Production Details

Product Photos

Product Introduction

(1). Equipment overview

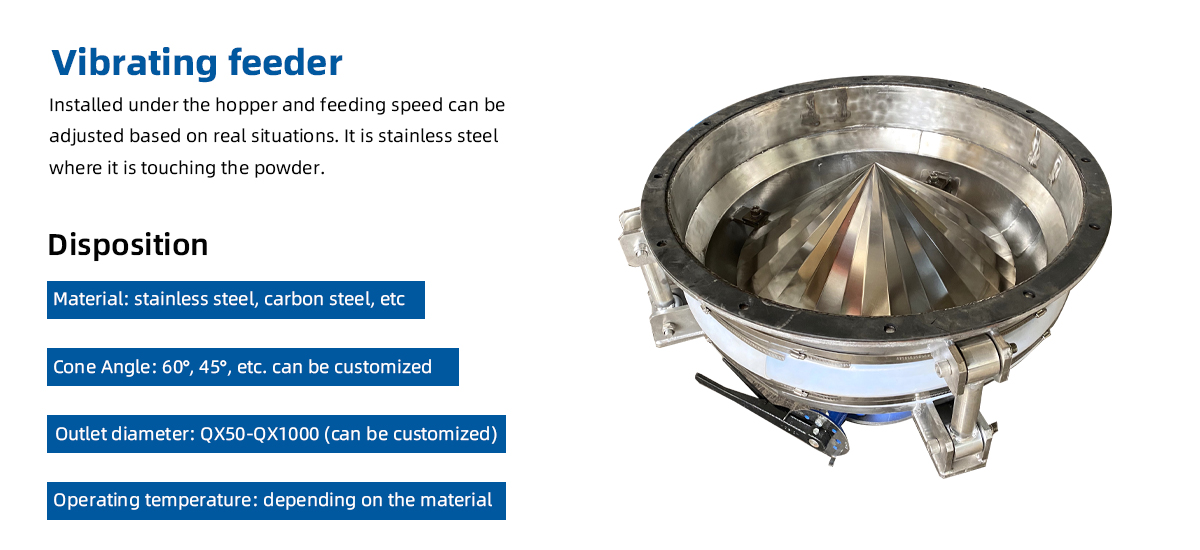

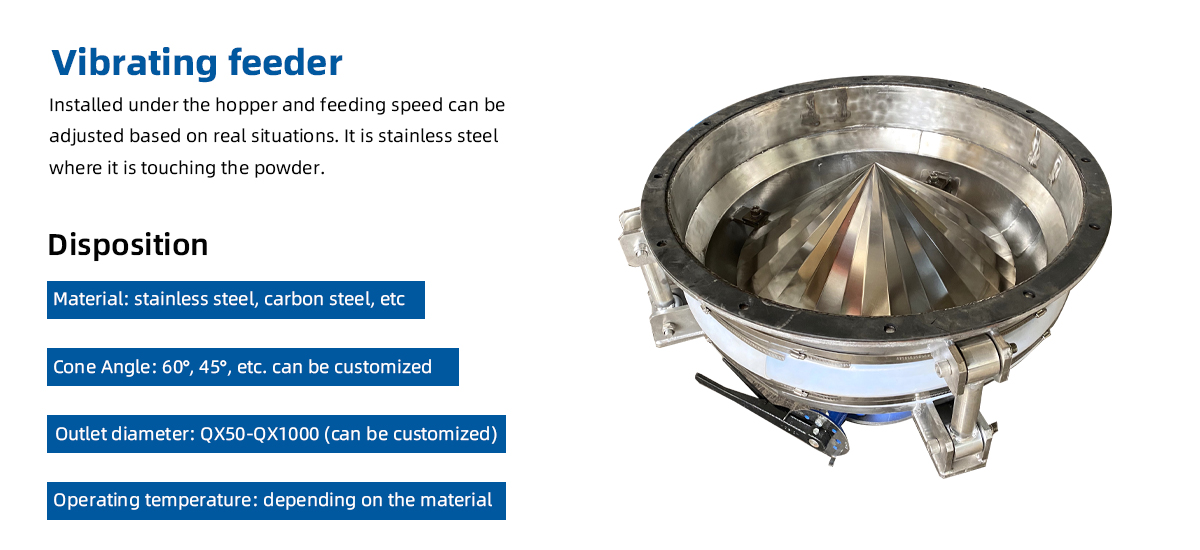

silo Vibrating feeding hooper is a kind of key equipment widely used in powder and particle material handling system. It is usually installed at the bottom of equipment such as silos, hoppers or dust collectors to discharge materials stably and evenly. By adjusting the flow speed and direction of the material, the cone feeder ensures the smoothness and continuity of the material in the conveying process, and effectively prevents the blockage and accumulation of the material.

(2).the working principle

The working principle of the silo Vibrating feeding hooper mainly depends on its special tapered design and adjustable outlet. Under the action of gravity and its own fluidity, the material slides down the conical wall and flows out through the exit. By adjusting the opening of the outlet or installing different valves (such as rotary valves, plug valves, etc.), the flow rate and velocity of the material can be controlled to meet different production needs.

(3). Product parameters

The following are the basic parameters of a typical silo Vibrating feeding hooper (the specific parameters may vary depending on the product model and specifications) :

Material: stainless steel, carbon steel, etc

Cone Angle: 60°, 45°, etc. (can be customized according to material characteristics)

Outlet diameter: DN50-DN1000 (can be customized)

Flow range: depends on material characteristics and outlet opening

Working pressure: ≤0.6MPa

Operating temperature: depending on the material

(4). advantages and characteristics

1. Simple structure, convenient installation, easy to connect with various silos, hoppers and other equipment.

2. Cone design is conducive to material flow and reduce blockage and accumulation.

3. Adjustable outlet design, easy to control material flow and velocity.

4. Made of wear-resistant and corrosion-resistant material, suitable for various material environments.

5. Easy maintenance, easy parts replacement.

(5). Application fields

silo Vibrating feeding hooper is widely used in the following fields:

1. Chemical industry: In the powder, particle material processing system, such as plastics, rubber, pigments, etc.

2. Pharmaceutical: In the drug production process of material transportation, ingredients and other links.

3. Food: in the process of food processing and packaging, such as flour, powdered sugar, milk powder, etc.

4. Metallurgy: in the processing and transportation of mineral powder, slag and other materials.

5. Environmental protection: In environmental protection equipment such as dust removal and desulfurization, it is used to collect and treat dust and other pollutants.

(6). Use method and maintenance

1. Usage: Install the silo Vibrating feeding hooper at the bottom of the bin, hopper and other equipment to ensure that the connection is firm. Adjust the outlet opening according to the production demand, start the conveying equipment, and make the material flow out smoothly.

2. Maintenance: Regularly check whether the connection of the Vibrating feeder is loose, and tighten it in time if it is loose. Clean conical walls and exits of accumulated material, keep equipment inside clean. Regularly check the wear of valve and other wearing parts, if there is wear should be replaced in time.

(7). Precautions

1. In the installation and use process, it should be ensured that the connection between the Vibrating feeder and the conveying equipment is firm and reliable to prevent material leakage and environmental pollution.

2. According to the material characteristics and production needs, reasonably adjust the outlet opening and flow rate to avoid material blockage and accumulation.

3. Check the operation of the equipment regularly. If any abnormal situation is found, stop the equipment for maintenance in time.

4. When cleaning and maintaining the equipment, follow the safety operation rules to avoid accidents.

Through the correct use and maintenance of the Vibrating feeder, it can ensure its stable operation and efficient work in the material handling system, and create more economic benefits for the enterprise.

Packing And Shipping

Cooperative Parts Supplier

FAQ

1.Are you a factory or trading company?

Qinxiang:We are a factory.

2.Can we visit your machine operation in your factory?

Qinxiang:You can see machine operation in our factory.

3.Can the machine be customized?

Qinxiang:Yes,it can.

4.How many electric, water, air need for the machines?

Qinxiang: technical department supply the whole layout for workshop details.

5.Can I operate machine if don’t have experienced engineers?

Qinxiang: (1) short-time engineers to customer company (5-15days) (2) Year-time working as requirements

6.Any quality checking before shipment?

Qinxiang: 100% confirm, run and test machines before shipment with quality certificate.

7.How long is the guarantee?

Qinxiang: 12 months since the first day customer operates (except wear parts).

8.How can u help us when face some technical problem?

Qinxiang: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

9.Where can we get spare part?

Qinxiang: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.