▏Product Vedio

▏The Whole Pipe Extrusion Line

Click here to know the whole PVC irrigation pipe extrusion line:

https://www.qinxmachinery.com/High-speed-PVC-drip-irrigation-pipe-extrusion-line-pd542852258.html

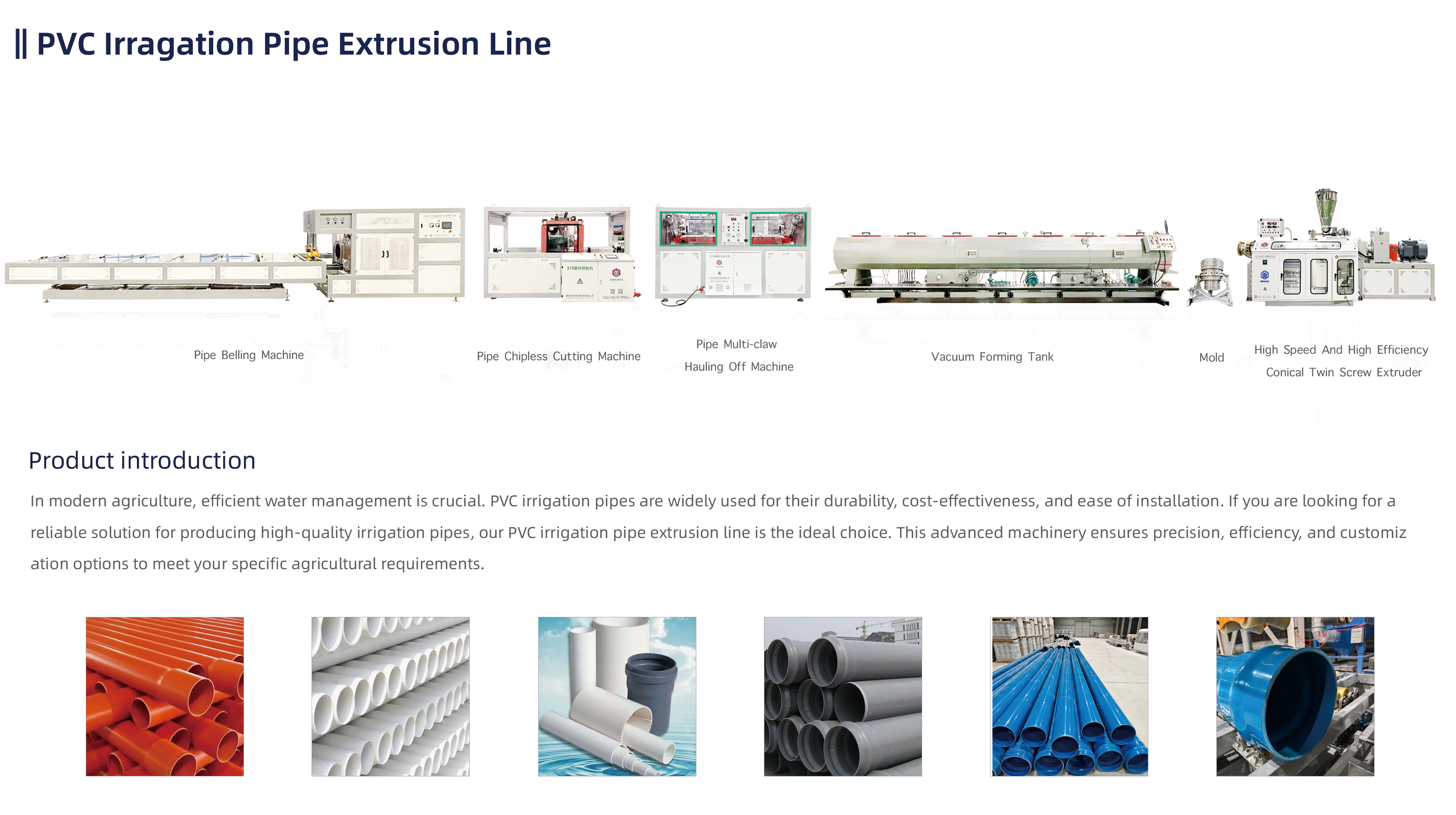

In modern agricultural irrigation systems, PVC pipes play a crucial role in delivering water efficiently across farms. A reliable PVC irrigation pipe extruder is essential for producing high-quality, durable, and cost-effective irrigation pipes. Our SJSZ80-156 conical twin screw extruder – a state-of-the-art twin-screw PVC pipe extrusion machine – is engineered for high-output and energy-efficient manufacturing, making it the ideal solution for PVC pipe production.

▏Main Features of the Extruder

| High-Speed & High-Efficiency Production

The SJSZ80-156 conical twin screw extruder leverages advanced twin-screw technology to deliver exceptionally high production speeds, meeting the demands of mass production. Its advanced screw design ensures stable extrusion, uniform output, and high precision in pipe dimensions. |

| Precision Screw Design

The state-of-the-art twin-screw configuration guarantees optimal melting, mixing, and plasticizing of the PVC compound, effectively preventing temperature fluctuations and material segregation. The modular screw system allows for flexible adjustments when changing materials, ensuring consistent and stable production parameters. |

| Fully Automated Control System

Equipped with a PLC touchscreen control system, our extruder provides full automation in monitoring, data collection, and production parameter adjustments. Real-time monitoring enables automatic regulation of temperature and pressure, ensuring every PVC pipe meets the highest quality standards. |

| Energy-Saving & Eco-Friendly Design

The intelligent temperature control system combined with an efficient cooling setup significantly reduces energy consumption. Optimized barrel design minimizes material wastage and complies with international energy conservation standards. |

| Durable & Stable Construction

Constructed from high-strength stainless steel and alloy materials, the extruder offers excellent resistance to corrosion and wear, ensuring a long service life. A well-engineered structure guarantees stable performance even under continuous high-load operation. |

| User-Friendly Automation

|

▏Product Photo

▏Customer Case

▏Applications of the Extruder

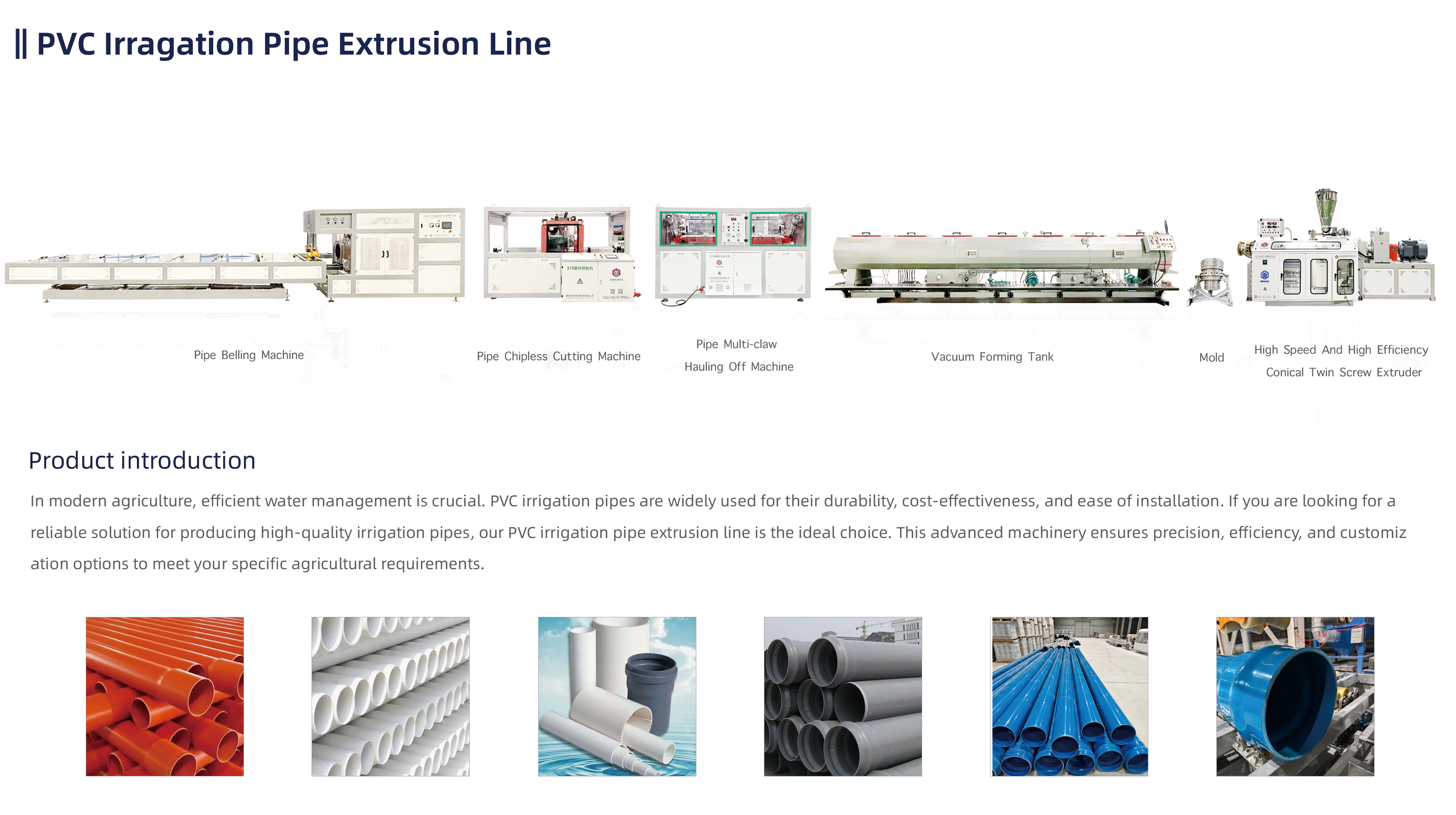

| 3.1 Agricultural Irrigation Pipe Production

Ideal for manufacturing various types of PVC irrigation pipes, particularly for drip and micro-sprinkler systems in farmlands. Customizable to produce pipes with varying diameters, wall thicknesses, and multi-layer structures tailored to diverse irrigation needs. |

| 3.2 Industrial Pressure Pipes

In addition to agriculture, the extruder is suitable for producing high-pressure water pipes and industrial pipelines. Applicable in urban water supply systems, industrial liquid transportation, and other heavy-duty applications. |

| 3.3 Special Purpose Pipes

Utilizing multilayer coextrusion technology, the machine can manufacture pipes with UV protection, heat resistance, and anti-aging properties. Custom additive options enable the production of multifunctional pipes designed for specific industrial or environmental conditions. |

▏Advantages of the Extruder

| 4.1 Superior Production Efficiency

Our SJSZ80-156 conical twin screw extruder features an innovative twin-screw structure and intelligent automation, significantly reducing production cycle times. Advanced cooling and calibration systems ensure that even at high speeds, the quality of the pipes remains excellent. |

| 4.2 Cost Savings

Optimized design reduces energy consumption and material wastage, lowering overall production costs and enhancing the product's cost-effectiveness. High-speed production capabilities allow businesses to achieve greater economies of scale and profit margins. |

| 4.3 Consistent High-Quality Output

Fully automated monitoring guarantees a stable production process, ensuring that the pipes maintain consistent quality and reducing defect rates. Precision control of temperature and pressure ensures that every pipe conforms to stringent industry standards. |

| 4.4 Flexible & Versatile Product Options

The extruder supports various production specifications and customization options, allowing manufacturers to adjust production parameters according to market demands. Its modular design facilitates quick maintenance and upgrades, reducing downtime and increasing operational flexibility. |

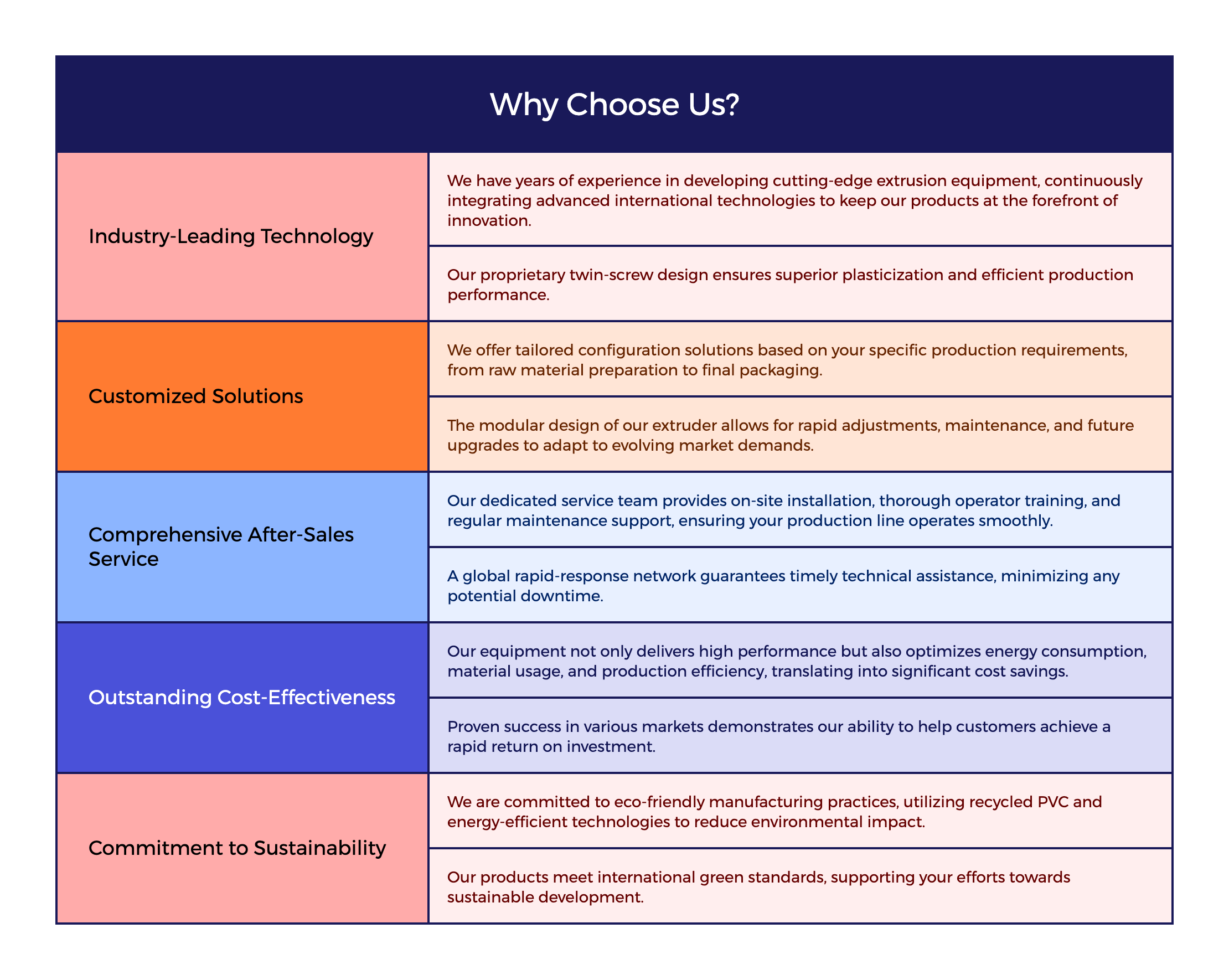

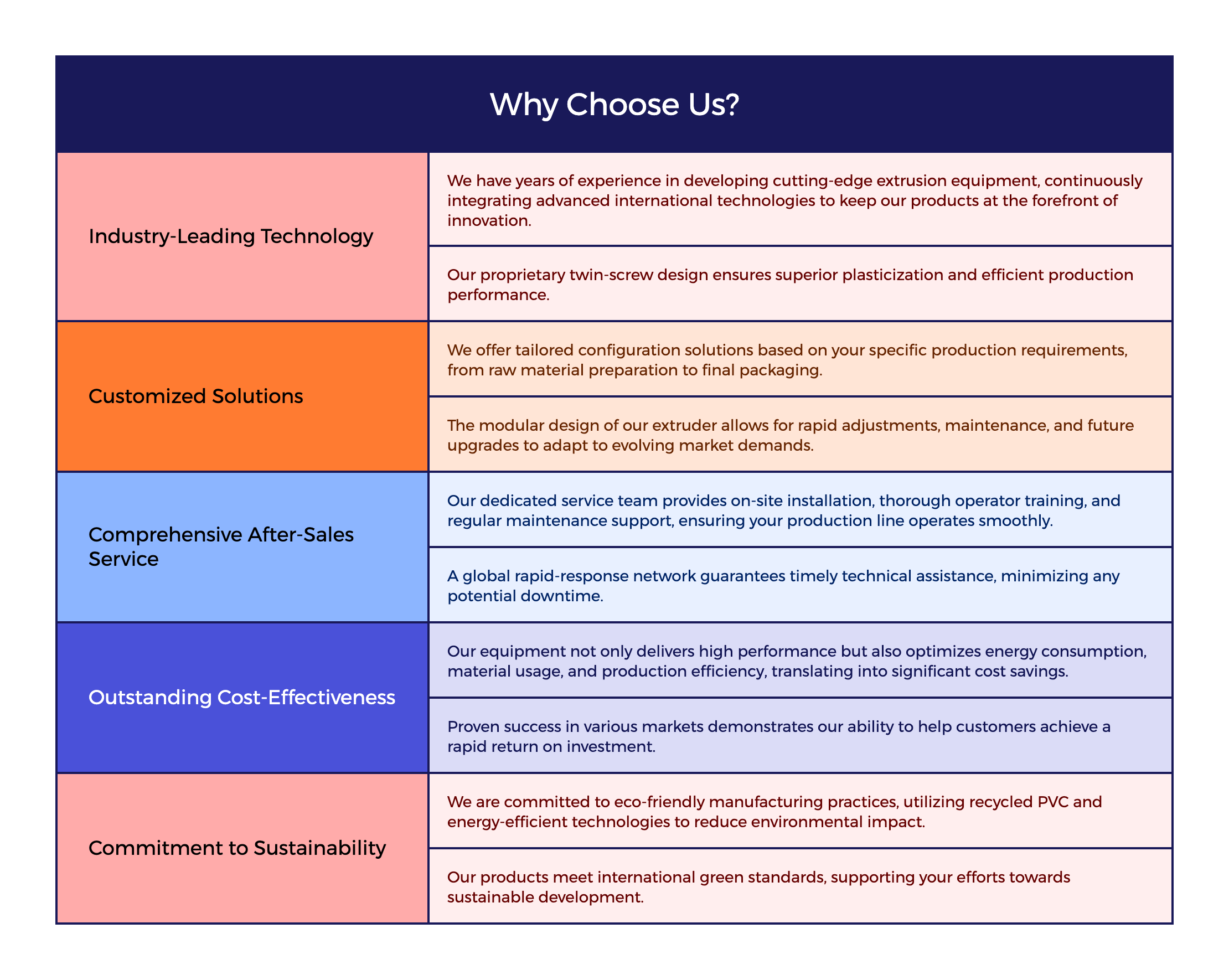

| 4.5 Comprehensive After-Sales Support

We offer full-scale after-sales services including on-site installation, operator training, and routine maintenance to ensure optimal machine performance. A rapid-response service network is available globally to promptly resolve any issues during operation. |

▏Extruder Configuration

To meet diverse production needs, our extruder is available in multiple configurations. Common configuration details include:

| Configuration Item | Details |

| Model | SJSZ80-156 Conical Twin-Screw Extruder |

| Screw Diameter | Main screw: 80mm; Secondary screw: 156mm |

| Production Output | 350-450kg/h |

| Pipe Diameter Range | 20mm - 630mm |

| Cooling System | Multi-stage vacuum calibration and water cooling system |

| Haul-Off System | Multi-belt servo-controlled traction system |

| Cutting System | Planetary cutter with automatic length detection |

| Control System | PLC touchscreen automation with remote monitoring |

| Auxiliary Systems | Automatic feeding, smart barrel design, exhaust cooling, bundling system |

Customized accessory and integration options are also available to tailor the production line to your specific needs.

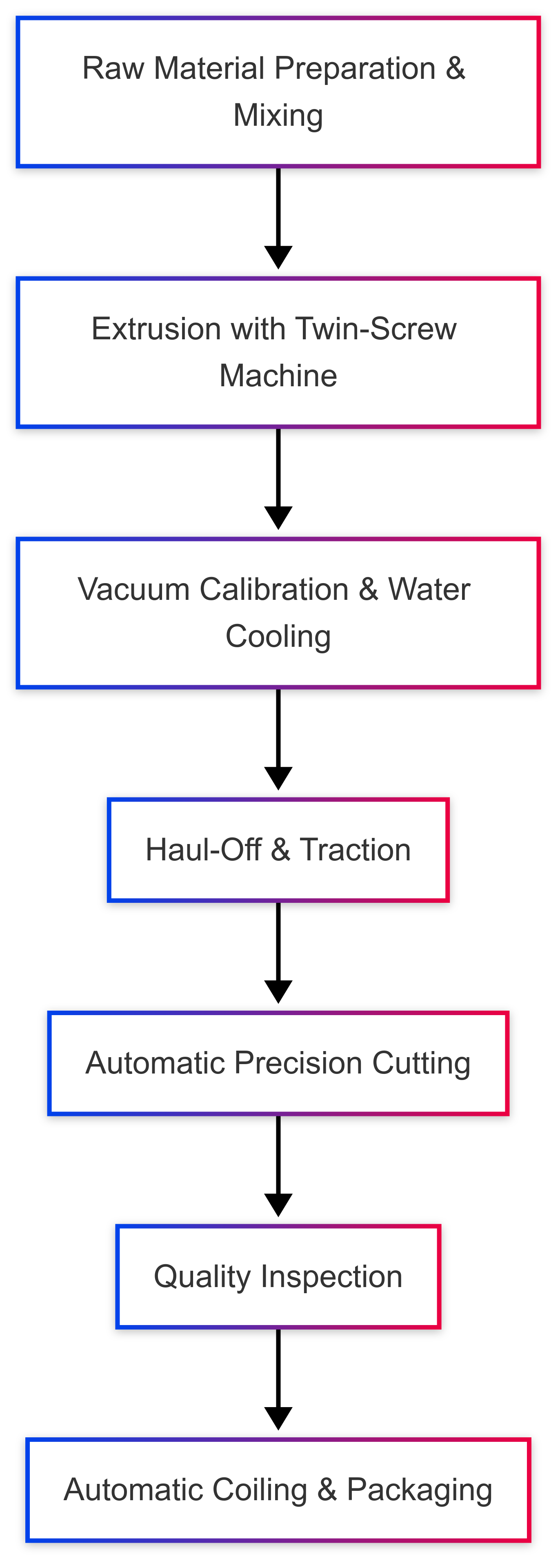

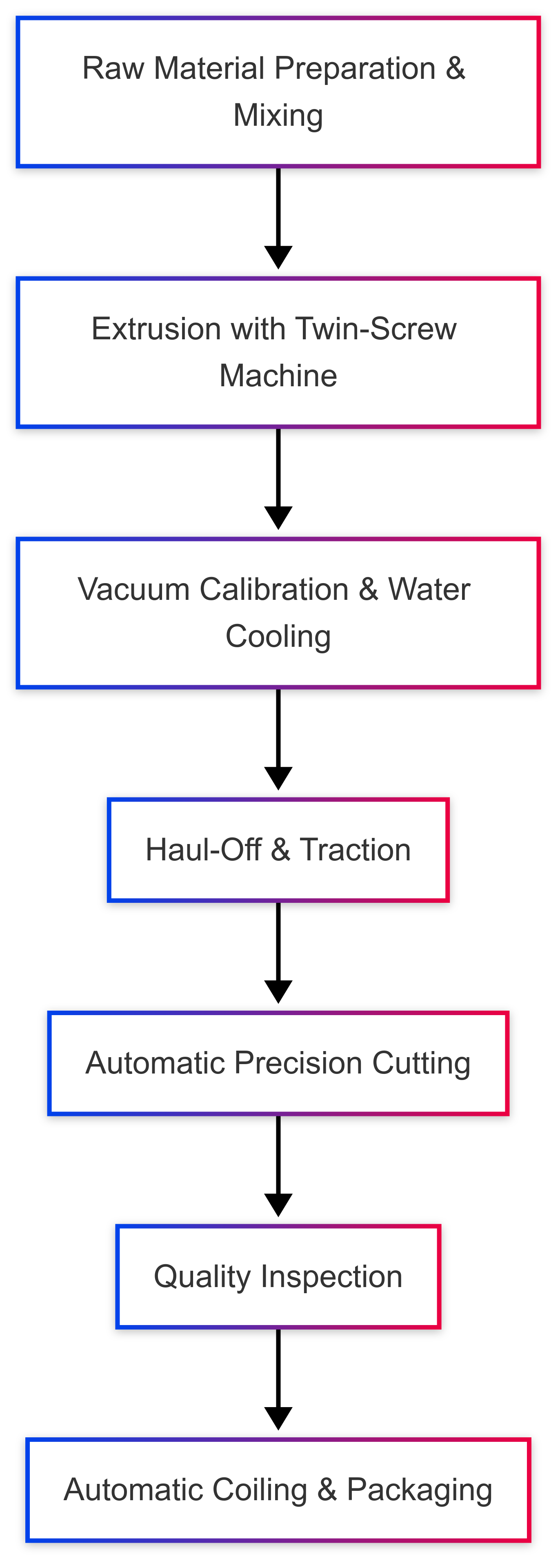

▏PVC Pipe Production Process

Detailed Production Steps

| Raw Material Preparation & Mixing PVC resin, stabilizers, lubricants, and UV additives are blended in precise ratios to ensure consistency. An automatic feeding system guarantees a steady supply of raw materials. |

| Extrusion with Twin-Screw Machine |

| Vacuum Calibration & Water Cooling The extruded PVC pipe enters a multi-stage vacuum calibration section, which ensures precise pipe dimensions. A high-efficiency water cooling system quickly solidifies the pipe structure, maintaining its shape. |

| Haul-Off & Traction A servo-controlled, multi-belt haul-off system provides consistent traction, preventing deformation. Real-time tension monitoring ensures continuous and uniform pipe production. |

| Automatic Precision Cutting The pipe is automatically cut to pre-set lengths using a planetary cutter, ensuring smooth and burr-free edges. Length sensors and automated measurement ensure every section is precise. |

| Quality Inspection Pipes undergo rigorous quality control tests for pressure resistance, wall thickness, and flexibility. Data from the inspection process is fed back into the system for continuous process improvement. |

| Automatic Coiling & Packaging |

▏Customer Case Studies

| Case Study 1: Agricultural Irrigation Company in Mexico

Background:

A large-scale agricultural irrigation company in Mexico was experiencing low production efficiency and inconsistent product quality with their previous setup. By upgrading to our PVC irrigation pipe extruder equipped with the SJSZ80-156 conical twin screw extruder, they achieved remarkable improvements. Results: Production capacity increased by 40% due to the high-speed twin-screw system. Consistent pipe quality with uniform wall thickness led to a significant reduction in customer complaints. Energy-efficient operation and reduced material wastage resulted in overall cost savings of approximately 30%. |

| Case Study 2: Drip Irrigation Supplier in the Middle East

Background:

A Middle Eastern drip irrigation supplier faced challenges related to extreme climatic conditions, which affected the durability and UV resistance of their pipes. They implemented our twin-screw PVC pipe extrusion machine to overcome these issues. Results: Pipe lifespan improved by 30%, reducing the frequency of replacements. Enhanced production efficiency allowed them to meet increased market demands. Lower material waste and improved quality control helped achieve significant cost reductions. |

| Case Study 3: High-End PVC Pipe Manufacturer in Europe

Background:

A European manufacturer specializing in high-end PVC pipes sought to enhance product consistency and reduce defect rates to better compete in premium markets. They turned to our SJSZ80-156 conical twin screw extruder for a reliable solution. Results: Achieved a 20% reduction in defective products through improved automation and real-time monitoring. Consistent product quality enabled the company to enter new markets and secure high-value contracts. The overall production cost dropped by nearly 20% due to optimized processes and reduced downtime. |

▏Why Choose Us

The SJSZ80-156 conical twin screw extruder, a premier PVC irrigation pipe extruder and twin-screw PVC pipe extrusion machine, offers a high-performance, energy-efficient, and cost-effective solution for producing top-quality PVC irrigation pipes. With its advanced twin-screw technology, fully automated control systems, and robust design, this extruder not only meets the rigorous demands of modern agricultural and industrial applications but also delivers consistent and precise results.

Our comprehensive solution—from optimized raw material handling and precise extrusion to advanced cooling, automated cutting, and quality control—ensures that every pipe produced is of exceptional quality and reliability. Backed by detailed technical configurations, proven customer case studies, and an unwavering commitment to after-sales service and sustainability, our equipment is designed to help you achieve superior productivity and competitiveness in the global market.

Whether you are a supplier of agricultural irrigation systems or an industrial pipe manufacturer, our solution is tailored to meet your needs. Choose our innovative extrusion technology to boost production efficiency, reduce costs, and ensure a high return on investment.

Contact us today to discuss your production requirements and discover how our PVC irrigation pipe extruder can transform your manufacturing process!

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping