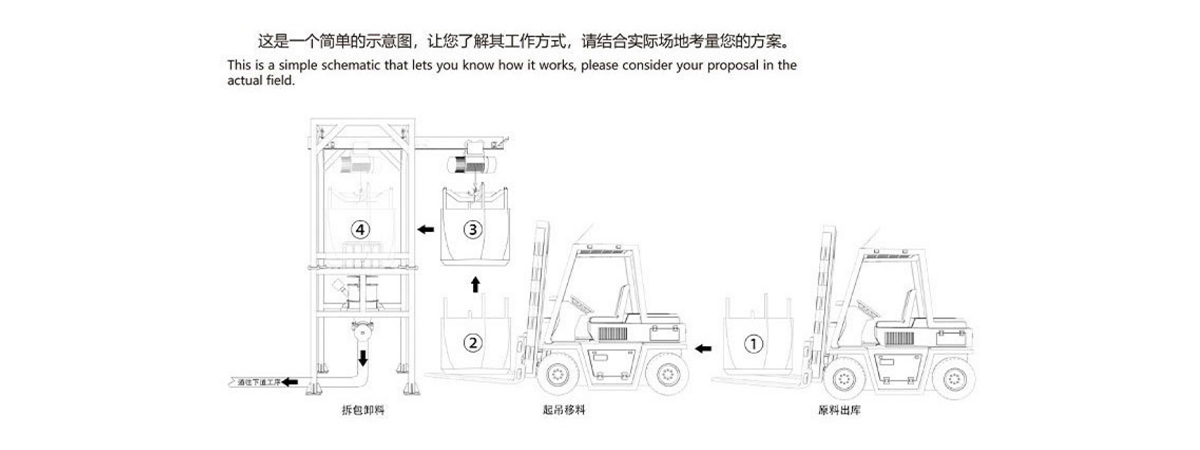

▏How the Big Bag Discharge Station Works

The operation of the Big Bag Discharge Station is simple yet efficient. The first step involves placing the bulk bag on the system’s lifting frame. Once the bag is securely positioned, the bag’s discharge spout is attached to the discharge chute or hopper. The station uses a lifting mechanism, which can be either pneumatic or mechanical, to elevate the bag and ensure it is held securely while unloading.

Next, the material is gently discharged from the bulk bag. This may be facilitated by a vibrating system, which helps break up compacted material, or an airflow system, which promotes the flow of dry or fine powders. Some models use rotary valves or screw conveyors to feed the material into the next phase of the production process.

The Big Bag Discharge Station also has a control panel that enables operators to adjust parameters such as flow rate, vibration speed, and material transfer speed, depending on the material type and the specific requirements of the production line. Once the bag has been emptied, it is safely removed from the system, and a new bag can be loaded, ensuring continuous operation.

▏Benefits of the Big Bag Discharge Station

| Increased Operational Efficiency

By automating the unloading process, the Big Bag Discharge Station significantly reduces the need for manual labor. The system can operate continuously, improving throughput and efficiency while eliminating the delays associated with manual unloading. As a result, production lines can run smoother, leading to increased productivity and reduced downtime. |

| Reduced Material Waste

The controlled and precise unloading mechanism minimizes material loss, especially during the handling of fine powders or fragile materials. The system’s ability to prevent bridging and blockages ensures that nearly every particle is transferred to the next phase of production, which reduces waste and improves the overall yield of the material. |

| Improved Worker Safety

Manual unloading of bulk bags can present various safety hazards, including lifting injuries and exposure to hazardous materials. The Big Bag Discharge Station automates this process, allowing operators to remain at a safe distance from the material being unloaded. Furthermore, with integrated dust containment systems and safety features like emergency stop buttons, the risk of accidents is greatly minimized. |

| Enhanced Product Quality

The system ensures that materials are handled with precision, which helps maintain the integrity of the product. For example, when dealing with sensitive or fragile materials, such as pharmaceutical powders or food ingredients, the controlled discharge system prevents contamination, breakage, or degradation of the product. This leads to better-quality products that meet the required industry standards. |

▏Applications of the Big Bag Discharge Station

| Chemical Industry

In the chemical industry, the Big Bag Discharge Station is used to unload a wide range of materials, including resins, pigments, and additives. The system’s ability to handle various types of bulk chemicals efficiently and safely makes it an essential piece of equipment in chemical production plants. |

| Pharmaceutical Manufacturing

Pharmaceutical companies often use the Big Bag Discharge Station for the handling of active pharmaceutical ingredients (APIs) and excipients. The system provides a controlled, hygienic, and safe environment for unloading sensitive materials, ensuring that the highest standards of quality are maintained during the process. |

| Food Processing

In food processing, the Big Bag Discharge Station is crucial for the handling of dry ingredients like flour, sugar, spices, or grains. The equipment is designed to meet food safety standards and prevent contamination, ensuring that food-grade materials are transferred safely and efficiently. |

| Plastics and Polymers

The plastics and polymers industry relies on the Big Bag Discharge Station for the unloading of resin pellets and other bulk materials used in the production of plastic products. The system ensures a smooth and continuous flow of materials, helping to streamline the manufacturing process. |

The Big Bag Discharge Station is an indispensable solution for industries that handle large volumes of bulk materials. With its robust design, precise material flow control, and advanced safety features, it ensures the efficient, safe, and reliable unloading of materials. By automating the bulk bag discharge process, it improves operational efficiency, reduces material waste, and enhances workplace safety.

Whether in the chemical, pharmaceutical, food, or plastics industries, the Big Bag Discharge Station plays a key role in optimizing material handling operations and maintaining high standards of product quality. As businesses continue to scale up production, this system will remain a vital component of modern material handling solutions.

▏Operation Method