▏Screw Feeder Conveyor: Efficient Material Handling and Transport

▏Introduction to the Screw Feeder Conveyor

The Screw Feeder Conveyor is a mechanical device designed to transport materials through a rotating helical screw. These systems are widely used in various industries for the efficient and controlled feeding of bulk materials into processing or packaging machines. Known for their simplicity, durability, and versatility, screw feeders are commonly employed in industries such as agriculture, chemicals, food processing, plastics, and pharmaceuticals.

Unlike traditional conveyor systems that rely on belts or rollers, the screw feeder conveyor uses a rotating screw element to move materials. This method of transport allows for continuous, consistent, and precise movement of materials, making it an ideal solution for applications where accurate dosing and controlled flow are necessary. Whether transporting powders, granules, or even liquids, the screw feeder conveyor can handle a wide variety of materials with ease.

▏Key Features of the Screw Feeder Conveyor

| Precise Material Feeding and Flow Control

One of the standout features of the Screw Feeder Conveyor is its ability to provide precise material feeding. The screw element, which is typically housed within a tube or trough, rotates to push the material forward. This process ensures a steady and uniform flow of materials, which is essential for operations that require accurate and consistent dosing. By adjusting the screw’s rotational speed, operators can easily control the flow rate, providing flexibility in material handling. |

| Versatility in Material Handling

The Screw Feeder Conveyor is incredibly versatile and can handle a wide range of materials, from granular solids to powders and even slurries. Whether it is used for feeding raw materials into a processing machine or for transporting products between stages in a manufacturing line, the system can accommodate materials of varying sizes, shapes, and consistencies. Some systems are even equipped to handle difficult materials like sticky substances or materials that tend to clump, ensuring smooth operation and preventing blockages. |

| Customizable Design for Different Applications

Screw feeder conveyors are available in a variety of designs, allowing for customization based on the specific needs of the application. For example, screw conveyors can be configured with different screw types (e.g., solid, flighted, or shaftless) and materials (e.g., stainless steel, carbon steel, or plastic) to ensure compatibility with different types of materials. The conveyor's length, diameter, and discharge angle can also be adjusted to meet spatial constraints or processing requirements, making these conveyors suitable for a wide range of industrial environments. |

| Durable and Low Maintenance

Built for heavy-duty operation, the Screw Feeder Conveyor is constructed using high-quality materials that ensure long-lasting performance, even under challenging conditions. The system’s rotating screw is typically made from corrosion-resistant materials, such as stainless steel, which extends the lifespan of the equipment, especially when used with harsh chemicals or abrasive materials. Additionally, screw feeders have fewer moving parts compared to other types of conveyors, which results in lower maintenance costs and reduced risk of mechanical failure. |

| Hygienic Design for Food and Pharma Industries

In industries where hygiene and sanitation are critical, such as food processing or pharmaceuticals, the Screw Feeder Conveyor is designed with cleanability in mind. The conveyor can be disassembled easily for cleaning, ensuring that it meets the rigorous standards required by food safety and pharmaceutical regulations. Smooth surfaces and easy access to parts further enhance the system's ability to meet sanitary requirements, preventing cross-contamination between materials. |

▏Production Details

▏Product Photos

▏How the Screw Feeder Conveyor Works

The Screw Feeder Conveyor operates based on a relatively simple but effective principle: the rotation of a screw element inside a trough or tube. Here’s a breakdown of how it works:

| 1. Material Loading

Materials are typically loaded into the screw feeder conveyor through a hopper or storage bin. Once the material enters the system, the rotating screw (also known as an auger) begins to move the material along the conveyor path. |

| 2. Material Transport

As the screw rotates, it pushes the material forward. The helical design of the screw allows it to move materials steadily and consistently without disturbing their integrity. The rotation of the screw is powered by a motor that can be adjusted to control the speed of the material flow. |

| 3. Flow Control

The flow of material can be regulated by adjusting the speed of the screw, allowing for precise control over the rate at which materials are fed into a machine or production line. This feature is particularly useful in processes that require accurate and controlled dosing of materials. |

| 4. Discharge

At the discharge end of the conveyor, the material is either delivered to a processing machine, storage bin, or packaging station. In some systems, the discharge point can be customized to suit specific operational needs, such as a controlled drop, distribution, or transfer into different stages of production. |

| 5. Recycling and Return

Some screw feeder conveyors are designed with a return feature that allows for the reuse or recycling of material. This system can be incorporated into the design to minimize material loss and reduce waste, making it a more sustainable solution for operations that require continuous material handling. |

▏Benefits of the Screw Feeder Conveyor

| 1. Improved Productivity

The Screw Feeder Conveyor enhances productivity by automating the material feeding process. This reduces the need for manual labor and allows for continuous, hands-free operation. By maintaining a constant flow of materials, the system ensures that downstream processes, such as mixing, packaging, or manufacturing, can operate without interruptions, improving overall efficiency. |

| 2. Enhanced Material Control

Precise flow control is essential for many applications, such as dosing and mixing. The Screw Feeder Conveyor allows operators to adjust the flow rate based on the material type and required processing speed. This level of control ensures that the right amount of material is consistently supplied to subsequent stages, helping to maintain consistency in the final product. |

| 3. Cost-Effective Solution

Screw feeder conveyors offer a cost-effective solution for material handling compared to other types of conveyors. Their low energy consumption, minimal maintenance requirements, and long lifespan make them a durable and economical investment. Additionally, their ability to handle a wide range of materials without the need for multiple systems results in lower capital and operational costs. |

| 4. Reduced Downtime

The simplicity of the screw feeder conveyor design means fewer moving parts and less potential for mechanical failure. As a result, the system experiences less downtime due to breakdowns or malfunctions. Additionally, many models are designed with quick and easy maintenance procedures, ensuring that the system can be serviced with minimal disruption to operations. |

| 5. Adaptability to Various Industries

The versatility of the Screw Feeder Conveyor allows it to be used in a broad range of industries, including: Agriculture: Transporting grains, seeds, and fertilizers. Chemical: Handling bulk chemicals, powders, and pellets. Food Processing: Moving ingredients, spices, and additives. Pharmaceutical: Handling powders and tablets in a hygienic environment. Recycling: Moving materials like plastics, metals, and waste products. |

▏Applications of the Screw Feeder Conveyor

| 1. Food and Beverage Industry

In the food and beverage industry, screw feeder conveyors are used to transport ingredients, spices, flour, and other bulk food products. The ability to control material flow precisely makes these conveyors ideal for applications where accurate ingredient dosing is required. |

| 2. Chemical Manufacturing

In chemical manufacturing, screw feeders are used to handle bulk chemicals, powders, and additives. The system’s versatility allows it to handle a wide variety of materials, from fine powders to larger granules, ensuring a smooth and efficient transport process. |

| 3. Agriculture

Screw feeder conveyors are commonly used in agriculture to transport grains, seeds, and fertilizers. The ability to handle dry, free-flowing materials makes this type of conveyor system essential for feeding equipment, processing plants, or packaging lines in the agricultural sector. |

| 4. Plastics and Recycling

In the plastics and recycling industries, screw feeder conveyors are used to transport pellets, shreds, or granules of plastic, as well as recycled materials. Their robust design ensures that they can handle the wear and tear of these demanding environments. |

| 5. Pharmaceuticals

In pharmaceutical manufacturing, screw feeder conveyors are utilized for transporting active ingredients, powders, and tablets. The system can be designed to meet strict hygiene standards, ensuring that the materials remain uncontaminated throughout the transport process. |

▏The Versatility of the Screw Feeder Conveyor

The Screw Feeder Conveyor is a highly effective solution for the transport and handling of bulk materials across various industries. Its ability to deliver precise, consistent, and chip-free material flow makes it invaluable for operations that require accuracy, reliability, and efficiency. With a customizable design, low maintenance needs, and versatile material handling capabilities, the Screw Feeder Conveyor continues to be a critical component in optimizing production processes, reducing waste, and improving overall productivity across diverse industries.

▏Production Introduction

| 1 | Definition and application |

| Screw feeder conveyor machine, also known as screw conveyor machine, is a mechanical equipment that uses the rotating motion of spiral blades to push materials forward. It is widely used in food, chemical, building materials, metallurgy and other industries of the material conveying system, especially suitable for powder, granular and small block material horizontal or inclined conveying. |

| 2 | the working principle |

| The working principle of the Screw feeder conveyor machine is that the spiral shaft is rotated by the motor, and the spiral blade pushes the material into the spiral groove when it is rotating, and moves forward along the spiral axis. Due to the continuous rotation of the spiral shaft, the material can be continuously transported to the destination. |

| 3 | Composition structure |

| Screw feeder conveyor machine is mainly composed of the following parts: 1. Spiral shaft: It is the core part of the spiral feeding machine, which is driven by the motor to rotate and drive the spiral blade to rotate. 2. Spiral blade: fixed on the spiral shaft, used to push the material forward. 3. Shell: the spiral shaft and spiral blade are installed in the shell, and the shell protects the spiral shaft and spiral blade from the interference of the external environment. 4. Feed port: used to add the material into the spiral groove. 5. Discharge port: The material is finally discharged from the discharge port through the push of the spiral shaft and spiral blade. 6. Transmission device: including motor, reducer, coupling, etc., used to drive spiral shaft rotation. |

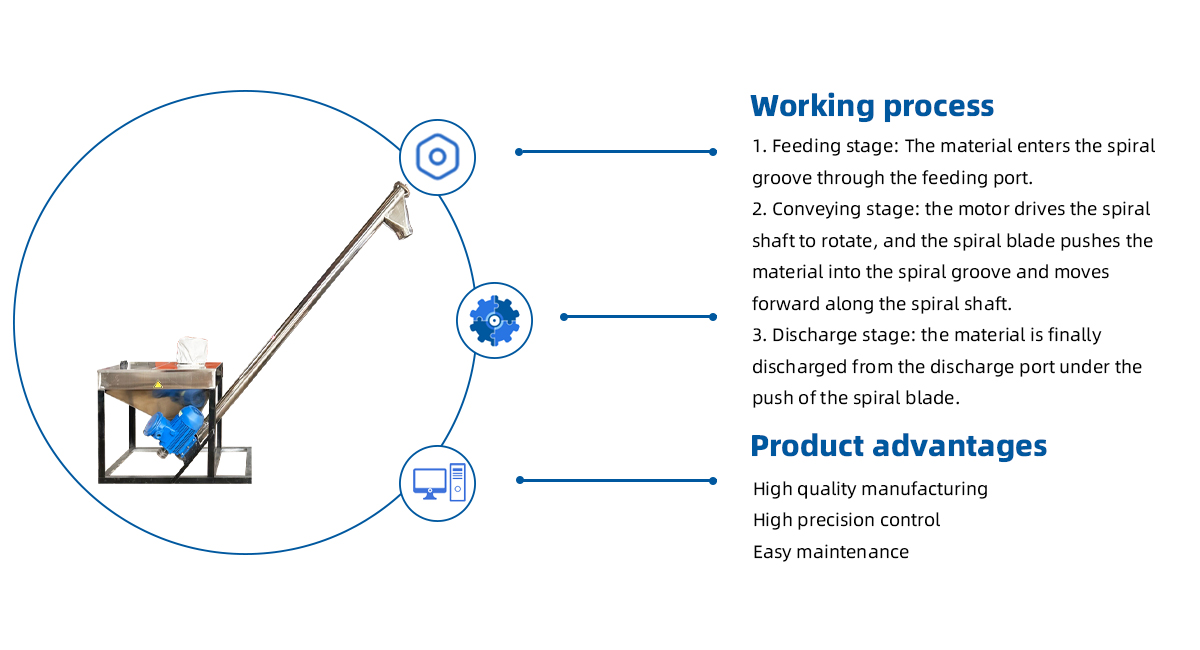

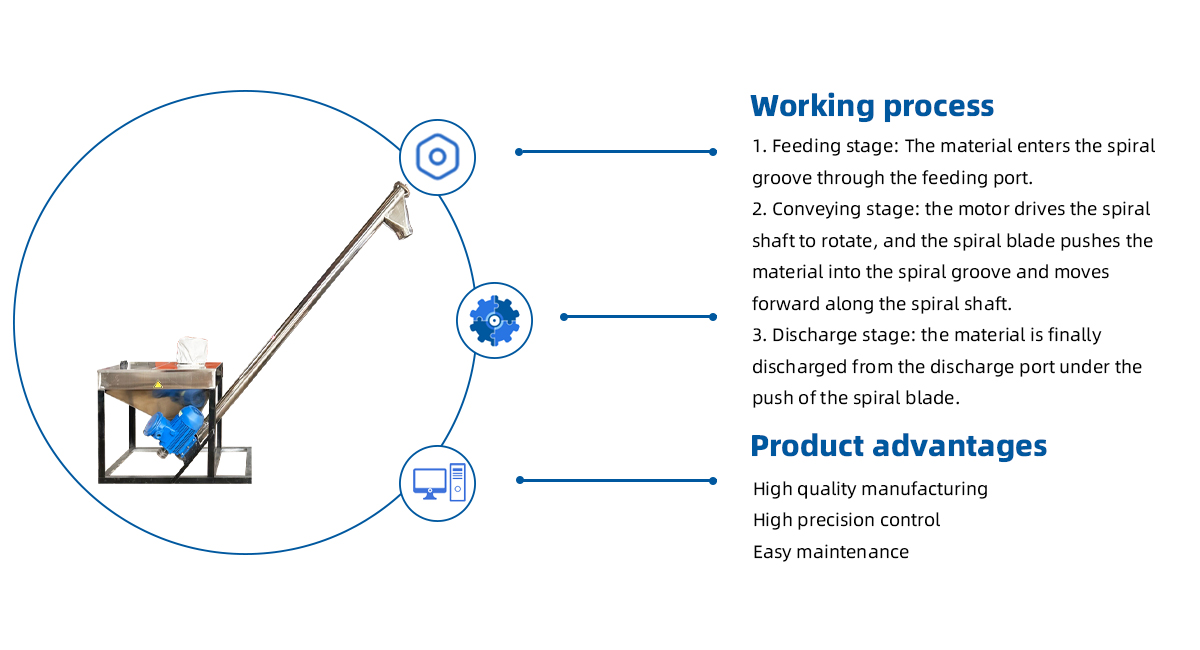

| 4 | Work phase |

|

The working process of the Screw feeder conveyor machine can be divided into the following stages: 1. Feeding stage: The material enters the spiral groove through the feeding port. 2. Conveying stage: the motor drives the spiral shaft to rotate, and the spiral blade pushes the material into the spiral groove and moves forward along the spiral shaft. 3. Discharge stage: the material is finally discharged from the discharge port under the push of the spiral blade. |

| 5 | Advantages |

|

1. Simple structure, convenient installation, easy maintenance. 2. High conveying efficiency, continuous material conveying. 3. Long conveying distance, strong adaptability, can adjust the conveying length according to production needs. 4. The material is not easy to scatter during the conveying process, reducing environmental pollution. |

| 6 | Use and maintenance |

|

1. Use precautions: Before use, check whether the spiral shaft, spiral blade and other parts are in good condition, and replace them in time if damaged. Regularly check the operation of the motor, reducer and other transmission devices to ensure their normal operation. During the conveying process, attention should be paid to whether the material enters the spiral groove evenly to avoid blockage or accumulation. Avoid overload operation, so as not to damage the equipment or affect the delivery effect. 2. Maintenance method: Clean and maintain spiral shaft, blade and other parts regularly to remove attached materials and dirt. Periodically check and tighten the bolts and nuts of the connecting parts to ensure the stability of the equipment. If the equipment is found to have abnormal noise, vibration or excessive temperature rise, it should be stopped in time to check and troubleshoot. If the equipment is not used for a long time, it should be treated with dust and moisture to avoid rust or damage. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping