▏Product Vedio

▏Product Introduction

▏Production Details

▏Product Photos

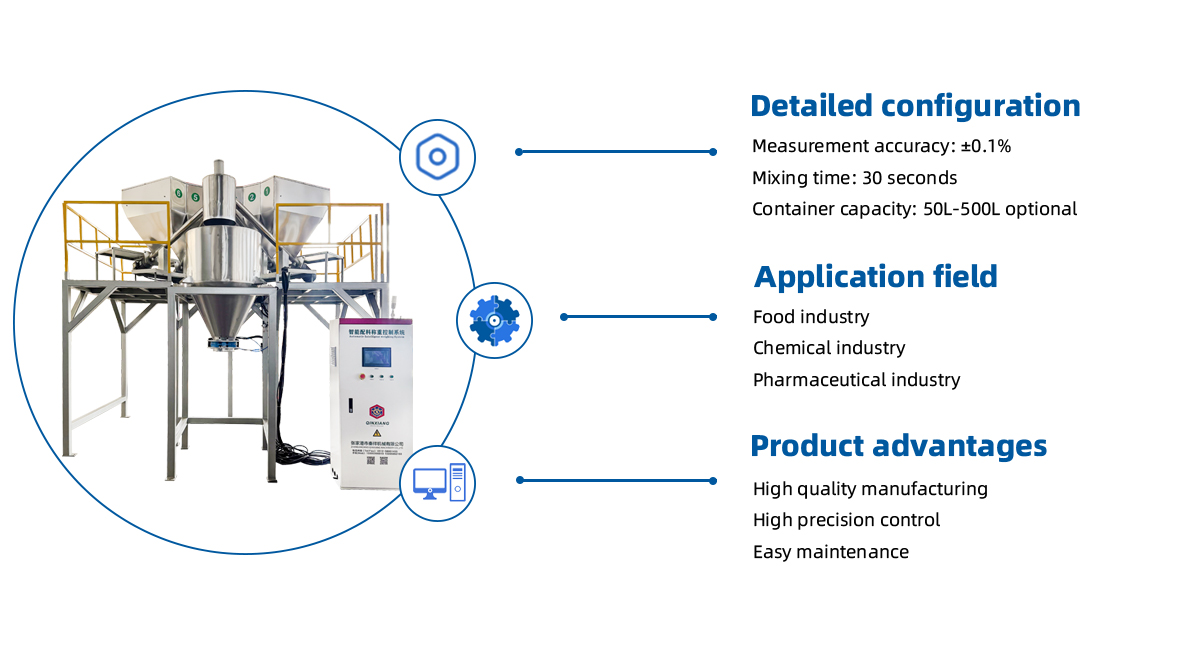

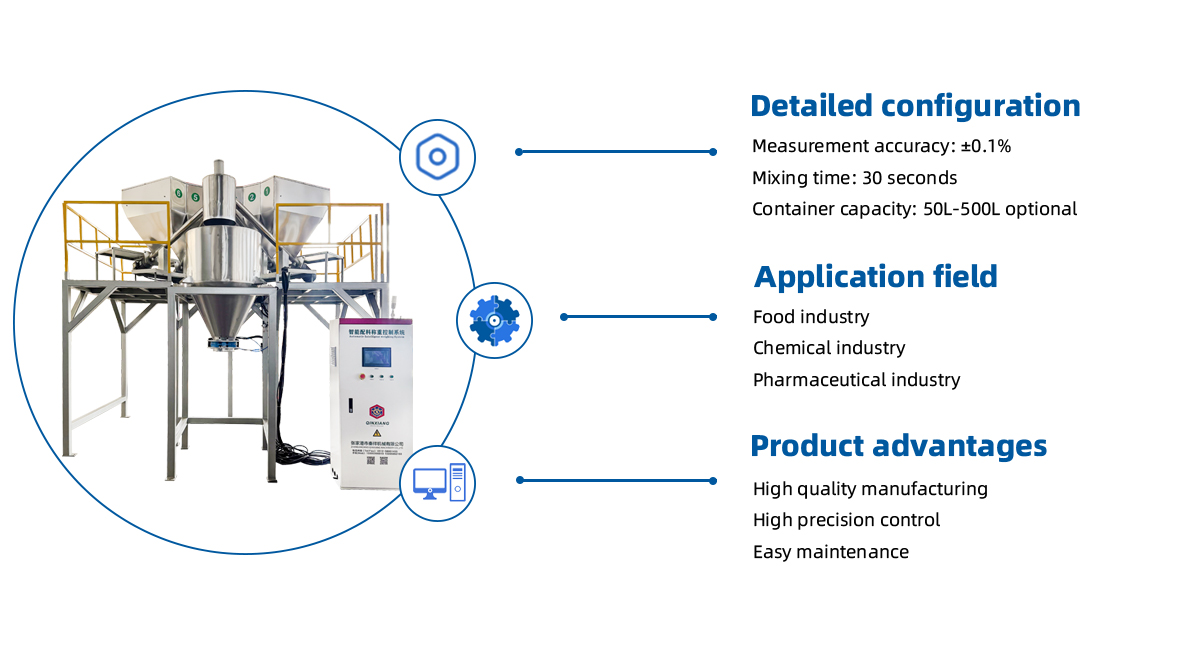

▏Introduction Of An Automatic Batching Dosing Machine

An Automatic Batching Dosing Machine is an advanced system designed to automatically measure and dispense raw materials in precise quantities for various manufacturing processes. These machines are widely used in industries such as food processing, pharmaceuticals, chemicals, plastics, and construction, where accurate mixing and formulation of ingredients are essential.

The primary function of an automatic batching dosing machine is to automate the process of weighing, dosing, and mixing ingredients based on predefined recipes or production requirements. Unlike manual systems, which rely on human intervention, these machines utilize sensors, controllers, and automation technology to ensure precise measurement and efficient material handling.

▏Key Features of an Automatic Batching Dosing Machine

| 1 | Automated Operation |

|

Once programmed, the system independently handles the entire batching process, including ingredient selection, weighing, dosing, and mixing. |

| 2 | High Accuracy and Precision |

|

Automatic Batching Dosing Machine uses load cells, weight sensors, and flow meters to ensure that materials are dispensed accurately to the desired specifications. |

| 3 | Real-Time Monitoring and Control |

|

The control system continuously monitors the process, allowing for real-time adjustments to ensure that the desired quantities and ratios are maintained. |

| 4 | Flexibility and Adaptability |

|

Automatic batching dosing machines are versatile and can handle a wide range of materials, such as powders, liquids, or granular substances. The system can be easily adjusted to accommodate different recipes or formulations. |

| 5 | Integration with Other Systems |

|

These machines can be integrated into larger production lines or enterprise resource planning (ERP) systems, allowing for seamless production control, reporting, and data collection. |

| 6 | User-Friendly Interface |

|

Many systems feature touchscreen displays or remote interfaces for easy setup, programming, and troubleshooting. |

| 7 | Hygienic Design |

|

In industries like food and pharmaceuticals, the machine is designed with easy-to-clean surfaces and materials compliant with hygiene standards. |

▏Components of an Automatic Batching Dosing Machine:

| 1 | Components of an Automatic Batching Dosing Machine |

|

• Material Storage: Bins or hoppers where the raw materials are stored before they are fed into the system. • Weighing Mechanism: Accurate load cells or scales that measure the weight of each ingredient in real time. • Dosing System: Automated valves, feeders, or pumps that accurately dispense the ingredients into the mixing chamber. • Control Panel: Centralized interface to set parameters, monitor the batching process, and make adjustments when needed. • Mixing Unit: A section where the ingredients are blended together, if required, before being sent to the next production stage. |

▏Applications And Benefits

| 1 | Applications |

|

• Food Industry: Precise mixing of ingredients for baked goods, snacks, beverages, and dairy products. • Pharmaceuticals: Accurate dosing of active pharmaceutical ingredients (APIs) and excipients. • Chemicals: Mixing of raw materials for adhesives, coatings, and specialty chemicals. • Plastics: Proportioning of additives, colorants, and resins. • Construction: Batching of cement, sand, and aggregates for concrete production. |

| 2 | Benefits |

|

• Improved Product Quality: Ensures consistent and accurate ingredient ratios. • Cost Efficiency: Reduces material waste and labor costs. • Enhanced Productivity: Speeds up the production process with automated operations. • Compliance: Helps meet industry standards and regulatory requirements. |

The Automatic Batching Dosing Machine is a key innovation in modern manufacturing, offering precision, speed, and flexibility in the material dosing process. By automating the batching process, these machines help manufacturers improve production efficiency, maintain product quality, and reduce costs. Whether in food production, pharmaceuticals, chemicals, or construction, automatic batching dosing machines are essential for ensuring that materials are dispensed accurately and consistently, supporting high-quality end products.

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping