▏Plastic Pipe Production Line

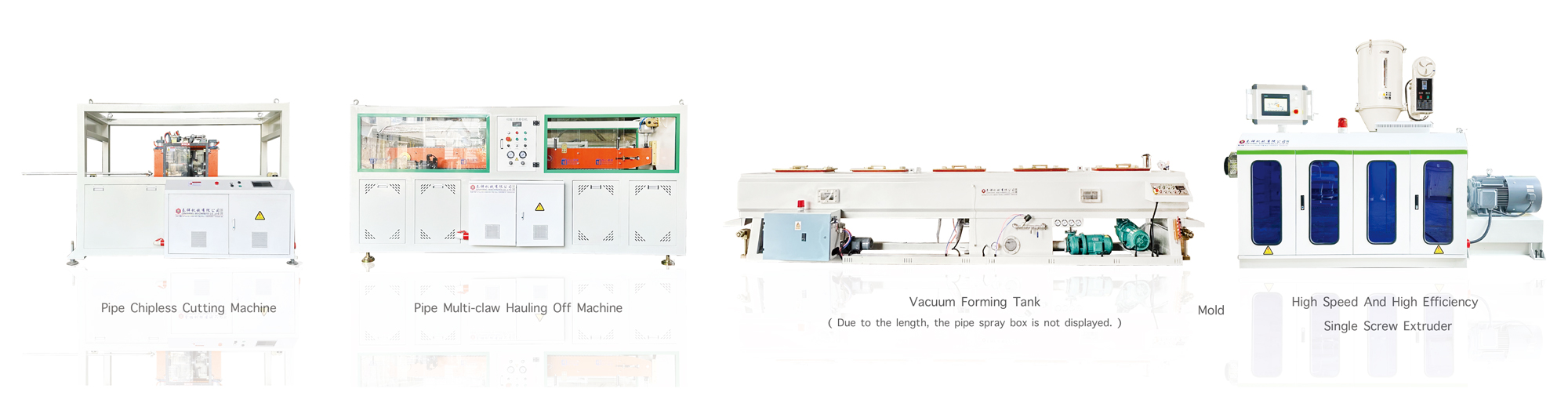

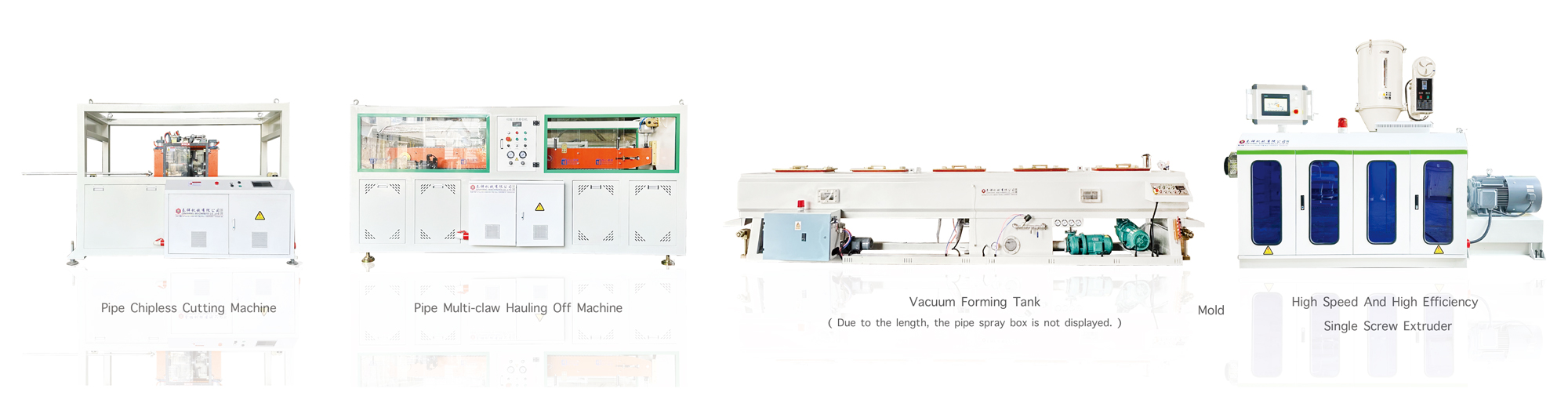

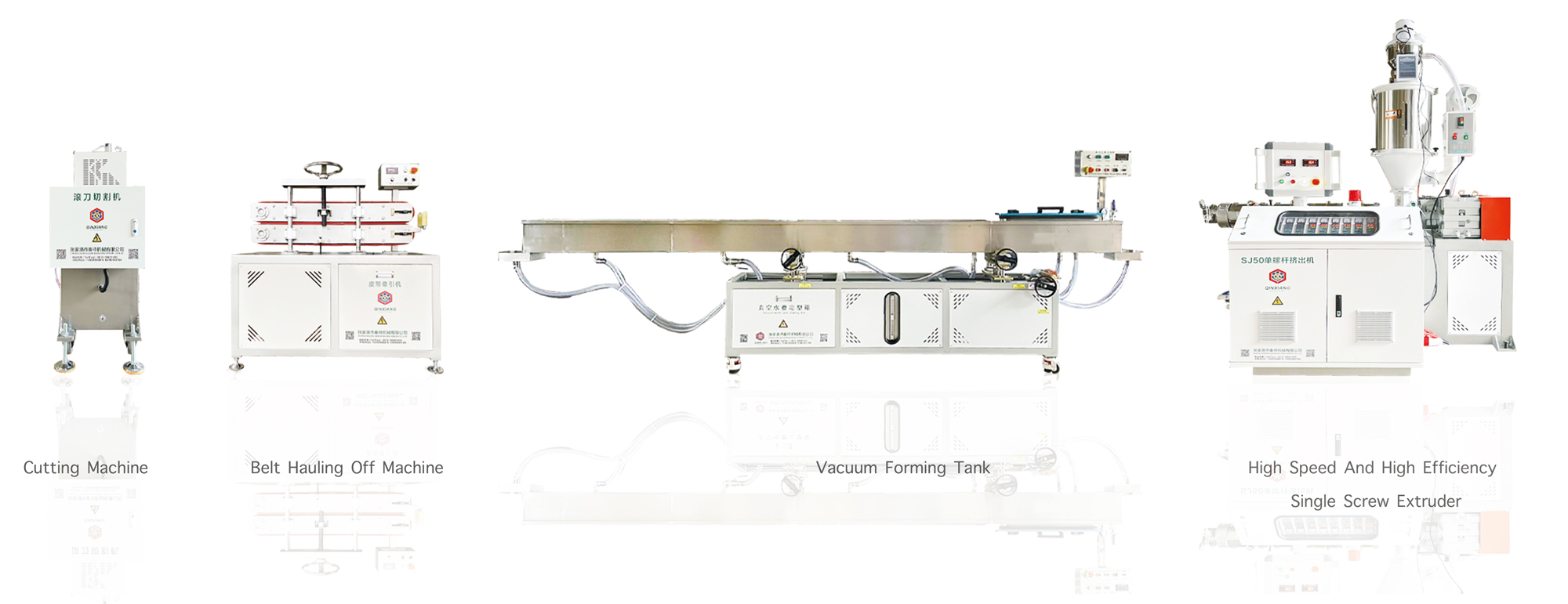

▏Production line components

The plastic pipe production line consists of several key components to ensure the smooth operation of the entire production process. The main components include:

Control system: responsible for the control and scheduling of the overall production process.

Extruder: responsible for melting and extrusion of raw materials into tubes.

Head: The end of the extruder, responsible for forming the tube.

Styling cooling system: Cooling and styling pipes to ensure stable size and shape.

Traction machine: continuously pull the cooled pipe to ensure the continuity of the production line.

Cutting device: Cut the tube to the required length.

Tilting rack: used to unload the cut pipe.

▏Plastic PE Pipe Extrusion Line

PE (polyethylene) pipe production line has the following characteristics:

Unique structure: high degree of automation, easy operation, stable and reliable continuous production.

High efficiency extrusion: PE high efficiency screw and slotted barrel, with strong water jacket cooling, improve the conveying capacity.

High torque vertical gearbox: Ensure the stability of efficient extrusion.

High precision control: double chamber vacuum sizing technology and spray cooling water tank are used to improve the yield of the pipe.

High quality material: The produced pipe has moderate rigidity, strength, and good flexibility, creep resistance, environmental stress cracking resistance and hot melt performance.

▏Plastic PVC Pipe Extrusion Line

The process flow of PVC pipe production line includes:

Raw material mixing: PVC stabilizer, plasticizer, antioxidant and other auxiliary materials are added to the high-speed mixer in proportion, and cooled to 40-50 degrees after heating.

Extruder part: Through the quantitative feeding device to ensure that the amount of extrusion and feeding amount match, the screw will plasticize the PVC mixture and push it to the head.

Extrusion die: The key component of pipe forming, extrusion the melted PVC into a tube shape.

Vacuum shaping water tank: used for shaping and cooling of pipes.

Traction machine: continuously and automatically leads the cooled and hardened pipe from the head.

Cutting machine: automatically cut the pipe according to the required length, and delay the turnover.

Tilting rack: used to unload the cut pipe.

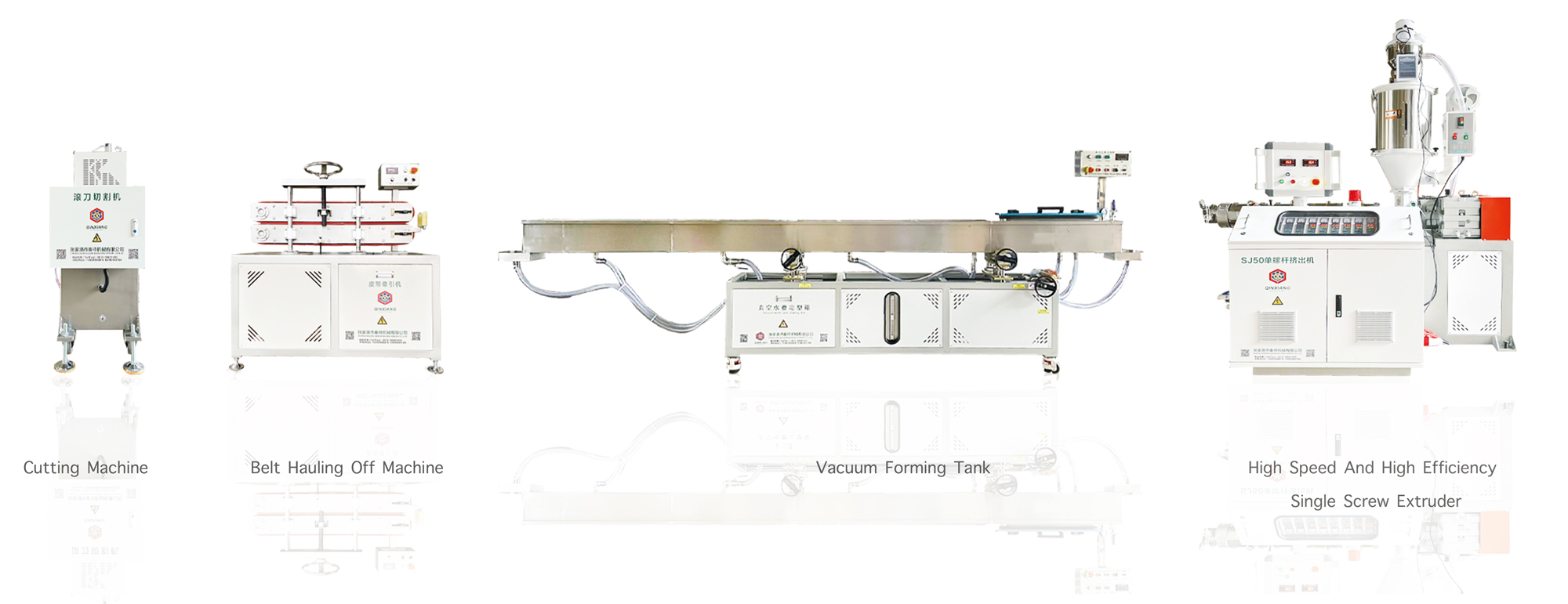

▏PC/PETG/PMMA Precise Pipe Extrusion Line

Plastic PC/PETG/PMMA Precise Pipe Extrusion Line is mainly composed of raw material supply system, extruder, mold, cooling device, traction cutting system and automatic control system and other core equipment. The equipment in the production line works together precisely to melt, extrude, cool, pull and cut raw materials to produce high-quality transparent pipes.

▏TPE/PE Hose Extrusion Line

The Plastic TPE/PE Filling Pillow Core Extrusion Line is a specialized production system designed to manufacture pillow cores using TPE (Thermoplastic Elastomer) and PE (Polyethylene) materials.

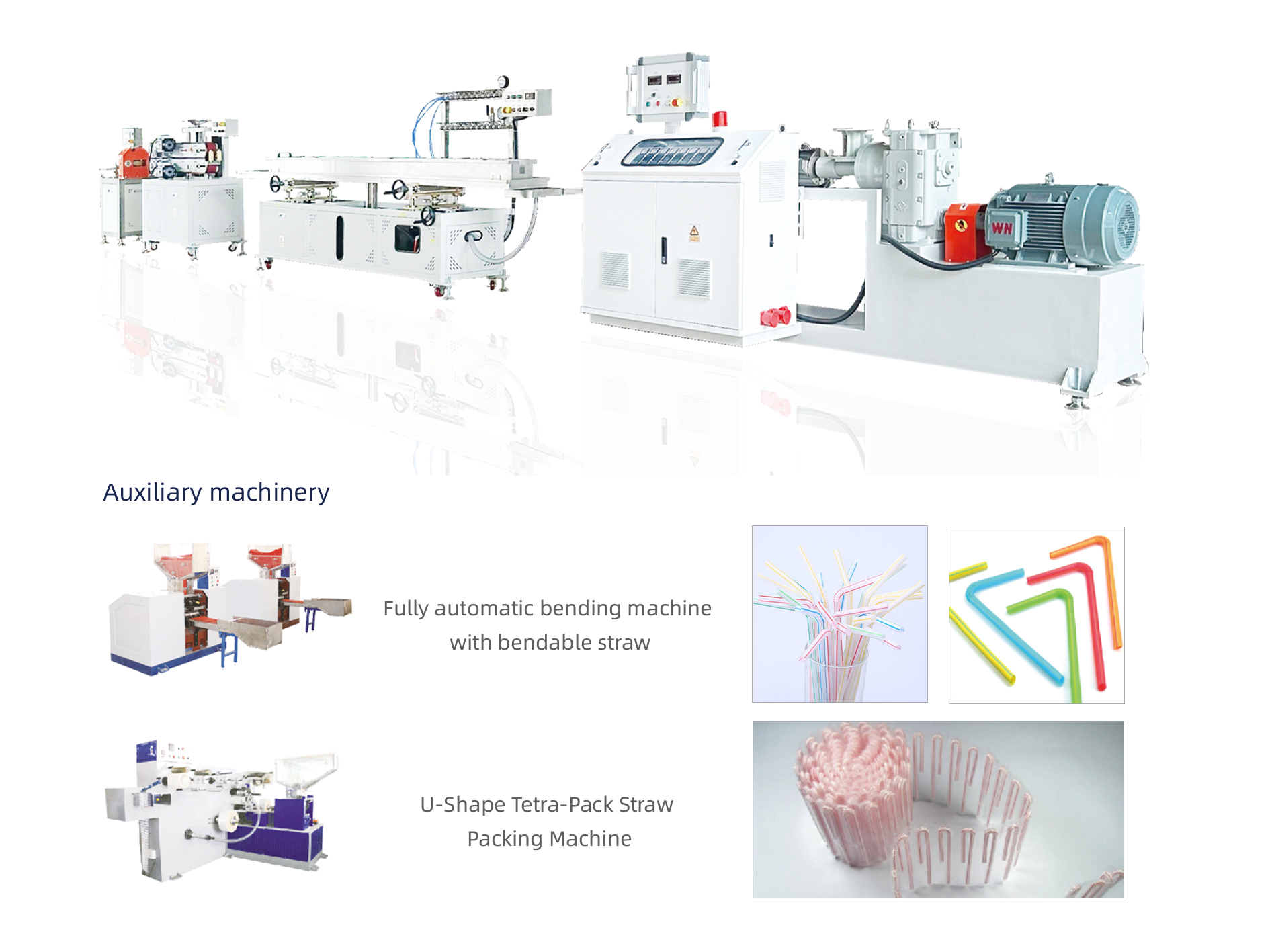

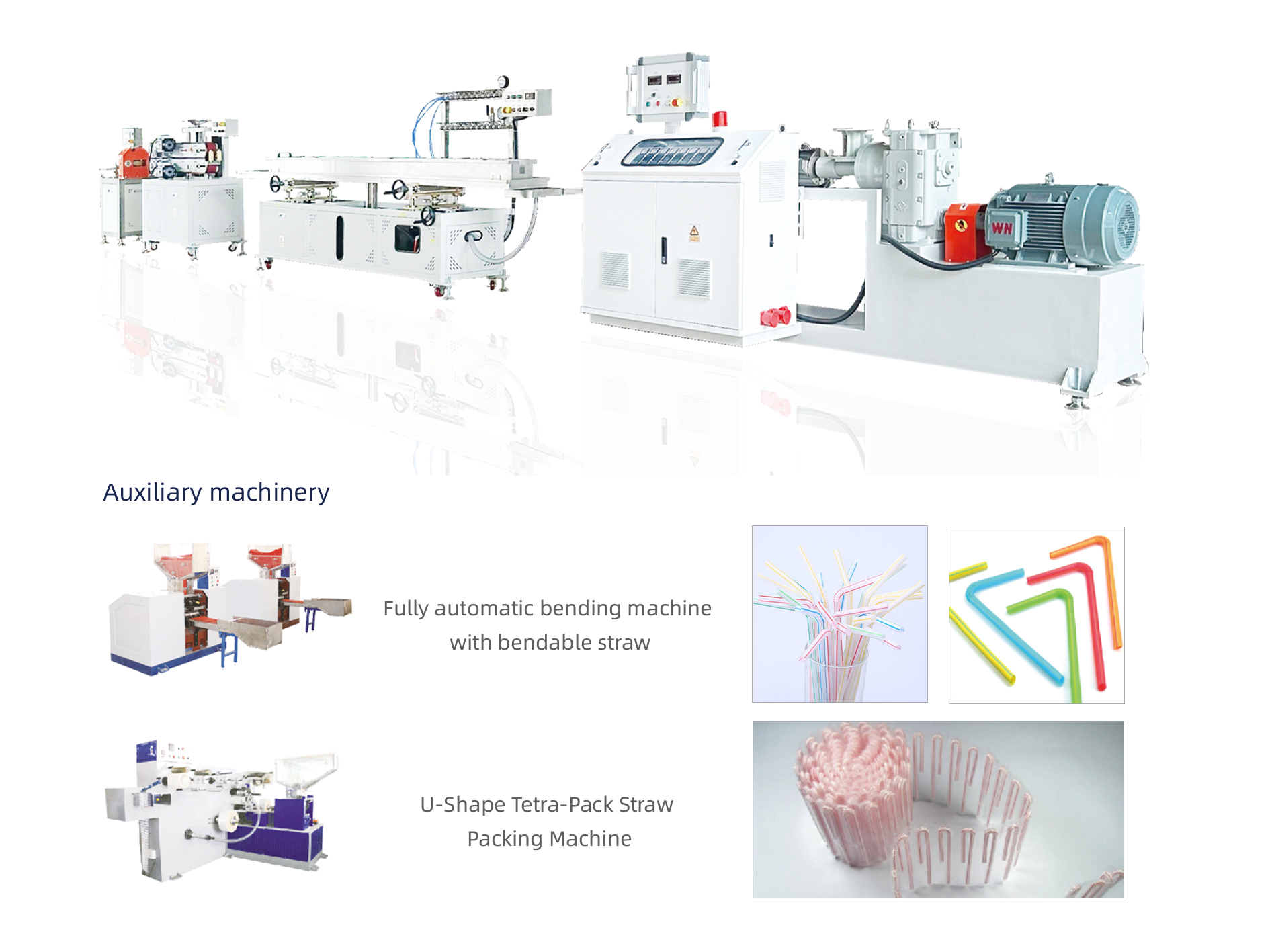

▏PP/PLA Straw Extrusion Line

The PP/PLA Straw extrusion line is a combination of equipment dedicated to the production of polypropylene (PP) and polylactic acid (PLA) straws. The line combines efficient extrusion technology, precision mold design and automated control systems to ensure high quality and production efficiency. PP/PLA straw extrusion production line is widely used in catering, drinks, medical, family and other fields. With people's attention to environmental protection and health, PLA straws are favored for their degradability, and the market demand is growing.

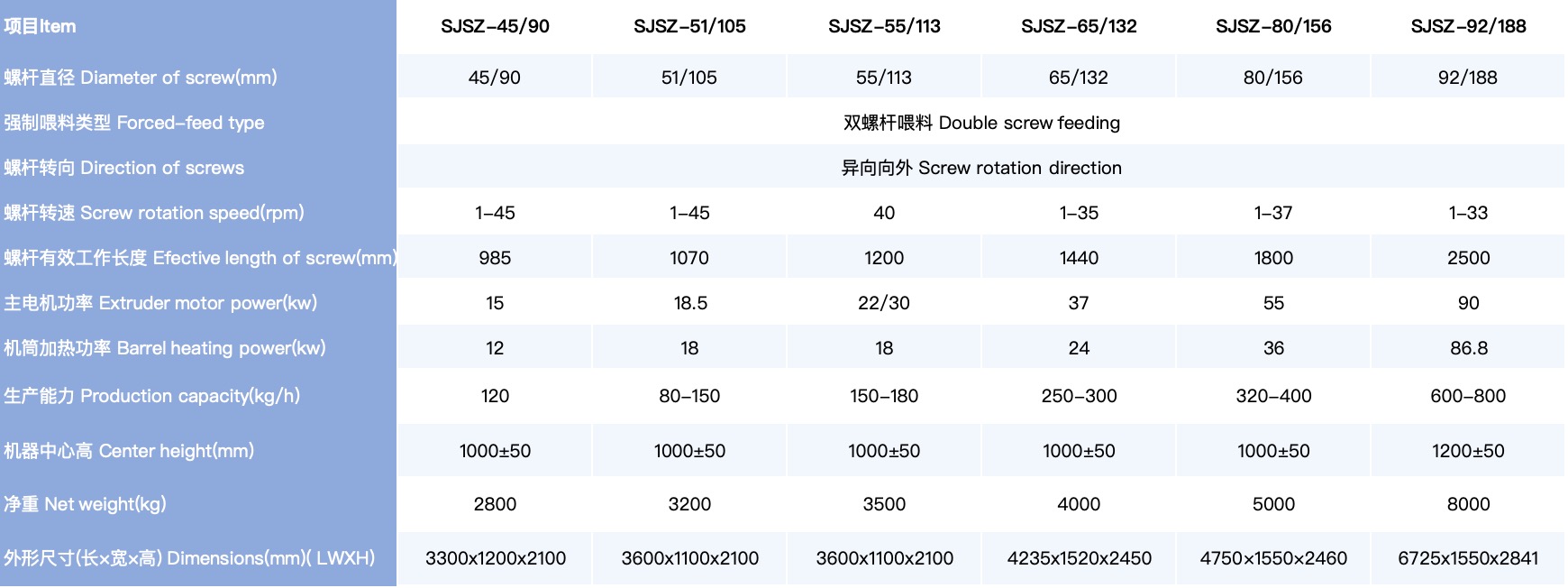

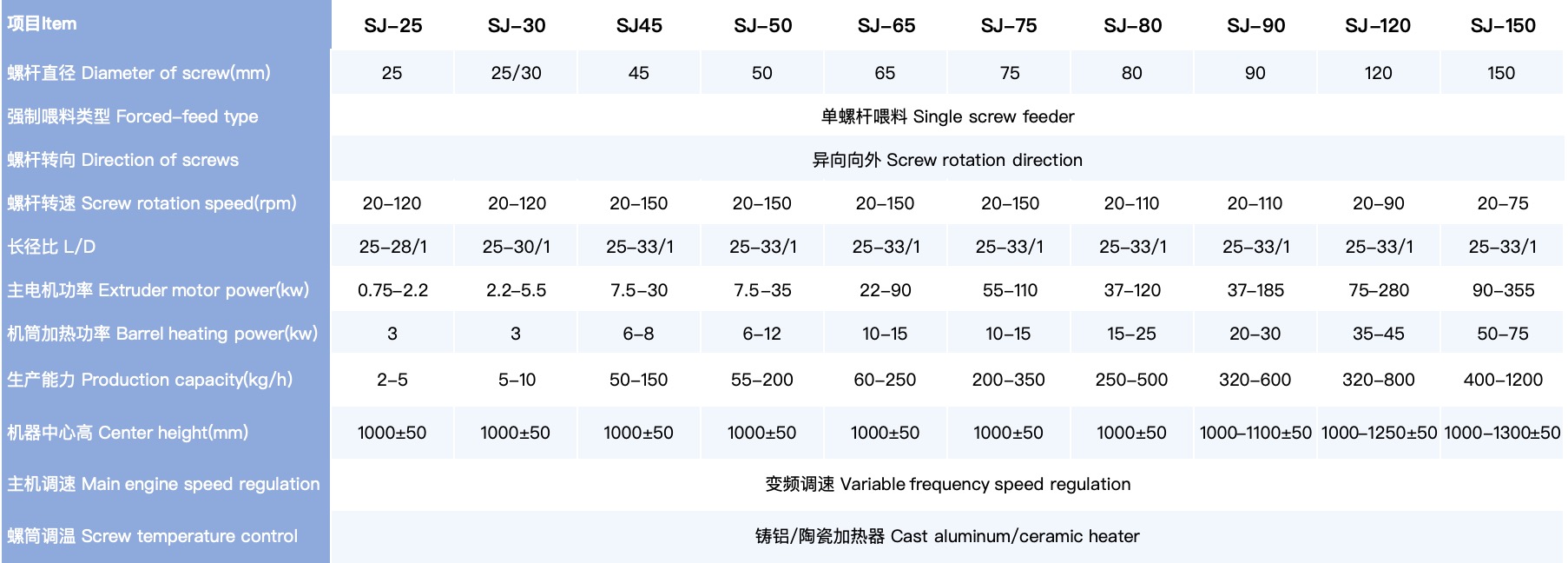

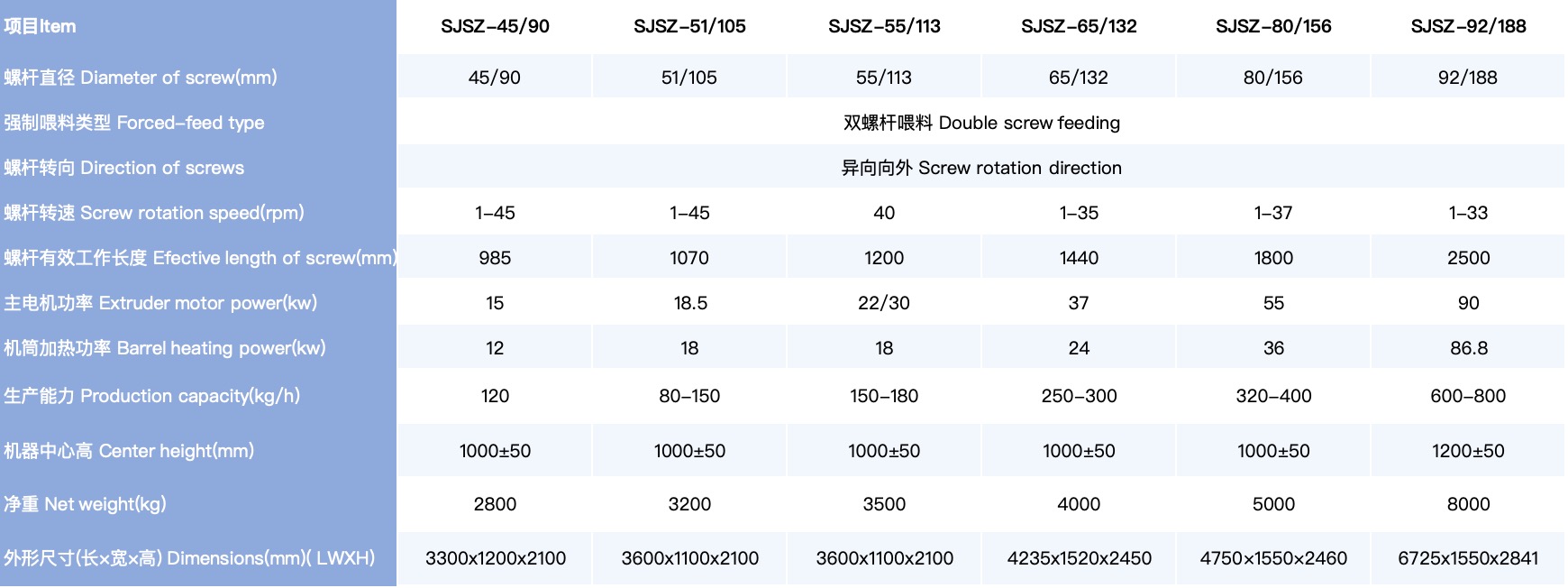

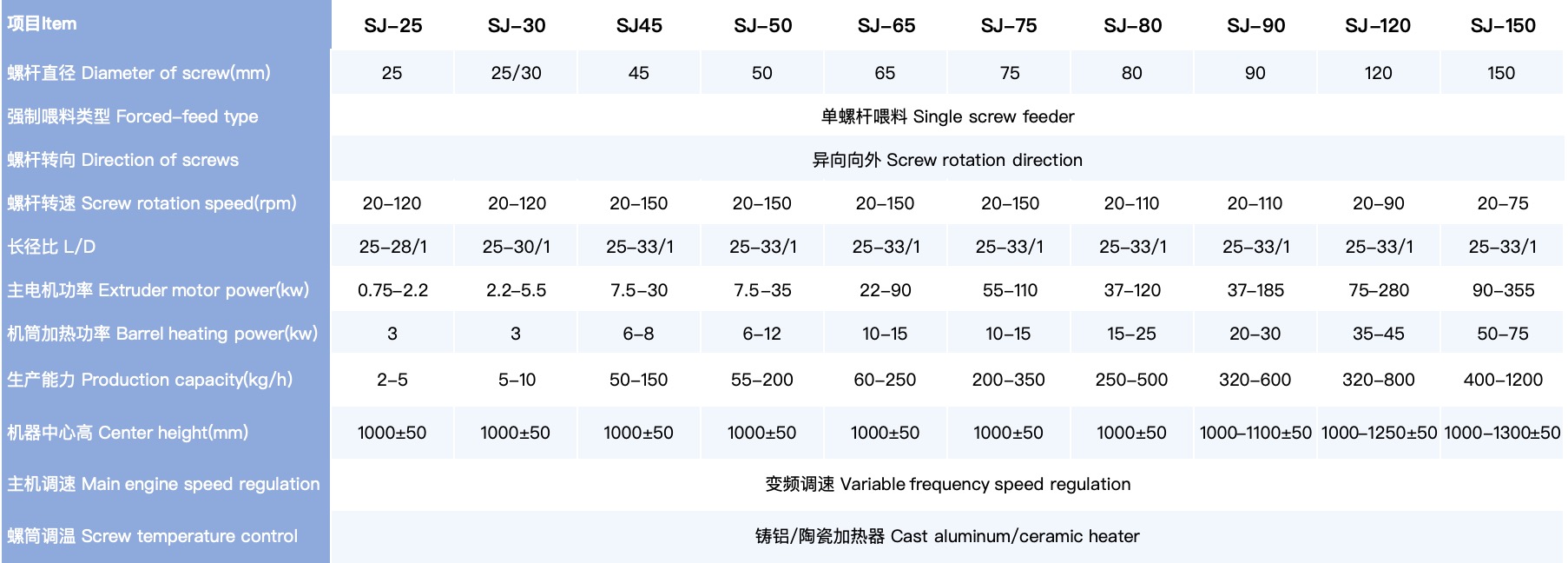

▏Configuration parameter

▏Pipe type and application

There are various types of plastic pipes, mainly including:

PP (polypropylene) : used to make injection molded products, films, pipes, etc., widely used in household appliances, steam, chemical, construction and other fields.

PVC (polyvinyl chloride) : used to make plates, pipes, storage tanks, etc., with acid and alkali resistance, wear resistance, good electrical insulation and other characteristics, widely used in drainage, building water supply and drainage, power cable laying.

PE (polyethylene) : used in the production of film, wire and cable sheath, pipe, etc., widely used in agriculture, packaging, electronic appliances and other fields.

▏Production technical parameters

The technical parameters of the production line mainly include:

Pipe diameter range: 16mm-800mm, can be adjusted according to customer special requirements.

Extruder power: Depending on the production speed and pipe specifications, the power is between 32kw-150kw.

Extrusion capacity: According to the extruder model number and the different raw materials, the extrusion capacity is between 30kg/ H-400kg /h.

Production speed: up to 100m/min or more.

▏Pipe performance and quality

Plastic pipes have a variety of excellent properties:

PE pipe: has moderate rigidity, strength, and good flexibility, creep resistance, environmental stress cracking resistance and hot melt performance.

PVC pipe: has the characteristics of acid and alkali resistance, wear resistance, good electrical insulation, low softening temperature, limited to use below 80℃.

PP pipe: odorless, tasteless, non-toxic, good heat resistance, good chemical stability and so on.

▏Common faults and troubleshooting

Plastic pipe production line common faults include:

Rough surface: Adjust the process temperature, reduce the cooling water temperature, check whether the waterway is blocked.

Internal jitter ring: Adjust the water discharge of the sizing sleeve to ensure that the water discharge is uniform, and check whether the vacuum gasket is too tight.

No vacuum: Check whether the inlet of the vacuum pump is blocked and whether the vacuum pump works normally.

Uneven wall thickness of the pipe: adjust the wall thickness of the mold, adjust the Angle of the vacuum setting machine and the nozzle in the spray box.

▏Care and maintenance

1. Regular inspection: Regular inspection of various components on the production line, including extruder, head, styling cooling system, tractor and cutting device, etc., to ensure that they are in good condition.

2. Cleaning and lubrication: regularly clean the dust and stains on the production line, and lubricate the parts that need to be lubricated to reduce wear and failure.

3. Replace the worn parts: for the parts with serious wear, such as screw, head mold, etc., it should be replaced in time to avoid affecting the production quality and efficiency.

4. Adjust the process parameters: according to the actual production situation, timely adjust the process parameters, such as temperature, pressure, speed, etc., to ensure product quality and production efficiency.

▏Training and operation

1. Staff training: Regular training of production line operators to improve their operational skills and safety awareness and reduce the impact of human factors on production.

2. Standard operation: Formulate and strictly implement the operation procedures of the production line to ensure that the operators operate in accordance with the procedures to avoid misoperation and illegal operation.

3. Handover system: Establish a sound handover system to ensure that the production line is in good condition at the time of handover, while recording the production situation and equipment status.

▏Safety and environmental protection

1. Safety production: Strengthen safety production management, ensure that equipment and facilities on the production line meet safety standards, and operators wear safety protective equipment to prevent accidents.

2. Environmental protection measures: Take effective measures to reduce the discharge of waste gas, waste water, waste residue and other pollutants in the production process to protect the environment and employee health.

▏Summary and prospect

With the progress of science and technology and the constant changes of the market, plastic pipe production lines are also constantly developing and improving. In the future, our production lines will be more intelligent, automated and environmentally friendly. At the same time, in order to meet the needs of different customers, we will provide more types and specifications of pipe production line equipment.