled plastic materials for reuse in production processes.

Why Choose the Plastic Raw Material Silo?

| 1 | Enhanced Material Quality |

| The silo ensures that plastic raw materials are stored in optimal conditions, preserving their quality and consistency. |

| 2 | Increased Productivity |

| By providing a steady supply of materials, the silo reduces downtime and enhances production efficiency. |

| 3 | Cost Savings |

| The efficient storage and discharge systems minimize material waste and reduce operational costs. |

| 4 | Reliability and Durability |

| Built to withstand heavy-duty use, the silo offers unmatched reliability and a long service life, ensuring a high return on investment. |

| 5 | Sustainability |

| By optimizing material usage and reducing waste, the silo supports environmentally friendly manufacturing practices. |

| 6 | Customization and Flexibility |

| The ability to tailor the silo to specific needs makes it suitable for diverse applications and industries. |

Technical Specifications

- Capacity: Available in various sizes, from 1 ton to 100+ tons.

- Material Compatibility: Suitable for plastic pellets, granules, powders, and flakes.

- Construction Material: High-grade stainless steel or carbon steel.

- Discharge Systems: Cone bottoms, vibratory feeders, screw conveyors, or pneumatic systems.

- Optional Features: Humidity control, level sensors, and explosion-proof designs.

The Plastic Raw Material Silo is the ultimate storage solution for plastic manufacturers seeking to optimize their material handling processes. With its advanced technology, robust design, and user-friendly features, it delivers unmatched efficiency, reliability, and performance. Whether you're producing injection-molded parts, extruded profiles, or blow-molded containers, the Plastic Raw Material Silo is the ideal choice for ensuring consistent material quality and enhancing production efficiency.

Invest in the Plastic Raw Material Silo today and take your plastic manufacturing process to the next level with superior storage technology and unmatched quality!

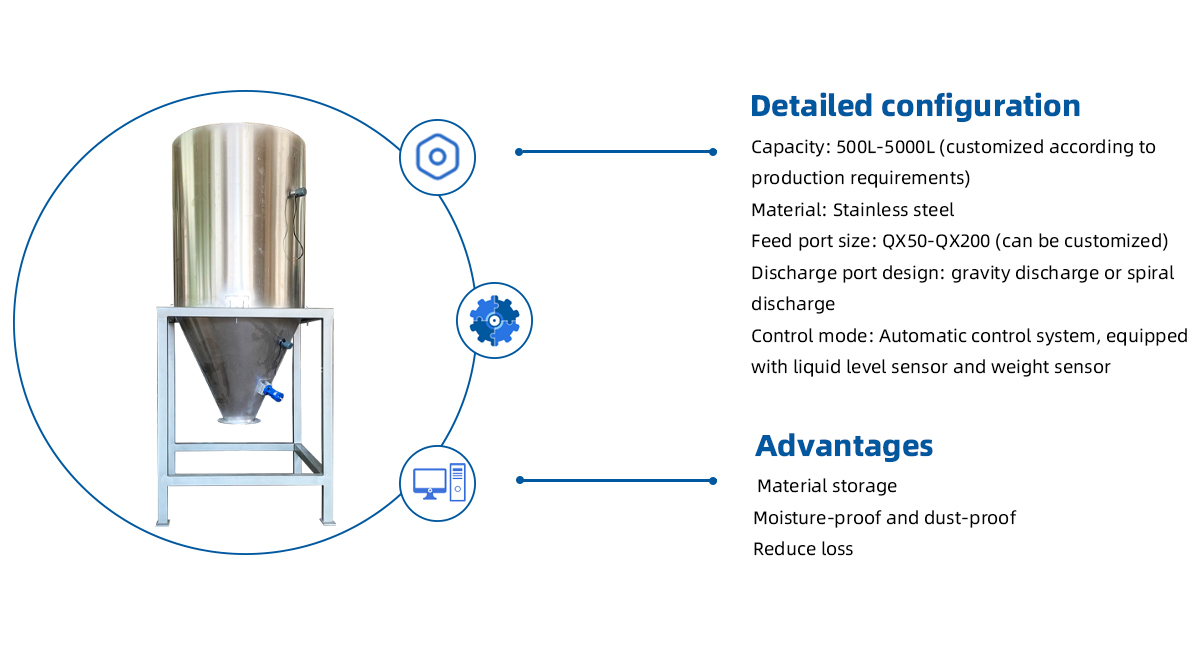

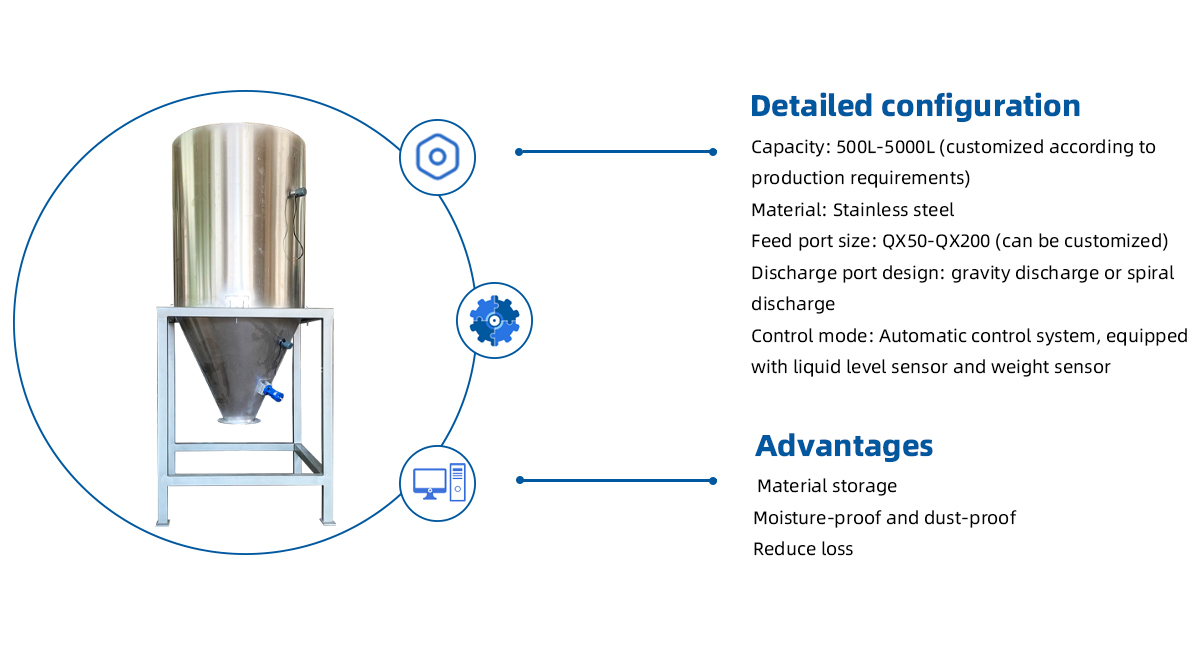

| 1 | Equipment overview |

| Plastic raw material silo is an indispensable equipment in the plastic processing industry, which is mainly used to store and manage plastic raw materials to ensure the continuity and stability of the production process. Silos are usually made of materials such as high-density polyethylene, which have good corrosion resistance, moisture resistance and dust resistance, can cope with high temperature and high pressure environments, and protect raw materials from external pollution. |

| 2 | structure composition |

| 1. Main structure : the main body of the silo is generally cylindrical or rectangular, and the bottom is often designed as a cone to facilitate the smooth discharge of materials. The capacity of the silo is designed according to the needs of the production line to ensure that production needs can be met without frequent feeding. 2. Inlet and outlet device : The silo is equipped with inlet and outlet. The feed port is designed to be large enough to facilitate material input and can be equipped with an automatic feed system to increase efficiency. The discharge port ensures that the material can be discharged smoothly, and common designs include gravity discharge and spiral discharge. 3. Control system : The silo is equipped with an automated control system, including liquid level sensors and weight sensors, for real-time monitoring of the material in the silo. These sensors are combined with the control system to achieve automatic control of feed, discharge and material mixing. |

| 3 | advantages and characteristics |

|

1. Material storage : The silo is an important storage device for plastic raw materials, which can ensure that there is sufficient supply of raw materials in the production process and avoid downtime due to lack of materials. 2. Moisture-proof and dust-proof : The sealing design of the silo effectively prevents moisture and dust from entering and ensures the quality of the stock materials. 3. Reduce loss : Good sealing and automatic control system reduce the loss of material loss, saving costs for enterprises. 4. Material mixing : In some applications, the silo is also used for mixing a variety of materials to ensure the quality and consistency of the final product. 5. Improve production efficiency : The silo is connected with the central feeding system and conveying equipment to ensure the continuous supply of materials from storage to processing equipment and improve production efficiency. |

| 4 | Technical Parameters (Examples) |

|

The following are the technical parameters of a typical plastic material bin (the specific parameters may vary depending on the product model and specifications) : * Capacity: 500L-5000L (customized according to production requirements) * Material: High density polyethylene (or other corrosion resistant material) * Feed port size: DN50-DN200 (can be customized) * Discharge port design: gravity discharge or spiral discharge * Control mode: Automatic control system, equipped with liquid level sensor and weight sensor |

| 5 | Application fields |

|

Plastic raw material silos are widely used in plastic processing, chemical, pharmaceutical and other industries to provide a stable and reliable supply of raw materials for the production process. |

| 6 | Use and maintenance |

|

1. Use precautions : Avoid prolonged exposure to the sun and high temperature environment, while avoiding physical damage such as collisions with heavy objects. Comply with the maximum load of the bin and try to avoid overloading. During use, pay attention to keep the silo clean and dry to prevent moisture and contamination of the material. 2. Maintenance Suggestions : Check the seal performance of the silo regularly, and replace the seal in time if there is damage. Check the operating status of sensors and control systems regularly to ensure that they are working properly. Clean the accumulated material and impurities inside the bin regularly to keep the bin clean and unobstructed. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping