▏Product Vedio

▏Introduction to Plastic Plate Board Extrusion Line

The Plastic Plate Board Extrusion Line is a state-of-the-art manufacturing solution designed for producing high-quality plastic sheets and boards. This fully automated system integrates advanced extrusion technology, precision control mechanisms, and energy-efficient processes to deliver consistent output for industries such as packaging, construction, automotive, and advertising. By leveraging cutting-edge engineering, this line ensures optimal material utilization, reduced waste, and enhanced productivity.

Core Components of the Extrusion Line

The extrusion line comprises several critical components, including a high-performance extruder, calibration unit, cooling system, haul-off machine, and cutting device. Each module is engineered to work seamlessly, ensuring smooth material flow from raw polymer pellets to finished plastic plates or boards.

▏Key Features of the Plastic Plate Board Extrusion Line

| Advanced Extrusion Technology

Equipped with a twin-screw extruder, the Plastic Plate Board Extrusion Line guarantees uniform melting and mixing of polymers like PP, PE, PVC, or ABS. The dual-screw design enhances material homogeneity, minimizing defects such as air bubbles or uneven thickness. |

| Precision Control Systems

An integrated PLC (Programmable Logic Controller) enables real-time monitoring and adjustment of temperature, speed, and pressure. Operators can fine-tune parameters via a user-friendly interface, ensuring consistent product quality and adaptability to diverse material specifications. |

| Energy Efficiency

With optimized heating and cooling mechanisms, this extrusion line reduces power consumption by up to 25% compared to conventional systems. Heat recovery units and variable frequency drives (VFDs) further enhance sustainability, aligning with eco-friendly manufacturing practices. |

▏Applications of Plastic Plate Boards

| Boards produced by the Plastic Plate Board Extrusion Line are widely used in:

Packaging: Lightweight yet durable sheets for food containers and industrial packaging. Construction: Weather-resistant boards for partitions, signage, and false ceilings. Advertising: Smooth-surface boards for high-quality printing and displays. Automotive: Impact-resistant components for vehicle interiors. |

▏Advantages Over Traditional Manufacturing

| High Production Capacity

The line supports continuous 24/7 operation with a maximum output of [insert capacity] kg/hour, significantly reducing lead times for large orders. |

| Customization Flexibility

Adjustable die heads and modular designs allow quick configuration changes to produce boards of varying thicknesses (1mm–20mm), widths (up to 2500mm), and surface textures (glossy, matte, or embossed). |

| Low Maintenance Requirements

Durable components and self-lubricating systems minimize downtime, while accessible maintenance points simplify servicing. |

▏Technical Specifications

| Parameter | Specification |

| Extruder Type | Twin-Screw |

| Max Output | 500–2000 kg/h |

| Power Consumption | 150–350 kW |

| Board Width | 600–2500 mm |

| Cooling Method | Water or Air |

▏Why Choose Our Extrusion Line?

Our Plastic Plate Board Extrusion Line combines innovation, reliability, and affordability. Backed by a 2-year warranty and global technical support, we ensure minimal operational disruptions and maximum ROI. Partner with us to transform your plastic manufacturing capabilities.

As demand for versatile plastic boards grows, investing in an efficient Plastic Plate Board Extrusion Line is critical for staying competitive. With its blend of automation, precision, and sustainability, this system empowers manufacturers to meet diverse market needs while reducing costs and environmental impact.

▏Product Introduction

‖ Plastic ABS/PVC/PE/PP plate board sheet extrusion line

Plastic ABS/PVC/PE/PP sheet plate board extrusion line is an automatic production line for continuous production of PVC, PE, PP and other materials. This production line integrates a variety of key equipment to transform raw materials into sheet products with specific shapes and sizes through a series of coordinated workflows. PVC/PE/PP sheet extrusion line is an efficient and automated production equipment that integrates a variety of key equipment and technologies to produce high-quality sheet products that meet the needs of different fields.

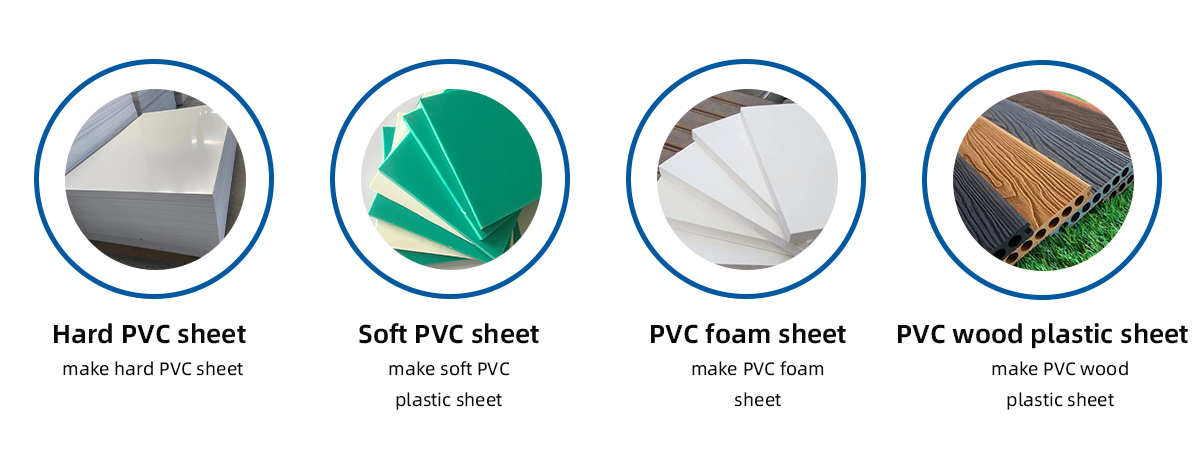

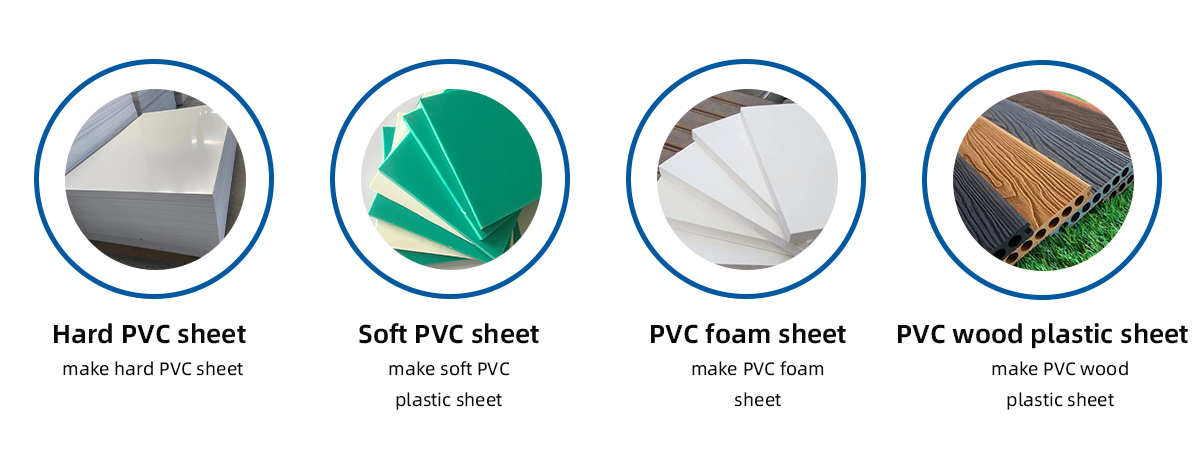

▏Range Of Application

▏Technical Parameters

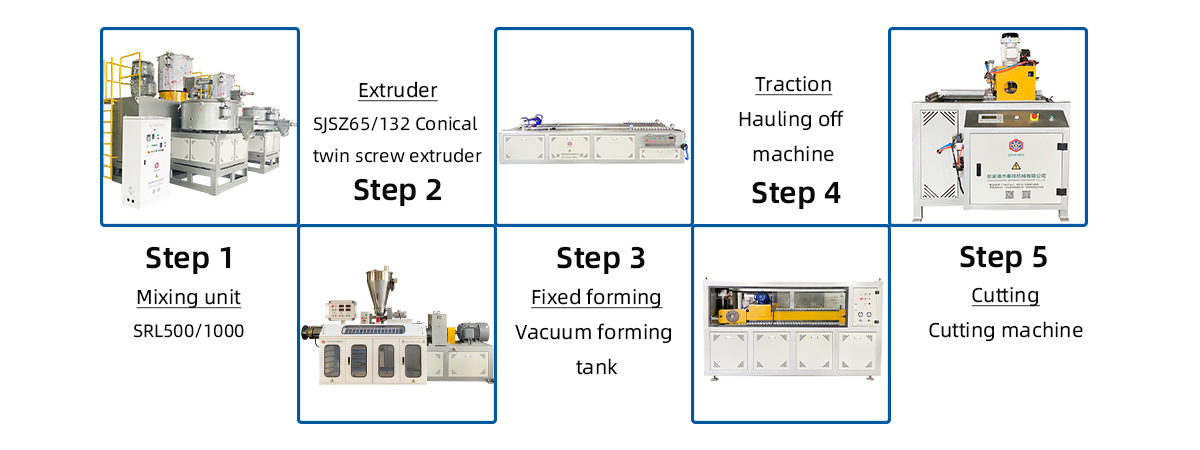

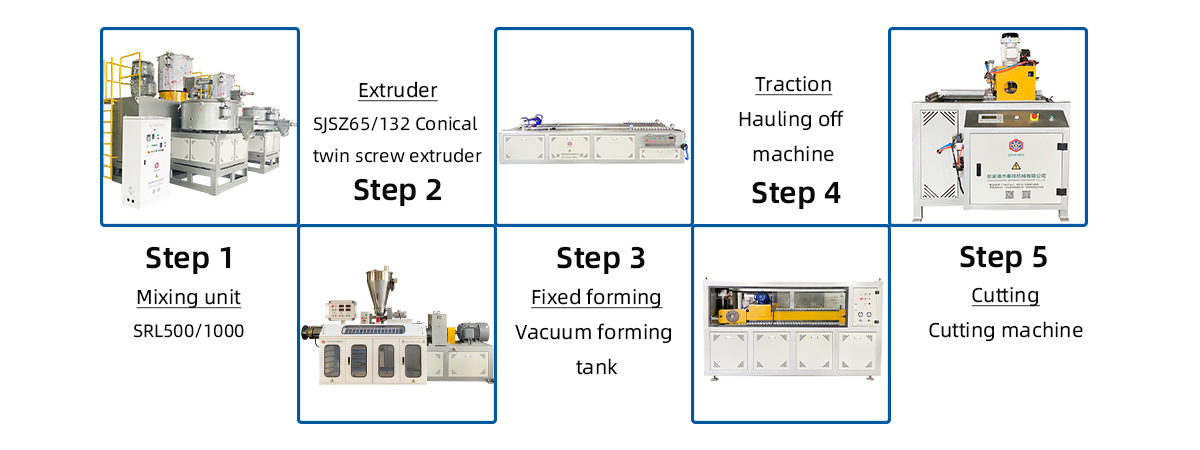

Production line configuration | Quantity | Detail |

QX-800 automatic vacuum feeding system | 1 set | 450KG/H |

QX-75 hopper dryer | 1 set | 75 kg |

SJSZ6-132 conical twin screw extruder | 1 set | 180-250 kg/h |

Vacuum forming tank | 1 set | 4.5m |

Hauling off machine | 1 set | 2700mm |

Cutting machine | 1 set | Transverse cutting |

▏Production Procedure

▏Product Photos

▏Product Introduction

| 1 | Equipment composition and structure |

| Plastic ABS/PVC/PE/PP sheet plate board extrusion line is mainly composed of extruder, mold, cooling device, traction device, cutting device and control system. Extruder is responsible for the molten plastic raw materials through the mold extrusion molding; The cooling device is used for cooling and shaping the extruded sheet; The traction device can stably stretch the plate to ensure the flatness and thickness uniformity of the plate; The cutting device cuts the plate according to the set length; The control system monitors and regulates the entire production process. |

| 2 | Material and characteristics |

| The materials used in the plastic ABS/PVC/PE/PP sheet plate board extrusion line equipment are mostly stainless steel and high-quality alloy materials, which have high corrosion resistance and wear resistance. The features of the equipment include compact structure, simple operation, stable operation and high production efficiency. In addition, the equipment has good adaptability and can produce plastic sheets of different thicknesses, widths and lengths. |

| 3 | Processing raw materials |

| The plastic ABS/PVC/PE/PP sheet plate board extrusion line mainly processes various plastic raw materials, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and so on. After the raw material is pre-treated, it is sent to the extruder for melting and extrusion, and the required plastic sheet is finally obtained. |

| 4 | Application field |

| Plastic ABS/PVC/PE/PP sheet plate board extrusion line equipment is widely used in construction, packaging, advertising, decoration and other fields. In the field of construction, plastic sheets can be used to make wall panels, roofs, partitions, etc. In the field of packaging, it can be used as raw materials for packaging boxes, pallets and other products; In the field of advertising and decoration, we can produce a variety of display cards, display boards, etc. |

| 5 | Production process and operation |

| The production process mainly includes raw material preparation, melting extrusion, cooling and shaping, traction and drawing, cutting and stacking. During the operation, the operator must follow the equipment operation rules to ensure the stable running of the equipment and production quality. At the same time, the equipment is equipped with an automatic control system, which can realize the automatic monitoring and regulation of the production process. |

| 6 | Output and efficiency |

| The plastic ABS/PVC/PE/PP sheet plate board extrusion line equipment has high yield and efficiency. Depending on the type and configuration of the equipment, tens to hundreds of square meters of plastic sheet can be produced per hour. At the same time, the equipment adopts advanced extrusion and cooling technology to ensure the flatness and thickness uniformity of the plate, and improve product quality and production efficiency. |

| 7 | Maintenance and maintenance |

| In order to maintain the normal operation of the equipment and extend the service life, regular maintenance and maintenance of the equipment is essential. The main maintenance includes cleaning equipment surfaces, checking electrical wiring and sensors, and lubricating mechanical parts. In addition, it is necessary to regularly replace the wearing parts, such as filters, seals, etc. Maintenance work should be carried out by professionals to ensure the safety and stability of the equipment. |

| 8 | Customization and upgrade services |

| We offer personalized customization and upgrade services to meet the special needs of our customers and improve production efficiency. Customers can choose different models and configurations of equipment according to actual needs to meet the production of different specifications and performance of plastic sheets. At the same time, we also provide equipment upgrade services to improve equipment performance and production efficiency by optimizing equipment structures and control systems. |

▏Product Advantage

| 1 | High degree of automation |

| Plastic ABS/PVC/PE/PP sheet plate board extrusion line adopts advanced automatic control system, which can realize the automatic operation of the entire production process. From the transportation of raw materials, melting and extrusion, cooling to cutting and stacking and other links, can be automatically controlled through the preset program, reducing the dependence on manual operation, improve production efficiency. |

| 2 | The operation is simple and flexible |

| The operation interface of the equipment is simple and clear, and the operator can quickly master the operation skills of the equipment through simple training and guidance. At the same time, the equipment also has high flexibility, which can adjust the production parameters according to the production needs, and adapt to the production of plastic sheets with different specifications and properties. |

| 3 | Continuous and stable production |

| Plastic ABS/PVC/PE/PP sheet plate board extrusion line has high continuity and stability during operation, which can ensure long-term continuous production without failure. The equipment adopts high-quality electrical components and mechanical components to ensure the stability and reliability of the equipment and improve the production efficiency. |

| 4 | The sheet thickness is uniform |

| The precision extrusion and cooling system ensures uniform thickness of the sheet. In the production process, the equipment monitors and adjusts the thickness of the plate in real time to ensure that the thickness of each sheet is within the allowable error range, which improves product quality and customer satisfaction. |

| 5 | Precise temperature control system |

| The temperature control system of plastic sheet production line equipment adopts advanced PID control algorithm, which can realize accurate control of extruder temperature. By precisely controlling the temperature, the plastic raw materials can be ensured to achieve the best plasticizing state during the melting process and improve the molding quality of the sheet. |

| 6 | Plasticizing mixing excellent |

| The temperature control system of plastic ABS/PVC/PE/PP sheet plate board extrusion line equipment adopts advanced PID control algorithm, which can realize accurate control of extruder temperature. By precisely controlling the temperature, the plastic raw materials can be ensured to achieve the best plasticizing state during the melting process and improve the molding quality of the sheet. |

| 7 | The plate quality is good |

| Because the equipment has high precision and high efficiency production characteristics, the plastic sheet produced is of good quality. The surface of the plate is smooth, smooth, no bubbles, cracks and other defects, and has good mechanical properties and weather resistance, which can meet the application needs of different fields. |

| 8 | Precise speed control and temperature control |

| The equipment is equipped with accurate speed regulation and temperature control system, which can adjust the extrusion speed and temperature according to the production needs. This precise control ensures the consistency and stability of plate production, while also improving production efficiency. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping