▏Product Vedio

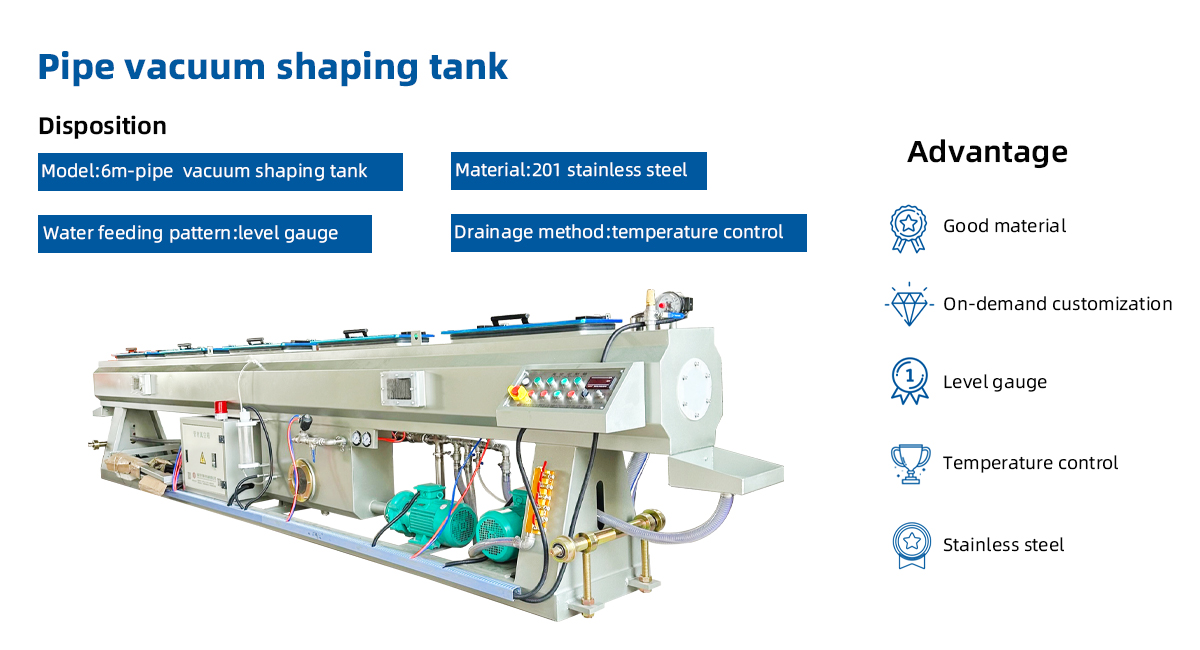

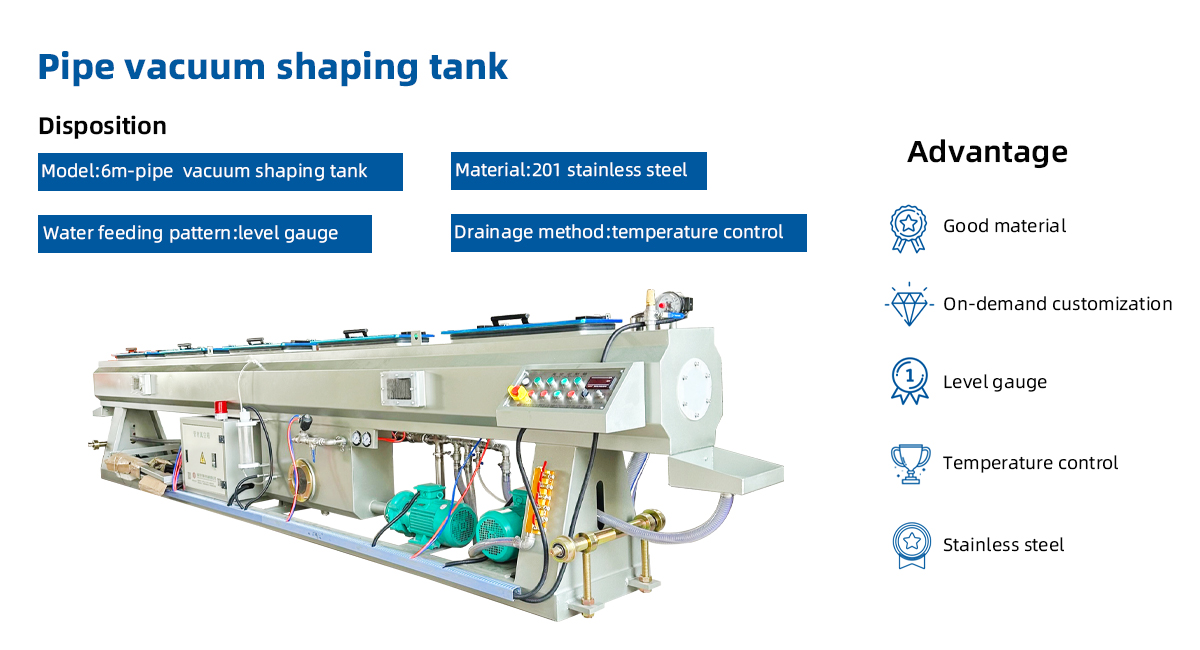

▏Product Introduction

▏Technical parameter

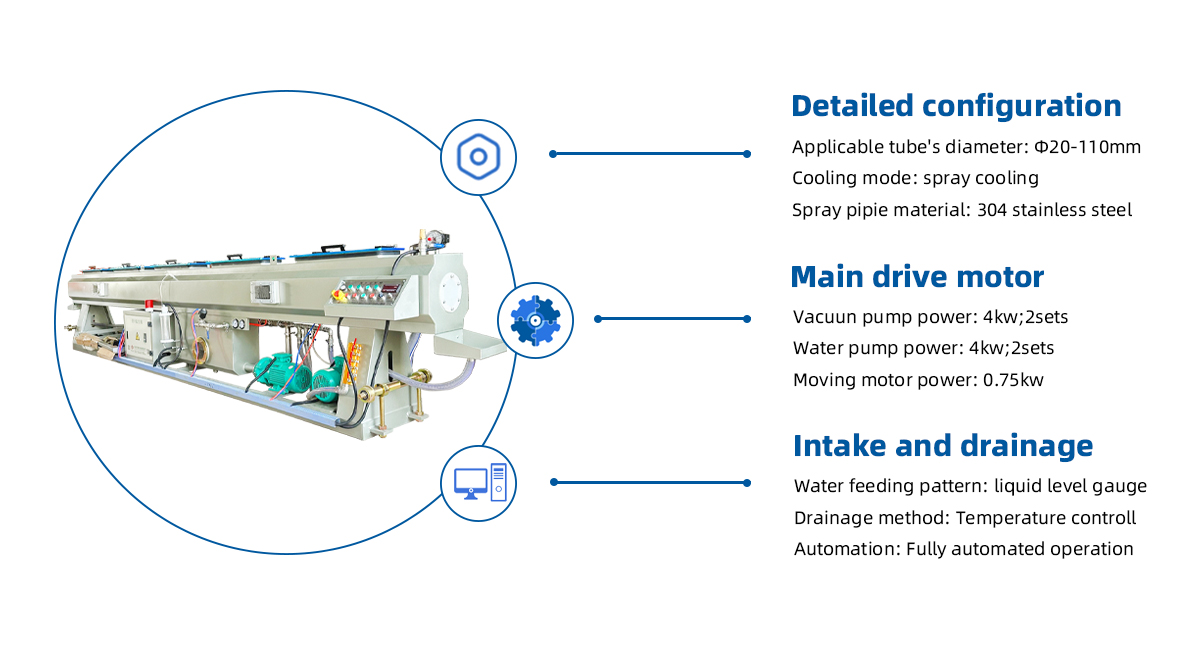

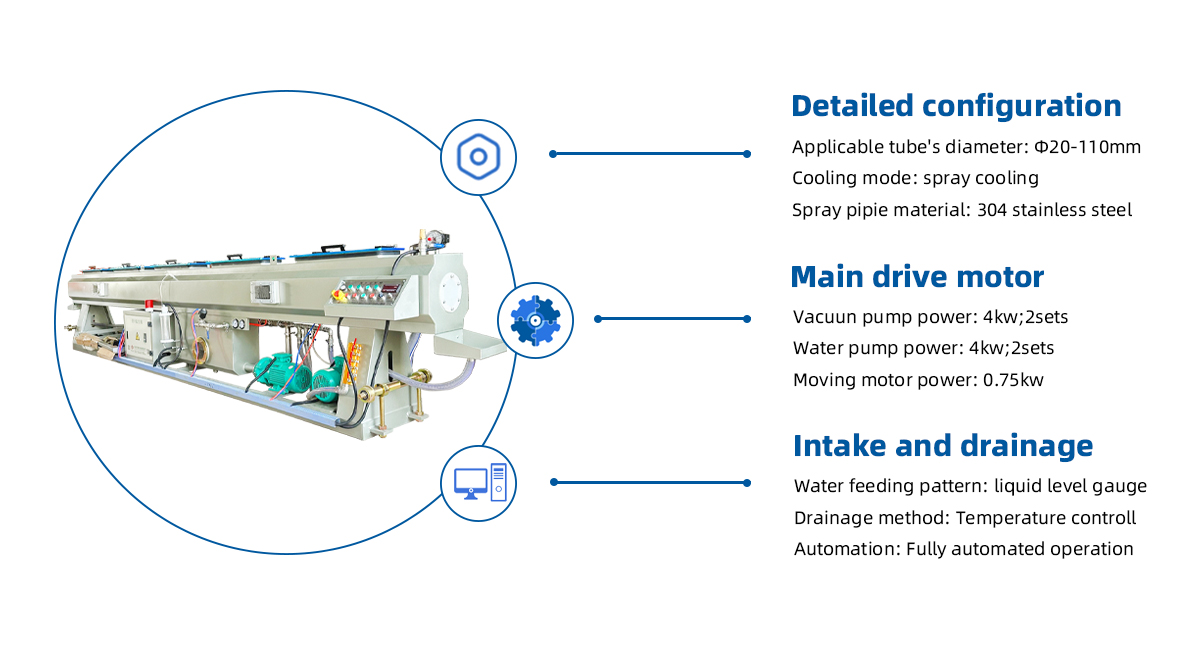

Applicable tube's diameter | Φ20-110mm |

Cooling mode | spray cooling |

| Spray pipie material: | 304 stainless steel |

Vacuun pump power: | 4kw;2sets |

| Water pump power | 4kw;2sets |

| Moving motor power | 0.75kw |

▏Main Details

▏Product Photos

▏Product Application

| 1 | Vacuum shaping and cooling process |

| Vacuum shaping and cooling process is the core function of vacuum forming cooling tank of pipe. In the process of pipe production, the pipe vacuum forming cooling tank is vacuumed to make the pipe cool and set quickly in the mold. This process not only improves the shaping and cooling speed of the pipe, but also eliminates the stress and deformation inside the pipe, making the pipe size more accurate and the appearance more smooth. At the same time, vacuum shaping can also effectively prevent bubbles and defects in the production process of the pipe, and further improve the quality of the pipe. |

| 2 | The production efficiency |

| The production efficiency can be significantly improved through the application of pipe vacuum forming cooling tank. Because the pipe vacuum forming cooling tank has the characteristics of rapid setting and cooling, the production cycle of the pipe is greatly shortened. In addition, pipe vacuum forming cooling tank can also realize automatic operation, reducing the manual operation link, and further improve the production efficiency. |

| 3 | The quality of pipe |

| The application of pipe vacuum forming cooling tank can also improve the quality of pipe. The dimensional accuracy and appearance quality of the pipe can be ensured by precise vacuum shaping technology. At the same time, vacuum shaping can also improve the physical properties and chemical stability of the pipe, making the pipe more durable and safe during use. |

▏Cooperative Parts Supplier

▏Packing And Shipping

▏FAQ

1.Are you a factory or trading company?

Qinxiang:We are a factory.

2.Can we visit your machine operation in your factory?

Qinxiang:You can see machine operation in our factory.

3.Can the machine be customized?

Qinxiang:Yes,it can.

4.How many electric, water, air need for the machines?

Qinxiang: technical department supply the whole layout for workshop details.

5.Can I operate machine if don’t have experienced engineers?

Qinxiang: (1) short-time engineers to customer company (5-15days) (2) Year-time working as requirements

6.Any quality checking before shipment?

Qinxiang: 100% confirm, run and test machines before shipment with quality certificate.

7.How long is the guarantee?

Qinxiang: 12 months since the first day customer operates (except wear parts).

8.How can u help us when face some technical problem?

Qinxiang: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

9.Where can we get spare part?

Qinxiang: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.